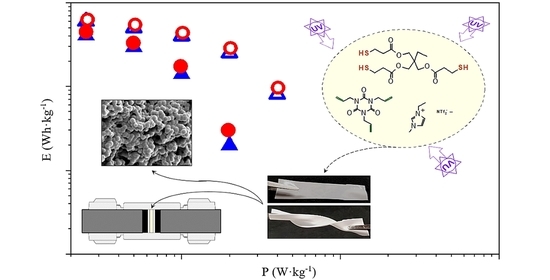

Ionogels Obtained by Thiol-Ene Photopolymerization—Physicochemical Characterization and Application in Electrochemical Capacitors

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Used Reagents

3.2. Ionogels Synthesis

3.3. Physicochemical Characterization

3.3.1. Scanning Electron Microscope—SEM

3.3.2. Puncture Resistance

3.3.3. Ionic Conductivity

3.3.4. Infrared Spectroscopy (FTIR-ATR)

3.3.5. Differential Scanning Calorimetry—DSC

3.4. Electrochemical Measurements of Capacitors

3.4.1. Preparation of Electrodes

3.4.2. Electrochemical Investigations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, B.K.; Sy, S.; Yu, A.; Zhang, J. Electrochemical Supercapacitors for Energy Storage and Conversion. In Handbook of Clean Energy Systems; Yan, J., Ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2015; pp. 1–25. [Google Scholar]

- Lin, Z.; Taberna, P.-L.; Simon, P. Electrochemical double layer capacitors: What is next beyond the corner? Curr. Opin. Electrochem. 2017, 6, 115–119. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Yu, M.; Wang, G.; Tong, Y.; Li, Y. Flexible solid-state supercapacitors: Design, fabrication and applications. Energy Environ. Sci. 2014, 7, 2160–2181. [Google Scholar] [CrossRef]

- Zhong, C.; Deng, Y.; Hu, W.; Qiao, J.; Zhang, L.; Zhang, J. A review of electrolyte materials and compositions for electrochemical supercapacitors. Chem. Soc. Rev. 2015, 44, 7484–7539. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.H.; Isa, M. Structural and Ionic Conductivity Studies of CMC Based Polymer Electrolyte Doped with NH4Cl. Adv. Mater. Res. 2015, 1107, 247–252. [Google Scholar] [CrossRef]

- Li, H.; Lv, T.; Li, N.; Yao, Y.; Liu, K.; Chen, T. Ultraflexible and tailorable all-solid-state supercapacitors using polyacrylamide-based hydrogel electrolyte with high ionic conductivity. Nanoscale 2017, 9, 18474–18481. [Google Scholar] [CrossRef]

- Choudhury, N.A.; Sampath, S.; Shukla, A.K. Hydrogel-polymer electrolytes for electrochemical capacitors: An overview. Energy Environ. Sci. 2009, 2, 55–67. [Google Scholar] [CrossRef] [Green Version]

- Alexandre, S.A.; Silva, G.G.; Santamaría, R.; Trigueiro, J.P.C.; Lavall, R.L. A highly adhesive PIL/IL gel polymer electrolyte for use in flexible solid state supercapacitors. Electrochim. Acta 2019, 299, 789–799. [Google Scholar] [CrossRef]

- Ortega, P.F.; Trigueiro, J.P.C.; Silva, G.G.; Lavall, R.L. Improving supercapacitor capacitance by using a novel gel nanocomposite polymer electrolyte based on nanostructured SiO2, PVDF and imidazolium ionic liquid. Electrochim. Acta 2016, 188, 809–817. [Google Scholar] [CrossRef]

- Huber, B.; Rossrucker, L.; Sundermeyer, J.; Roling, B. Ion transport properties of ionic liquid-based polyelectrolytes. Solid State Ionics 2013, 247-248, 15–21. [Google Scholar] [CrossRef]

- Juger, J.; Vancaeyzeele, C.; Plesse, C.; Nguyen, G.; Ribeiro, F.B.; Teyssié, D.; Vidal, F. Polymeric ionic liquid based interpenetrating polymer network for all-solid self-standing polyelectrolyte material. Eur. Polym. J. 2018, 106, 257–265. [Google Scholar] [CrossRef]

- Balducci, A. Electrolytes for high voltage electrochemical double layer capacitors: A perspective article. J. Power Sources 2016, 326, 534–540. [Google Scholar] [CrossRef]

- Arora, P.; Zhang, Z.J. Battery separators. Chem. Rev. 2004, 104, 4419–4462. [Google Scholar] [CrossRef] [PubMed]

- Ayalneh Tiruye, G.; Muñoz-Torrero, D.; Palma, J.; Anderson, M.; Marcilla, R. All-solid state supercapacitors operating at 3.5 V by using ionic liquid based polymer electrolytes. J. Power Sources 2015, 279, 472–480. [Google Scholar] [CrossRef]

- Andrzejewska, E. Photopolymerization kinetics of multifunctional monomers. Prog. Polym. Sci. 2001, 26, 605–665. [Google Scholar] [CrossRef]

- Marcinkowska, A.; Zgrzeba, A.; Lota, G.; Kopczyński, K.; Andrzejewska, E. Ionogels by thiol-ene photopolymerization in ionic liquids: Formation, morphology and properties. Polymer 2019, 160, 272–281. [Google Scholar] [CrossRef]

- Hoyle, C.E.; Bowman, C.N. Thiol-ene click chemistry. Angew. Chem. Int. Ed. 2010, 49, 1540–1573. [Google Scholar] [CrossRef]

- Hoyle, C.E.; Lowe, A.B.; Bowman, C.N. Thiol-click chemistry: A multifaceted toolbox for small molecule and polymer synthesis. Chem. Soc. Rev. 2010, 39, 1355–1387. [Google Scholar] [CrossRef]

- Hou, J.; Liu, X.; Shen, J.; Zhao, G.; Wang, P.G. The impact of click chemistry in medicinal chemistry. Expert Opin. Drug Dis. 2012, 7, 489–501. [Google Scholar] [CrossRef]

- Konuray, O.; Fernández-Francos, X.; De la Flor, S.; Ramis, X.; Serra, À. The use of click-type reactions in the preparation of thermosets. Polymer 2020, 12, 1–44. [Google Scholar]

- Nair, D.P.; Podgórski, M.; Chantani, S.; Gong, T.; Xi, W.; Fenoli, C.R.; Bowman, C.N. The thiol-Michael addition click reaction: A powerful and widely used tool inmaterials chemistry. Chem. Mater. 2014, 26, 724–744. [Google Scholar] [CrossRef]

- Yigit, S.; Sanyal, R.; Sanyal, A. Fabrication and functionalization of hydrogels through “click” chemistry. Chem. Asian J. 2011, 6, 2648–2659. [Google Scholar] [CrossRef] [PubMed]

- Thirumurugan, P.; Matosiuk, D.; Jozwiak, K. Click chemistry for drug development and diverse chemical-biology applications. Chem. Rev. 2013, 113, 4905–4979. [Google Scholar] [CrossRef] [PubMed]

- Kolb, H.C.; Sharpless, K.B. The growing impact of click chemistry on drug discovery. Drug Discov. Today 2003, 8, 1128–1137. [Google Scholar] [CrossRef]

- Moses, J.E.; Moorhouse, A.D. The growing applications of click chemistry. Chem. Soc. Rev. 2007, 36, 1249–1262. [Google Scholar] [CrossRef]

- Jiang, X.; Hao, X.; Jing, L.; Wu, G.; Kang, D.; Liu, X.; Zhan, P. Recent applications of click chemistry in drug discovery. Expert Opin. Drug Discov. 2019, 14, 779–789. [Google Scholar] [CrossRef]

- Agalave, S.G.; Maujan, S.R.; Pore, V.S. Click chemistry: 1,2,3-triazoles as pharmacophores. Chem. Asian J. 2011, 4, 2696–2718. [Google Scholar] [CrossRef] [PubMed]

- Arslan, M.; Tasdelen, M.A. Polymer Nanocomposites via Click Chemistry Reactions. Polymer 2017, 9, 499. [Google Scholar] [CrossRef]

- Binder, W.H.; Sachsenhofer, R. ‘Click’ chemistry in polymer and material science: An update. Macromol. Rapid Commun. 2008, 29, 952–981. [Google Scholar] [CrossRef]

- Segura, J.L.; Salavagione, H.J. Graphene in copper catalyzed azide-alkyne cycloaddition reactions: Evolution from [60] fullerene and carbon nanotubes strategies. Curr. Org. Chem. 2013, 17, 1680–1693. [Google Scholar] [CrossRef]

- Lowe, A.B. Thiol-ene “click” reactions and recent applications in polymer and materials synthesis. Polym. Chem. 2010, 1, 17–36. [Google Scholar] [CrossRef]

- Castelaín, M.; Martínez, G.; Marco, C.; Ellis, G.; Salavagione, H.J. Effect of Click-Chemistry Approaches for Graphene Modification on the Electrical, Thermal, and Mechanical Properties of Polyethylene/Graphene Nanocomposites. Macromolecules 2013, 46, 8980–8987. [Google Scholar] [CrossRef]

- Schreck, K.M.; Leung, D.; Bowman, C.N. Hybrid organic/inorganic thiol-ene-based photopolymerized networks. Macromolecules 2011, 44, 7520–7529. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Resetco, C.; Hendriks, B.; Badi, N.; Du Prez, F. Thiol–ene chemistry for polymer coatings and surface modification—Building in sustainability and performance. Mater. Horiz. 2017, 4, 1041–1053. [Google Scholar] [CrossRef]

- Liu, Y.; Hou, W.; Sun, H.; Cui, C.; Zhang, L.; Jiang, Y.; Wu, Y.; Wang, Y.; Li, J.; Sumerlin, B.S.; et al. Thiol–ene click chemistry: A biocompatible way for orthogonal bioconjugation of colloidal nanoparticles. Chem. Sci. 2017, 8, 6182–6187. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- García-Astrain, C.; Miljevic, M.; Ahmed, I.; Martin, L.; Eceiza, A.; Fruk, L.; Corcuera, M.; Gabilondo, N. Designing hydrogel nanocomposites using TiO2 as clickable cross-linkers. J. Mater. Sci. 2016, 51, 5073–5081. [Google Scholar] [CrossRef]

- Zhang, Y.; Chu, C.W.; Ma, W.; Takahara, A. Functionalization of Metal Surface via Thiol-Ene Click Chemistry: Synthesis, Adsorption Behavior, and Postfunctionalization of a Catechol- and Allyl-Containing Copolymer. ACS Omega 2020, 5, 7488–7496. [Google Scholar] [CrossRef]

- Zgrzeba, A.; Andrzejewska, E.; Marcinkowska, A. Ionic liquid—Containing ionogels by thiol–ene photopolymerization. Kinetics and solvent effect. RSC Adv. 2015, 5, 100354–100361. [Google Scholar] [CrossRef]

- Chiou, B.-S.; English, R.J.; Khan, S.A. Rheology and Photo-Cross-Linking of Thiol−Ene Polymers. Macromolecules 1996, 29, 5368–5374. [Google Scholar]

- Zhou, H.; Li, Q.; Shin, J.; Hoyle, C.E. Effects of Monomer Functionality and Hydrogen Bonding on the Polymerization Kinetics and Properties of Thiol−Ene Networks. Macromolecules 2009, 42, 2994–2999. [Google Scholar] [CrossRef]

- Cláudio, A.F.M.; Swift, L.; Hallett, J.P.; Welton, T.; Coutinho, J.A.P.; Freire, M.G. Extended scale for the hydrogen-bond basicity of ionic liquids. Phys. Chem. Chem. Phys. 2014, 16, 6593–6601. [Google Scholar] [CrossRef] [Green Version]

- Jessop, P.G.; Jessop, D.A.; Fu, D.; Phan, L. Solvatochromic parameters for solvents of interest in green chemistry. Green Chem. 2012, 14, 1245–1259. [Google Scholar] [CrossRef]

| Poly(TATT + TMPTP) | Poly(TATT + TMPTP) + 50 wt.% of IL | |||

|---|---|---|---|---|

| EMImNTf2 | BMImNTf2 | EMImOTf | BMImOTf * | |

| Tg °C | ||||

| 21.4 | 16.1 | 15.3 | 15.8 | - |

| Matrix Poly(TATT + TMPTP) with IL | CIL, wt.% | Spheres Size, µm |

|---|---|---|

| EMImNTf2 | 50 | 0.51–0.74 |

| 70 | 0.24–0.40 | |

| BMImNTf2 | 50 | 0.37–0.56 |

| 70 | 0.20–0.32 | |

| EMImOTf | 50 | 0.50–1.00 |

| 70 | 0.60–0.90 | |

| BMImOTf | 50 | 0.30–0.53 |

| 70 | 0.28–0.46 |

Sample Availability: Samples of the ionogels are available from the authors. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marcinkowska, A.; Gajewski, P.; Szcześniak, K.; Sadej, M.; Lewandowska, A. Ionogels Obtained by Thiol-Ene Photopolymerization—Physicochemical Characterization and Application in Electrochemical Capacitors. Molecules 2021, 26, 758. https://doi.org/10.3390/molecules26030758

Marcinkowska A, Gajewski P, Szcześniak K, Sadej M, Lewandowska A. Ionogels Obtained by Thiol-Ene Photopolymerization—Physicochemical Characterization and Application in Electrochemical Capacitors. Molecules. 2021; 26(3):758. https://doi.org/10.3390/molecules26030758

Chicago/Turabian StyleMarcinkowska, Agnieszka, Piotr Gajewski, Katarzyna Szcześniak, Mariola Sadej, and Aneta Lewandowska. 2021. "Ionogels Obtained by Thiol-Ene Photopolymerization—Physicochemical Characterization and Application in Electrochemical Capacitors" Molecules 26, no. 3: 758. https://doi.org/10.3390/molecules26030758