Biophenolic Compounds Influence the In-Mouth Perceived Intensity of Virgin Olive Oil Flavours and Off-Flavours

Abstract

:1. Introduction

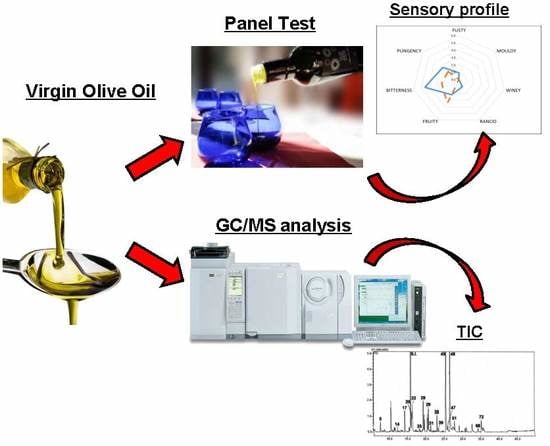

2. Results and Discussion

2.1. Quality Indices and Phenolic Compounds

2.2. Volatile Compounds

2.3. Sensory Analysis

3. Materials and Methods

3.1. Samples, Standards and Reagents

3.2. Sample Preparation

3.2.1. Preparation of MOO Samples with the Addition of Virgin Olive Oil Phenolic Compounds

3.2.2. Preparation of MOO+P and MOO++P Samples with the Addition of the Defected Reference Oils

3.3. EVOO and MOO Analysis

3.3.1. Free Acidity, Peroxide Value and Specific Ultraviolet Absorbance K232 and K270

3.3.2. Extraction and Analysis of Phenolic Compounds

3.3.3. Extraction and Analysis of Volatile Compounds

3.3.4. Sensory Analysis

3.4. Statistical Analysis of Data

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- The European Commission. Commission Regulation (EEC) No. 2568/91 of 11 July 1991 on the Characteristics of Olive Oil and Olive Residue Oil and on the Relevant Methods of Analysis; The European Commission: Brussels, Belgium, 1991; pp. 1–83. [Google Scholar]

- Tena, N.; Wang, S.C.; Aparicio-Ruiz, R.; Garcia-Gonzalez, D.L.; Aparicio, R. In-depth assessment of analytical methods for olive oil purity, safety, and quality characterization. J. Agr. Food Chem. 2015, 63, 4509–4526. [Google Scholar] [CrossRef]

- De Santis, D.; Frangipane, M.T. Sensory perceptions of virgin olive oil: New panel evaluation method and the chemical compounds responsible. Nat. Sci. 2015, 7, 132–142. [Google Scholar] [CrossRef] [Green Version]

- International Olive Council. Sensory Analysis of Olive Oil Method for the Organoleptic Assessment of Virgin Olive Oil; International Olive Council: Madrid, Spain, 2015. [Google Scholar]

- EFSA. Scientific Opinion on the substantiation of health claims related to polyphenols in olive and protection of LDL particles from oxidative damage (ID ,1696, 2865), “maintenance of normal blood HDL-cholesterol concentrations” (ID 1639), “maintenance of normal blood pressure” (ID 3781), “anti-inflammatory” (ID 1882), “contributes to the upper respiratory tract health” (ID 3468), “can help to maintain a function of gastrointestinal tract” (3779), and “contributes to body defences against external agents” (ID 3467) pursuant to Article 13 (1) of Regulation (EC) No 1924/2006. EFSA J. 2011, 9, 2033–2058. [Google Scholar]

- Vitaglione, P.; Savarese, M.; Paduano, A.; Scalfi, L.; Fogliano, V.; Sacchi, R. Healthy virgin olive oil: A matter of bitterness. Crit. Rev. Food Sci. 2015, 55, 1808–1818. [Google Scholar] [CrossRef]

- Servili, M.; Esposto, S.; Fabiani, R.; Urbani, S.; Taticchi, A.; Mariucci, F.; Montedoro, G.F. Phenolic compounds in olive oil: Antioxidant, health and organoleptic activities according to their chemical structure. Inflammopharmacology 2009, 17, 76–84. [Google Scholar] [CrossRef]

- Taticchi, A.; Esposto, S.; Servili, M. The basis of the sensory properties of virgin olive oil. In Olive Oil Sensory Science; Monteleone, E., Langstaff, S., Eds.; John Wiley & Sons: New York, NY, USA, 2014; pp. 33–54. [Google Scholar]

- Beltrán, G.; Ruano, M.T.; Jiménez, A.; Uceda, M.; Aguilera, M.P. Evaluation of virgin olive oil bitterness by total phenol content analysis. Eur. J. Lipid Sci. Tech. 2007, 108, 193–197. [Google Scholar] [CrossRef]

- Genovese, A.; Yang, N.; Linforth, R.; Sacchi, R.; Fisk, I. The role of phenolic compounds on olive oil aroma release. Food Res. Int. 2018, 112, 319–327. [Google Scholar] [CrossRef]

- Genovese, A.; Caporaso, N.; Villani, V.; Paduano, A.; Sacchi, R. Olive oil phenolic compounds affect the release of aroma compounds. Food Chem. 2015, 181, 284–294. [Google Scholar] [CrossRef]

- Morales, M.T.; Luna, G.; Aparicio, R. Comparative study of virgin olive oil sensory defects. Food Chem. 2005, 91, 293–301. [Google Scholar] [CrossRef]

- Angerosa, F.; Servili, M.; Selvaggini, R.; Taticchi, A.; Esposto, S.; Montedoro, G. Volatile compounds in virgin olive oil: Occurrence and their relationship with the quality. J. Chromatogr. A 2004, 1054, 17–31. [Google Scholar] [CrossRef]

- García-González, D.L.; Aparicio, R. Research in olive oil: Challenges for the near future. J. Agr. Food Chem. 2010, 58, 12569–12577. [Google Scholar] [CrossRef]

- Aparicio, R.; Morales, M.T.; García-González, D.L. Towards new analyses of aroma and volatiles to understand sensory perception of olive oil. Eur. J. Lipid Sci. Tech. 2012, 114, 1114–1125. [Google Scholar] [CrossRef]

- Paiva-Martins, F.; Gordon, M.H.; Gameiro, P. Activity and location of olive oil phenolic antioxidants in liposomes. Chem. Phys. Lipids, 2003, 124, 23–36. [Google Scholar] [CrossRef]

- Angerosa, F. Influence of volatile compounds on virgin olive oil quality evaluated by analytical approaches and sensor panels. Eur. J. Lipid Sci. Tech. 2002, 104, 639–660. [Google Scholar] [CrossRef]

- Angerosa, F.; Campestre, C. Sensory Quality: Methodologies and Applications. In Handbook of Olive Oil-Analysis and Properties, 2nd ed.; Aparicio, R., Harwood, J., Eds.; Springer: Massachusetts, MA, USA, 2013; pp. 523–560. [Google Scholar]

- Langstaff, S. Sensory Quality Control. In Olive Oil Sensory Science; Monteleone, E., Langstaff, S., Eds.; John Wiley & Sons: New York, NY, USA, 2014; pp. 81–108. [Google Scholar]

- Reiners, J.; Grosch, W. Odorants of virgin olive oils with different flavor profiles. J. Agr. Food Chem. 1998, 46, 2754–2763. [Google Scholar] [CrossRef]

- Genovese, A.; Caporaso, N.; Leone, T.; Paduano, A.; Mena, C.; Perez-Jimenez, M.A.; Sacchi, R. Use of odorant series for extra virgin olive oil aroma characterisation. J. Sci. Food Agric. 2019, 99, 1215–1224. [Google Scholar] [CrossRef]

- Ginsburg, I.; Koren, E.; Shalish, M.; Kanner, J.; Kohen, R. Saliva increases the availability of lipophilic polyphenols as antioxidants and enhances their retention in the oral cavity. Arch. Oral Biol. 2012, 57, 1327–1334. [Google Scholar] [CrossRef]

- Muñoz-González, C.; Feron, G.; Guichard, E.; Rodríguez-Bencomo, J.J.; Martin-Alvarez, P.J.; Moreno-Arribas, M.V.; Pozo-Bayón, M.A. Understanding the role of saliva in aroma release from wine by using static and dynamic headspace conditions. J. Agr. Food Chem. 2014, 62, 8274–8288. [Google Scholar] [CrossRef] [Green Version]

- Esteban-Fernández, A.; Muñoz-González, C.; Jiménez-Girón, A.; Pérez-Jiménez, M.; Pozo-Bayón, M.Á. Aroma release in the oral cavity after wine intake is influenced by wine matrix composition. Food Chem. 2018, 243, 125–133. [Google Scholar] [CrossRef]

- Perez-Jiménez, M.; Chaya, C.; Pozo-Bayón, M.Á. Individual differences and effect of phenolic compounds in the immediate and prolonged in-mouth aroma release and retronasal aroma intensity during wine tasting. Food Chem. 2019, 285, 147–155. [Google Scholar] [CrossRef] [Green Version]

- Goldner, M.C.; di Leo Lira, P.; van Baren, C.; Bandoni, A. Influence of polyphenol levels on the perception of aroma in Vitis vinifera cv. Malbec wine. S. Afr. J. Enol. Vitic. 2016, 32, 21–27. [Google Scholar] [CrossRef] [Green Version]

- Sacchi, R.; Caporaso, N.; Paduano, A.; Genovese, A. Industrial-scale filtration affects volatile compounds in extra virgin olive oil cv. Ravece. Eur. J. Lipid Sci. Tech. 2015, 117, 2007–2014. [Google Scholar] [CrossRef]

- Romero, I.; García-González, D.L.; Aparicio-Ruiz, R.; Morales, M.T. Validation of SPME–GCMS method for the analysis of virgin olive oil volatiles responsible for sensory defects. Talanta 2015, 134, 394–401. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples are not available from the authors. |

| MOO+P | MOO++P | Legal Limits | |

|---|---|---|---|

| Quality indices | |||

| Acidity | 0.38 ± 0.05a | 0.37 ± 0.02a | ≤0.80 |

| Peroxide value | 6.4 ± 0.1a | 6.3 ± 0.1a | ≤20 |

| K232 | 1.821 ± 0.050a | 1.837 ± 0.012a | ≤2.50 |

| K270 | 0.120 ± 0.003a | 0.128 ± 0.003a | ≤0.22 |

| ΔK | 0.004 ± 0.001a | 0.004 ± 0.001a | ≤0.01 |

| Phenolic compound | |||

| Hydroxytyrosol | 10.0 ± 0.4a | 12.6 ± 0.2b | - |

| Tyrosol | 7.4 ± 0.1a | 11.6 ± 0.6b | - |

| 3,4-DHPEA-EDA | 48.3 ± 2.1a | 72.1 ± 0.8b | - |

| p-HPEA-EDA | 44.7 ± 2.0a | 72.2 ± 0.6b | - |

| Lignans | 29.2 ± 1.8a | 46.2 ± 0.5b | - |

| 3,4-DHPEA-EA | 40.2 ± 0.8a | 68.5 ± 0.3b | - |

| p-HPEA-EA | 13.1 ± 0.9a | 23.2 ± 0.0b | - |

| Total phenolics (HPLC) | 192.8 ± 4.3a | 306.4 ± 3.0b | - |

| Total phenolics (Folin–Ciocalteau) | 297.5 ± 8.7a | 510.8 ± 9.3b | - |

| Compound | MOO | MOO with the Addition of VOO Off-Flavour | ||||||

|---|---|---|---|---|---|---|---|---|

| Rancid | Winey–Vinegary | Fusty–Muddy | ||||||

| MOO+P | MOO++P | MOO+P | MOO++P | MOO+P | MOO++P | MOO+P | MOO++P | |

| octane | nf A | nf A | 0.36 ± 0.02 aC | 0.30 ± 0.01 aC | 0.07 ± 0.02 aB | 0.09 ± 0.00 aB | 0.09 ± 0.00 aB | 0.08 ± 0.00 aB |

| ethyl acetate | 0.18 ± 0.07 aAB | 0.22 ± 0.00 aA | 0.25 ± 0.01 aB | 0.45 ± 0.05 bC | 0.12 ± 0.00 aAB | 0.33 ± 0.01 bAB | 0.10 ± 0.00 aA | 0.35 ± 0.01 bBC |

| ethanol | 30.08 ± 2.43 aA | 31.89 ± 1.17 aA | 32.6 ± 2.51 aA | 34.97 ± 0.13 aA | 43.31 ± 0.89 aB | 44.97 ± 0.69 aB | 34.28 ± 2.96 aAB | 31.43 ± 1.82 aA |

| ethyl propanoate | nf A | nf A | nf A | nf A | nf A | nf A | 0.01 ± 0.00 aB | 0.01 ± 0.00 aB |

| 3-pentanone | 0.32 ± 0.00 aA | 0.32 ± 0.03 aAB | 0.40 ± 0.01 aB | 0.36 ± 0.02 aB | 0.29 ± 0.00 aA | 0.28 ± 0.01 aA | 0.31 ± 0.02 aA | 0.29 ± 0.00 aAB |

| 1-penten-3-one | 0.24 ± 0.01 aA | 0.23 ± 0.01 aA | 0.26 ± 0.02 aA | 0.23 ± 0.02 aA | 0.28 ± 0.03 aA | 0.25 ± 0.00 aA | 0.24 ± 0.03 aA | 0.24 ± 0.00 aA |

| ethyl butanoate | nf A | nf A | nf A | nf A | nf A | nf A | 0.04 ± 0.00 aB | 0.04 ± 0.00 aB |

| hexanal | 2.23 ± 0.15 aA | 2.24 ± 0.06 aA | 3.12 ± 0.11 aB | 2.87 ± 0.23 aB | 2.27 ± 0.10 aA | 2.25 ± 0.12 aA | 2.38 ± 0.27 aA | 2.23 ± 0.04 aA |

| trans-2-pentenal | nf A | nf A | 0.09 ± 0.01 aB | 0.09 ± 0.00 aC | 0.11 ± 0.02 aB | 0.07 ± 0.01 aBC | 0.10 ± 0.01 aB | 0.07 ± 0.01 aB |

| 1-penten-3-ol | 0.25 ± 0.03 aA | 0.26 ± 0.03 aA | 0.21 ± 0.02 aA | 0.18 ± 0.01 aA | 0.25 ± 0.01 aA | 0.24 ± 0.01 aA | 0.23 ± 0.00 aA | 0.23 ± 0.03 aA |

| 2-heptanone | nf A | nf A | 0.38 ± 0.04 aC | 0.38 ± 0.00 aC | 0.11 ± 0.01 aB | 0.15 ± 0.00 aB | nf A | nf A |

| heptanal | nf A | nf A | 0.26 ± 0.01 aB | 0.21 ± 0.02 aB | nf A | nf A | nf A | nf A |

| 3-methyl-1-butanol | nf A | nf A | nf A | nf A | 0.08 ± 0.00 aB | 0.09 ± 0.01 aB | 0.07 ± 0.01 aB | 0.08 ± 0.00 aB |

| trans-2-hexenal | 29.03 ± 1.84 aA | 26.91 ± 2.17 aA | 32.4 ± 0.79 aA | 27.9 ± 1.98 aA | 28.55 ± 0.81 aA | 26.13 ± 3.63 aA | 31.22 ± 2.44 aA | 26.43 ± 1.50 aA |

| 1-butanol | nf A | nf A | 0.04 ± 0.00 aB | 0.04 ± 0.00 aB | nf A | nf A | nf A | nf A |

| hexyl acetate | 0.31 ± 0.02 aAB | 0.28 ± 0.03 aA | 0.34 ± 0.00 aB | 0.30 ± 0.02 aA | 0.26 ± 0.00 aA | 0.25 ± 0.03 aA | 0.31 ± 0.02 aAB | 0.26 ± 0.00 aA |

| 2-octanone | nf A | nf A | 0.10 ± 0.00 aB | 0.08 ± 0.01 aB | nf A | nf A | nf A | nf A |

| octanal | nf A | nf A | 0.84 ± 0.04 aC | 0.69 ± 0.05 aB | 0.05 ± 0.01 aBC | 0.05 ± 0.00 aA | 0.1 ± 0.01 aB | 0.11 ± 0.01 aA |

| trans, trans-2,6,10-dodecatrienal | nf A | nf A | nf A | nf A | nf A | nf A | 0.12 ± 0.02 aB | 0.13 ± 0.00 aB |

| cis-3-hexen-1-ol acetate | 1.89 ± 0.17 aA | 1.71 ± 0.20 aA | 2.03 ± 0.05 aA | 1.74 ± 0.18 aA | 1.70 ± 0.11 aA | 1.58 ± 0.25 aA | 1.97 ± 0.21 aA | 1.62 ± 0.07 aA |

| trans-2-heptenal | nf A | nf A | 0.20 ± 0.01 aB | 0.30 ± 0.03 aC | nf A | nf A | 0.2 ± 0.01 aB | 0.19 ± 0.01 aB |

| 1-hexanol | 2.58 ± 0.21 aA | 2.36 ± 0.15 aA | 2.89 ± 0.05 aA | 2.39 ± 0.16 aA | 2.66 ± 0.16 aA | 2.42 ± 0.44 aA | 2.84 ± 0.19 aA | 2.34 ± 0.13 aA |

| cis-3-hexen-1-ol | 3.04 ± 0.21 aA | 2.81 ± 0.27 aA | 3.39 ± 0.07 aA | 2.82 ± 0.24 aA | 3.20 ± 0.17 aA | 2.92 ± 0.44 aA | 3.37 ± 0.02 aA | 2.76 ± 0.21 aA |

| nonanal | nf A | nf A | 0.60 ± 0.03 aC | 0.52 ± 0.05 aC | 0.16 ± 0.01 aB | 0.19 ± 0.03 aB | 0.2 ± 0.02 aB | 0.17 ± 0.00 aB |

| trans-2-hexen-1-ol | 4.46 ± 0.32 aA | 4.12 ± 0.34 aA | 5.06 ± 0.16 aA | 4.16 ± 0.36 aA | 4.70 ± 0.26 aA | 4.24 ± 0.69 aA | 4.97 ± 0.31 aA | 4.06 ± 0.26 aA |

| decanal | nf A | nf A | 0.05 ± 0.00 aB | 0.03 ± 0.00 aB | nf A | nf A | nf A | nf A |

| trans-2-octenal | nf A | nf A | 0.06 ± 0.01 aB | 0.06 ± 0.00 aB | nf A | nf A | nf A | nf A |

| trans, trans-2,4-heptadienal | nf A | nf A | 0.08 ± 0.00 aC | 0.08 ± 0.01 aC | 0.06 ± 0.00 aB | 0.05 ± 0.00 aB | nf A | nf A |

| acetic acid | nf A | nf A | nf A | nf A | 1.22 ± 0.11 aB | 0.83 ± 0.09 aB | nf A | nf A |

| butanoic acid | nf A | nf A | nf A | nf A | nf A | nf A | 0.34 ± 0.01 aB | 0.33 ± 0.01 aB |

| pentanoic acid | nf A | nf A | 0.50 ± 0.02 aB | 0.37 ± 0.05 aB | nf A | nf A | nf A | nf A |

| hexanoic acid | nf A | nf A | 2.7 ± 0.11 aB | 2.3 ± 0.09 aC | 0.2 ± 0.07 aA | 0.22 ± 0.04 aB | 0.25 ± 0.07 aA | 0.23 ± 0.03 aB |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Genovese, A.; Mondola, F.; Paduano, A.; Sacchi, R. Biophenolic Compounds Influence the In-Mouth Perceived Intensity of Virgin Olive Oil Flavours and Off-Flavours. Molecules 2020, 25, 1969. https://doi.org/10.3390/molecules25081969

Genovese A, Mondola F, Paduano A, Sacchi R. Biophenolic Compounds Influence the In-Mouth Perceived Intensity of Virgin Olive Oil Flavours and Off-Flavours. Molecules. 2020; 25(8):1969. https://doi.org/10.3390/molecules25081969

Chicago/Turabian StyleGenovese, Alessandro, Ferdinando Mondola, Antonello Paduano, and Raffaele Sacchi. 2020. "Biophenolic Compounds Influence the In-Mouth Perceived Intensity of Virgin Olive Oil Flavours and Off-Flavours" Molecules 25, no. 8: 1969. https://doi.org/10.3390/molecules25081969