A Perfect Plastic Material for Studies on Self-Propelled Motion on the Water Surface

Abstract

:1. Introduction

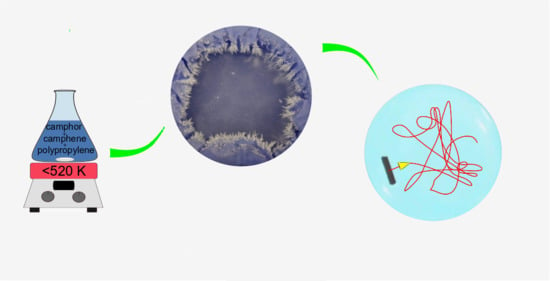

2. Materials and Methods

3. Results and Discussion

3.1. Time Evolution of Pills Made of Camphene–Polypropylene Plastics

3.2. Self-Motion of a Pill Made of Camphene–Camphor–Polypropylene Plastic

3.3. Long-Term Behavior of a Pill Made of 10% Polypropylene, 45% Camphene, and 45% Camphor

3.4. Motion of Self-Propelled Rods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nakata, S.; Pimienta, V.; Kitahata, H.; Lagzi, I. Self-organized Motion: Physicochemical Design Based on Non-linear Dynamics; Theoretical and Computational Chemistry Series; Royal Society of Chemistry: Cambridge, UK, 2019. [Google Scholar] [CrossRef]

- Tomlinson, C. On the Motions of Camphor on the Surface of Water. Proc. R. Soc. Lond. 1862, 11, 575–577. [Google Scholar] [CrossRef]

- Rayleigh, L. Measurements of the amount of oil necessary in order to check the motions of camphor upon water. Proc. R. Soc. Lond. 1890, 47, 364–367. [Google Scholar] [CrossRef]

- Nakata, S.; Iguchi, Y.; Ose, S.; Kuboyama, M.; Ishii, T.; Yoshikawa, K. Self-Rotation of a Camphor Scraping on Water: New Insight into the Old Problem. Langmuir 1997, 13, 4454–4458. [Google Scholar] [CrossRef]

- O’Neil, M.E. The Merck Index—An Encyclopedia of Chemicals, Drugs, and Biologicals; Royal Society of Chemistry: Cambridge, UK, 2013; p. 300. [Google Scholar]

- Hayashima, Y.; Nagayama, M.; Doi, Y.; Nakata, S.; Kimura, M.; Iida, M. Self-motion of a camphoric acid boat sensitive to the chemical environment. Phys. Chem. Chem. Phys. 2002, 4, 1386–1392. [Google Scholar] [CrossRef]

- Nagayama, M.; Nakata, S.; Doi, Y.; Hayashima, Y. A theoretical and experimental study on the unidirectional motion of a camphor disk. Phys. D Nonlinear Phenom. 2004, 194, 151–165. [Google Scholar] [CrossRef]

- Nakata, S.; Nagayama, M.; Kitahata, H.; Suematsu, N.J.; Hasegawa, T. Physicochemical design and analysis of self-propelled objects that are characteristically sensitive to environments. Phys. Chem. Chem. Phys. 2015, 17, 10326–10338. [Google Scholar] [CrossRef] [PubMed]

- Suematsu, N.J.; Sasaki, T.; Nakata, S.; Kitahata, H. Quantitative Estimation of the Parameters for Self-Motion Driven by Difference in Surface Tension. Langmuir 2014, 30, 8101–8108. [Google Scholar] [CrossRef]

- Karasawa, Y.; Oshima, S.; Nomoto, T.; Toyota, T.; Fujinami, M. Simultaneous Measurement of Surface Tension and Its Gradient around Moving Camphor Boat on Water Surface. Chem. Lett. 2014, 43, 1002–1004. [Google Scholar] [CrossRef]

- Nakata, S.; Kayahara, K.; Yamamoto, H.; Skrobanska, P.; Gorecki, J.; Awazu, A.; Nishimori, H.; Kitahata, H. Reciprocating Motion of a Self-Propelled Rotor Induced by Forced Halt and Release Operations. J. Phys. Chem. C 2018, 122, 3482–3487. [Google Scholar] [CrossRef]

- Shao, D.; Rappel, W.J.; Levine, H. Computational Model for Cell Morphodynamics. Phys. Rev. Lett. 2010, 105, 108104. [Google Scholar] [CrossRef]

- Yoshinaga, N. Spontaneous motion and deformation of a self-propelled droplet. Phys. Rev. E 2014, 89, 012913. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kitahata, H.; Iida, K.; Nagayama, M. Spontaneous motion of an elliptic camphor particle. Phys. Rev. E 2013, 87, 010901. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iida, K.; Kitahata, H.; Nagayama, M. Theoretical study on the translation and rotation of an elliptic camphor particle. Phys. D Nonlinear Phenom. 2014, 272, 39–50. [Google Scholar] [CrossRef] [Green Version]

- Ei, S.I.; Kitahata, H.; Koyano, Y.; Nagayama, M. Interaction of non-radially symmetric camphor particles. Phys. D Nonlinear Phenom. 2018, 366, 10–26. [Google Scholar] [CrossRef]

- Kitahata, H.; Koyano, Y. Spontaneous Motion of a Camphor Particle with a Triangular Modification from a Circle. J. Phys. Soc. Jpn. 2020, 89, 094001. [Google Scholar] [CrossRef]

- Koyano, Y.; Kitahata, H. Imperfect bifurcation in the rotation of a propeller-shaped camphor rotor. Phys. Rev. E 2021, 103, 012202. [Google Scholar] [CrossRef] [PubMed]

- Koyano, Y.; Kitahata, H.; Nakata, S.; Gorecki, J. On a simple model that explains inversion of a self-propelled rotor under periodic stop-and-release-operations. Chaos Interdiscip. J. Nonlinear Sci. 2020, 30, 023105. [Google Scholar] [CrossRef]

- Suematsu, N.J.; Ikura, Y.; Nagayama, M.; Kitahata, H.; Kawagishi, N.; Murakami, M.; Nakata, S. Mode-switching of the self-motion of a camphor boat depending on the diffusion distance of camphor molecules. J. Phys. Chem. C 2010, 114, 9876–9882. [Google Scholar] [CrossRef]

- Ikura, Y.S.; Heisler, E.; Awazu, A.; Nishimori, H.; Nakata, S. Collective motion of symmetric camphor papers in an annular water channel. Phys. Rev. E 2013, 88, 012911. [Google Scholar] [CrossRef]

- Hayakawa, M.; Onoe, H.; Nagai, K.; Takinoue, M. Influence of Asymmetry and Driving Forces on the Propulsion of Bubble-Propelled Catalytic Micromotors. Micromachines 2016, 7, 229. [Google Scholar] [CrossRef] [Green Version]

- Nanzai, B.; Ban, T. Chapter 6 Physical Chemistry of Energy Conversion in Self-propelled Droplets Induced by Dewetting Effect. In Self-Organized Motion: Physicochemical Design based on Nonlinear Dynamics; The Royal Society of Chemistry: London, UK, 2019; pp. 139–166. [Google Scholar] [CrossRef]

- Löffler, R.J.G.; Hanczyc, M.M.; Gorecki, J. A hybrid camphor–camphene wax material for studies on self-propelled motion. Phys. Chem. Chem. Phys. 2019. [Google Scholar] [CrossRef] [Green Version]

- Camphene Safety Data Sheet. Available online: http://www.inchem.org/documents/icsc/icsc/eics1704.htm (accessed on 14 March 2021).

- Nakata, S.; Doi, Y.; Hayashima, Y. Intermittent motion of a camphene disk at the center of a cell. J. Phys. Chem. B 2002, 106, 11681–11684. [Google Scholar] [CrossRef]

- FFmpeg Distribution. Available online: https://www.ffmpeg.org/ (accessed on 14 March 2021).

- ImageJ Distribution. Available online: https://imagej.net/Welcome (accessed on 14 March 2021).

- Wolfram. Mathematica Software. Available online: https://www.wolfram.com/mathematica/ (accessed on 14 March 2021).

- Koyano, Y.; Suematsu, N.J.; Kitahata, H. Rotational motion of a camphor disk in a circular region. Phys. Rev. E 2019, 99, 022211. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Löffler, R.J.G.; Hanczyc, M.M.; Gorecki, J. A Perfect Plastic Material for Studies on Self-Propelled Motion on the Water Surface. Molecules 2021, 26, 3116. https://doi.org/10.3390/molecules26113116

Löffler RJG, Hanczyc MM, Gorecki J. A Perfect Plastic Material for Studies on Self-Propelled Motion on the Water Surface. Molecules. 2021; 26(11):3116. https://doi.org/10.3390/molecules26113116

Chicago/Turabian StyleLöffler, Richard J. G., Martin M. Hanczyc, and Jerzy Gorecki. 2021. "A Perfect Plastic Material for Studies on Self-Propelled Motion on the Water Surface" Molecules 26, no. 11: 3116. https://doi.org/10.3390/molecules26113116