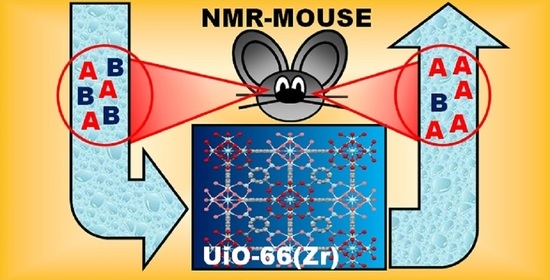

Screening Metal–Organic Frameworks for Separation of Binary Solvent Mixtures by Compact NMR Relaxometry

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Samples

3.2. NMR Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Li, H.; Eddaoudi, M.; O’Keeffe, M.; Yaghi, O.M. Design and synthesis of an exceptionally stable and highly porous metal-organic framework. Nature 1999, 402, 276–279. [Google Scholar] [CrossRef] [Green Version]

- Furukawa, H.; Ko, N.; Go, Y.B.; Aratani, N.; Choi, S.B.; Choi, E.; Yazaydin, A.Ö.; Snurr, R.Q.; O’Keeffe, M.; Kim, J.; et al. Ultrahigh porosity in metal-organic frameworks. Science 2010, 329, 424–428. [Google Scholar] [CrossRef] [Green Version]

- Davis, M.E. Ordered porous materials for emerging applications. Nature 2002, 417, 813–821. [Google Scholar] [CrossRef]

- Ferey, G. Hybrid porous solids: Past, present, future. Chem. Soc. Rev. 2008, 37, 191–214. [Google Scholar] [CrossRef]

- Zhao, D.; Timmons, D.J.; Yuan, D.; Zhou, H.C. Tuning the Topology and Functionality of Metal-Organic Frameworks by Ligand Design. Acc. Chem. Res. 2011, 44, 123–133. [Google Scholar] [CrossRef] [PubMed]

- Eddaoudi, M.; Kim, J.; Rosi, N.; Vodak, D.; Wachter, J.; O’Keeffe, M.; Yaghi, O.M. Systematic design of pore size and functionality in isoreticular MOFs and their application in methane storage. Science 2002, 295, 469–472. [Google Scholar] [CrossRef] [Green Version]

- Czaja, A.U.; Trukhan, N.; Müller, U. Industrial applications of metal–organic frameworks. Chem. Soc. Rev. 2009, 38, 1284–1293. [Google Scholar] [CrossRef] [PubMed]

- Millward, A.R.; Yaghi, O.M. Metal−Organic Frameworks with Exceptionally High Capacity for Storage of Carbon Dioxide at Room Temperature. J. Am. Chem. Soc. 2005, 127, 17998–17999. [Google Scholar] [CrossRef] [PubMed]

- Murray, L.J.; Dincă, M.; Long, J.R. Hydrogen storage in metal–organic frameworks. Chem. Soc. Rev. 2009, 38, 1294–1314. [Google Scholar] [CrossRef]

- Lee, J.; Farha, O.K.; Roberts, J.; Scheidt, K.A.; Nguyen, S.T.; Hupp, J.T. Metal-organic framework materials as catalysts. Chem. Soc. Rev. 2009, 38, 1450–1459. [Google Scholar] [CrossRef]

- Kirchon, A.; Feng, L.; Drake, H.F.; Joseph, E.A.; Zhou, H. From fundamentals to applications: A toolbox for robust and multifunctional MOF materials. Chem. Soc. Rev. 2018, 47, 8611–8638. [Google Scholar] [CrossRef]

- Rasheed, T.; Rizwan, K.; Bilal, M.; Iqbal, H.M.N. Metal-Organic Framework-Based Engineered Materials—Fundamentals and Applications. Molecules 2020, 25, 1598. [Google Scholar] [CrossRef] [Green Version]

- Kuppler, R.J.; Timmons, D.J.; Fang, Q.; Li, J.; Makal, T.A.; Young, M.D.; Yuan, D.; Zhao, D.; Zhuang, W.; Zhou, H. Potential applications of metal-organic frameworks. Coord. Chem. Rev. 2009, 253, 3042–3066. [Google Scholar] [CrossRef]

- Bai, Y.; Dou, Y.; Xie, L.; Rutledge, W.; Li, J.; Zhou, H. Zr-based metal–organic frameworks: Design, synthesis, structure, and applications. Chem. Soc. Rev. 2016, 45, 2327–2367. [Google Scholar] [CrossRef]

- Herm, Z.R.; Wiers, B.M.; Mason, J.A.; van Baten, J.M.; Hudson, M.R.; Zajdel, P.; Brown, C.M.; Masciocchi, N.; Krishna, R.; Long, J.R. Separation of Hexane Isomers in a Metal-Organic Framework with Triangular Channels. Science 2015, 340, 960–964. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bloch, E.D.; Queen, W.L.; Krishna, R.; Zadrozny, J.M.; Brown, C.M.; Long, J.R. Hydrocarbon Separations in a Metal-Organic Framework with Open Iron(II) Coordination Sites. Science 2012, 335, 1606–1610. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, W.; Jiang, J.; Wu, D.; Xu, J.; Xue, B.; Kirillov, A.M. A Highly Stable Nanotubular MOF Rotator for Selective Adsorption of Benzene and Separation of Xylene Isomers. Inorg. Chem. 2015, 54, 10524–10526. [Google Scholar] [CrossRef]

- Herm, Z.R.; Bloch, E.D.; Long, J.R. Hydrocarbon Separations in Metal−Organic Frameworks. Chem. Mater. 2014, 26, 323–338. [Google Scholar] [CrossRef]

- Mukherjee, S.; Desai, A.V.; Ghosh, S.K. Potential of metal–organic frameworks for adsorptive separation of industrially and environmentally relevant liquid mixtures. Coord. Chem. Rev. 2018, 367, 82–126. [Google Scholar] [CrossRef]

- Sholl, D.S.; Lively, R.P. Seven chemical separations to change the world. Nature 2016, 532, 435–437. [Google Scholar] [CrossRef]

- Oak Ridge National Laboratories. Materials for Separation Technologies: Energy and Emission Reduction Opportunities; Oak Ridge National Laboratories: Oak Ridge, TN, USA, 2005.

- Gadalla, M.A.; Olujic, Z.; Jansens, P.J.; Jobson, M.; Smith, R. Reducing CO2 Emissions and Energy Consumption of Heat-Integrated Distillation Systems. Environ. Sci. Technol. 2005, 39, 6860–6870. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, L.; Wang, Y.; Li, J.-R.; Li, J. Exploiting the Pore Size and Functionalization Effect in UiO Topology Structures Used for the Separation of Light Hydrocarbons. Cryst. Eng. Commun. 2017, 19, 1729–1737. [Google Scholar] [CrossRef]

- Gutierrez-Sevillano, J.; Calero, S.; Krishna, R. Selective Adsorption of Water from Mixtures with 1-Alcohols by Exploitation of Molecular Packing Effects in CuBTC. J. Phys. Chem. C 2015, 119, 3658–3666. [Google Scholar] [CrossRef]

- Lin, J.M.; He, C.T.; Liu, Y.; Liao, P.Q.; Zhou, D.D.; Zhang, J.P.; Chen, X.M. Metal-organic framework with a pore size/shape suitable for strong binding and close packing of methane. Angew. Chem. Int. Ed. 2016, 55, 4674–4678. [Google Scholar] [CrossRef] [PubMed]

- Henke, S.; Schneemann, A.; Wütscher, A.; Fischer, R.A. Directing the Breathing Behavior of Pillared-Layered Metal–Organic Frameworks via a Systematic Library of Functionalized Linkers Bearing Flexible Substituents. J. Am. Chem. Soc. 2012, 134, 9464–9474. [Google Scholar] [CrossRef]

- Grape, E.S.; Xu, H.; Cheung, O.; Calmels, M.; Zhao, J.; Dejoie, C.; Proserpio, D.M.; Zou, X.; Inge, A.K. Breathing Metal–Organic Framework Based on Flexible Inorganic Building Units. Cryst. Growth Des. 2020, 20, 320–329. [Google Scholar] [CrossRef]

- Shi, Y.X.; Li, W.X.; Zhang, W.H.; Lang, J.P. Guest-Induced Switchable Breathing Behavior in a Flexible Metal–Organic Framework with Pronounced Negative Gas Pressure. Inorg. Chem. 2018, 57, 8627–8633. [Google Scholar] [CrossRef]

- Furukawa, H.; Cordova, K.E.; O’Keeffe, M.; Yaghi, O.M. The chemistry and applications of metal-organic frameworks. Science 2013, 341, 1230444. [Google Scholar] [CrossRef] [Green Version]

- Wilmer, C.E.; Leaf, M.; Lee, C.Y.; Farka, O.K.; Hauser, B.G.; Hupp, J.T.; Snurr, R.Q. Large-scale screening of hypothetical metal-organic frameworks. Nat. Chem. 2012, 4, 83–89. [Google Scholar] [CrossRef]

- Colón, Y.J.; Snurr, R.Q. High-throughput computational screening of metal–organic frameworks. Chem. Soc. Rev. 2014, 43, 5735–5749. [Google Scholar] [CrossRef]

- Chung, Y.G.; Bai, P.; Haranczyk, M.; Leperi, K.T.; Li, P.; Zhang, H.; Wang, T.C.; Duerinck, T.; You, F.; Hupp, J.T.; et al. Computational Screening of Nanoporous Materials for Hexane and Heptane Isomer Separation. Chem. Mater. 2017, 29, 6315–6328. [Google Scholar] [CrossRef]

- Tian, F.; Zhang, X.; Chen, Y. Highly selective adsorption and separation of dichloromethane/trichloromethane on a copper-based metal–organic framework. RSC Adv. 2016, 6, 31214–31224. [Google Scholar] [CrossRef]

- Krishna, R. Screening metal-organic frameworks for mixture separations in fixed-bed adsorbers using a combined selectivity/capacity metric. RSC Adv. 2017, 7, 35724–35737. [Google Scholar] [CrossRef] [Green Version]

- Gutierrez-Sevillano, J.J.; Calero, S.; Krishna, R. Separation of benzene from mixtures with water, methanol, ethanol, and acetone: Highlighting hydrogen bonding and molecular clustering influences in CuBTC. Phys. Chem. Chem. Phys. 2015, 17, 20114–20124. [Google Scholar] [CrossRef]

- Zalesskiy, S.S.; Danieli, E.; Blümich, B.; Ananikov, V.P. Miniaturization of NMR systems: Desktop spectrometers, microcoil spectroscopy, and “NMR on a chip” for chemistry, biochemistry, and industry. Chem. Rev. 2014, 114, 5641–5694. [Google Scholar] [CrossRef]

- Mitchell, J.; Gladden, L.; Chandrasekera, T.; Fordham, E. Low-field permanent magnets for industrial process and quality control. Prog. Nucl. Mag. Res. Spectrosc. 2014, 76, 1–60. [Google Scholar] [CrossRef] [PubMed]

- Adams, A. Analysis of solid technical polymers by compact NMR. Trends Anal. Chem. 2016, 83, 107–119. [Google Scholar] [CrossRef]

- Adams, A.; Kwamen, R.; Woldt, B.; Graß, M. Nondestructive quantification of local plasticizer concentration in PVC by 1H NMR relaxometry. Macromol. Rapid Commun. 2015, 36, 2171–2175. [Google Scholar] [CrossRef]

- Adams, A. Non-destructive analysis of polymers and polymer-based materials by compact NMR. Magn. Reson. Imaging 2019, 56, 119–125. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.J.; Kong, X.; Sumida, K.; Manumpil, M.A.; Long, J.R.; Reimer, J.A. Ex situ NMR relaxometry of metal-organic frameworks for rapid surface-area screening. Angew. Chem. Int. Ed. 2013, 52, 12043–12046. [Google Scholar] [CrossRef] [PubMed]

- Witherspoon, V.J.; Yu, L.M.; Jawahery, S.; Braun, E.; Moosavi, S.M.; Schnell, S.K.; Smit, B.; Reimer, J.A. Translational and Rotational Motion of C8 Aromatics Adsorbed in Isotropic Porous Media (MOF-5): NMR Studies and MD Simulations. J. Phys. Chem. C 2017, 121, 15456–15462. [Google Scholar] [CrossRef] [Green Version]

- Horch, C.; Schlayer, S.; Stallmach, F. High-pressure low-field 1H NMR relaxometry in nanoporous materials. J. Magn. Reson. 2014, 240, 24–33. [Google Scholar] [CrossRef] [PubMed]

- Carr, H.; Purcell, E. Effects of Diffusion on Free Precession in Nuclear Magnetic Resonance Experiments. Phys. Rev. 1954, 94, 630–638. [Google Scholar] [CrossRef]

- Meiboom, S.; Gill, D. Modified Spin-Echo Method for Measuring Nuclear Relaxation Times. Rev. Sci. Instrum. 1958, 29, 688–691. [Google Scholar] [CrossRef] [Green Version]

- Tofts, P.S.; Lloyd, D.; Clark, C.A.; Barker, G.J.; Parker, G.J.M.; McConville, P.; Baldock, C.; Pope, J.M. Test Liquids for Quantitative MRI Measurements of Self-Diffusion Coefficient In Vivo. Magn. Reson. Med. 2000, 43, 368–374. [Google Scholar] [CrossRef] [Green Version]

- Korb, J.-P. Multiscale nuclear magnetic relaxation dispersion of complex liquids in bulk and confinement. Prog. Nucl. Magn. Reson. Spectrosc. 2018, 104, 12–55. [Google Scholar] [CrossRef]

- UiO-66 Metal Organic Framework. Available online: https://www.chemtube3d.com/mof-uio66/ (accessed on 23 April 2021).

- Cavka, J.H.; Jakobsen, S.; Olsbye, U.; Guillou, N.; Lamberti, C.; Bordiga, S.; Lillerud, K.P. A New Zirconium Inorganic Building Brick Forming Metal Organic Frameworks with Exceptional Stability. J. Am. Chem. Soc. 2008, 130, 13850–13851. [Google Scholar] [CrossRef] [PubMed]

- Biswas, S.; van der Voort, P.A. General Strategy for the Synthesis of Functionalised UiO-66 Frameworks: Characterisation, Stability and CO2 Adsorption Properties. Eur. J. Inorg. Chem. 2013, 2154–2160. [Google Scholar] [CrossRef]

- Barcia, P.S.; Guimaraes, D.; Mendes, P.A.P.; Silva, J.A.C.; Guillerm, V.; Chevreau, H.; Serre, C.; Rodrigues, A.E. Reverse Shape Selectivity in the Adsorption of Hexane and Xylene Isomers in MOF UiO-66. Microporous Mesoporous Mater. 2011, 139, 67–73. [Google Scholar] [CrossRef] [Green Version]

- Duerinck, T.; Bueno-Perez, R.; Vermoortele, F.; De Vos, D.E.; Calero, S.; Baron, G.V.; Denayer, J.F.M. Understanding Hydrocarbon Adsorption in the UiO-66 Metal-Organic Framework: Separation of (Un)saturated Linear, Branched, Cyclic Adsorbates, Including Stereoisomers. J. Phys. Chem. C 2013, 117, 12567–12578. [Google Scholar] [CrossRef]

- Bozbiyik, B.; Duerinck, T.; Lannoeye, J.; De Vos, D.E.; Baron, G.V.; Denayer, J.F.M. Adsorption and separation of n-hexane and cyclohexane on the UiO-66 metal–organic framework. Microporous Mesoporous Mater. 2014, 183, 143–149. [Google Scholar] [CrossRef]

- Usman, M.; Helal, A.; Abdelnaby, M.M.; Alloush, A.M.; Zeama, M.; Yamini, Z.H. Trends and Prospects in UiO-66 Metal-Organic Framework for CO2 Capture, Separation, and Conversion. Chem. Rec. 2021, 21, 1–22. [Google Scholar] [CrossRef]

- Thomas, L.L.; Christakis, T.J.; Jorgensen, W.L. Conformation of Alkanes in the Gas Phase and Pure Liquids. J. Phys. Chem. B 2006, 110, 21198–21204. [Google Scholar] [CrossRef]

- Nikki, K.; Inakura, H.; Wu-Le; Suzuki, N.; Endo, T. Remarkable changes in conformations of n-alkanes with their carbon numbers and aromatic solvents. J. Chem. Soc. Perkin Trans. 2000, 2370–2373. [Google Scholar] [CrossRef]

- Yang, Q.; Jobic, H.; Salles, F.; Kolokolov, D.; Guillerm, V.; Serre, C.; Maurin, G. Probing the Dynamics of CO2 and CH4 within the Porous Zirconium Terephthalate UiO-66(Zr): A Synergic Combination of Neutron Scattering Measurements and Molecular Simulations. Chem. Eur. J. 2011, 17, 8882–8889. [Google Scholar] [CrossRef]

- Zhao, W.W.; Zhang, C.Y.; Yan, Z.G.; Bai, L.P.; Wang, X.; Huang, H.; Zhou, Y.Y.; Xie, Y.; Li, F.S.; Li, J.R. Separations of substituted benzenes and polycyclic aromatic hydrocarbons using normal- and reverse-phase high performance liquid chromatography with UiO-66 as the stationary phase. J. Chromatogr. A 2014, 1370, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Strem Chemicals. Available online: https://www.strem.com/catalog/v/40-1105/85/zirconium_1072413-89-8 (accessed on 23 April 2021).

- Fischer, J.; Weiss, A. Transport properties of liquids. V. self-diffusion, viscosity, and mass density of ellipsoidal shaped molecules in the pure liquid phase. Ber. Bunsenges. Phys. Chem. 1986, 90, 896–905. [Google Scholar] [CrossRef]

- Funke, H.H.; Argo, A.M.; Falconer, J.L.; Noble, R.D. Separations of Cyclic, Branched, and Linear Hydrocarbon Mixtures through Silicalite Membranes. Ind. Eng. Chem. Res. 1997, 36, 137–143. [Google Scholar] [CrossRef]

- Chua, L.M.; Hitchcock, I.; Fletcher, R.S.; Holt, E.M.; Lowe, J.; Rigby, S.P. Understanding the Spatial Distribution of Coke Deposition within Bimodal Micro-/Mesoporous Catalysts using a Novel Sorption Method in Combination with Pulsed-gradient Spin echo NMR. J. Catal. 2012, 286, 260–265. [Google Scholar] [CrossRef] [Green Version]

- Van der Perre, S.; Van Assche, T.; Bozbiyik, B.; Lannoeye, J.; De Vos, D.E.; Baron, G.V.; Denayer, J.F.M. Adsorptive Characterization of the ZIF-68 Metal-Organic Framework: A Complex Structure with Amphiphilic Properties. Langmuir 2014, 30, 8416–8424. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagemann, M.; Radzik, N.; Krzyżak, A.; Adams, A. Screening Metal–Organic Frameworks for Separation of Binary Solvent Mixtures by Compact NMR Relaxometry. Molecules 2021, 26, 3481. https://doi.org/10.3390/molecules26123481

Wagemann M, Radzik N, Krzyżak A, Adams A. Screening Metal–Organic Frameworks for Separation of Binary Solvent Mixtures by Compact NMR Relaxometry. Molecules. 2021; 26(12):3481. https://doi.org/10.3390/molecules26123481

Chicago/Turabian StyleWagemann, Marc, Natalia Radzik, Artur Krzyżak, and Alina Adams. 2021. "Screening Metal–Organic Frameworks for Separation of Binary Solvent Mixtures by Compact NMR Relaxometry" Molecules 26, no. 12: 3481. https://doi.org/10.3390/molecules26123481