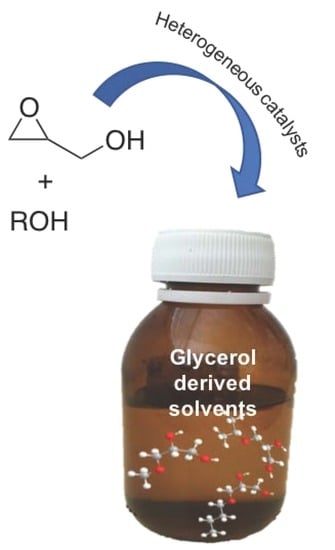

Optimization of the Synthesis of Glycerol Derived Monoethers from Glycidol by Means of Heterogeneous Acid Catalysis

Abstract

:1. Introduction

2. Results and Discussion

2.1. Reaction of Glycidol and Methanol by Means of Heterogeneous Brønsted Acid Catalysis

2.2. Reaction of Glycidol and Methanol by Means of Heterogeneous Lewis Catalysis

2.3. Reaction of Glycidol with Several Alcohols for the Synthesis of GMEs

2.4. Comparison of Synthetic Methodologies for Obtaining GMEs

3. Materials and Methods

3.1. Preparation of the Catalysts

3.2. Reaction Procedure for the Synthesis of Glycerol Monoethers

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- García, J.I.; García-Marín, H.; Pires, E. Glycerol based solvents: Synthesis, properties and applications. Green Chem. 2014, 16, 1007–1033. [Google Scholar] [CrossRef]

- Díaz-Álvarez, A.E.; Francos, J.; Lastra-Barreira, B.; Crochet, P.; Cadierno, V. Glycerol and derived solvents: New sustainable reaction media for organic synthesis. Chem. Commun. 2011, 47, 6208–6227. [Google Scholar] [CrossRef] [PubMed]

- Wolfson, A.; Snezhko, A.; Meyouhas, T.; Tavor, D. Glycerol derivatives as green reaction mediums. Green Chem. Lett. Rev. 2012, 5, 7–12. [Google Scholar] [CrossRef] [Green Version]

- Gu, Y.; Jerome, F. Glycerol as a sustainable solvent for green chemistry. Green Chem. 2010, 12, 1127–1138. [Google Scholar] [CrossRef]

- Garcia, J.I.; Garcia-Marin, H.; Mayoral, J.A.; Perez, P. Green solvents from glycerol. Synthesis and physico-chemical properties of alkyl glycerol ethers. Green Chem. 2010, 12, 426–434. [Google Scholar] [CrossRef]

- Perales, E.; García, J.I.; Pires, E.; Aldea, L.; Lomba, L.; Giner, B. Ecotoxicity and QSAR studies of glycerol ethers in Daphnia magna. Chemosphere 2017, 183, 277–285. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perales, E.; García, C.B.; Lomba, L.; García, J.I.; Pires, E.; Sancho, M.C.; Navarro, E.; Giner, B. Comparative ecotoxicity study of glycerol-biobased solvents. Environ. Chem. 2017, 14, 370. [Google Scholar] [CrossRef]

- García, J.I.; Pires, E.; Aldea, L.; Lomba, L.; Perales, E.; Giner, B. Ecotoxicity studies of glycerol ethers in Vibrio fischeri: Checking the environmental impact of glycerol-derived solvents. Green Chem. 2015, 17, 4326–4333. [Google Scholar] [CrossRef]

- Leal-Duaso, A.; Pérez, P.; Mayoral, J.A.; Pires, E.; García, J.I. Glycerol as a source of designer solvents: Physicochemical properties of low melting mixtures containing glycerol ethers and ammonium salts. Phys. Chem. Chem. Phys. 2017, 19, 28302–28312. [Google Scholar] [CrossRef] [PubMed]

- Male, S.R.; Panjala, L.; Kolte, A.; Pawar, S.L. Aqueous Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts. WO/2018/142313, 20 August 2018. [Google Scholar]

- Kim, J.Y.; Son, S.K.; Chang, S.Y.; Choi, J.J.; Kim, H.S. Amphiphilic Solvent for Cleaning and Dry-Cleaning, and Composition Containing the Same Solvent. KR20130021731 (A), 20 March 2013. [Google Scholar]

- Stark, J. Recent advances in the field of cement hydration and microstructure analysis. Cem. Concr. Res. 2011, 41, 666–678. [Google Scholar] [CrossRef]

- Park, J.U.; Choi, J.J.; Gu, M.J.; Jeong, G. in; Chang, S.Y.; Park, S.E.; Song, B.J. Environment-Friendly Water-Soluble Cutting Fluid for Wafer, and Composition Containing the Same Cutting Fluid. KR20120035891 (A), 20 April 2012. [Google Scholar]

- Gershun, A.; Mercer, W.; Woyciesjes, P. Neoacid Corrosion Inhibitors. WO9720901 (A1), 19 June 1997. [Google Scholar]

- Kubota, Y.; Murata, D.; Yoshioka, S.; Yano, S. Liquid Detergent Composition. WO2011114875 (A1), 20 September 2011. [Google Scholar]

- Bui, L.; Subbaraman, R.; Desai, S.; Brucker, B.; Ranganathan, N.K. Fast-Drying Ink Composition. WO2011072155A1, 16 June 2011. [Google Scholar]

- Marinho, F.J.; Yang, B. Heat Transfer System, Fluid, and Method. US2012270129 (A1), 20 October 2012. [Google Scholar]

- Sutter, M.; Silva, E.D.; Duguet, N.; Raoul, Y.; Métay, E.; Lemaire, M. Glycerol ether synthesis: A bench test for green chemistry concepts and technologies. Chem. Rev. 2015, 115, 8609–8651. [Google Scholar] [CrossRef] [PubMed]

- Flowers, B.S.; Mittenthal, M.S.; Jenkins, A.H.; Wallace, D.A.; Whitley, J.W.; Dennis, G.P.; Wang, M.; Turner, C.H.; Emel’yanenko, V.N.; Verevkin, S.P.; et al. 1,2,3-Trimethoxypropane: A glycerol-derived physical solvent for CO2 absorption. ACS Sustain. Chem. Eng. 2017, 5, 911–921. [Google Scholar] [CrossRef]

- Sutter, M.; Dayoub, W.; Métay, E.; Raoul, Y.; Lemaire, M. 1,2,3-Trimethoxypropane and glycerol ethers as bio-sourced solvents from glycerol: Synthesis by solvent-free phase-transfer catalysis and utilization as an alternative solvent in chemical transformations. ChemCatChem 2013, 5, 2893–2904. [Google Scholar] [CrossRef]

- Sutter, M.; Dayoub, W.; Métay, E.; Raoul, Y.; Lemaire, M. 1-O-Alkyl (di)glycerol ethers synthesis from methyl esters and triglycerides by two pathways: Catalytic reductive alkylation and transesterification/reduction. Green Chem. 2013, 15, 786–797. [Google Scholar] [CrossRef]

- Liu, F.; Vigier, K.D.O.; Pera-Titus, M.; Pouilloux, Y.; Clacens, J.-M.; Decampo, F.; Jérôme, F. Catalytic etherification of glycerol with short chain alkyl alcohols in the presence of lewis acids. Green Chem. 2013, 15, 901–909. [Google Scholar] [CrossRef]

- Veiga, P.M.; Gomes, A.C.L.; Veloso, C.O.; Henriques, C.A. Acid zeolites for glycerol etherification with ethyl alcohol: Catalyst activity and catalyst properties. Appl. Catal. A-Gen. 2017, 548, 2–15. [Google Scholar] [CrossRef]

- Cucciniello, R.; Ricciardi, M.; Vitiello, R.; Di Serio, M.; Proto, A.; Capacchione, C. Synthesis of monoalkyl glyceryl ethers by ring opening of glycidol with alcohols in the presence of lewis acids. ChemSusChem 2016, 9, 3272–3275. [Google Scholar] [CrossRef] [PubMed]

- Ricciardi, M.; Passarini, F.; Vassura, I.; Proto, A.; Capacchione, C.; Cucciniello, R.; Cespi, D. Glycidol, a Valuable substrate for the synthesis of monoalkyl glyceryl ethers: A simplified life cycle approach. ChemSusChem 2017, 10, 2291–2300. [Google Scholar] [CrossRef] [PubMed]

- Leal-Duaso, A.; Caballero, M.; Urriolabeitia, A.; Mayoral, J.A.; García, J.I.; Pires, E. Synthesis of 3-alkoxypropan-1,2-diols from glycidol: Experimental and theoretical studies for the optimization of the synthesis of glycerol derived solvents. Green Chem. 2017, 19, 4176–4185. [Google Scholar] [CrossRef]

- Ricciardi, M.; Passarini, F.; Capacchione, C.; Proto, A.; Barrault, J.; Cucciniello, R.; Cespi, D. First attempt of glycidol-to-monoalkyl glyceryl ethers conversion by acid heterogeneous catalysis: Synthesis and simplified sustainability assessment. ChemSusChem 2018, 11, 1829–1837. [Google Scholar] [CrossRef] [PubMed]

- Thapa, I.; Mullen, B.; Saleem, A.; Leibig, C.; Baker, R.T.; Giorgi, J.B. Efficient green catalysis for the conversion of fructose to levulinic acid. Appl. Catal. A-Gen. 2017, 539, 70–79. [Google Scholar] [CrossRef]

- Goerbe, T.; Lihammar, R.; Baeckvall, J.-E. Heterogeneous acid-catalyzed racemization of tertiary alcohols. Chem. Eur. J. 2018, 24, 77–80. [Google Scholar] [CrossRef] [PubMed]

- De la Calle, C.; Fraile, J.M.; Garcia-Bordeje, E.; Pires, E.; Roldan, L. Biobased catalyst in biorefinery processes: Sulphonated hydrothermal carbon for glycerol esterification. Catal. Sci. Technol. 2015, 5, 2897–2903. [Google Scholar] [CrossRef]

- Cativiela, C.; Garcia, J.; Garciamatres, M.; Mayoral, J.; Figueras, F.; Fraile, J.; Cseri, T.; Chiche, B. Clay-catalyzed Friedel-Crafts alkylation of anisole with dienes. Appl. Catal. A-Gen. 1995, 123, 273–287. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are available from the authors. |

| Entry | Catalyst | T (°C) Activation | Time (h) 2 | Products Yield | 3a/3b |

|---|---|---|---|---|---|

| 1 | K10-Al | 120 | 0.5 | 94 | 82:18 |

| 2 | K10-Fe | 120 | 0.5 | 86 | 70:30 |

| 3 | K10-Zn | 120 | 18 | 91 | 93:7 |

| 4 | K10-Al-calc | 550 | 1.5 | 84.9 | 89:11 |

| 5 | K10-Fe-calc | 550 | 1.5 | 74.8 | 91:9 |

| 6 | K10-Zn-calc | 550 | 24 | 79.1 | 90:10 |

| Alcohol | Catalyst | Time (h) 2 | Products Yield | 4–5a/4–5b |

|---|---|---|---|---|

| 2b | K10-H+ | 0.5 | 70 | 83:17 |

| 2b | K10-Al | 0.5 | 79 | 76:24 |

| 2b | K10-Zn | 24 | 65 3 | 88:12 |

| 2c | K10-H+ | 2 | 78 | 91:9 |

| 2c | K10-Al | 1 | 75 | 85:15 |

| 2c | K10-Zn | 24 | 72 | 95:5 |

| Alcohol | Catalyst | Catalyst Loading (% mol) | Alcohol/Glycidol Molar Ratio | Time (h) | Reaction T (°C) | Conversion (Selectivity) | a/b | Ref. |

|---|---|---|---|---|---|---|---|---|

| 2a | KOH 1 | 20 | 15 | 2 | 65 | 100 (93) | 100:0 | [26] |

| 2a | Al(OTf)3 | 0.01 | 9 | 1 | 80 | 100 (94) | 66:34 | [24] |

| 2a | Nafion NR50 | 0.5 | 9 | 1 | 80 | 85 (79) | 77:23 | [27] |

| 2a | Nafion NR50 | 10 | 9 | 2 | 25 | 100 (67) | 72:28 | |

| 2a | K10-H+1 | 10 | 15 | 0.5 | 25 | 100 (83) | 80:20 | |

| 2a | K10-Al 1 | 5 | 15 | 0.5 | 25 | 100 (94) | 82:18 | |

| 2a | K10-Zn 1 | 5 | 15 | 24 | 25 | 100 (91) | 93:7 | |

| 2b | KOH 1 | 20 | 15 | 1.5 | 65 | 100 (60) | 100:0 | |

| 2b | Al(OTf)3 | 0.01 | 9 | 1 | 80 | 94 (91) | 66:34 | [24] |

| 2b | Nafion NR50 | 0.5 | 9 | 15 | 80 | 39 (37) | 72:28 | [27] |

| 2b | K10-H+1 | 10 | 15 | 0.5 | 25 | 100 (70) | 83:13 | |

| 2b | K10-Al 1 | 5 | 15 | 0.5 | 25 | 100 (79) | 76:24 | |

| 2c | K10-Zn 1 | 5 | 15 | 24 | 25 | 85 (65) | 88:12 | |

| 2c | KOH 1 | 20 | 15 | 2 | 65 | 100 (30) | 100:0 | |

| 2c | Al(OTf)3 | 0.01 | 9 | 1 | 80 | 85 (87) | 66:34 | [24] |

| 2c | Nafion NR50 | 0.5 | 9 | 15 | 80 | 95 (86) | 78:22 | [27] |

| 2c | K10-H+1 | 10 | 15 | 2 | 25 | 100 (78) | 91:9 | |

| 2c | K10-Al 1 | 5 | 15 | 1 | 25 | 100 (75) | 85:15 | |

| 2c | K10-Zn 1 | 5 | 15 | 24 | 25 | 100 (72) | 95:5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pires, E.; García, J.I.; Leal-Duaso, A.; Mayoral, J.A.; García-Peiro, J.I.; Velázquez, D. Optimization of the Synthesis of Glycerol Derived Monoethers from Glycidol by Means of Heterogeneous Acid Catalysis. Molecules 2018, 23, 2887. https://doi.org/10.3390/molecules23112887

Pires E, García JI, Leal-Duaso A, Mayoral JA, García-Peiro JI, Velázquez D. Optimization of the Synthesis of Glycerol Derived Monoethers from Glycidol by Means of Heterogeneous Acid Catalysis. Molecules. 2018; 23(11):2887. https://doi.org/10.3390/molecules23112887

Chicago/Turabian StylePires, Elisabet, José Ignacio García, Alejandro Leal-Duaso, José Antonio Mayoral, José Ignacio García-Peiro, and David Velázquez. 2018. "Optimization of the Synthesis of Glycerol Derived Monoethers from Glycidol by Means of Heterogeneous Acid Catalysis" Molecules 23, no. 11: 2887. https://doi.org/10.3390/molecules23112887