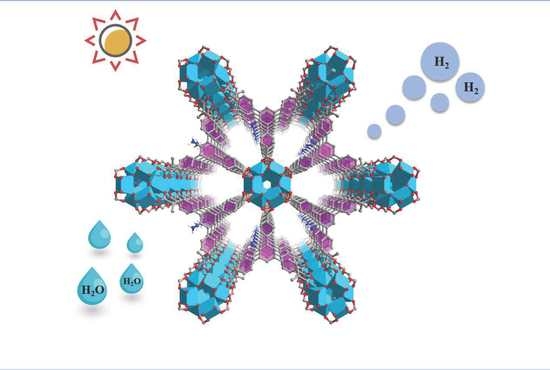

Amino-Functionalized Titanium Based Metal-Organic Framework for Photocatalytic Hydrogen Production

Abstract

:1. Introduction

2. Results and Discussions

2.1. Structural Characterizations of Photocatalysts

2.2. Photoelectrochemical Characterizations of Photocatalysts

2.3. Photocatalytic Hydrogen Production of Photocatalysts

3. Experimental

3.1. Synthesis of NH2-ZSTU-2

3.2. Synthesis of Pt@NH2-ZSTU-2

3.3. Photoelectrochemical Measurementsz

3.4. Photocatalytic Hydrogen Production Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Zhang, X.; Tong, S.; Huang, D.; Liu, Z.; Shao, B.; Liang, Q.; Wu, T.; Pan, Y.; Huang, J.; Liu, Y.; et al. Recent advances of Zr based metal organic frameworks photocatalysis: Energy production and environmental remediation. Coord. Chem. Rev. 2021, 448, 214177. [Google Scholar] [CrossRef]

- Sui, J.; Liu, H.; Hu, S.; Sun, K.; Wan, G.; Zhou, H.; Zheng, X.; Jiang, H.L. A General Strategy to Immobilize Single-Atom Catalysts in Metal-Organic Frameworks for Enhanced Photocatalysis. Adv. Mater. 2022, 34, 2109203. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Dai, Z.; Kang, J.; Fu, F.; Zhang, T.; Wang, S. A TiO2 nanocomposite hydrogel for Hydroponic plants in efficient water improvement. Mater. Chem. Phys. 2018, 215, 242–250. [Google Scholar] [CrossRef]

- Jiang, G.; Wang, R.; Wang, X.; Xi, X.; Hu, R.; Zhou, Y.; Wang, S.; Wang, T.; Chen, W. Novel highly active visible-light-induced photocatalysts based on BiOBr with Ti doping and Ag decorating. ACS Appl. Mater. Interfaces 2012, 4, 4440–4444. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Wang, T.; Ding, Y.; Su, Q.; Xu, Y.; Xu, Z.; Jiang, G.; Chen, W. Air-Water Interface Photocatalysis: A Realizable Approach for Decomposition of Aqueous Organic Pollutants. Sci. Adv. Mater. 2013, 5, 1006–1012. [Google Scholar] [CrossRef]

- Melchionna, M.; Fornasiero, P. Updates on the Roadmap for Photocatalysis. ACS Catal. 2020, 10, 5493–5501. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.S.; Li, L.; Li, D.; Ye, J. Recent Progress on Exploring Stable Metal–Organic Frameworks for Photocatalytic Solar Fuel Production. Sol. RRL 2020, 4, 1900547. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, D.; Cheng, M.; Liu, Z.; Lai, C.; Zhang, C.; Zhou, C.; Xiong, W.; Qin, L.; Shao, B.; et al. Metal sulfide/MOF-based composites as visible-light-driven photocatalysts for enhanced hydrogen production from water splitting. Coord. Chem. Rev. 2020, 409, 213220. [Google Scholar] [CrossRef]

- Li, L.; Wang, X.S.; Liu, T.F.; Ye, J. Titanium-Based MOF Materials: From Crystal Engineering to Photocatalysis. Small Methods 2020, 4, 2000486. [Google Scholar] [CrossRef]

- Wang, X.; Yang, X.; Chen, C.; Li, H.; Huang, Y.; Cao, R. Graphene Quantum Dots Supported on Fe-based Metal-Organic Frameworks for Efficient Photocatalytic CO2 Reduction. Acta Chim. Sin. 2022, 80, 22–28. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, J.; Wang, L.; Sun, P.; Wang, P.; Yao, Z.; Yang, Y. Coupling Bimetallic NiMn-MOF Nanosheets on NiCo2O4 Nanowire Arrays with Boosted Electrochemical Performance for Hybrid Supercapacitor. Mater. Res. Bull. 2022, 149, 111707. [Google Scholar] [CrossRef]

- Li, G.; Cai, H.; Li, X.; Zhang, J.; Zhang, D.; Yang, Y.; Xiong, J. Construction of Hierarchical NiCo2O4@Ni-MOF Hybrid Arrays on Carbon Cloth as Superior Battery-Type Electrodes for Flexible Solid-State Hybrid Supercapacitors. ACS Appl. Mater. Interfaces 2019, 11, 37675–37684. [Google Scholar] [CrossRef]

- Gao, J.; Cai, Y.; Qian, X.; Liu, P.; Wu, H.; Zhou, W.; Liu, D.X.; Li, L.; Lin, R.B.; Chen, B. A Microporous Hydrogen-Bonded Organic Framework for the Efficient Capture and Purification of Propylene. Angew. Chem. Int. Ed. 2021, 60, 20400–20406. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Qian, X.; Lin, R.B.; Krishna, R.; Wu, H.; Zhou, W.; Chen, B. Mixed Metal-Organic Framework with Multiple Binding Sites for Efficient C2H2 /CO2 Separation. Angew. Chem. Int. Ed. 2020, 59, 4396–4400. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-S.; Chen, C.-H.; Ichihara, F.; Oshikiri, M.; Liang, J.; Li, L.; Li, Y.; Song, H.; Wang, S.; Zhang, T.; et al. Integration of adsorption and photosensitivity capabilities into a cationic multivariate metal-organic framework for enhanced visible-light photoreduction reaction. Appl. Catal. B Environ. 2019, 253, 323–330. [Google Scholar] [CrossRef]

- Huang, H.; Wang, X.-S.; Philo, D.; Ichihara, F.; Song, H.; Li, Y.; Li, D.; Qiu, T.; Wang, S.; Ye, J. Toward visible-light-assisted photocatalytic nitrogen fixation: A titanium metal organic framework with functionalized ligands. Appl. Catal. B Environ. 2020, 267, 118686. [Google Scholar] [CrossRef]

- Luo, X.; Abazari, R.; Tahir, M.; Fan, W.K.; Kumar, A.; Kalhorizadeh, T.; Kirillov, A.M.; Amani-Ghadim, A.R.; Chen, J.; Zhou, Y. Trimetallic metal–organic frameworks and derived materials for environmental remediation and electrochemical energy storage and conversion. Coord. Chem. Rev. 2022, 461, 214505. [Google Scholar] [CrossRef]

- Anwar, S.; Khan, F.; Zhang, Y.; Djire, A. Recent development in electrocatalysts for hydrogen production through water electrolysis. Int. J. Hydrogen Energy 2021, 46, 32284–32317. [Google Scholar] [CrossRef]

- Zhou, Y.; Abazari, R.; Chen, J.; Tahir, M.; Kumar, A.; Ikreedeegh, R.R.; Rani, E.; Singh, H.; Kirillov, A.M. Bimetallic metal–organic frameworks and MOF-derived composites: Recent progress on electro- and photoelectrocatalytic applications. Coord. Chem. Rev. 2022, 451, 214264. [Google Scholar] [CrossRef]

- Yan, Y.; Abazari, R.; Yao, J.; Gao, J. Recent strategies to improve the photoactivity of metal-organic frameworks. Dalton Trans. 2021, 50, 2342–2349. [Google Scholar] [CrossRef]

- Gao, J.; Huang, Q.; Wu, Y.; Lan, Y.-Q.; Chen, B. Metal–Organic Frameworks for Photo/Electrocatalysis. Adv. Energy Sustain. Res. 2021, 2, 2100033. [Google Scholar] [CrossRef]

- Kataoka, Y.; Sato, K.; Miyazaki, Y.; Masuda, K.; Tanaka, H.; Naito, S.; Mori, W. Photocatalytic hydrogen production from water using porous material [Ru2(p-BDC)2]n. Energy Environ. Sci. 2009, 2, 397–400. [Google Scholar] [CrossRef]

- Kong, X.J.; Lin, Z.; Zhang, Z.M.; Zhang, T.; Lin, W. Hierarchical Integration of Photosensitizing Metal-Organic Frameworks and Nickel-Containing Polyoxometalates for Efficient Visible-Light-Driven Hydrogen Evolution. Angew. Chem. Int. Ed. 2016, 55, 6411–6416. [Google Scholar] [CrossRef]

- Han, S.Y.; Pan, D.L.; Chen, H.; Bu, X.B.; Gao, Y.X.; Gao, H.; Tian, Y.; Li, G.S.; Wang, G.; Cao, S.L.; et al. A Methylthio-Functionalized-MOF Photocatalyst with High Performance for Visible-Light-Driven H2 Evolution. Angew. Chem. Int. Ed. 2018, 57, 9864–9869. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Xu, C.; Li, D.; Jiang, H.L. Photocatalytic Hydrogen Production Coupled with Selective Benzylamine Oxidation over MOF Composites. Angew. Chem. Int. Ed. 2018, 57, 5379–5383. [Google Scholar] [CrossRef]

- Xiao, J.D.; Han, L.; Luo, J.; Yu, S.H.; Jiang, H.L. Integration of Plasmonic Effects and Schottky Junctions into Metal-Organic Framework Composites: Steering Charge Flow for Enhanced Visible-Light Photocatalysis. Angew. Chem. Int. Ed. 2018, 57, 1103–1107. [Google Scholar] [CrossRef]

- Xiao, Y.; Qi, Y.; Wang, X.; Wang, X.; Zhang, F.; Li, C. Visible-Light-Responsive 2D Cadmium-Organic Framework Single Crystals with Dual Functions of Water Reduction and Oxidation. Adv. Mater. 2018, 30, 1803401. [Google Scholar] [CrossRef]

- Yuan, S.; Qin, J.S.; Xu, H.Q.; Su, J.; Rossi, D.; Chen, Y.; Zhang, L.; Lollar, C.; Wang, Q.; Jiang, H.L.; et al. [Ti8Zr2O12(COO)16] Cluster: An Ideal Inorganic Building Unit for Photoactive Metal-Organic Frameworks. ACS Cent. Sci. 2018, 4, 105–111. [Google Scholar] [CrossRef] [Green Version]

- Kamakura, Y.; Chinapang, P.; Masaoka, S.; Saeki, A.; Ogasawara, K.; Nishitani, S.R.; Yoshikawa, H.; Katayama, T.; Tamai, N.; Sugimoto, K.; et al. Semiconductive Nature of Lead-Based Metal-Organic Frameworks with Three-Dimensionally Extended Sulfur Secondary Building Units. J. Am. Chem. Soc. 2020, 142, 27–32. [Google Scholar] [CrossRef]

- Zhu, J.; Li, P.-Z.; Guo, W.; Zhao, Y.; Zou, R. Titanium-based metal–organic frameworks for photocatalytic applications. Coord. Chem. Rev. 2018, 359, 80–101. [Google Scholar] [CrossRef]

- Yuan, S.; Feng, L.; Wang, K.; Pang, J.; Bosch, M.; Lollar, C.; Sun, Y.; Qin, J.; Yang, X.; Zhang, P.; et al. Stable Metal-Organic Frameworks: Design, Synthesis, and Applications. Adv. Mater. 2018, 30, 1704303. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Serre, C.; Groves, J.A.; Lightfoot, P.; Slawin, A.M.Z.; Wright, P.A.; Stock, N.; Bein, T.; Haouas, M.; Taulelle, F.; Férey, G. Synthesis, Structure and Properties of Related Microporous N,N′-Piperazinebismethylenephosphonates of Aluminum and Titanium. Chem. Mater. 2006, 18, 1451–1457. [Google Scholar] [CrossRef]

- Dan-Hardi, M.; Serre, C.; Frot, T.; Rozes, L.; Maurin, G.; Sanchez, C.; Ferey, G. A new photoactive crystalline highly porous titanium(IV) dicarboxylate. J. Am. Chem. Soc. 2009, 131, 10857–10859. [Google Scholar] [CrossRef] [PubMed]

- Bueken, B.; Vermoortele, F.; Vanpoucke, D.E.P.; Reinsch, H.; Tsou, C.-C.; Valvekens, P.; De Baerdemaeker, T.; Ameloot, R.; Kirschhock, C.E.A.; Van Speybroeck, V.; et al. A Flexible Photoactive Titanium Metal-Organic Framework Based on a [Ti(IV)3(μ3-O)(O)2(COO)6] Cluster. Angew. Chem. Int. Ed. 2015, 127, 14118–14123. [Google Scholar] [CrossRef]

- Keum, Y.; Park, S.; Chen, Y.P.; Park, J. Titanium-Carboxylate Metal-Organic Framework Based on an Unprecedented Ti-Oxo Chain Cluster. Angew. Chem. Int. Ed. 2018, 57, 14852–14856. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Kitao, T.; Guillou, N.; Wahiduzzaman, M.; Martineau-Corcos, C.; Nouar, F.; Tissot, A.; Binet, L.; Ramsahye, N.; Devautour-Vinot, S.; et al. A phase transformable ultrastable titanium-carboxylate framework for photoconduction. Nat. Commun. 2018, 9, 1660. [Google Scholar] [CrossRef] [Green Version]

- Ziebel, M.E.; Darago, L.E.; Long, J.R. Control of Electronic Structure and Conductivity in Two-Dimensional Metal-Semiquinoid Frameworks of Titanium, Vanadium, and Chromium. J. Am. Chem. Soc. 2018, 140, 3040–3051. [Google Scholar] [CrossRef]

- Li, C.; Xu, H.; Gao, J.; Du, W.; Shangguan, L.; Zhang, X.; Lin, R.-B.; Wu, H.; Zhou, W.; Liu, X.; et al. Tunable titanium metal–organic frameworks with infinite 1D Ti–O rods for efficient visible-light-driven photocatalytic H2 evolution. J. Mater. Chem. A 2019, 7, 11928–11933. [Google Scholar] [CrossRef]

- Padial, N.M.; Castells-Gil, J.; Almora-Barrios, N.; Romero-Angel, M.; da Silva, I.; Barawi, M.; Garcia-Sanchez, A.; de la Pena O’Shea, V.A.; Marti-Gastaldo, C. Hydroxamate Titanium-Organic Frameworks and the Effect of Siderophore-Type Linkers over Their Photocatalytic Activity. J. Am. Chem. Soc. 2019, 141, 13124–13133. [Google Scholar] [CrossRef]

- Smolders, S.; Willhammar, T.; Krajnc, A.; Sentosun, K.; Wharmby, M.T.; Lomachenko, K.A.; Bals, S.; Mali, G.; Roeffaers, M.B.J.; De Vos, D.E.; et al. A Titanium(IV)-Based Metal-Organic Framework Featuring Defect-Rich Ti-O Sheets as an Oxidative Desulfurization Catalyst. Angew. Chem. Int. Ed. 2019, 58, 9160–9165. [Google Scholar] [CrossRef]

- Cadiau, A.; Kolobov, N.; Srinivasan, S.; Goesten, M.G.; Haspel, H.; Bavykina, A.V.; Tchalala, M.R.; Maity, P.; Goryachev, A.; Poryvaev, A.S.; et al. A Titanium Metal-Organic Framework with Visible-Light-Responsive Photocatalytic Activity. Angew. Chem. Int. Ed. 2020, 59, 13468–13472. [Google Scholar] [CrossRef] [PubMed]

- Keum, Y.; Kim, B.; Byun, A.; Park, J. Synthesis and Photocatalytic Properties of Titanium-Porphyrinic Aerogels. Angew. Chem. Int. Ed. 2020, 59, 21591–21596. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Cabrero-Antonino, M.; Navalón, S.; Cao, C.-c.; Tissot, A.; Dovgaliuk, I.; Marrot, J.; Martineau-Corcos, C.; Yu, L.; Wang, H.; et al. A Robust Titanium Isophthalate Metal-Organic Framework for Visible-Light Photocatalytic CO2 Methanation. Chem 2020, 6, 3409–3427. [Google Scholar] [CrossRef]

- Wang, S.; Reinsch, H.; Heymans, N.; Wahiduzzaman, M.; Martineau-Corcos, C.; De Weireld, G.; Maurin, G.; Serre, C. Toward a Rational Design of Titanium Metal-Organic Frameworks. Matter 2020, 2, 440–450. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.P.; Yin, J.; Abou-Hamad, E.; Liu, X.; Chen, W.; Yao, T.; Mohammed, O.F.; Alshareef, H.N. Highly Stable Phosphonate-Based MOFs with Engineered Bandgaps for Efficient Photocatalytic Hydrogen Production. Adv. Mater. 2020, 32, 1906368. [Google Scholar] [CrossRef]

- Fujishima, A.; Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef]

- Yan, Y.; Li, C.; Wu, Y.; Gao, J.; Zhang, Q. From isolated Ti-oxo clusters to infinite Ti-oxo chains and sheets: Recent advances in photoactive Ti-based MOFs. J. Mater. Chem. A 2020, 8, 15245–15270. [Google Scholar] [CrossRef]

- Kim, M.; Razzaq, A.; Kim, Y.K.; Kim, S.; In, S.-I. Synthesis and characterization of platinum modified TiO2-embedded carbon nanofibers for solar hydrogen generation. RSC Adv. 2014, 4, 51286–51293. [Google Scholar] [CrossRef]

- Castells-Gil, J.; Padial, N.M.; Almora-Barrios, N.; da Silva, I.; Mateo, D.; Albero, J.; García, H.; Martí-Gastaldo, C. De novo synthesis of mesoporous photoactive titanium(iv)–organic frameworks with MIL-100 topology. Chem. Sci. 2019, 10, 4313–4321. [Google Scholar] [CrossRef] [Green Version]

- Castells-Gil, J.; Padial, N.M.; Almora-Barrios, N.; Albero, J.; Ruiz-Salvador, A.R.; Gonzalez-Platas, J.; Garcia, H.; Marti-Gastaldo, C. Chemical Engineering of Photoactivity in Heterometallic Titanium-Organic Frameworks by Metal Doping. Angew. Chem. Int. Ed. 2018, 57, 8453–8457. [Google Scholar] [CrossRef] [Green Version]

- Horiuchi, Y.; Toyao, T.; Saito, M.; Mochizuki, K.; Iwata, M.; Higashimura, H.; Anpo, M.; Matsuoka, M. Visible-Light-Promoted Photocatalytic Hydrogen Production by Using an Amino-Functionalized Ti(IV) Metal–Organic Framework. J. Phys. Chem. C 2012, 116, 20848–20853. [Google Scholar] [CrossRef]

- Remiro-Buenamañana, S.; Cabrero-Antonino, M.; Martínez-Guanter, M.; Álvaro, M.; Navalón, S.; García, H. Influence of co-catalysts on the photocatalytic activity of MIL-125(Ti)-NH2 in the overall water splitting. Appl. Catal. B Environ. 2019, 254, 677–684. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, N.; Cai, Y.; Li, L.; Wang, X.; Gao, J. Amino-Functionalized Titanium Based Metal-Organic Framework for Photocatalytic Hydrogen Production. Molecules 2022, 27, 4241. https://doi.org/10.3390/molecules27134241

Hu N, Cai Y, Li L, Wang X, Gao J. Amino-Functionalized Titanium Based Metal-Organic Framework for Photocatalytic Hydrogen Production. Molecules. 2022; 27(13):4241. https://doi.org/10.3390/molecules27134241

Chicago/Turabian StyleHu, Niannian, Youlie Cai, Lan Li, Xusheng Wang, and Junkuo Gao. 2022. "Amino-Functionalized Titanium Based Metal-Organic Framework for Photocatalytic Hydrogen Production" Molecules 27, no. 13: 4241. https://doi.org/10.3390/molecules27134241