Dried Destoned Virgin Olive Pomace: A Promising New By-Product from Pomace Extraction Process

Abstract

:1. Introduction

2. Materials and Methods

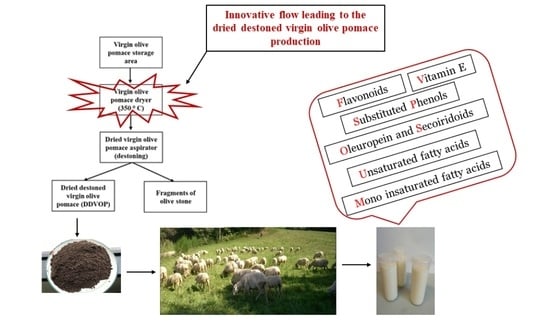

2.1. Dried Destoned Virgin Olive Pomace (DDVOP)

2.2. DDVOP Phenols Analysis

2.3. DDVOP Tocopherols Analysis

2.4. DDVOP Fatty Acid Analysis

2.5. Experimental Trial on Sheep and Milk Analyses

2.6. Chemical Analyses of DDVOP for Animal Feed

2.7. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Neifar, M.; Jaouani, A.; Ayari, A.; Abid, O.; Ben Salem, H.; Boudabous, A.; Najar, T.; Ghorbel, R.E. Improving the nutritive value of Olive Cake by solid state cultivation of the medicinal mushroom Fomes fomentarius. Chemosphere 2013, 91, 110–114. [Google Scholar] [CrossRef]

- Valiente, C.; Arrigoni, E.; Corrales, J.R.; Esteban, R.M.; Amadò, R. Composition of Dietary Fiber in Olive Cake. Amino Acids Associated with Insoluble, Soluble and Total Dietary Fiber. Grasas Aceites 1995, 46, 98–102. [Google Scholar] [CrossRef] [Green Version]

- Kumar, R.; Singh, M. Tannins: Their adverse role in ruminant nutrition. J. Agric. Food Chem. 1984, 32, 447–453. [Google Scholar] [CrossRef]

- Pagnanelli, F.; Viggi, C.C.; Toro, L. Development of new composite biosorbents from olive pomace wastes. Appl. Surf. Sci. 2010, 256, 5492–5497. [Google Scholar] [CrossRef]

- Yucel, Y. Optimization of immobilization conditions of Thermomyces lanuginosus lipase on olive pomace powder using response surface methodology. Biotechnology 2012, 1, 39–44. [Google Scholar] [CrossRef]

- Benincasa, C.; La Torre, C.; Plastina, P.; Fazio, A.; Perri, E.; Caroleo, M.C.; Gallelli, L.; Cannataro, R.; Cione, E. Hydroxytyrosyl Oleate: Improved Extraction Procedure from Olive Oil and By-Products, and In Vitro Antioxidant and Skin Regenerative Properties. Antioxidants 2019, 8, 233. [Google Scholar] [CrossRef] [Green Version]

- Benincasa, C.; Muccilli, S.; Amenta, M.; Perri, E.; Romeo, F.V. Phenolic trend and hygienic quality of green table olives fermented with Lactobacillus plantarum starter culture. Food Chem. 2015, 186, 271–276. [Google Scholar] [CrossRef] [PubMed]

- Campolo, M.; Di Paola, R.; Impellizzeri, D.; Crupi, R.; Morittu, V.M.; Procopio, A.; Perri, E.; Britti, D.; Peli, A.; Esposito, E.; et al. Effects of a polyphenol present in olive oil, oleuropein aglycone, in a murine model of intestinal ischemia/reperfusion injury. J. Leukoc. Biol. 2013, 93, 277–287. [Google Scholar] [CrossRef]

- Impellizzeri, D.; Esposito, E.; Mazzon, E.; Paterniti, I.; Di Paola, R.; Bramanti, P.; Morittu, V.M.; Procopio, A.; Perri, E.; Britti, D.; et al. The effects of a polyphenol present in olive oil, oleuropein aglycone, in an experimental model of spinal cord injury in mice. Biochem. Pharmacol. 2012, 83, 1413–1426. [Google Scholar] [CrossRef]

- Tutino, V.; Caruso, M.G.; Messa, C.; Perri, E.; Notarnicola, M. Antiproliferative, antioxidant and anti-inflammatory effects of hydroxytyrosol on human hepatoma HepG2 and Hep3B cell lines. Anticancer Res. 2012, 32, 5371–5377. [Google Scholar] [PubMed]

- Rhouma, H.; Trabelsi, N.; Chimento, A.; Benincasa, C.; Tamaalli, A.; Perri, E.; Zarrouk, M.; Pezzi, V. Olea europaea L. Flowers as a new promising anticancer natural product: Phenolic composition, antiproliferative activity and apoptosis induction. Nat. Prod. Res. 2021, 35, 1836–1839. [Google Scholar] [CrossRef]

- Lupinacci, S.; Toteda, G.; Vizza, D.; Perri, A.; Benincasa, C.; Mollica, A.; La Russa, A.; Gigliotti, P.; Leone, F.; Lofaro, D.; et al. Active compounds extracted from extra virgin olive oil counteract mesothelial-to-mesenchymal transition of peritoneal mesothelium cells exposed to conventional peritoneal dialysate: In vitro and in vivo evidences. J. Nephrol. 2017, 30, 841–850. [Google Scholar] [CrossRef] [PubMed]

- Toteda, G.; Lupinacci, S.; Vizza, D.; Bonofiglio, R.; Perri, E.; Bonofiglio, M.; Lofaro, D.; La Russa, A.; Leone, F.; Gigliotti, P.; et al. High doses of hydroxytyrosol induce apoptosis in papillary and follicular thyroid cancer cells. J. Endocrinol. Investig. 2017, 40, 153–162. [Google Scholar] [CrossRef]

- Sabatini, N.; Perri, E.; Rongai, D. Olive Oil Antioxidants and Aging, Food Quality: Balancing Health and Disease. In Handbook of Food Bioengineering; Elsevier: San Diego, CA, USA, 2018; Volume 4, pp. 145–157. [Google Scholar]

- Plastina, P.; Benincasa, C.; Perri, E.; Fazio, A.; Augimeri, G.; Poland, M.; Witkamp, R.; Meijerink, J. Identification of hydroxytyrosyl oleate, a derivative of hydroxytyrosol with anti-inflammatory properties, in olive oil by-products. Food Chem. 2019, 279, 105–113. [Google Scholar] [CrossRef]

- Ćepo, V.D.; Radić, K.; Jurmanović, S.; Jug, M.; Grdić Rajković, M.; Pedisić, S.; Moslavac, T.; Albahari, P. Valorization of Olive Pomace-Based Nutraceuticals as Antioxidants in Chemical, Food, and Biological Models. Molecules 2018, 23, 2070. [Google Scholar] [CrossRef] [Green Version]

- De Marco, E.; Savarese, M.; Paduano, A.; Sacchi, R. Characterization and fractionation of phenolic compounds extracted from olive oil mill wastewaters. Food Chem. 2007, 104, 858–867. [Google Scholar] [CrossRef]

- Saez, L.; Perez, J.; Martinez, J. Low molecular weight phenolics attenuation during simulated treatment of wastewaters from olive oil mills in evaporation ponds. Water Res. 1992, 26, 1261–1266. [Google Scholar] [CrossRef]

- Ben Sassi, A.; Boularbah, A.; Jaouad, A.; Walker, G.; Boussaid, A. A comparison of Olive oil Mill Wastewaters (OMW) from three different processes in Morocco. Process. Biochem. 2006, 41, 74–78. [Google Scholar] [CrossRef]

- Karpouzas, D.G.; Ntougias, S.; Iskidou, E.; Rousidou, C.; Papadopoulou, K.K.; Zervakis, G.I.; Ehaliotis, C. Olive mill wastewater affects the structure of soil bacterial communities. Appl. Soil Ecol. 2010, 45, 101–111. [Google Scholar] [CrossRef]

- Fiorentino, A.; Gentili, A.; Isidori, M.; Monaco, P.; Nardelli, A.; Parrella, A.; Temussi, F. Environmental effects caused by olive mill wastewaters: Toxicity comparison of low-molecular-weight phenol components. J. Agric. Food Chem. 2003, 51, 1005–1009. [Google Scholar] [CrossRef] [PubMed]

- Greco, G., Jr.; Colarieti, M.L.; Toscano, G.; Iamarino, G.; Rao, M.A.; Gianfreda, L. Mitigation of olive mill wastewater toxicity. J. Agric. Food Chem. 2006, 54, 6776–6782. [Google Scholar] [CrossRef]

- Hanifi, S.; El Hadrami, I. Olive mill wastewaters: Diversity of the fatal product in olive oil industry and its valorisation as agronomical amendment of poor soils: A review. J. Agron. 2009, 8, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Peixoto, F.; Martins, F.; Amaral, C.; Gomes-Laranjo, J.; Almeida, J.; Palmeira, C.M. Evaluation of olive oil mill wastewater toxicity on the mitochondrial bioenergetics after treatment with Candida oleophila. Ecotoxicol. Environ. Saf. 2008, 70, 266–275. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yangui, T.; Sayadi, S.; Gargoubi, A.; Dhouib, A. Fungicidal effect of hydroxytyrosol-rich preparations from olive mill wastewater against Verticillium dahlia. Crop Prot. 2010, 29, 1208–1213. [Google Scholar] [CrossRef]

- Friedman, M.; Rasooly, R.; Do, P.M.; Henika, P.R. The olive compound 4-hydroxytyrosol inactivates Staphylococcus aureus bacteria and Staphylococcal Enterotoxin A (SEA). J. Food Sci. 2011, 76, M558–M563. [Google Scholar] [CrossRef] [PubMed]

- Cayuela, M.L.; Mondini, C.; Sánchez-Monedero, M.A.; Roig, A. Chemical properties and hydrolytic enzyme activities for the characterisation of two-phase olive mill wastes composting. Bioresour. Technol. 2008, 99, 4255–4262. [Google Scholar] [CrossRef] [PubMed]

- Zema, D.A.; Calabrò, P.S.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S.M. Valorisation of citrus processing waste: A review. Waste Manag. 2018, 80, 252–273. [Google Scholar] [CrossRef]

- Reboredo-Rodríguez, P.; Figueiredo-González, M.; González-Barreiro, C.; Simal-Gándara, J.; Desamparados Salvador, M.; Cancho-Grande, B.; Fregapane, G. State of the Art on Functional Virgin Olive Oils Enriched with Bioactive Compounds and Their Properties. Int. J. Mol. Sci. 2017, 18, 668. [Google Scholar] [CrossRef] [Green Version]

- Caputo, A.R.; Morone, G.; Di Napoli, M.A.; Rufrano, D.; Sabia, E.; Paladino, F.; Sepe, L.; Claps, S. Effect of destoned olive cake on the aromatic profile of cows’ milk and dairy products: Comparison of two techniques for the headspace aroma profile analysis. Ital. J. Agron. 2015, 10, 15–20. [Google Scholar] [CrossRef]

- Terramoccia, S.; Bartocci, S.; Taticchi, A.; Di Giovanni, S.; Pauselli, M.; Mourvaki, E.; Urbani, S.; Servili, M. Use of Dried Stoned Olive Pomace in the Feeding of Lactating Buffaloes: Effect on the Quantity and Quality of the Milk Produced, Asian Australas. J. Anim. Sci. 2013, 26, 971–980. [Google Scholar] [CrossRef]

- Tufariello, M.; Durante, M.; Veneziani, G.; Taticchi, A.; Servili, M.; Bleve, G.; Mita, G. Patè Olive Cake: Possible Exploitation of a By-Product for Food Applications. Front. Nutr. 2019, 6, 3. [Google Scholar] [CrossRef]

- Hume, D.A.; Whitelaw, C.B.A.; Archibald, A.L. The future of animal production: Improving productivity and sustainability. J. Agric. Sci. 2011, 149, 9–16. [Google Scholar] [CrossRef] [Green Version]

- Rupić, V.; Jerković, I.; Bozac, R.; Glowattzky, D.; Muźic, S.; Hrabak, V. Olive by-products in pig fattening. Acta Vet. Hung. 1997, 45, 53–66. [Google Scholar] [PubMed]

- Mele, C.; Pels, J.; Storbacka, K. A holistic market conceptualization. J. Acad. Mark. Sci. 2015, 43, 100–114. [Google Scholar] [CrossRef]

- Luciano, G.; Monahan, F.J.; Vasta, V.; Pennisi, P.; Bella, M.; Priolo, A. Lipid and colour stability of meat from lambs fed fresh herbage or concentrate. Meat Sci. 2009, 82, 193–199. [Google Scholar] [CrossRef] [PubMed]

- Estaún, J.; Dosil, J.; Al Alami, A.; Gimeno, A.; De Vega, A. Effects of including olive cake in the diet on performance and rumen function of beef cattle. Anim. Prod. Sci. 2014, 54, 1817–1821. [Google Scholar] [CrossRef]

- Dal Bosco, A.; Mourvaki, E.; Cardinali, R.; Servili, M.; Sebastiani, B.; Ruggeri, S.; Castellini, C. Effect of dietary supplementation with olive pomaces on the performance and meat quality of growing rabbits. Meat Sci. 2012, 92, 783–788. [Google Scholar] [CrossRef]

- Foti, S.; Sambuelli, L.; Socco, V.L.; Strobbia, C. Experiments of joint acquisition of seismic refraction and surface wave data. Near Surf. Geophys. 2003, 1, 119–129. [Google Scholar] [CrossRef]

- Mele, M.; Serra, A.; Pauselli, M.; Luciano, G.; Lanza, M.; Pennisi, P.; Conte, G.; Taticchi, A.; Esposto, S.; Morbidini, L. The use of stoned olive cake and rolled linseed in the diet of intensively reared lambs: Effect on the intramuscular fatty-acid composition. Animal 2014, 8, 152–162. [Google Scholar] [CrossRef] [PubMed]

- Claps, S.; Rossi, R.; Di Trana, A.; Di Napoli, M.A.; Giorgio, D.; Sepe, L. Bioactive Compounds in Goat Milk and Cheese: The Role of Feeding System and Breed; InTech: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Benincasa, C.; Russo, A.; Romano, E.; Elsorady, M.; Perri, E.; Muzzalupo, I. Chemical and sensory analysis of some Egyptian virgin olive oils. J. Nutr. Food Sci. 2011, 5, 118. [Google Scholar] [CrossRef] [Green Version]

- Vázquez, C.V.; Rojas, M.G.V.; Ramírez, C.A.; Chávez-Servín, J.L.; García-Gasca, T.; Martínez, R.A.F.; García, O.P.; Rosado, J.L.; López-Sabater, C.M.; Castellote, A.I.; et al. Total phenolic compounds in milk from different species. Design of an extraction technique for quantification using the Folin–Ciocalteu method. Food Chem. 2015, 176, 480–486. [Google Scholar] [CrossRef]

- Permanyer, M.; Castellote, A.I.; Carmen López-Sabater, M.C. Effects of pasteurisation and high-pressure processing on vitamin C, tocopherols and fatty acids in mature human milk. Food Chem. 2011, 124, 697–702. [Google Scholar]

- Goering, H.K.; Van Soest, P.J. Forage Fibre Analysis (Apparatus, Reagents, Procedures and Some Applications). In ARS USDA Agriculture Hand Book; US Agricultural Research Service: Washington, DC, USA, 1970; Volume 379, pp. 387–598. [Google Scholar]

- Abdel-Hamid, N.M.; El-Moselhy, M.A.; El-Baz, A. Hepatocyte lysosomal membrane stabilization by olive leaves against chemically induced hepatocellular neoplasia in rats. Int. J. Hepatol. 2011, 2011, 736581. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohagheghi, F.; Bigdeli, M.R.; Rasoulian, B.; Hashemi, P.; Pour, M.R. The neuroprotective effect of olive leaf extract is related to improved blood-brain barrier permeability and brain edema in rat with experimental focal cerebral ischemia. Phytomedicine 2011, 18, 170–175. [Google Scholar] [CrossRef] [PubMed]

- Khalifa, T.I.; Muhtadi, F.J.; Hassan, M.M.A. Rutin. In Analytical Profiles of Drug Substances; Florey, K., Ed.; Academic Press: New York, NY, USA, 1983; pp. 623–675. [Google Scholar]

- Nijveldt, R.J.; van Nood, E.; van Hoorn, D.E.; Boelens, P.G.; van Norren, K.; van Leeuwen, P.A. Flavonoids: A review of probable mechanisms of action and potential applications. Am. J. Clin. Nutr. 2001, 74, 418–425. [Google Scholar] [CrossRef] [PubMed]

- Seelinger, G.; Merfort, I.; Schempp, C.M. Antioxidant, antiinflammatory and antiallergic activities of luteolin. Planta Med. 2008, 74, 1667–1677. [Google Scholar] [CrossRef] [PubMed]

| Phenolic Compound | [M − H]− | Main Fragment Ion | DP | EP | CE | CXP |

|---|---|---|---|---|---|---|

| (m/z) | (m/z) | (V) | (V) | (V) | (V) | |

| Catechol | 108.8 | 90.9 | −83 | −11 | −22 | −5 |

| Caffeic acid | 178.8 | 135.1 | −60 | −11 | −20 | −6 |

| Vanillin | 150.9 | 135.9 | −61 | −10 | −25 | −6 |

| Vanillic acid | 166.8 | 108.1 | −33 | −10 | −25 | −4 |

| p-Coumaric acid | 162.8 | 119.0 | −31 | −7 | −17 | −5 |

| o-Coumaric acid | 162.8 | 119.0 | −27 | −7 | −17 | −5 |

| Ferulic acid | 192.9 | 134.1 | −35 | −10 | −21 | −5 |

| Apigenin | 269.0 | 117.0 | −96 | −11 | −44 | −5 |

| Apigenin-7-O-Glucoside | 431.0 | 267.1 | −90 | −10 | −40 | −6 |

| Diosmetin | 299.0 | 284.1 | −107 | −11 | −35 | −13 |

| Hydroxytyrosol | 152.9 | 123.0 | −80 | −11 | −22 | −5 |

| Tyrosol | 136.9 | 119.1 | −60 | −8 | −20 | −6 |

| Oleuropein | 539.3 | 377.1 | −65 | −10 | −20 | −5 |

| Luteolin | 284.5 | 133.2 | −104 | −5 | −37 | −6 |

| Verbascoside | 623.3 | 161.1 | −83 | −11 | −39 | −15 |

| Luteolin-7-O-Glucoside | 447.1 | 285.1 | −82 | −11 | −35 | −7 |

| Luteolin-4-O-Glucoside | 447.1 | 285.1 | −60 | −10 | −32 | −15 |

| Rutin | 609.2 | 301.0 | −116 | −11 | −50 | −15 |

| Syringic acid | 196.8 | 120.9 | −70 | −11 | −25 | −6 |

| Operational Spry Drying Conditions | Traditional Process | New Process |

|---|---|---|

| Oven outlet air temperature | 550 °C | 350 °C |

| Dryer outlet air temperature | 80 °C | 70 °C |

| Dried olive pomace temperature | 70 °C | 40 °C |

| Residual moisture of dried olive pomace | 8% | 8% |

| Chemical Characteristics | Value |

|---|---|

| Crude Protein | 8.7 ± 0.4 |

| Ether Extract | 17.6 ± 3.3 |

| Neutral Detergent Fiber | 59.9 ± 1.3 |

| Acid Detergent Fiber | 39.7 ± 1.1 |

| Acid Detergent Lignin | 14.8 ± 0.3 |

| Ash | 7.7 ± 0.4 |

| Total Phenols | 6156 ± 187 |

| Moisture | 11.2 ± 0.1 |

| Fatty Acids | % |

|---|---|

| C14:0 | 0.02 ± 0.00 |

| C16:0 | 13.49 ± 1.41 |

| C16:1 | 1.61 ± 0.31 |

| C17:0 | 0.13 ± 0.02 |

| C17:1 | 0.31 ± 0.08 |

| C18:0 | 2.27 ± 0.13 |

| C18:1n9 | 72.29 ± 2.38 |

| C18:2n6 | 8.37 ± 0.71 |

| C18:3n3 | 0.60 ± 0.07 |

| C20:0 | 0.34 ± 0.06 |

| C20:1n9 | 0.32 ± 0.08 |

| C22:0 | 0.11 ± 0.02 |

| C24:0 | 0.13 ± 0.04 |

| Tocopherol | mg/kg |

|---|---|

| α-tocopherol | 2.69 ± 0.11 |

| ß-tocopherol | 4.32 ± 0.09 |

| δ-tocopherol | 0.29 ± 0.12 |

| γ-tocotrienol | 0.48 ± 0.10 |

| Total tocopherols | 7.78 ± 0.42 |

| Phenolic Compound | mg/kg |

|---|---|

| Catechol | 220.32 ± 0.54 |

| Tyrosol | 512.25 ± 39.62 |

| Vanillin | 20.36 ± 1.89 |

| Hydroxytyrosol | 339.27 ± 4.77 |

| p-Cumaric acid | 73.25 ± 15.13 |

| Syringic acid | 0.35 ± 0.08 |

| o-Cumaric acid | 25.44 ± 5.66 |

| Caffeic acid | 83.85 ± 5.73 |

| Ferulic acid | 3.88 ± 0.05 |

| Vanillic acid | 89.54 ± 7.93 |

| Apigenin | 17.87 ± 5.49 |

| Apigenin-7-O-glucoside | 0.13 ± 0.01 |

| Luteolin | 1248 ± 104 |

| Luteolin-7-O-glucoside | 43.66 ± 5.28 |

| Luteolin-4-O-glucoside | 26.89 ± 4.41 |

| Diosmetin | 27.84 ± 8.58 |

| Rutin | 51.48 ± 7.44 |

| Oleuropein | 30.22 ± 1.73 |

| Verbascoside | 541.08 ± 23.26 |

| Oleuropein derivatives | 149.37 ± 5.20 |

| Ligstroside derivatives | 433.72 ± 9.50 |

| Sum of phenols | 3795 ± 209 |

| Group | PUFA | SFA | UFA | Phenols | Tocopherols |

|---|---|---|---|---|---|

| M1 | 0.179 b ± 0.028 | 5.126 a ± 0.477 | 2.161 b ± 0.211 | 4.316 b ± 0.301 | 0.891 b ± 0.094 |

| M2 | 0.211 a ± 0.039 | 4.756 b ± 0.452 | 2.423 a ± 0.282 | 10,346 a ± 1.221 | 1.034 a ± 0.063 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benincasa, C.; Pellegrino, M.; Veltri, L.; Claps, S.; Fallara, C.; Perri, E. Dried Destoned Virgin Olive Pomace: A Promising New By-Product from Pomace Extraction Process. Molecules 2021, 26, 4337. https://doi.org/10.3390/molecules26144337

Benincasa C, Pellegrino M, Veltri L, Claps S, Fallara C, Perri E. Dried Destoned Virgin Olive Pomace: A Promising New By-Product from Pomace Extraction Process. Molecules. 2021; 26(14):4337. https://doi.org/10.3390/molecules26144337

Chicago/Turabian StyleBenincasa, Cinzia, Massimiliano Pellegrino, Lucia Veltri, Salvatore Claps, Carmelo Fallara, and Enzo Perri. 2021. "Dried Destoned Virgin Olive Pomace: A Promising New By-Product from Pomace Extraction Process" Molecules 26, no. 14: 4337. https://doi.org/10.3390/molecules26144337