One-Pot Graphene Supported Pt3Cu Nanoparticles—From Theory towards an Effective Molecular Oxygen Reduction Reaction Catalyst

Abstract

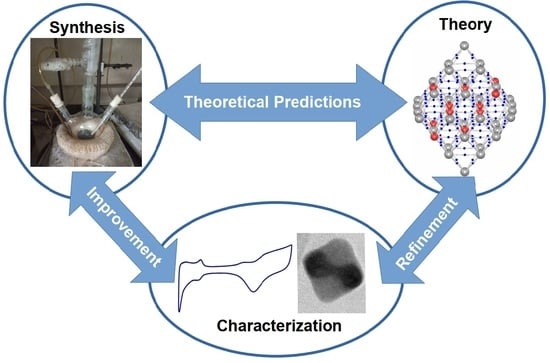

:1. Introduction

2. Results and Discussion

2.1. MEP Bond Paths and Critical Points Search

- (3, +3): local minimum (three positive eigenvalues)

- (3, +1): saddle point (two positive and one negative eigenvalues)

- (3, −1): saddle point (one positive and two negative eigenvalues)

- (3, −3): local maximum (three negative eigenvalues)

2.2. Physical Characterization

2.2.1. X-ray Diffraction Analysis (XRD)

2.2.2. BET Surface Area Measurement

2.2.3. Scanning Electron Microscopy and Energy Dispersive Spectroscopy

2.2.4. Transmission Electron Microscopy

2.3. Electrochemical Characterization

2.4. Electrochemical Stability Test

3. Materials and Methods

3.1. Computational Details

3.2. Synthesis Methods

- TBAH synthesis: The method used has been reported in the literature with minimal modifications [61]. Equimolar quantities of K2PtCl6 (Sigma-Aldrich, St. Louis, MO, USA, 98%) and TBAB (STREM Chemicals, Newburyport, MA, USA, 99%) were weighed and dissolved in water and chloroform, respectively. The TBAB solution was poured into the K2PtCl6 and was left under vigorous agitation for 5–6 h or until the aqueous phase became transparent. The organic phase was separated and distilled, from which a further recrystallization was performed in acetone.

- Pt3Cu/GNPp composite synthesis: In a three-way flask, 0.0100 g of GNPps (STREM Chemicals), 0.0413 g of the prepared TBAH (0.0465 mmol), 0.0041 mg of copper acetylacetonate (Sigma-Aldrich, ≥99.9%, 0.0155 mmol), and 0.0250 mg of TBAB were added to and dissolved in 10 mL of oleylamine (SAFC, Darmstadt, Germany, ≥98%). The reaction mixture was heated at 120 °C for 30 min into N2 (Infra, ultrapure) inert atmosphere to extract all the water and oxygen present in the mixture, and then the mixture was heated to 250 °C for 15 min. The N2 atmosphere was conserved in all the experiment until the mixture was cooled to room temperature. After the heating time, the mixture was left to cool and washed using a blend of ethanol:hexane. The first washing began with pure ethanol, and then the mixture was centrifugated at 12k rpm for 10 min to precipitate the composite. The washing process was then repeated, augmenting the hexane concentration until the composite was dispersed and precipitated in pure hexane. The composite was left in an oven to dry at 80 °C overnight. A black powder similar to the GNPps was finally obtained.

- Electrochemical Ink Formulation: The obtained Pt3Cu/GNPp composite was extracted of the oven and left to cool. A total of 3.6 mg of the material was dispersed in a mixture of ultrapure miliQ water (18.2 MΩ) in acetone (Sigma-Aldrich) at 20% in volume. This concentration was obtained from an experiment of graphene liquid phase exfoliation as the best mixture to disperse graphene [62], and it was also able to disperse graphene composites. A total of 5 μL of Nafion solution (Sigma-Aldrich, 5 wt%) was added to the ink formulation. The ink was sonicated for 1 h in a bath with ice to prevent the heating of the ink.

- Electrochemical Technique: A total of 20 μL of the ink explained above was deposited into a glassy carbon electrode (7 mm, 0.3848 cm2) and left to dry. No rotation was required to dry the electrode. The ink-type electrode was tested in a three-electrode electrochemical cell. A Pt foil was used as the counter electrode, and a Pt wire was used to form an H2 bubble electrolytically, which served as the RHE. All experiments were performed in a solution of 0.1 M HClO4 (Sigma-Aldrich, 70 wt%) in miliQ water, bubbling with N2 in order to remove all oxygen from the solution in the profile and CO-stripping experiments and O2 (Infra, ultrapure) in the ORR hydrodynamic voltammetry. All experiments were conducted with a Metrohm PGSTAT 302N potenciostat.

- Activation CV: The material was electrochemically cleaned using cyclic voltammetry at 100 mV/s in a window of 0.05 V–1.2 V vs. RHE for 250 cycles until the CV was stable.

- Profile CV: The profile was obtained at 20 mV/s in a window of 0.05 V–1.2 V vs. RHE, after two cycles. The last cycle was selected and presented.

- CO stripping: The solution was bubbled with CO gas for 300 s with the electrode polarized at 0.1 V vs. RHE to promote the adhesion of the CO over the surface of the composite. This was followed by a vigorous bubbling of N2 for 300 s to remove all the CO that did not react with the solution. After the time passed, a CV experiment was performed at 20 mV/s in a window of 0.05 V–1.2 V vs. RHE, after two cycles. The last cycle was rested from the first cycle, and the resultant peak was integrated and converted into ECSA using a factor of 420 µC/cm2.

- Hydrodynamic ORR curves: The solution was saturated with vigorous O2 bubbling for 25 min. Then, the glassy carbon electrode was rotated using an electric motor at speeds of 400, 900, 1600, and 2500 rpm. A CV experiment was performed for each rotation at 20 mV/s in a window of 1.03 V–0.05 V vs. RHE after two cycles. The last anodic sweep was selected from all rotations. The Tafel slope was obtained from the 1600 rpm anodic sweep cycle.

- Stability testing: To assess the stability of the catalyst with respect to a similar behavior of a real fuel cell, 10,000 cycles of CV of 0.7–1.0 V vs. RHE were performed. The complete set of experiments described above (activation CV, profile CV, CO stripping, and hydrodynamic ORR curves) were performed on the catalyst before and after the test.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- ‘Lifeline’ of Renewable Energy Can Steer World out of Climate Crisis: UN Chief|UN News. Available online: https://news.un.org/en/story/2022/05/1118452 (accessed on 11 May 2023).

- Cruz-Martínez, H.; Tellez-Cruz, M.M.; Guerrero-Gutiérrez, O.X.; Ramírez-Herrera, C.A.; Salinas-Juárez, M.G.; Velázquez-Osorio, A.; Solorza-Feria, O. Mexican Contributions for the Improvement of Electrocatalytic Properties for the Oxygen Reduction Reaction in PEM Fuel Cells. Int. J. Hydrogen Energy 2019, 44, 12477–12491. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, K.S.; Mishler, J.; Cho, S.C.; Adroher, X.C. A Review of Polymer Electrolyte Membrane Fuel Cells: Technology, Applications, and Needs on Fundamental Research. Appl. Energy 2011, 88, 981–1007. [Google Scholar] [CrossRef] [Green Version]

- Debe, M.K. Electrocatalyst Approaches and Challenges for Automotive Fuel Cells. Nature 2012, 486, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Ortíz-Herrera, J.C.; Tellez-Cruz, M.M.; Solorza-Feria, O.; Medina, D.I. Effect of Different Carbon Supports on the Activity of PtNi Bimetallic Catalysts toward the Oxygen Reduction. Catalysts 2022, 12, 477. [Google Scholar] [CrossRef]

- Cruz-Martínez, H.; Rojas-Chávez, H.; Matadamas-Ortiz, P.T.; Ortiz-Herrera, J.C.; López-Chávez, E.; Solorza-Feria, O.; Medina, D.I. Current Progress of Pt-Based ORR Electrocatalysts for PEMFCs: An Integrated View Combining Theory and Experiment. Mater. Today Phys. 2021, 19, 100406. [Google Scholar] [CrossRef]

- Cruz-Martínez, H.; Tellez-Cruz, M.M.; Rojas-Chávez, H.; Ramírez-Herrera, C.A.; Calaminici, P.; Solorza-Feria, O. NiPdPt Trimetallic Nanoparticles as Efficient Electrocatalysts towards the Oxygen Reduction Reaction. Int. J. Hydrogen Energy 2019, 44, 12463–12469. [Google Scholar] [CrossRef]

- Flores-Rojas, E.; Cruz-Martínez, H.; Rojas-Chávez, H.; Tellez-Cruz, M.M.; Reyes-Rodríguez, J.L.; Cabañas-Moreno, J.G.; Calaminici, P.; Solorza-Feria, O. A Combined DFT and Experimental Investigation of Pt-Wrapped CoNi Nanoparticles for the Oxygen Reduction Reaction. Electrocatalysis 2018, 9, 662–672. [Google Scholar] [CrossRef]

- Duan, S.; Du, Z.; Fan, H.; Wang, R. Nanostructure Optimization of Platinum-Based Nanomaterials for Catalytic Applications. Nanomaterials 2018, 8, 949. [Google Scholar] [CrossRef] [Green Version]

- Luo, W.; Jiang, Y.; Wang, M.; Lu, D.; Sun, X.; Zhang, H. Design Strategies of Pt-Based Electrocatalysts and Tolerance Strategies in Fuel Cells: A Review. RSC Adv. 2023, 13, 4803–4822. [Google Scholar] [CrossRef]

- Poudel, M.B.; Logeshwaran, N.; Kim, A.R.; Karthikeyan, S.C.; Vijayapradeep, S.; Yoo, D.J. Integrated core–shell assembly of Ni3S2 nanowires and CoMoP nanosheets as highly efficient bifunctional electrocatalysts for overall water splitting. J. Alloys Compd. 2023, 960, 170678. [Google Scholar] [CrossRef]

- Poudel, M.B.; Kim, A.A.; Lohani, P.C.; Yoo, D.J.; Kim, H.J. Assembling zinc cobalt hydroxide/ternary sulfides heterostructure and iron oxide nanorods on three-dimensional hollow porous carbon nanofiber as high energy density hybrid supercapacitor. J. Energy Storage 2023, 60, 106713. [Google Scholar] [CrossRef]

- Sun, X.; Jiang, K.; Zhang, N.; Guo, S.; Huang, X. Crystalline Control of {111} Bounded Pt3Cu Nanocrystals: Multiply Twinned Pt3Cu Icosahedra with Enhanced Electrocatalytic Properties. ACS Nano 2015, 9, 7634–7640. [Google Scholar] [CrossRef]

- Kuang, Y.; Cai, Z.; Zhang, Y.; He, D.; Yan, X.; Bi, Y.; Li, Y.; Li, Z.; Sun, X. Ultrathin Dendritic Pt3Cu Triangular Pyramid Caps with Enhanced Electrocatalytic Activity. ACS Appl. Mater. Interfaces 2014, 6, 17748–17752. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Yang, Z.; Zhang, W.; Hu, H.; Wang, C.; Huang, C.; Wang, Y. Tailoring the Morphology of Pt3Cu1 Nanocrystals Supported on Graphene Nanoplates for Ethanol Oxidation. Nanoscale 2016, 8, 3075–3084. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Dang, D.; Tian, X. Designing Robust Support for Pt Alloy Nanoframes with Durable Oxygen Reduction Reaction Activity. ACS Appl. Mater. Interfaces 2019, 11, 9117–9124. [Google Scholar] [CrossRef] [PubMed]

- Oezaslan, M.; Hasché, F.; Strasser, P. PtCu3, PtCu and Pt3Cu Alloy Nanoparticle Electrocatalysts for Oxygen Reduction Reaction in Alkaline and Acidic Media. J. Electrochem. Soc. 2012, 159, B444. [Google Scholar] [CrossRef]

- Pham, H.Q.; Huynh, T.T. Platinum–Copper Bimetallic Nanodendritic Electrocatalyst on a TiO2-Based Support for Methanol Oxidation in Alkaline Fuel Cells. ACS Appl. Nano Mater. 2021, 4, 4983–4993. [Google Scholar] [CrossRef]

- Magalhães, M.M.; Gomes, J.F.; Tremiliosi-Filho, G.; De Figueiredo, P.B.S.; De Lima, R.B.; Colmati, F. Ethanol Electro-Oxidation on Carbon-Supported Pt3Sn/C, Pt3Cu/C and PtSnCu/C Catalysts: CV and in Situ FTIR Study. J. Appl. Electrochem. 2021, 51, 173–181. [Google Scholar] [CrossRef]

- Galindo-Uribe, C.D.; Calaminici, P.; Cruz-Martínez, H.; Cruz-Olvera, D.; Solorza-Feria, O. First-Principle Study of the Structures, Growth Pattern, and Properties of (Pt3Cu)n, n = 1–9, Clusters. J. Chem. Phys. 2021, 154, 154302. [Google Scholar] [CrossRef]

- Galindo-Uribe, C.D.; Calaminici, P.; Solorza-Feria, O. First-Principle Investigation of Structures and Energy Properties of (Pt3Cu)n, n = 10–11 Nanoclusters. Theor. Chem. Acc. 2023, 142, 23. [Google Scholar] [CrossRef]

- Pauling, L. The Nature of the Chemical Bond. II. The One-Electron Bond and the Three-Electron Bond. Available online: https://pubs.acs.org/doi/pdf/10.1021/ja01360a004 (accessed on 13 May 2023).

- Hirshfeld, F.L. Bonded-Atom Fragments for Describing Molecular Charge Densities. Theor. Chim. Acta 1977, 44, 129–138. [Google Scholar] [CrossRef]

- Löwdin, P. On the Non-Orthogonality Problem Connected with the Use of Atomic Wave Functions in the Theory of Molecules and Crystals. J. Chem. Phys. 2004, 18, 365–375. [Google Scholar] [CrossRef]

- Coppens, P. Comparative X-ray and Neutron Diffraction Study of Bonding Effects in s-Triazine. Science 1967, 158, 1577–1579. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, Y.V.; Belokoneva, E.L. Multipole Refinement and Electron Density Analysis in Natural Borosilicate Datolite Using X-ray Diffraction Data. Acta Crystallogr. B 2007, 63, 49–55. [Google Scholar] [CrossRef] [PubMed]

- Martínez, A.; Calaminici, P.; Köster, A.M.; Salahub, D.R. Bonding in Nb3O, Nb3S and Nb3Se: A Topological Analysis of the Electrostatic Potential. J. Chem. Phys. 2001, 114, 819–825. [Google Scholar] [CrossRef]

- Cruz-Olvera, D.; Geudtner, G.; Calaminici, P. Molecular Graphs of Mo2nCn, (n = 1–10) Clusters. Theor. Chem. Acc. 2016, 135, 247. [Google Scholar] [CrossRef]

- López-Estrada, O.L.; Torres-Moreno, J.; Zuniga-Gutierrez, B.; Calaminici, P.; Malola, S.M.; Köster, A.; Häkkinen, H. 1 H NMR Global Diatropicity in Copper Hydride Complexes. Nanoscale 2022, 14, 12668–12676. [Google Scholar] [CrossRef] [PubMed]

- Calaminici, P.; Dominguez-Soria, V.D.; Geudtner, G.; Köster, A.M. Molecular Graphs of Lin Clusters (n = 2–6) from the Density and the Molecular Electrostatic Potential. J. Comput. Methods Sci. Eng. 2007, 7, 383–394. [Google Scholar] [CrossRef]

- Geudtner, G.; Domínguez-Soria, V.D.; Calaminici, P.; Köster, A.M. Molecular Graphs of Lin, Nan and Cun (n = 6–9) Clusters from the Density and the Molecular Electrostatic Potential. Comput. Theor. Chem. 2015, 1053, 337–342. [Google Scholar] [CrossRef]

- Wang, C.; Ricketts, M.; Soleymani, A.P.; Jankovic, J.; Waldecker, J.; Chen, J. Effect of Carbon Support Characteristics on Fuel Cell Durability in Accelerated Stress Testing. J. Electrochem. Soc. 2021, 168, 044507. [Google Scholar] [CrossRef]

- Schonvogel, D.; Hülstede, J.; Wagner, P.; Kruusenberg, I.; Tammeveski, K.; Dyck, A.; Agert, C.; Wark, M. Stability of Pt Nanoparticles on Alternative Carbon Supports for Oxygen Reduction Reaction. J. Electrochem. Soc. 2017, 164, F995. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The Rise of Graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Yang, M.; Zhou, M.; Zhang, A.; Zhang, C. Graphene Oxide: An Ideal Support for Gold Nanocatalysts. J. Phys. Chem. C 2012, 116, 22336–22340. [Google Scholar] [CrossRef]

- Mladenović, D.; Daş, E.; Santos, D.M.F.; Bayrakçeken Yurtcan, A.; Šljukić, B. Highly Efficient Oxygen Electrode Obtained by Sequential Deposition of Transition Metal-Platinum Alloys on Graphene Nanoplatelets. Materials 2023, 16, 3388. [Google Scholar] [CrossRef]

- Galindo Uribe, C.D.; Calaminici, P.; Solorza Feria, O. Revisión sobre la síntesis de grafeno por exfoliación en fase líquida: Mecanismos, factores y técnicas. Uniciencia 2022, 36, 1–14. [Google Scholar] [CrossRef]

- Lowry, T.M. Valence and the Structure of Atoms and Molecules. By Prof. G. N. Lewis. Pp. 172. American Chemical Monograph Series. New York: The Chemical Catalog Co., Inc., 1923. Price $3. J. Soc. Chem. Ind. 1924, 43, 17. [Google Scholar] [CrossRef]

- Atkins, P. Shriver and Atkins’ Inorganic Chemistry; OUP Oxford: Oxford, UK, 2010; ISBN 978-0-19-923617-6. [Google Scholar]

- Bader, R.F.W. Atoms in Molecules: A Quantum Theory; International Series of Monographs on Chemistry; Oxford University Press: Oxford, UK, 1994; ISBN 978-0-19-855865-1. [Google Scholar]

- Tal, Y.; Bader, R.F.W.; Erkku, J. Structural Homeomorphism between the Electronic Charge Density and the Nuclear Potential of a Molecular System. Phys. Rev. A 1980, 21, 1–11. [Google Scholar] [CrossRef]

- Bader, R.F.W.; Essén, H. The Characterization of Atomic Interactions. J. Chem. Phys. 1984, 80, 1943–1960. [Google Scholar] [CrossRef]

- Cabral, A.R.; Skála, R.; Vymazalová, A.; Maixner, J.; Stanley, C.J.; Lehmann, B.; Jedwab, J. Orthocuproplatinum, Pt3Cu, a New Mineral from the Lubero Region, North Kivu, Democratic Republic of the Congo. Mineral. Petrol. 2019, 113, 527–532. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Liu, R.; Niu, Y. Synthesis of High-Quality Graphene by Electrochemical Anodic and Cathodic Co-Exfoliation Method. Chem. Eng. J. 2023, 461, 141985. [Google Scholar] [CrossRef]

- Nam, K.-W.; Song, J.; Oh, K.-H.; Choo, M.-J.; Park, H.; Park, J.-K.; Choi, J.W. Monodispersed PtCo Nanoparticles on Hexadecyltrimethylammonium Bromide Treated Graphene as an Effective Oxygen Reduction Reaction Catalyst for Proton Exchange Membrane Fuel Cells. Carbon 2012, 50, 3739–3747. [Google Scholar] [CrossRef]

- Frelink, T.; Visscher, W.; Van Veen, J.A.R. The Third Anodic Hydrogen Peak on Platinum; Subsurface H2 Adsorption. Electrochim. Acta 1995, 40, 545–549. [Google Scholar] [CrossRef] [Green Version]

- Ciapina, E.G.; Santos, S.F.; Gonzalez, E.R. Electrochemical CO Stripping on Nanosized Pt Surfaces in Acid Media: A Review on the Issue of Peak Multiplicity. J. Electroanal. Chem. 2018, 815, 47–60. [Google Scholar] [CrossRef] [Green Version]

- Shao, Y.; Zhang, S.; Wang, C.; Nie, Z.; Liu, J.; Wang, Y.; Lin, Y. Highly Durable Graphene Nanoplatelets Supported Pt Nanocatalysts for Oxygen Reduction. J. Power Sources 2010, 195, 4600–4605. [Google Scholar] [CrossRef]

- Kocha, S.S.; Shinozaki, K.; Zack, J.W.; Myers, D.J.; Kariuki, N.N.; Nowicki, T.; Stamenkovic, V.; Kang, Y.; Li, D.; Papageorgopoulos, D. Best Practices and Testing Protocols for Benchmarking ORR Activities of Fuel Cell Electrocatalysts Using Rotating Disk Electrode. Electrocatalysis 2017, 8, 366–374. [Google Scholar] [CrossRef]

- Geudtner, G.; Calaminici, P.; Carmona-Espíndola, J.; Del Campo, J.M.; Domínguez-Soria, V.D.; Moreno, R.F.; Gamboa, G.U.; Goursot, A.; Köster, A.M.; Reveles, J.U.; et al. DeMon2k. WIREs Comput. Mol. Sci. 2012, 2, 548–555. [Google Scholar] [CrossRef]

- Köster, A.M.; Geudtner, G.; Alvarez-Ibarra, A.; Calaminici, P.; Casida, M.E.; Carmona-Espindola, J.; Dominguez, V.D.; Flores-Moreno, R.; Gamboa, G.U.; Goursot, A.; et al. deMon2k, Version 6, The deMon Developers; Cinvestav: Mexico City, Mexico, 2018. [Google Scholar]

- Dunlap, B.I.; Connolly, J.W.D.; Sabin, J.R. On First-row Diatomic Molecules and Local Density Models. J. Chem. Phys. 2008, 71, 4993–4999. [Google Scholar] [CrossRef]

- Mintmire, J.W.; Dunlap, B.I. Fitting the Coulomb Potential Variationally in Linear-Combination-of-Atomic-Orbitals Density-Functional Calculations. Phys. Rev. A 1982, 25, 88–95. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.; Yang, W. Comment on “Generalized Gradient Approximation Made Simple”. Phys. Rev. Lett. 1998, 80, 890. [Google Scholar] [CrossRef]

- Calaminici, P.; Janetzko, F.; Köster, A.M.; Mejia-Olvera, R.; Zuniga-Gutierrez, B. Density Functional Theory Optimized Basis Sets for Gradient Corrected Functionals: 3D Transition Metal Systems. J. Chem. Phys. 2007, 126, 044108. [Google Scholar] [CrossRef]

- Martins, L.S.C.; Jorge, F.E.; Machado, S.F. All-Electron Segmented Contraction Basis Sets of Triple Zeta Valence Quality for the Fifth-Row Elements. Mol. Phys. 2015, 113, 3578–3586. [Google Scholar] [CrossRef]

- Leboeuf, M.; Köster, A.M.; Jug, K.; Salahub, D.R. Topological Analysis of the Molecular Electrostatic Potential. J. Chem. Phys. 1999, 111, 4893–4905. [Google Scholar] [CrossRef]

- VUChem—InVisu Inc. Available online: https://www.invisu.ca/en/products/vuchem.php (accessed on 25 May 2023).

- GNU Octave. Available online: https://octave.org/index (accessed on 25 May 2023).

- Iovel, I.G.; Goldberg, Y.S.; Shymanska, M.V.; Lukevics, E. Quaternary Onium Hexachloroplatinates: Novel Hydrosilylation Catalysts. Organometallics 1987, 6, 1410–1413. [Google Scholar] [CrossRef]

- Yi, M.; Shen, Z.; Zhang, X.; Ma, S. Achieving Concentrated Graphene Dispersions in Water/Acetone Mixtures by the Strategy of Tailoring Hansen Solubility Parameters. J. Phys. Appl. Phys. 2012, 46, 025301. [Google Scholar] [CrossRef] [Green Version]

| # of Pt3Cu Units (n) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CN MEP Cu | 3 | 5 | 5 | 6 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| CN MEP Pt | 3 | 5 | 5 | 5 | 8 | 9 | 9 | 9 | 9 | 9 | 9 |

| Symmetry | Cell Parameter a | Atomic Radius | Vegard Pt f | Vegard Cu f | Crystallite Size |

|---|---|---|---|---|---|

| Fm-3m | 0.3843 nm | 0.1358 nm | 0.7427 | 0.2572 | 8.02 nm |

| Element | Series | Unnormalized C (wt%) | Normalized C (wt%) | Normalized C (at%) | Error (1σ, wt%) |

|---|---|---|---|---|---|

| Oxygen | K-series | 1.91 | 2.23 | 2.99 | 0.41 |

| Copper | K-series | 4.31 | 5.02 | 1.69 | 0.17 |

| Platinum | L-series | 35.76 | 41.64 | 4.58 | 1.11 |

| Potassium | K-series | 0.27 | 0.31 | 0.17 | 0.04 |

| Aluminum | K-series | 0.12 | 0.14 | 0.11 | 0.03 |

| Carbon | K-series | 43.52 | 50.67 | 90.46 | 5.25 |

| Material | Mass Activity (mA/mgPt) | ECSA (m2/gPt) | Specific Activity (μA/cm2Pt) | Tafel Slope (mV/dec) | KL B (mA/cm2) |

|---|---|---|---|---|---|

| Pt3Cu/GNPp | 53.1 | 22.13 | 194.9 | 90.2 | 0. 1186 |

| Pt/C Etek 20% | 222 | 68.6 | 324 | 68.9 | 0.1217 |

| Material | Mass Activity (mA/mgPt) | ECSA (m2/gPt) | Specific Activity (μA/cm2Pt) | Tafel Slope (mV/dec) | KL B (mA/cm2) |

|---|---|---|---|---|---|

| Fresh | 53.1 | 22.13 | 243.9 | 90.2 | 0.1186 |

| After 10,000 cycles | 48.1 | 17.06 | 285.5 | 94.2 | 0.1101 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galindo-Uribe, C.D.; Geudtner, G.; Calaminici, P.; Solorza-Feria, O. One-Pot Graphene Supported Pt3Cu Nanoparticles—From Theory towards an Effective Molecular Oxygen Reduction Reaction Catalyst. Molecules 2023, 28, 5072. https://doi.org/10.3390/molecules28135072

Galindo-Uribe CD, Geudtner G, Calaminici P, Solorza-Feria O. One-Pot Graphene Supported Pt3Cu Nanoparticles—From Theory towards an Effective Molecular Oxygen Reduction Reaction Catalyst. Molecules. 2023; 28(13):5072. https://doi.org/10.3390/molecules28135072

Chicago/Turabian StyleGalindo-Uribe, Carlos Daniel, Gerald Geudtner, Patrizia Calaminici, and Omar Solorza-Feria. 2023. "One-Pot Graphene Supported Pt3Cu Nanoparticles—From Theory towards an Effective Molecular Oxygen Reduction Reaction Catalyst" Molecules 28, no. 13: 5072. https://doi.org/10.3390/molecules28135072