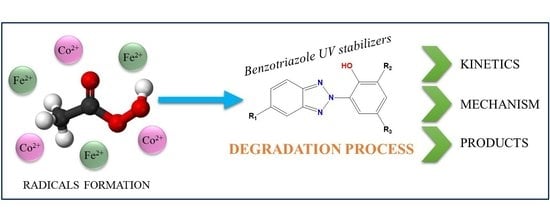

Degradation of Benzotriazole UV Stabilizers in PAA/d-Electron Metal Ions Systems—Removal Kinetics, Products and Mechanism Evaluation

Abstract

:1. Introduction

2. Results and Discussion

2.1. Optimization of the UV Stabilizers Oxidation Process

2.2. UV Stabilizers Degradation Kinetics

2.3. Mechanism of UV Stabilizers Degradation

2.4. Benzotriazole UV Stabilizers Degradation Products

3. Materials and Methods

3.1. Materials and Characterizaton

3.2. Procedure of Ultrasound-Assisted Emulsification Microextraction

3.3. Degradation Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UV Absorbers Market Global Forecast to 2022|MarketsandMarkets. Available online: https://www.marketsandmarkets.com/Market-Reports/uv-absorber-market-39452163.html (accessed on 26 February 2022).

- UV Stabilizers. In Handbook of UV Degradation and Stabilization; Elsevier: Amsterdam, The Netherlands, 2015; pp. 67–139.

- Heller, H.; Keller, E.; Land, B.; Gysling, H.; Basel, N.; Mindermann, F. United States Patent Office Ultraviolet Light Absorbed Composition of Matter. US3004896A, 17 October 1961. [Google Scholar]

- Cantwell, M.G.; Sullivan, J.C.; Burgess, R.M. Benzotriazoles: History, Environmental Distribution, and Potential Ecological Effects. In Comprehensive Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2015; Volume 67, pp. 513–545. [Google Scholar]

- Smyrniotakis, C.G.; Archontaki, H.A. Development and Validation of a Non-Aqueous Reversed-Phase High-Performance Liquid Chromatographic Method for the Determination of Four Chemical UV Filters in Suncare Formulations. J. Chromatogr. A 2004, 1031, 319–324. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, J.; Du, T.; Kou, H.; Du, X.; Lu, X. Determination of Six Benzotriazole Ultraviolet Filters in Water and Cosmetic Samples by Graphene Sponge-Based Solid-Phase Extraction Followed by High-Performance Liquid Chromatography. Anal. Bioanal. Chem. 2018, 410, 6955–6962. [Google Scholar] [CrossRef] [PubMed]

- OECD Existing Chemicals Database. Available online: http://webnet.oecd.org/hpv/ui/Search.aspx (accessed on 7 July 2021).

- SPIN Substances in Preparations in Nordic Countries. Available online: http://spin2000.net/ (accessed on 7 July 2021).

- Parajulee, A.; Lei, Y.D.; Kananathalingam, A.; Mitchell, C.P.J.; Wania, F. Investigating the Sources and Transport of Benzotriazole UV Stabilizers during Rainfall and Snowmelt across an Urbanization Gradient. Environ. Sci. Technol. 2018, 52, 2595–2602. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhang, Z.F.; Xu, L.; Liu, L.Y.; Song, W.W.; Zhu, F.J.; Li, Y.F.; Ma, W.L. Occurrence and Fate of Benzotriazoles UV Filters in a Typical Residential Wastewater Treatment Plant in Harbin, China. Environ. Pollut. 2017, 227, 215–222. [Google Scholar] [CrossRef]

- Ruan, T.; Liu, R.; Fu, Q.; Wang, T.; Wang, Y.; Song, S.; Wang, P.; Teng, M.; Jiang, G. Concentrations and Composition Profiles of Benzotriazole UV Stabilizers in Municipal Sewage Sludge in China. Environ. Sci. Technol. 2012, 46, 2071–2079. [Google Scholar] [CrossRef] [PubMed]

- Montesdeoca-Esponda, S.; Álvarez-Raya, C.; Torres-Padrón, M.E.; Sosa-Ferrera, Z.; Santana-Rodríguez, J.J. Monitoring and Environmental Risk Assessment of Benzotriazole UV Stabilizers in the Sewage and Coastal Environment of Gran Canaria (Canary Islands, Spain). J. Environ. Manag. 2019, 233, 567–575. [Google Scholar] [CrossRef]

- Casado, J.; Rodríguez, I.; Carpinteiro, I.; Ramil, M.; Cela, R. Gas Chromatography Quadrupole Time-of-Flight Mass Spectrometry Determination of Benzotriazole Ultraviolet Stabilizers in Sludge Samples. J. Chromatogr. A 2013, 1293, 126–132. [Google Scholar] [CrossRef]

- Zhang, Z.; Ren, N.; Li, Y.F.; Kunisue, T.; Gao, D.; Kannan, K. Determination of Benzotriazole and Benzophenone UV Filters in Sediment and Sewage Sludge. Environ. Sci. Technol. 2011, 45, 3909–3916. [Google Scholar] [CrossRef]

- Kotowska, U.; Struk-Sokołowska, J.; Piekutin, J. Simultaneous Determination of Low Molecule Benzotriazoles and Benzotriazole UV Stabilizers in Wastewater by Ultrasound-Assisted Emulsification Microextraction Followed by GC–MS Detection. Sci. Rep. 2021, 11, 10098. [Google Scholar] [CrossRef]

- Liu, R.; Ruan, T.; Wang, T.; Song, S.; Guo, F.; Jiang, G. Determination of Nine Benzotriazole UV Stabilizers in Environmental Water Samples by Automated On-Line Solid Phase Extraction Coupled with High-Performance Liquid Chromatography-Tandem Mass Spectrometry. Talanta 2014, 120, 158–166. [Google Scholar] [CrossRef] [Green Version]

- Nakata, H.; Murata, S.; Filatreau, J. Occurrence and Concentrations of Benzotriazole UV Stabilizers in Marine Organisms and Sediments from the Ariake Sea, Japan. Environ. Sci. Technol. 2009, 43, 6920–6926. [Google Scholar] [CrossRef] [PubMed]

- Nakata, H.; Shinohara, R.I.; Murata, S.; Watanabe, M. Detection of Benzotriazole UV Stabilizers in the Blubber of Marine Mammals by Gas Chromatography-High Resolution Mass Spectrometry (GC-HRMS). J. Environ. Monit. 2010, 12, 2088–2092. [Google Scholar] [CrossRef] [PubMed]

- Apel, C.; Tang, J.; Ebinghaus, R. Environmental Occurrence and Distribution of Organic UV Stabilizers and UV Filters in the Sediment of Chinese Bohai and Yellow Seas. Environ. Pollut. 2018, 235, 85–94. [Google Scholar] [CrossRef] [PubMed]

- Wick, A.; Jacobs, B.; Kunkel, U.; Heininger, P.; Ternes, T.A. Benzotriazole UV Stabilizers in Sediments, Suspended Particulate Matter and Fish of German Rivers: New Insights into Occurrence, Time Trends and Persistency. Environ. Pollut. 2016, 212, 401–412. [Google Scholar] [CrossRef]

- Vimalkumar, K.; Arun, E.; Krishna-Kumar, S.; Poopal, R.K.; Nikhil, N.P.; Subramanian, A.; Babu-Rajendran, R. Occurrence of Triclocarban and Benzotriazole Ultraviolet Stabilizers in Water, Sediment, and Fish from Indian Rivers. Sci. Total Environ. 2018, 625, 1351–1360. [Google Scholar] [CrossRef]

- Lu, Z.; De Silva, A.O.; Zhou, W.; Tetreault, G.R.; de Solla, S.R.; Fair, P.A.; Houde, M.; Bossart, G.; Muir, D.C.G. Substituted Diphenylamine Antioxidants and Benzotriazole UV Stabilizers in Blood Plasma of Fish, Turtles, Birds and Dolphins from North America. Sci. Total Environ. 2019, 647, 182–190. [Google Scholar] [CrossRef]

- Lu, Z.; De Silva, A.O.; Peart, T.E.; Cook, C.J.; Tetreault, G.R.; Servos, M.R.; Muir, D.C.G. Distribution, Partitioning and Bioaccumulation of Substituted Diphenylamine Antioxidants and Benzotriazole UV Stabilizers in an Urban Creek in Canada. Environ. Sci. Technol. 2016, 17, 9089–9097. [Google Scholar] [CrossRef]

- Kim, J.W.; Isobe, T.; Malarvannan, G.; Sudaryanto, A.; Chang, K.H.; Prudente, M.; Tanabe, S. Contamination of Benzotriazole Ultraviolet Stabilizers in House Dust from the Philippines: Implications on Human Exposure. Sci. Total Environ. 2012, 424, 174–181. [Google Scholar] [CrossRef]

- Carpinteiro, I.; Abuín, B.; Rodríguez, I.; Ramil, M.; Cela, R. Pressurized Solvent Extraction Followed by Gas Chromatography Tandem Mass Spectrometry for the Determination of Benzotriazole Light Stabilizers in Indoor Dust. J. Chromatogr. A 2010, 1217, 3729–3735. [Google Scholar] [CrossRef]

- Maceira, A.; Borrull, F.; Marcé, R.M. Occurrence of Plastic Additives in Outdoor Air Particulate Matters from Two Industrial Parks of Tarragona, Spain: Human Inhalation Intake Risk Assessment. J. Hazard. Mater. 2019, 373, 649–659. [Google Scholar] [CrossRef]

- Montesdeoca-Esponda, S.; Torres-Padrón, M.E.; Sosa-Ferrera, Z.; Santana-Rodríguez, J.J. Fate and Distribution of Benzotriazole UV Filters and Stabilizers in Environmental Compartments from Gran Canaria Island (Spain): A Comparison Study. Sci. Total Environ. 2021, 756, 144086. [Google Scholar] [CrossRef] [PubMed]

- Gimeno-Monforte, S.; Montesdeoca-Esponda, S.; Sosa-Ferrera, Z.; Santana-Rodríguez, J.J.; Castro, Ó.; Pocurull, E.; Borrull, F. Multiresidue Analysis of Organic UV Filters and UV Stabilizers in Fish of Common Consumption. Foods 2020, 9, 1827. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-W.; Ramaswamy, R.; Chang, K.-H.; Isobe, T.; Tanabe, S. Multiresidue Analytical Method for the Determination of Antimicrobials, Preservatives, Benzotriazole UV Stabilizers, Flame Retardants and Plasticizers in Fish Using Ultra High Performance Liquid Chromatography Coupled with Tandem Mass Spectrometry. J. Chromatogr. A 2011, 1218, 3511–3520. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; De Silva, A.O.; Peart, T.E.; Cook, C.J.; Tetreault, G.R. Tissue Distribution of Substituted Diphenylamine Antioxidants and Benzotriazole Ultraviolet Stabilizers in White Sucker (Catostomus Commersonii) from an Urban Creek in Canada. Environ. Sci. Technol. Lett. 2017, 4, 433–438. [Google Scholar] [CrossRef]

- Zhu, M.Q.; Cui, R. Determination of UV-327 and UV-328 in Mouse Plasma by High Performance Liquid Chromatography. Beijing Da Xue Xue Bao. 2020, 52, 591–596. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Kim, S.; Park, J.; Kim, H.J.; Jae Lee, J.; Choi, G.; Choi, S.; Kim, S.; Young Kim, S.; Choi, K.; et al. Synthetic Musk Compounds and Benzotriazole Ultraviolet Stabilizers in Breast Milk: Occurrence, Time-Course Variation and Infant Health Risk. Environ. Res. 2015, 140, 466–473. [Google Scholar] [CrossRef]

- Kim, J.W.; Chang, K.H.; Prudente, M.; Viet, P.H.; Takahashi, S.; Tanabe, S.; Kunisue, T.; Isobe, T. Occurrence of Benzotriazole Ultraviolet Stabilizers (BUVSs) in Human Breast Milk from Three Asian Countries. Sci. Total Environ. 2019, 655, 1081–1088. [Google Scholar] [CrossRef]

- Molins-Delgado, D.; Olmo-Campos, M.d.M.; Valeta-Juan, G.; Valeta-Juan, G.; Pleguezuelos-Hernández, V.; Barceló, D.; Díaz-Cruz, M.S. Determination of UV Filters in Human Breast Milk Using Turbulent Flow Chromatography and Babies’ Daily Intake Estimation. Environ. Res. 2018, 161, 532–539. [Google Scholar] [CrossRef]

- Environment and Climate Change Canada; Health Canada. Draft Screening Assessment Benzotriazoles and Benzothiazoles Group; Government of Canada: Ottawa, ON, Canada, 2021.

- Nakata, H.; Shinohara, R.I.; Nakazawa, Y.; Isobe, T.; Sudaryanto, A.; Subramanian, A.; Tanabe, S.; Zakaria, M.P.; Zheng, G.J.; Lam, P.K.S.; et al. Asia-Pacific Mussel Watch for Emerging Pollutants: Distribution of Synthetic Musks and Benzotriazole UV Stabilizers in Asian and US Coastal Waters. Mar. Pollut. Bull. 2012, 64, 2211–2218. [Google Scholar] [CrossRef]

- Nagayoshi, H.; Kakimoto, K.; Takagi, S.; Konishi, Y.; Kajimura, K.; Matsuda, T. Benzotriazole Ultraviolet Stabilizers Show Potent Activities as Human Aryl Hydrocarbon Receptor Ligands. Environ. Sci. Technol. 2015, 49, 578–587. [Google Scholar] [CrossRef]

- Geneva International Conference Centre (CICG). Ninth Meeting of the Conference of the Parties to the Stockholm Convention. In Proceedings of the Stockholm Convention of Persistent Organic Pollutants Report of the Conference of the Parties to the Stockholm Convention on Persistent Organic Pollutants on the Work of Its Ninth Meeting, Geneva, Switzerland, 29 April–10 May 2019. [Google Scholar]

- Fent, K.; Chew, G.; Li, J.; Gomez, E. Benzotriazole UV-Stabilizers and Benzotriazole: Antiandrogenic Activity in Vitro and Activation of Aryl Hydrocarbon Receptor Pathway in Zebrafish Eleuthero-Embryos. Sci. Total Environ. 2014, 482–483, 125–136. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Cao, H.; Li, J.; Zhang, H.; Xue, Q.; Liu, X.; Zhang, A.; Fu, J. Estrogenic Activity of Benzotriazole UV Stabilizers Evaluated through in Vitro Assays and Computational Studies. Sci. Total Environ. 2020, 727, 138549. [Google Scholar] [CrossRef] [PubMed]

- Fischer, C.; Leibold, E.; Göen, T. Identification of in Vitro Phase I Metabolites of Benzotriazole UV Stabilizer UV-327 Using HPLC Coupled with Mass Spectrometry. Toxicol. Vitr. 2020, 68, 104932. [Google Scholar] [CrossRef]

- Denghel, H.; Leibold, E.; Göen, T. Oxidative Phase I Metabolism of the UV Absorber 2-(2H-Benzotriazol-2-Yl)-4,6-Di-Tert-Pentylphenol (UV 328) in an in Vitro Model with Human Liver Microsomes. Toxicol. Vitr. 2019, 60, 313–322. [Google Scholar] [CrossRef]

- Denghel, H.; Göen, T. Determination of the UV Absorber 2-(2H-Benzotriazol-2-Yl)-4,6-Di-Tert-Pentylphenol (UV 328) and Its Oxidative Metabolites in Human Urine by Dispersive Liquid-Liquid Microextraction and GC–MS/MS. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2020, 1144, 122071. [Google Scholar] [CrossRef]

- Denghel, H.; Göen, T. Dispersive Liquid-Liquid Microextraction (DLLME) and External Real Matrix Calibration for the Determination of the UV Absorber 2-(2H-Benzotriazol-2-Yl)-4,6-Di-Tert-Pentylphenol (UV 328) and Its Metabolites in Human Blood. Talanta 2021, 223, 121699. [Google Scholar] [CrossRef]

- Zhuang, S.; Lv, X.; Pan, L.; Lu, L.; Ge, Z.; Wang, J.; Wang, J.; Liu, J.; Liu, W.; Zhang, C. Benzotriazole UV 328 and UV-P Showed Distinct Antiandrogenic Activity upon Human CYP3A4-Mediated Biotransformation. Environ. Pollut. 2017, 220, 616–624. [Google Scholar] [CrossRef]

- Liang, X.; Li, J.; Martyniuk, C.J.; Wang, J.; Mao, Y.; Lu, H.; Zha, J. Benzotriazole Ultraviolet Stabilizers Alter the Expression of the Thyroid Hormone Pathway in Zebrafish (Danio Rerio) Embryos. Chemosphere 2017, 182, 22–30. [Google Scholar] [CrossRef]

- Hemalatha, D.; Rangasamy, B.; Nataraj, B.; Maharajan, K.; Narayanasamy, A.; Ramesh, M. Transcriptional, Biochemical and Histological Alterations in Adult Zebrafish (Danio Rerio) Exposed to Benzotriazole Ultraviolet Stabilizer-328. Sci. Total Environ. 2020, 739, 139851. [Google Scholar] [CrossRef]

- Giraudo, M.; Cottin, G.; Esperanza, M.; Gagnon, P.; Silva, A.O.D.; Houde, M. Transcriptional and Cellular Effects of Benzotriazole UV Stabilizers UV-234 and UV-328 in the Freshwater Invertebrates Chlamydomonas Reinhardtii and Daphnia Magna. Environ. Toxicol. Chem. 2017, 36, 3333–3342. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.W.; Chang, K.H.; Isobe, T.; Tanabe, S. Acute Toxicity of Benzotriazole Ultraviolet Stabilizers on Freshwater Crustacean (Daphnia Pulex). J. Toxicol. Sci. 2011, 36, 247–251. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, J.K.; Kim, K.B.; Lee, J.D.; Shin, C.Y.; Kwack, S.J.; Lee, B.M.; Lee, J.Y. Risk Assessment of Drometrizole, a Cosmetic Ingredient Used as an Ultraviolet Light Absorber. Toxicol. Res. 2019, 35, 119–129. [Google Scholar] [CrossRef] [PubMed]

- 2-(2H-Benzotriazol-2-Yl)-4,6-Ditertpentylphenol—Brief Profile—ECHA. Available online: https://www.echa.europa.eu/de/web/guest/brief-profile/-/briefprofile/100.043.062 (accessed on 8 July 2021).

- Annex XV-Identification of UV-328 as SVHC Annex XV Dossier. Available online: https://echa.europa.eu/documents/10162/13641/rac_opinion_annex_UV-328_en.pdf/6d264702-380f-45d4-8022-fb59ca44740f (accessed on 8 July 2021).

- Luukkonen, T.; Teeriniemi, J.; Prokkola, H.; Rämö, J.; Lassi, U. Chemical Aspects of Peracetic Acid Based Wastewater Disinfection. Water SA 2014, 40, 73–80. [Google Scholar] [CrossRef] [Green Version]

- Kiejza, D.; Kotowska, U.; Polińska, W.; Karpińska, J. Peracids - New Oxidants in Advanced Oxidation Processes: The Use of Peracetic Acid, Peroxymonosulfate, and Persulfate Salts in the Removal of Organic Micropollutants of Emerging Concern—A Review. Sci. Total Environ. 2021, 790, 148195. [Google Scholar] [CrossRef]

- Ao, X.-w.; Eloranta, J.; Huang, C.H.; Santoro, D.; Sun, W.-j.; Lu, Z.-d.; Li, C. Peracetic Acid-Based Advanced Oxidation Processes for Decontamination and Disinfection of Water: A Review. Water Res. 2021, 188, 116479. [Google Scholar] [CrossRef]

- Kim, J.; Huang, C.-H. Reactivity of Peracetic Acid with Organic Compounds: A Critical Review. ACS ES&T Water 2021, 1, 15–33. [Google Scholar] [CrossRef]

- Cai, M.; Sun, P.; Zhang, L.; Huang, C.H. UV/Peracetic Acid for Degradation of Pharmaceuticals and Reactive Species Evaluation. Environ. Sci. Technol. 2017, 51, 14217–14224. [Google Scholar] [CrossRef]

- Hollman, J.; Dominic, J.A.; Achari, G. Degradation of Pharmaceutical Mixtures in Aqueous Solutions Using UV/Peracetic Acid Process: Kinetics, Degradation Pathways and Comparison with UV/H2O2. Chemosphere 2020, 248, 125911. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Fu, Y. Degradation Kinetics and Mechanism of Diclofenac by UV/Peracetic Acid. RSC Adv. 2020, 10, 9907–9916. [Google Scholar] [CrossRef] [Green Version]

- Rizzo, L.; Agovino, T.; Nahim-Granados, S.; Castro-Alférez, M.; Fernández-Ibáñez, P.; Polo-López, M.I. Tertiary Treatment of Urban Wastewater by Solar and UV-C Driven Advanced Oxidation with Peracetic Acid: Effect on Contaminants of Emerging Concern and Antibiotic Resistance. Water Res. 2019, 149, 272–281. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Du, P.; Liu, W.; Luo, C.; Zhao, H.; Huang, C.H. Cobalt/Peracetic Acid: Advanced Oxidation of Aromatic Organic Compounds by Acetylperoxyl Radicals. Environ. Sci. Technol. 2020, 54, 5268–5278. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, J.; Xiong, B.; Bai, F.; Wang, S.; Wan, Y.; Zhang, L.; Xie, P.; Wiesner, M.R. Application of Cobalt/Peracetic Acid to Degrade Sulfamethoxazole at Neutral Condition: Efficiency and Mechanisms. Environ. Sci. Technol. 2019, 54, 464–475. [Google Scholar] [CrossRef]

- Popov, E.; Eloranta, J.; Hietapelto, V.; Vuorenpalo, V.M.; Aksela, R.; Jäkärä, J. Mechanism of Decomposition of Peracetic Acid by Manganese Ions and Diethylenetriaminepentaacetic Acid (DTPA). Holzforschung 2005, 59, 507–513. [Google Scholar] [CrossRef]

- Zhang, X.-Z.; Francis, R.C.; Dutton, D.B.; Hill, R.T. Decomposition of Peracetic Acid Catalyzed by Cobalt(II) and Vanadium(V). Can. J. Chem. 1998, 76, 1064–1069. [Google Scholar] [CrossRef]

- Zhou, F.; Lu, C.; Yao, Y.; Sun, L.; Gong, F.; Li, D.; Pei, K.; Lu, W.; Chen, W. Activated Carbon Fibers as an Effective Metal-Free Catalyst for Peracetic Acid Activation: Implications for the Removal of Organic Pollutants. Chem. Eng. J. 2015, 281, 953–960. [Google Scholar] [CrossRef]

- Wu, W.; Tian, D.; Liu, T.; Chen, J.; Huang, T.; Zhou, X.; Zhang, Y. Degradation of Organic Compounds by Peracetic Acid Activated with Co3O4: A Novel Advanced Oxidation Process and Organic Radical Contribution. Chem. Eng. J. 2020, 394, 124938. [Google Scholar] [CrossRef]

- Rokhina, E.V.; Makarova, K.; Lahtinen, M.; Golovina, E.A.; Van As, H.; Virkutyte, J. Ultrasound-Assisted MnO2 Catalyzed Homolysis of Peracetic Acid for Phenol Degradation: The Assessment of Process Chemistry and Kinetics. Chem. Eng. J. 2013, 221, 476–486. [Google Scholar] [CrossRef]

- Wang, J.; Xiong, B.; Miao, L.; Wang, S.; Xie, P.; Wang, Z.; Ma, J. Applying a Novel Advanced Oxidation Process of Activated Peracetic Acid by CoFe2O4 to Efficiently Degrade Sulfamethoxazole. Appl. Catal. B Environ. 2021, 280, 119422. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Cheng, Y.; Cao, L.; Bai, F.; Yue, S.; Xie, P.; Ma, J. Molybdenum Disulfide (MoS2): A Novel Activator of Peracetic Acid for the Degradation of Sulfonamide Antibiotics. Water Res. 2021, 201, 117291. [Google Scholar] [CrossRef]

- Zhou, X.; Hao, W.; Zhang, L.; Liang, B.; Sun, X.; Chen, J. Activation of Peracetic Acid with Lanthanum Cobaltite Perovskite for Sulfamethoxazole Degradation under a Neutral PH: The Contribution of Organic Radicals. Molecules 2020, 25, 2725. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Wang, H.; Liu, Y.; Fu, Y. Effective Degradation of Sulfamethoxazole with Fe2+-Zeolite/Peracetic Acid. Sep. Purif. Technol. 2020, 233, 115973. [Google Scholar] [CrossRef]

- Liu, Y.S.; Ying, G.G.; Shareef, A.; Kookana, R.S. Occurrence and Removal of Benzotriazoles and Ultraviolet Filters in a Municipal Wastewater Treatment Plant. Environ. Pollut. 2012, 165, 225–232. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wang, J.; Chen, J.; Zhou, C.; Cui, F.; Sun, G. Photodegradation of 2-(2-Hydroxy-5-Methylphenyl)Benzotriazole (UV-P) in Coastal Seawaters: Important Role of DOM. J. Environ. Sci. (China) 2019, 85, 129–137. [Google Scholar] [CrossRef]

- Pavanello, A.; Gomez-Mendoza, M.; de la Peña O’Shea, V.A.; Miranda, M.A.; Marin, M.L. Degradation of Benzotriazole UV-Stabilizers in the Presence of Organic Photosensitizers and Visible Light: A Time-Resolved Mechanistic Study. J. Photochem. Photobiol. B Biol. 2022, 230, 112444. [Google Scholar] [CrossRef]

- Kim, J.; Zhang, T.; Liu, W.; Du, P.; Dobson, J.T.; Huang, C.H. Advanced Oxidation Process with Peracetic Acid and Fe(II) for Contaminant Degradation. Environ. Sci. Technol. 2019, 53, 13312–13322. [Google Scholar] [CrossRef]

- El-Asmy, H.A.; Butler, I.S.; Mouhri, Z.S.; Jean-Claude, B.J.; Emmam, M.S.; Mostafa, S.I. Zinc(II), Ruthenium(II), Rhodium(III), Palladium(II), Silver(I), Platinum(II) and Complexes of 2-(2′-Hydroxy-5′-Methylphenyl)-Benzotriazole as Simple or Primary Ligand and 2,2′-Bipyridyl, 9,10-Phenanthroline or Triphenylphosphine as Secondary Ligands: Structure and Anticancer Activity. J. Mol. Struct. 2014, 1059, 193–201. [Google Scholar] [CrossRef]

- Alfassi, Z.B.; Schuler, R.H. Reaction of Azide Radicals with Aromatic Compounds. Azide as a Selective Oxidant. J. Phys. Chem. 1985, 89, 3359–3363. [Google Scholar] [CrossRef]

- McKeown, E.; Waters, W.A. The Oxidation of Organic Compounds by “Singlet” Oxygen. J. Chem. Soc. B Phys. Org. 1966, 1040–1046. [Google Scholar] [CrossRef]

- Lai, H.J.; Ying, G.G.; Ma, Y.B.; Chen, Z.F.; Chen, F.; Liu, Y.S. Occurrence and Dissipation of Benzotriazoles and Benzotriazole Ultraviolet Stabilizers in Biosolid-Amended Soils. Environ. Toxicol. Chem. 2014, 33, 761–767. [Google Scholar] [CrossRef]

- Brandt, M.; Becker, E.; Jöhncke, U.; Sättler, D.; Schulte, C. A Weight-of-Evidence Approach to Assess Chemicals: Case Study on the Assessment of Persistence of 4,6-Substituted Phenolic Benzotriazoles in the Environment. Environ. Sci. Eur. 2016, 28, 1–14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, J.; Xiong, Q.; Liang, J.; He, Q.; Yang, D.; Deng, R.; Chen, Y. Degradation of Benzotriazole by DBD Plasma and Peroxymonosulfate: Mechanism, Degradation Pathway and Potential Toxicity. Chem. Eng. J. 2020, 384, 123300. [Google Scholar] [CrossRef]

- Luukkonen, T. New Adsorption and Oxidation-Based Approaches for Water and Wastewater Treatment; Studies Regarding Organic Peracids, Boiler-Water Treatment, and Geopolymers, University of Oulu Graduate School; University of Oulu, Faculty of Science: Oulu, Finland, 2016. [Google Scholar]

| Sample | Location | UV–P | UV–326 | UV–327 | UV–328 | UV–329 | Determination Method | Ref. |

|---|---|---|---|---|---|---|---|---|

| Breast milk (ng/g lipid wt.) | South Korea | 19.2 | 1.77 | 10 | 64.3 | 4.54 | GC-MS | [32] |

| Japan | 21 | 0.08 | n.d. | 0.2 | 3.8 | UHPLC-MS/MS | [33] | |

| Philippines | 16/71 a | 34/64 | n.d. | 2.4/1.9 | n.d. | |||

| Vietnam | 91/3.9/32 | 0.53/n.d./2.1 | n.d./n.d./1.6 | 0.9/0.48/0.47 | 9.6/2.6/6 | |||

| Mussels (ng/g) | Asia-Pacific coastal waters | – | 150 | 68 | 130 | – | GC-MS | [36] |

| WWTP (ng/L) | China | 9.9–37.1 (7.2–15.9) b | – | – | 2.6–2.9 (0.60) | 3.8 | LC-MS/MS | [16] |

| Rivers in India (ng/L) | Water | 0.2–2.3 | 1.5–3.7 | 3.3–4.3 | 0.5–3.4 | 8.1–13.7 | GC-MS | [21] |

| Sediment | 0.1–0.3 | 0.2–0.5 | 0.6–2 | 0.2–0.9 | 0.9–1.41 | |||

| Fish | 2.2–6.9 | 0.6–1.6 | 1.0–3.2 | 0.2–1.6 | 3.0–7.4 | |||

| House dust (ng/L) | Philippines | – | 53/6.2 | 28/10 | 50/18 | – | UHPLC-ESI-MS/MS | [24] |

| Blood plasma of water animals (pg/g) | North America | – | – | – | 240–776 | <640 | UPLC-MS/MS | [22] |

| BUVs | Route | Living Organism | Acute Toxicity LD50/LC50 | Ref. |

|---|---|---|---|---|

| UV-P | oral | Freshwater crustacean (Daphnia pulex) | >10 mg/L | [49] |

| oral | mice | >5–>10 g/kg | [50] | |

| oral | rats | >15 g/kg | ||

| oral | rats | >5 g/kg | ||

| inhalation | rats | 1420 mg/m3 | ||

| dermal | rabbits | >2 g/kg | ||

| dermal | Guinea pigs | >3 g/kg | ||

| UV-328 | oral | Rat | 7750 mg/kg | [51] |

| inhalation | Rat | 400 mg/m3 | ||

| dermal | rabbit | 1100 mg/kg | ||

| direct | Algae Raphidocelis subcapitata | EC50 > 0.016 mg/L | [52] |

| [PAA]0 (mg/L) | [Me2+]0 (mol/L) | PAA/Fe2+ System | PAA/Co2+ System | |||||

|---|---|---|---|---|---|---|---|---|

| pH | RE% (exp.) | RE% (pred.) | pH | RE% (exp.) | RE% (pred.) | |||

| 1 | 45 | 3.45 × 10−4 | 4.6 | 91.01 | 100.00 | 7 | 57.35 | 63.37 |

| 2 | 45 | 3.45 × 10−4 | 3.4 | 94.13 | 97.24 | 4 | 76.25 | 77.84 |

| 3 | 45 | 1.45 × 10−5 | 4.6 | 36.99 | 55.25 | 7 | 73.69 | 72.96 |

| 4 | 45 | 1.45 × 10−5 | 3.4 | 33.35 | 46.27 | 4 | 55.32 | 60.78 |

| 5 | 15 | 3.45 × 10−4 | 4.6 | 97.44 | 100.00 | 7 | 66.91 | 64.61 |

| 6 | 15 | 3.45 × 10−4 | 3.4 | 92.99 | 97.24 | 4 | 75.48 | 79.08 |

| 7 | 15 | 1.45 × 10−5 | 4.6 | 20.10 | 55.25 | 7 | 75.22 | 74.20 |

| 8 | 15 | 1.45 × 10−5 | 3.4 | 23.84 | 46.27 | 4 | 49.54 | 62.02 |

| 9 | 55 | 7 × 10−5 | 4 | 78.68 | 66.76 | 5.5 | 67.55 | 66.21 |

| 10 | 5 | 7 × 10−5 | 4 | 93.51 | 66.76 | 5.5 | 65.49 | 68.28 |

| 11 | 30 | 1 × 10−3 | 4 | 90.15 | 87.04 | 5.5 | 65.51 | 64.61 |

| 12 | 30 | 5 × 10−6 | 4 | 41.04 | 53.29 | 5.5 | 55.44 | 66.56 |

| 13 | 30 | 7 × 10−5 | 5 | 93.50 | 61.48 | 8 | 64.78 | 76.62 |

| 14 | 30 | 7 × 10−5 | 3 | 57.71 | 46.51 | 3 | 58.76 | 63.78 |

| 15 | 30 | 7 × 10−5 | 4 | 75.96 | 66.76 | 5.5 | 69.46 | 67.68 |

| 16 | 30 | 7 × 10−5 | 4 | 76.79 | 66.76 | 5.5 | 77.01 | 67.68 |

| 17 | 30 | 7 × 10−5 | 4 | 71.59 | 66.76 | 5.5 | 77.37 | 67.68 |

| 18 | 30 | 7 × 10−5 | 4 | 72.02 | 66.76 | 5.5 | 77.74 | 67.68 |

| 19 | 30 | 7 × 10−5 | 4 | 72.57 | 66.76 | 5.5 | 81.38 | 67.68 |

| 20 | 30 | 7 × 10−5 | 4 | 78.93 | 66.76 | 5.5 | 76.76 | 67.68 |

| Source of Variation | Sum of Squares | DF | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| PAA concentration (square) | 128.572 | 1 | 128.5723 | 8.46121 | 0.033446 |

| Co2+ concentration (linear) | 103.937 | 1 | 103.9369 | 6.83998 | 0.047364 |

| Co2+ concentration (square) | 165.885 | 1 | 165.8846 | 10.91670 | 0.021380 |

| pH (square) | 308.624 | 1 | 308.6242 | 20.31025 | 0.006360 |

| Co2+ concentration-pH interactions | 585.017 | 1 | 585.0169 | 38.49937 | 0.001588 |

| Lack of fit | 507.354 | 9 | 56.3727 | ||

| Pure error | 75.977 | 5 | 15.1955 | ||

| Total | 1610.347 | 19 | |||

| R2 = 0.63776 | R2 (adjusted) = 0.50839 | p < 0.05 is considered as significant | |||

| Compound | Fe2+/PAA Process | Co2+/PAA Process | ||||

|---|---|---|---|---|---|---|

| R2 | k (min−1) | t1/2 (min) | R2 | k (min−1) | t1/2 (min) | |

| UV-P | 0.972 | 0.0059 | 117.48 | – | – | – |

| UV-326 | 0.992 | 0.0118 | 58.74 | 0.992 | 0.0150 | 46.21 |

| UV-327 | 0.967 | 0.0166 | 41.76 | 0.953 | 0.0107 | 64.78 |

| UV-328 | 0.976 | 0.0125 | 55.45 | 0.997 | 0.0116 | 59.75 |

| UV-329 | 0.991 | 0.0121 | 57.28 | 0.960 | 0.0088 | 78.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiejza, D.; Karpińska, J.; Kotowska, U. Degradation of Benzotriazole UV Stabilizers in PAA/d-Electron Metal Ions Systems—Removal Kinetics, Products and Mechanism Evaluation. Molecules 2022, 27, 3349. https://doi.org/10.3390/molecules27103349

Kiejza D, Karpińska J, Kotowska U. Degradation of Benzotriazole UV Stabilizers in PAA/d-Electron Metal Ions Systems—Removal Kinetics, Products and Mechanism Evaluation. Molecules. 2022; 27(10):3349. https://doi.org/10.3390/molecules27103349

Chicago/Turabian StyleKiejza, Dariusz, Joanna Karpińska, and Urszula Kotowska. 2022. "Degradation of Benzotriazole UV Stabilizers in PAA/d-Electron Metal Ions Systems—Removal Kinetics, Products and Mechanism Evaluation" Molecules 27, no. 10: 3349. https://doi.org/10.3390/molecules27103349