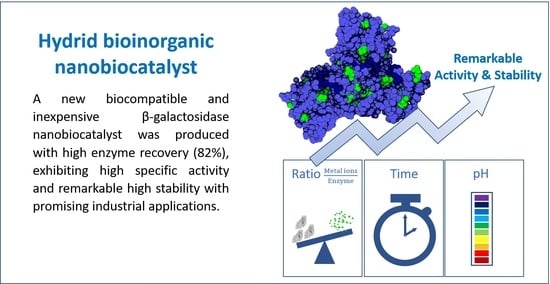

Development of a Hybrid Bioinorganic Nanobiocatalyst: Remarkable Impact of the Immobilization Conditions on Activity and Stability of β-Galactosidase

Abstract

:1. Introduction

2. Results and Discussion

2.1. Metal Ion Screening

2.2. Biomineralization of β-Galactosidase with Calcium

2.3. Effect of pH on the Biomineralization of β-Galactosidase

2.4. Thermal Stability of the β-Galactosidase Nanocrystals

2.5. In Silico Prediction of Metal-Ion Binding Regions

2.6. Characterization of the β-Galactosidase Nanocrystals

2.7. Synthesis of Galacto-Oligosaccharides

3. Materials and Methods

3.1. Chemicals and Reagents

3.2. Hydrolytic Activity of β-Galactosidase

3.3. Biomineralization of β-Galactosidase

3.4. Thermal Stability of the β-Galactosidase Bioinorganic Nanocrystals

3.5. In Silico Prediction of Calcium Binding Sites

3.6. Characterization of the β-Galactosidase Bioinorganic Nanocrystals

3.7. Synthesis of Galacto-Oligosaccharides

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Basso, A.; Serban, S. Industrial applications of immobilized Enzymes—A review. Mol. Catal. 2019, 479, 110607. [Google Scholar] [CrossRef]

- Cowan, D.A.; Fernandez-Lafuente, R. Enhancing the functional properties of thermophilic enzymes by chemical modification and immobilization. Enzym. Microb. Technol. 2011, 49, 326–346. [Google Scholar] [CrossRef]

- Godoy, C.A.; Romero, O.; De Las Rivas, B.; Mateo, C.; Fernandez-Lorente, G.; Guisan, J.M.; Palomo, J.M. Changes on enantioselectivity of a genetically modified thermophilic lipase by site-directed oriented immobilization. J. Mol. Catal. B Enzym. 2013, 87, 121–127. [Google Scholar] [CrossRef]

- Sheldon, R.A. Cleas, combi-cleas and ‘smart’ magnetic cleas: Biocatalysis in a bio-based economy. Catalysts 2019, 9, 261. [Google Scholar] [CrossRef] [Green Version]

- Misson, M.; Zhang, H.; Jin, B. Nanobiocatalyst advancements and bioprocessing applications. J. R. Soc. Interface 2015, 12, 20140891. [Google Scholar] [CrossRef] [Green Version]

- Cipolatti, E.P.; Valério, A.; Henriques, R.O.; Moritz, D.E.; Ninow, J.L.; Freire, D.M.G.; Manoel, E.A.; Fernandez-Lafuente, R.; De Oliveira, D. Nanomaterials for biocatalyst immobilization-state of the art and future trends. RSC Adv. 2016, 6, 104675–104692. [Google Scholar] [CrossRef]

- Ge, J.; Lei, J.; Zare, R.N. Protein-inorganic hybrid nanoflowers. Nat. Nanotechnol. 2012, 7, 428–432. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Hou, M.; Ge, J. Metal-organic frameworks and inorganic nanoflowers: A type of emerging inorganic crystal nanocarrier for enzyme immobilization. Catal. Sci. Technol. 2015, 5, 5077–5085. [Google Scholar] [CrossRef]

- Lee, S.W.; Cheon, S.A.; Kim, M.I.; Park, T.J. Organic-inorganic hybrid nanoflowers: Types, characteristics, and future prospects. J. Nanobiotechnol. 2015, 13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al Zoubi, W.; Kamil, M.P.; Fatimah, S.; Nisa, N.; Ko, Y.G. Recent advances in hybrid organic-inorganic materials with spatial architecture for state-of-the-art applications. Prog. Mater. Sci. 2020, 112, 100663. [Google Scholar] [CrossRef]

- Bilal, M.; Asgher, M.; Shah, S.Z.H.; Iqbal, H.M.N. Engineering enzyme-coupled hybrid nanoflowers: The quest for optimum performance to meet biocatalytic challenges and opportunities. Int. J. Biol. Macromol. 2019, 135, 677–690. [Google Scholar] [CrossRef]

- Shende, P.; Kasture, P.; Gaud, R.S. Nanoflowers: The future trend of nanotechnology for multi-applications. Artif. Cells Nanomed. Biotechnol. 2018, 46, 413–422. [Google Scholar] [CrossRef]

- Escobar, S.; Velasco-Lozano, S.; Lu, C.H.; Lin, Y.F.; Mesa, M.; Bernal, C.; López-Gallego, F. Understanding the functional properties of bio-inorganic nanoflowers as biocatalysts by deciphering the metal-binding sites of enzymes. J. Mater. Chem. B 2017, 5, 4478–4486. [Google Scholar] [CrossRef]

- Zhang, B.; Li, P.; Zhang, H.; Fan, L.; Wang, H.; Li, X.; Tian, L.; Ali, N.; Ali, Z.; Zhang, Q. Papain/Zn3(PO4)2 hybrid nanoflower: Preparation, characterization and its enhanced catalytic activity as an immobilized enzyme. RSC Adv. 2016, 6, 46702–46710. [Google Scholar] [CrossRef]

- Cui, J.; Jia, S. Organic–inorganic hybrid nanoflowers: A novel host platform for immobilizing biomolecules. Coord. Chem. Rev. 2017, 352, 249–263. [Google Scholar] [CrossRef]

- Liu, Y.; Ji, X.; He, Z. Organic-inorganic nanoflowers: From design strategy to biomedical applications. Nanoscale 2019, 11, 17179–17194. [Google Scholar] [CrossRef] [PubMed]

- Araya, E.; Urrutia, P.; Romero, O.; Illanes, A.; Wilson, L. Design of combined crosslinked enzyme aggregates (combi-CLEAs) of β-galactosidase and glucose isomerase for the one-pot production of fructose syrup from lactose. Food Chem. 2019, 288, 102–107. [Google Scholar] [CrossRef]

- Misson, M.; Dai, S.; Jin, B.; Chen, B.H.; Zhang, H. Manipulation of nanofiber-based β-galactosidase nanoenvironment for enhancement of galacto-oligosaccharide production. J. Biotechnol. 2016, 222, 56–64. [Google Scholar] [CrossRef]

- Banjanac, K.; Carević, M.; Ćorović, M.; Milivojević, A.; Prlainović, N.; Marinković, A.; Bezbradica, D. Novel β-galactosidase nanobiocatalyst systems for application in the synthesis of bioactive galactosides. RSC Adv. 2016, 6, 97216–97225. [Google Scholar] [CrossRef]

- Serey, M.; Vera, C.; Guerrero, C.; Illanes, A. Immobilization of Aspergillus oryzae β-galactosidase in cation functionalized agarose matrix and its application in the synthesis of lactulose. Int. J. Biol. Macromol. 2021, 167, 1564–1574. [Google Scholar] [CrossRef]

- Ureta, M.M.; Martins, G.N.; Figueira, O.; Pires, P.F.; Castilho, P.C.; Gomez-Zavaglia, A. Recent advances in β-galactosidase and fructosyltransferase immobilization technology. Crit. Rev. Food Sci. Nutr. 2020. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, B.; Ji, X.; He, Z. Self-assembled protein-enzyme nanoflower-based fluorescent sensing for protein biomarker. Anal. Bioanal. Chem. 2018, 410, 7591–7598. [Google Scholar] [CrossRef] [PubMed]

- Talens-Perales, D.; Fabra, M.J.; Martínez-Argente, L.; Marín-Navarro, J.; Polaina, J. Recyclable thermophilic hybrid protein-inorganic nanoflowers for the hydrolysis of milk lactose. Int. J. Biol. Macromol. 2020, 151, 602–608. [Google Scholar] [CrossRef] [PubMed]

- Fabra, M.J.; Talens-Perales, D.; Roman-Sarmiento, A.; López-Rubio, A.; Polaina, J. Effect of biopolymer matrices on lactose hydrolysis by enzymatically active hydrogel and aerogels loaded with β-galactosidase nanoflowers. Food Hydrocoll. 2021, 111, 106220. [Google Scholar] [CrossRef]

- Lei, Z.; Gao, C.; Chen, L.; He, Y.; Ma, W.; Lin, Z. Recent advances in biomolecule immobilization based on self-assembly: Organic-inorganic hybrid nanoflowers and metal-organic frameworks as novel substrates. J. Mater. Chem. B 2018, 6, 1581–1594. [Google Scholar] [CrossRef] [PubMed]

- Somturk, B.; Yilmaz, I.; Altinkaynak, C.; Karatepe, A.; Özdemir, N.; Ocsoy, I. Synthesis of urease hybrid nanoflowers and their enhanced catalytic properties. Enzym. Microb. Technol. 2016, 86, 134–142. [Google Scholar] [CrossRef]

- Li, Y.; Fei, X.; Liang, L.; Tian, J.; Xu, L.; Wang, X.; Wang, Y. The influence of synthesis conditions on enzymatic activity of enzyme-inorganic hybrid nanoflowers. J. Mol. Catal. B Enzym. 2016, 133, 92–97. [Google Scholar] [CrossRef]

- Guerrero, C.; Vera, C.; Serna, N.; Illanes, A. Immobilization of Aspergillus oryzae Β-galactosidase in an agarose matrix functionalized by four different methods and application to the synthesis of lactulose. Bioresour. Technol. 2017, 232, 53–63. [Google Scholar] [CrossRef]

- Urrutia, P.; Bernal, C.; Wilson, L.; Illanes, A. Use of chitosan heterofunctionality for enzyme immobilization: β-galactosidase immobilization for galacto-oligosaccharide synthesis. Int. J. Biol. Macromol. 2018, 116, 182–193. [Google Scholar] [CrossRef]

- Huerta, L.M.; Vera, C.; Guerrero, C.; Wilson, L.; Illanes, A. Synthesis of galacto-oligosaccharides at very high lactose concentrations with immobilized β-galactosidases from Aspergillus oryzae. Process Biochem. 2011, 46, 245–252. [Google Scholar] [CrossRef]

- Ansari, S.; Husain, Q. Immobilization of Aspergillus oryzae β galactosidase on concanavalin A-layered calcium alginate-cellulose beads and its application in lactose hydrolysis in continuous spiral bed reactors. Pol. J. Chem. Technol. 2011, 13, 15–20. [Google Scholar] [CrossRef] [Green Version]

- Gaur, R.; Pant, H.; Jain, R.; Khare, S.K. Galacto-oligosaccharide synthesis by immobilized Aspergillus oryzae β-galactosidase. Food Chem. 2006, 97, 426–430. [Google Scholar] [CrossRef]

- Albayrak, N.; Yang, S.T. Immobilization of β-galactosidase on fibrous matrix by polyethyleneimine for production of galacto-oligosaccharides from lactose. Biotechnol. Prog. 2002, 18, 240–251. [Google Scholar] [CrossRef] [PubMed]

- Souza, C.J.F.; Garcia-Rojas, E.E.; Souza, C.S.F.; Vriesmann, L.C.; Vicente, J.; de Carvalho, M.G.; Petkowicz, C.L.O.; Favaro-Trindade, C.S. Immobilization of β-galactosidase by complexation: Effect of interaction on the properties of the enzyme. Int. J. Biol. Macromol. 2019, 122, 594–602. [Google Scholar] [CrossRef] [PubMed]

- Guerrero, C.; Aburto, C.; Súarez, S.; Vera, C.; Illanes, A. Improvements in the production of Aspergillus oryzae β-galactosidase crosslinked aggregates and their use in repeated-batch synthesis of lactulose. Int. J. Biol. Macromol. 2020, 142, 452–462. [Google Scholar] [CrossRef]

- Guerrero, C.; Vera, C.; Araya, E.; Conejeros, R.; Illanes, A. Repeated-batch operation for the synthesis of lactulose with β-galactosidase immobilized by aggregation and crosslinking. Bioresour. Technol. 2015, 190, 122–131. [Google Scholar] [CrossRef] [PubMed]

- Illanes, A.; Wilson, L. Parameters for the evaluation of immobilized enzymes under process conditions. Methods Mol. Biol. 2020, 2100, 65–81. [Google Scholar]

- Lin, Y.F.; Cheng, C.W.; Shih, C.S.; Hwang, J.K.; Yu, C.S.; Lu, C.H. MIB: Metal ion-binding site prediction and docking server. J. Chem. Inf. Model. 2016, 56, 2287–2291. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aires, A.; Llarena, I.; Moller, M.; Castro-Smirnov, J.; Cabanillas-Gonzalez, J.; Cortajarena, A.L. A simple approach to design proteins for the sustainable synthesis of metal nanoclusters. Angew. Chem. Int. Ed. 2019, 58, 6214–6219. [Google Scholar] [CrossRef]

- Martínez-Rosell, G.; Giorgino, T.; De Fabritiis, G. PlayMolecule ProteinPrepare: A web application for protein preparation for molecular dynamics simulations. J. Chem. Inf. Model. 2017, 57, 1511–1516. [Google Scholar] [CrossRef]

- Orme, C.A.; Giocondi, J.L. Model systems for formation and dissolution of calcium phosphate minerals. Handb. Biominer.: Biol. Asp. Struct. Form. 2008, 2, 135–157. [Google Scholar]

- Tung, M.S. Calcium phosphates: Structure, composition, solubility, and stability. In Calcium Phosphates in Biological and Industrial Systems; Amjad, Z., Ed.; Springer: Boston, MA, USA, 1998; pp. 1–19. [Google Scholar] [CrossRef]

- Kim, K.H.; Jeong, J.M.; Lee, S.J.; Choi, B.G.; Lee, K.G. Protein-directed assembly of cobalt phosphate hybrid nanoflowers. J. Colloid Interface Sci. 2016, 484, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Ge, J.; Liu, W.; Lan, M.; Zhang, H.; Wang, P.; Wang, Y.; Niu, Z. Multi-enzyme co-embedded organic-inorganic hybrid nanoflowers: Synthesis and application as a colorimetric sensor. Nanoscale 2014, 6, 255–262. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Huang, J.; Liu, J.; Zhang, H.; Jiang, J.; Yu, R. A dual enzyme-inorganic hybrid nanoflower incorporated microfluidic paper-based analytic device (μPAD) biosensor for sensitive visualized detection of glucose. Nanoscale 2017, 9, 5658–5663. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.B.; Wang, Y.C.; He, R.; Zhuang, A.; Wang, X.; Zeng, J.; Hou, J.G. A new nanobiocatalytic system based on allosteric effect with dramatically enhanced enzymatic performance. J. Am. Chem. Soc. 2013, 135, 1272–1275. [Google Scholar] [CrossRef]

- Vera, C.; Córdova, A.; Aburto, C.; Guerrero, C.; Suárez, S.; Illanes, A. Synthesis and purification of galacto-oligosaccharides: State of the art. World J. Microbiol. Biotechnol. 2016, 32, 197. [Google Scholar] [CrossRef] [PubMed]

- Guerrero, C.; Aburto, C.; Suárez, S.; Vera, C.; Illanes, A. Effect of the type of immobilization of β-galactosidase on the yield and selectivity of synthesis of transgalactosylated oligosaccharides. Biocatal. Agric. Biotechnol. 2018, 16, 353–363. [Google Scholar] [CrossRef]

- Hoyos, P.; Bavaro, T.; Perona, A.; Rumbero, A.; Tengattini, S.; Terreni, M.; Hernaíz, M.J. Highly efficient and sustainable synthesis of neoglycoproteins using galactosidases. ACS Sustain. Chem. Eng. 2020, 8, 6282–6292. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Q. Freeze-dried capsules prepared from emulsions with encapsulated lactase as a potential delivery system to control lactose hydrolysis in milk. Food Chem. 2018, 241, 397–402. [Google Scholar] [CrossRef]

- Vera, C.; Guerrero, C.; Conejeros, R.; Illanes, A. Synthesis of galacto-oligosaccharides by β-galactosidase from Aspergillus oryzae using partially dissolved and supersaturated solution of lactose. Enzym. Microb. Technol. 2012, 50, 188–194. [Google Scholar] [CrossRef]

| Immobilization Methods | Support/Precipitant | Immobilization Yield [%] | Specific Activity [IU/g] 1 | Stability Factor | Reference |

|---|---|---|---|---|---|

| Biomineralization | - | 81.7 | 35,000 | 11.6 | This work |

| Covalent bonding | Glyoxyl-agarose | 85 | 2500 | 1.5 | [28] |

| Amino-glyoxyl-agarose | 57 | 7700 | 2.3 | [28] | |

| Carboxy-glyoxyl-agarose | 13.14 | 780 | 1.3 | [28] | |

| Chelate-glyoxyl-agarose | 5.13 | 455 | 1.4 | [28] | |

| Chitosan-epichlorohydrin | 54 | 2951 | 1.8 | [29] | |

| Amino-glyoxyl-agarose | 40 | 2294 | 2.5 | [29] | |

| Chitosan-glutaraldehyde | 70.5 | 3070 | 3.9 | [30] | |

| Alginate-cellulose beads | 70 | n.r. | 3.4 | [31] | |

| Chitosan-glutaraldehyde | 18.4 | n.r. | 1.2 | [32] | |

| Cotton fibers-PEI | 80 | n.r. | 10.3 | [33] | |

| Sodium alginate | n.r. | n.r. | 2.8 | [34] | |

| CLEAs | - | 100 | 64,000 | 1.1 | [35] |

| - | 90 | 44,560 | 2.3 | [35] | |

| - | 13.5 | Not reported | 1.2 | [32] | |

| - | 30 | 15,000 | 1.3 | [36] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tavernini, L.; Romero, O.; Aburto, C.; López-Gallego, F.; Illanes, A.; Wilson, L. Development of a Hybrid Bioinorganic Nanobiocatalyst: Remarkable Impact of the Immobilization Conditions on Activity and Stability of β-Galactosidase. Molecules 2021, 26, 4152. https://doi.org/10.3390/molecules26144152

Tavernini L, Romero O, Aburto C, López-Gallego F, Illanes A, Wilson L. Development of a Hybrid Bioinorganic Nanobiocatalyst: Remarkable Impact of the Immobilization Conditions on Activity and Stability of β-Galactosidase. Molecules. 2021; 26(14):4152. https://doi.org/10.3390/molecules26144152

Chicago/Turabian StyleTavernini, Luigi, Oscar Romero, Carla Aburto, Fernando López-Gallego, Andrés Illanes, and Lorena Wilson. 2021. "Development of a Hybrid Bioinorganic Nanobiocatalyst: Remarkable Impact of the Immobilization Conditions on Activity and Stability of β-Galactosidase" Molecules 26, no. 14: 4152. https://doi.org/10.3390/molecules26144152