Journal Description

Powders

Powders

is an international, peer-reviewed, open access journal on particle/powder science and technology published quarterly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 53.9 days after submission; acceptance to publication is undertaken in 7.5 days (median values for papers published in this journal in the second half of 2023).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

Latest Articles

Using Chia Powder as a Binder to Obtain Chewable Tablets Containing Quinoa for Dietary Fiber Supplementation

Powders 2024, 3(2), 202-216; https://doi.org/10.3390/powders3020013 - 07 Apr 2024

Abstract

►

Show Figures

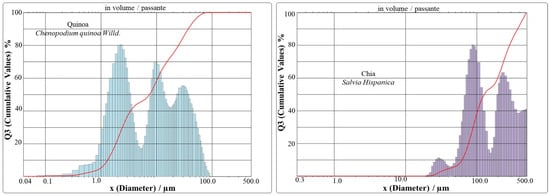

The consumption of fiber in the human diet is a global recommendation to ensure a healthy diet. Quinoa (Chenopodium quinoa Willd.), a gluten-free grain, and chia (Salvia hispanica), a seed, contain a high fiber content, and both have the

[...] Read more.

The consumption of fiber in the human diet is a global recommendation to ensure a healthy diet. Quinoa (Chenopodium quinoa Willd.), a gluten-free grain, and chia (Salvia hispanica), a seed, contain a high fiber content, and both have the potential to be used in the development of nutraceutical and pharmaceutical formulations. An interesting characteristic of chia is its ability to form viscous mucilage when in contact with water, making it a potential binder in solid formulations. However, there are no studies on chia as a binder, and therefore, the objective of the present study was to evaluate the feasibility of using chia as a binder to produce quinoa granules and, subsequently, develop chewable tablet formulations. The quinoa and chia were in a powder form and then transformed into a wet mass with the help of mixer torque rheometer (MTR) equipment. In the wet granulation form, the following parameters were tested: multiple additions, 15 g of material, and 25 timepoints for the addition of 1 mL of water. An experimental design was carried out to evaluate the impact of the variables on the MTR results for subsequent granulation. The granulation point was possible for T1–T9, and most formulations gave satisfactory results, such as an acceptable resistance of the granules. In the end, a formulation was selected for the development of chewable tablets containing quinoa and chia fibers.

Full article

Open AccessPerspective

Population Balance Modeling of Milling Processes: Are We Falsifying Breakage Kinetics and Distribution via Back-Calculation Methods?

by

Ecevit Bilgili

Powders 2024, 3(2), 190-201; https://doi.org/10.3390/powders3020012 - 03 Apr 2024

Abstract

►▼

Show Figures

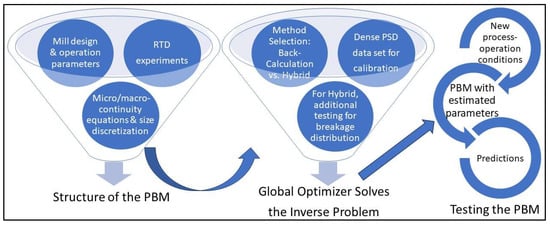

Population balance models (PBMs) for milling processes are based on two fundamental concepts: specific breakage rate function and breakage distribution function, which vary with particle size as well as design–operation conditions. The solution of the inverse problem, i.e., the estimation of these two

[...] Read more.

Population balance models (PBMs) for milling processes are based on two fundamental concepts: specific breakage rate function and breakage distribution function, which vary with particle size as well as design–operation conditions. The solution of the inverse problem, i.e., the estimation of these two functions’ parameters, may cause falsified kinetics and breakage distribution mechanisms. This perspective article aims to expose and mitigate various aspects of potential falsification, thus enabling the development of a robust PBM. Through an in-depth analysis of historical approaches to the PBM inverse problem and experimental observations, as well as the author’s recent contributions to the inverse methodology within the context of back-calculation methods, six principles have been offered: (i) include the governing physical phenomena and reduce errors in model building; (ii) reduce the number of model parameters via size–operation-dependent functional forms, hybrid approaches for back-calculation, and combination with CFD–DEM and other mechanistic models; (iii) generate a dense particle size distribution data set obtained at various milling times and/or locations; (iv) ensure a grid-independent solution with a sufficient number of size classes; (v) use a global optimization-based back-calculation method for parameter estimation and provide standard errors of the estimates; and (vi) test the predictive capability of the PBM. This perspective article boosts awareness of various challenges involved in the solution of the inverse PBM problem as pertinent to milling processes and provides researchers with six principles to minimize falsified kinetics.

Full article

Figure 1

Open AccessArticle

Hygroscopicity in Epoxy Powder Composites

by

James M. Maguire, Jin-Yu Wang and Conchúr M. Ó Brádaigh

Powders 2024, 3(2), 168-189; https://doi.org/10.3390/powders3020011 - 03 Apr 2024

Abstract

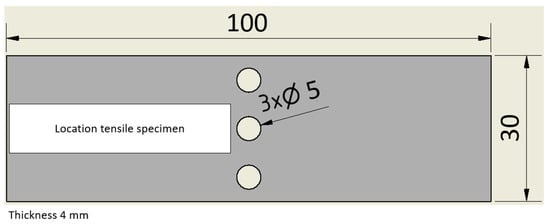

Epoxy powders offer a low-cost way of manufacturing thick-section composite parts, such as those found in wind and tidal turbines. Currently, their processing cycle includes a lengthy drying stage (≥15 h) to remove ambient moisture. This drying stage prevents void defect formation and,

[...] Read more.

Epoxy powders offer a low-cost way of manufacturing thick-section composite parts, such as those found in wind and tidal turbines. Currently, their processing cycle includes a lengthy drying stage (≥15 h) to remove ambient moisture. This drying stage prevents void defect formation and, thereby, a reduction in mechanical properties; however, it constitutes up to 60% of the processing time. Little research has been published which studies the drying stage or its optimisation. In the present work, experimental and simulated analyses are used to investigate the effects of hygroscopicity in epoxy powder composites. Tests are performed to quantify the void content of dried and undried laminates and to measure its impact on transverse flexural strength. Dynamic vapour sorption analysis is used to study the sorption behaviour of the epoxy powder. It is shown that the epoxy powder is slightly hygroscopic (1.36 wt%) and exhibits sorption behaviour that is characteristic of glassy polymers. This results in up to 4.8% voids (by volume) if processed in an undried state, leading to a 43% reduction in transverse flexural strength. A modified linear driving force model is fitted to the desorption data and then implemented in existing process-simulation tools. The drying of a thick epoxy powder composite section is simulated to investigate the influence of powder sintering on the duration of the drying stage. Process simulations reveal that a standard drying cycle prematurely sinters the powder, which inhibits moisture release. By maintaining the powder state, simulations show that the drying cycle can be reduced to 5 h.

Full article

(This article belongs to the Special Issue Feature Papers in Powders 2023)

►▼

Show Figures

Figure 1

Open AccessArticle

Reuse of Smoulder in Laser Powder-Bed Fusion of AlSi10Mg—Powder Characterization and Sample Analysis

by

Oliver Maurer, Heiko Jacob and Dirk Bähre

Powders 2024, 3(2), 154-167; https://doi.org/10.3390/powders3020010 - 27 Mar 2024

Abstract

►▼

Show Figures

Metal additive manufacturing technologies, such as Laser Powder-Bed Fusion, often rate as sustainable due to their high material efficiency. However, there are several drawbacks that reduce the overall sustainability and offer potential for improvement. One such drawback is waste emerging from the process.

[...] Read more.

Metal additive manufacturing technologies, such as Laser Powder-Bed Fusion, often rate as sustainable due to their high material efficiency. However, there are several drawbacks that reduce the overall sustainability and offer potential for improvement. One such drawback is waste emerging from the process. These smoulder particles form when the laser hits the powder-bed surface, are blown away from the part by the shielding gas stream and accumulate on the edge of the build chamber. Usually, smoulder does not contribute to the circular reuse of powder that was part of the powder-bed but was not integrated into a part. Instead, it marks an end-of-life state of powder. Significant amounts of smoulder accumulate depending on the irradiated area or the build volume in one job, respectively. This results in the waste of powder that was produced with low energy efficiency. This study investigates the question of whether smoulder can transform from waste to resource via common powder characterization methods and first build jobs using processed smoulder. The investigation of process-relevant powder properties like apparent density and flowability showed no significant difference between virgin powder and smoulder. Sample characterization indicated that neither porosity, surface quality nor mechanical properties deteriorate when samples contain about 50% smoulder. This allows for the reuse of smoulder in terms of powder characterization and part quality.

Full article

Figure 1

Open AccessArticle

New Die-Compaction Equations for Powders as a Result of Known Equations Correction: Part 2—Modernization of M Yu Balshin’s Equations

by

Anatolii V. Laptiev

Powders 2024, 3(1), 136-153; https://doi.org/10.3390/powders3010009 - 19 Mar 2024

Abstract

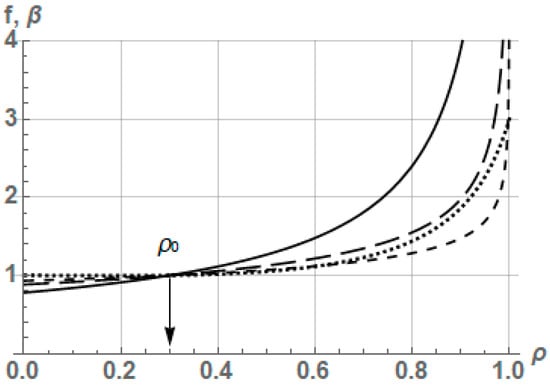

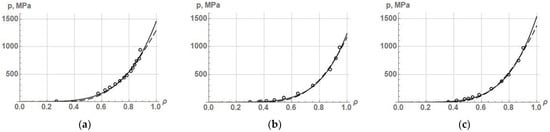

Based on the generalization of M. Yu. Balshin’s well-known equations in the framework of a discrete model of powder compaction process (PCP), two new die-compaction equations for powders have been derived that show the dependence of the compaction pressure p on the relative

[...] Read more.

Based on the generalization of M. Yu. Balshin’s well-known equations in the framework of a discrete model of powder compaction process (PCP), two new die-compaction equations for powders have been derived that show the dependence of the compaction pressure p on the relative density ρ of the powder sample. The first equation,

(This article belongs to the Special Issue Feature Papers in Powders 2023)

►▼

Show Figures

Figure 1

Open AccessReview

New Die-Compaction Equations for Powders as a Result of Known Equations Correction: Part 1–Review and Analysis of Various Die-Compaction Equations

by

Anatolii V. Laptiev

Powders 2024, 3(1), 111-135; https://doi.org/10.3390/powders3010008 - 18 Mar 2024

Cited by 1

Abstract

The well-known equations for the powder compaction process (PCP) in a rigid die published from the beginning of the last century until today were considered in this review. Most of the considered equations are converted into the dependences of densification pressure on the

[...] Read more.

The well-known equations for the powder compaction process (PCP) in a rigid die published from the beginning of the last century until today were considered in this review. Most of the considered equations are converted into the dependences of densification pressure on the powder’s relative density. The equations were analyzed and their ability to describe PCP was assessed by defining the coefficient of determination when approximating experimental data on the compaction of various powders. It was shown that most of the equations contain two constants the values of which are determined by fitting the mathematical dependence to the experimental curve. Such equations are able to describe PCP with high accuracy for the compaction of powders up to a relative density of 0.9–0.95. It was also shown that different equations can describe PCP in the density range from the initial density to 0.9 with the same high accuracy, but when the process of compaction is extrapolated to higher values of density, the curves diverge. This indicates the importance of equations that can unambiguously describe PCP to a relative density equal to or close to 1.0. For an adequate description of PCP for relative density greater than 0.95, equations containing three or four constants have proven useful.

Full article

(This article belongs to the Special Issue Feature Papers in Powders 2023)

►▼

Show Figures

Figure 1

Open AccessReview

Monitoring Aggregation Processes in Multiphase Systems: A Review

by

Maria Graça Rasteiro and Antti Koponen

Powders 2024, 3(1), 77-110; https://doi.org/10.3390/powders3010007 - 14 Mar 2024

Abstract

►▼

Show Figures

Particle aggregation is essential in many industrial processes, spanning the pharmaceutical and food industries, polymer production, and the environment, among others. However, aggregation can also occur, in some processes, as a non-desired side effect. Thus, to be able to monitor aggregation in industrial

[...] Read more.

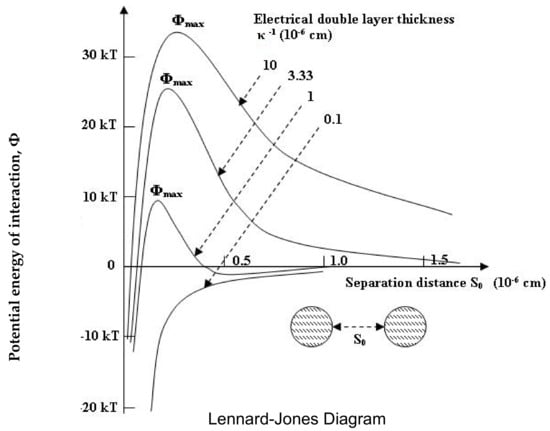

Particle aggregation is essential in many industrial processes, spanning the pharmaceutical and food industries, polymer production, and the environment, among others. However, aggregation can also occur, in some processes, as a non-desired side effect. Thus, to be able to monitor aggregation in industrial processes is of high importance to guarantee that the final, required product characteristics are obtained. In this paper, we present an extensive review of the different techniques available for monitoring particle characteristics in industrial processes involving particulate materials, with special emphasis on aggregation processes. These methods include both off-line and on-line techniques, based either on image acquisition techniques or different radiation scattering techniques (light-scattering and ultrasound spectroscopy). The principles behind each technique are addressed, together with their relevant applications, advantages, and disadvantages.

Full article

Figure 1

Open AccessReview

Factors Influencing Food Powder Flowability

by

Rajat Suhag, Abdessamie Kellil and Mutasem Razem

Powders 2024, 3(1), 65-76; https://doi.org/10.3390/powders3010006 - 28 Feb 2024

Abstract

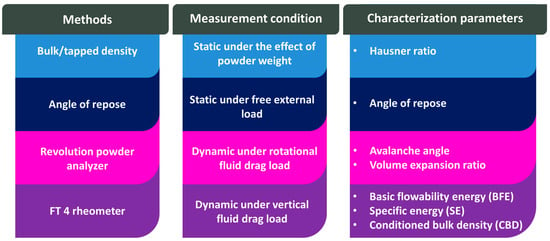

The flowability of food powders is a critical determinant of their processing efficiency, product quality, and overall operational success. This review delves into the intricacies of powder flowability, elucidating the factors that govern it and exploring various methods for its evaluation and enhancement.

[...] Read more.

The flowability of food powders is a critical determinant of their processing efficiency, product quality, and overall operational success. This review delves into the intricacies of powder flowability, elucidating the factors that govern it and exploring various methods for its evaluation and enhancement. Particle size and distribution, particle shape, surface properties, moisture content, and storage conditions stand as the key determinants of powder flowability. Finer powders, with their increased interparticle cohesive forces, tend to exhibit poorer flowability. Particle shape also plays a role, with irregular or elongated particles flowing less readily than spherical ones. Surface properties influence interparticle friction, thereby impacting flow behavior. Moisture content significantly affects flowability, as increased moisture can lead to liquid bridge formation, hindering powder movement. Storage temperature, on the other hand, generally enhances powder flow due to reduced interparticle cohesive forces at higher temperatures. This highlights the need to understand the factors influencing food powder flowability and to employ appropriate evaluation strategies for optimizing food powder processing efficiency, product quality, and overall production success.

Full article

(This article belongs to the Special Issue Feature Papers in Powders 2023)

►▼

Show Figures

Figure 1

Open AccessProject Report

Dielectrophoretic Particle Chromatography: From Batch Processing to Semi-Continuous High-Throughput Separation

by

Jasper Giesler, Laura Weirauch, Jorg Thöming, Georg R. Pesch and Michael Baune

Powders 2024, 3(1), 54-64; https://doi.org/10.3390/powders3010005 - 06 Feb 2024

Abstract

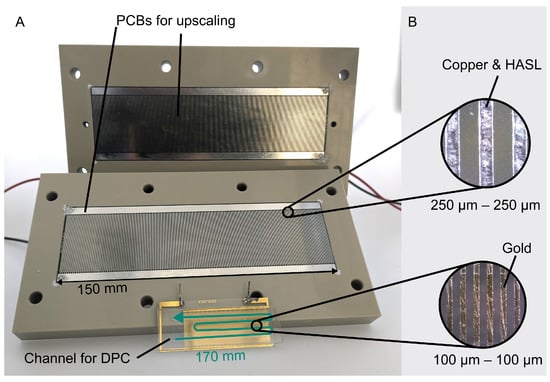

The development of highly selective separation processes is a focus of current research. In 2016, the German Science Foundation funded a priority program SPP 2045 “MehrDimPart—highly specific multidimensional fractionation of fine particles with technical relevance” that aims to develop new or enhance existing

[...] Read more.

The development of highly selective separation processes is a focus of current research. In 2016, the German Science Foundation funded a priority program SPP 2045 “MehrDimPart—highly specific multidimensional fractionation of fine particles with technical relevance” that aims to develop new or enhance existing approaches for the separation of nano- and micrometer-sized particles. Dielectrophoretic separators achieve highly selective separations of (bio-)particles in microfluidic devices or can handle large quantities when non-selective separation is sufficient. Recently, separator designs were developed that aim to combine a high throughput and high selectivity. Here, we summarize the development from a microfluidic fast chromatographic separation via frequency modulated dielectrophoretic particle chromatography (DPC) toward a macrofluidic high throughput separation. Further, we provide a starting point for future work by providing new experimental data demonstrating for the first time the trapping of 200 nm polystyrene particles in a dielectrophoretic high-throughput separator that uses printed circuit boards as alternatives for expensive electrode arrays.

Full article

(This article belongs to the Collection Multidimensional Particle Properties: Characterization, Description, Separation)

►▼

Show Figures

Figure 1

Open AccessArticle

Diborides of Multielement Transition Metals: Methods for Calculating Physical and Mechanical Characteristics

by

Dora Zakarian, Aik Khachatrian and Sergey Firstov

Powders 2024, 3(1), 44-53; https://doi.org/10.3390/powders3010004 - 25 Jan 2024

Abstract

From the first principles simulation (using the method of “a priori pseudopotential” and the “quasi-harmonic approximation” method- author’s developments), the basic characteristics of diborides and diborides of multielement transition metals (DMTMs) with an AlB2 type structure were calculated. For both diborides and DMTMs,

[...] Read more.

From the first principles simulation (using the method of “a priori pseudopotential” and the “quasi-harmonic approximation” method- author’s developments), the basic characteristics of diborides and diborides of multielement transition metals (DMTMs) with an AlB2 type structure were calculated. For both diborides and DMTMs, the linear coefficients of thermal expansion (LCTE) along the axial axes differ little from each other, i.e., transition metal diborides and hexagonal lattice DMTMs are quasi-isotropic. Quasi-isotropy makes it possible to estimate the LCTE using an analytical formula that depends on the melting temperature. In the absence of experimental data on the melting point of DMTMs, a method for calculating it from first principles is presented. The theoretical hardness values of transition metal diborides and DMTMs with averaged parameters were calculated from the first principles. The hardness of both bulk and nano-sized DMTMs was assessed using a hybrid method. There is agreement between the calculated and available experimental data.

Full article

Open AccessArticle

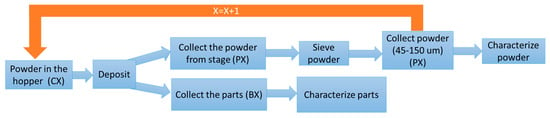

The Reusability of AlSi10Mg Powder in Directed Energy Deposition

by

Parnian Kiani, Alexander D. Dupuy, Kaka Ma and Julie M. Schoenung

Powders 2024, 3(1), 28-43; https://doi.org/10.3390/powders3010003 - 11 Jan 2024

Abstract

The low deposition efficiency in directed energy deposition (DED) has prompted the reuse of powders that do not fuse to the builds to make additive manufacturing more sustainable. It is unknown, however, how the properties of the powder and deposited parts change as

[...] Read more.

The low deposition efficiency in directed energy deposition (DED) has prompted the reuse of powders that do not fuse to the builds to make additive manufacturing more sustainable. It is unknown, however, how the properties of the powder and deposited parts change as powders are continuously reused. In this study, AlSi10Mg was investigated for five deposition cycles in DED. Exposing AlSi10Mg powder to DED conditions changes the morphology, size, and flowability. The mechanical properties of AlSi10Mg DED parts decreased after the feedstock powder was reused one time. Notably, no additional significant changes were observed when the powder was further reused.

Full article

(This article belongs to the Special Issue Feature Papers in Powders 2023)

►▼

Show Figures

Figure 1

Open AccessArticle

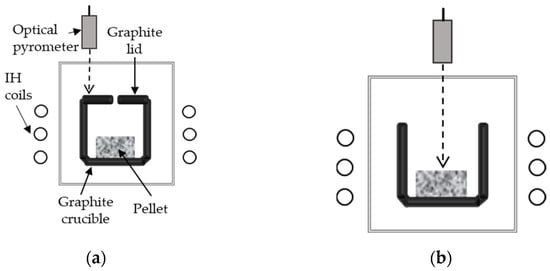

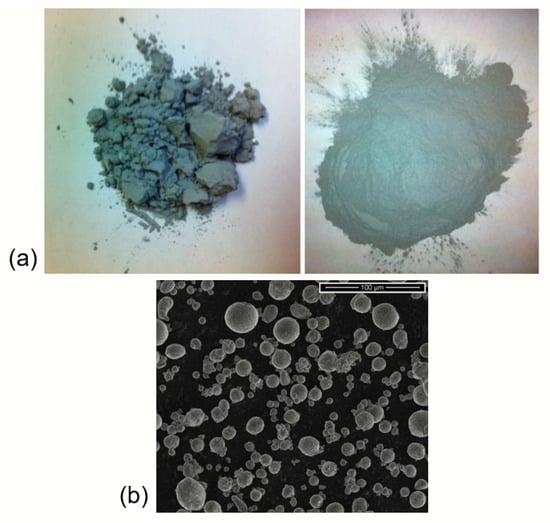

Fast Synthesis of Fine Boron Carbide Powders Using Electromagnetic Induction Synthesis Method

by

Anna V. Gubarevich and Katsumi Yoshida

Powders 2024, 3(1), 17-27; https://doi.org/10.3390/powders3010002 - 08 Jan 2024

Abstract

Boron carbide (B4C) powders with defined stoichiometry, high crystallinity, minimal impurity content, and a fine particle size are imperative for realizing the exceptional properties of this compound in advanced high-technology applications. Nevertheless, achieving the desired stoichiometry and particle size using traditional

[...] Read more.

Boron carbide (B4C) powders with defined stoichiometry, high crystallinity, minimal impurity content, and a fine particle size are imperative for realizing the exceptional properties of this compound in advanced high-technology applications. Nevertheless, achieving the desired stoichiometry and particle size using traditional synthesis methods, which rely on prolonged high-temperature processes, can be challenging. The primary objective of this study is to synthesize fine B4C powders characterized by high crystallinity and a sub-micron particle size, employing a fast and energy-efficient method. B4C powders are synthesized from elemental boron and carbon in a high-frequency induction heating furnace using the electromagnetic induction synthesis (EMIS) method. The rapid heating rate achieved through contactless heating promotes the ignition and propagation of the exothermic chemical reaction between boron and carbon. Additionally, electromagnetic effects accelerate atomic diffusion, allowing the reaction to be completed in an exceptionally short timeframe. The grain size and crystallinity of B4C can be finely tuned by adjusting various process parameters, including the post-ignition holding temperature and the duration of heating. As a result, fine B4C powders can be synthesized in under 10 min. Moreover, these synthesized B4C powders exhibit oxidation onset temperatures higher than 500 °C when exposed to air.

Full article

(This article belongs to the Special Issue Feature Papers in Powders 2023)

►▼

Show Figures

Figure 1

Open AccessArticle

Consolidation of Calcium Carbonate Using Polyacrylamides with Different Chemistries

by

Jin Hau Lew, Paul F. Luckham, Omar K. Matar, Erich A. Müller, Adrielle Sousa Santos and Myo Thant Maung Maung

Powders 2024, 3(1), 1-16; https://doi.org/10.3390/powders3010001 - 21 Dec 2023

Abstract

In this work, the consolidation of calcium carbonate (CaCO3) by polyacrylamide (PAM) of different molecular weights, charge densities, and functional groups was investigated via oscillatory rheology and unconfined compressive strength (UCS) analysis. Oscillatory rheology showed that the storage modulus G′ was

[...] Read more.

In this work, the consolidation of calcium carbonate (CaCO3) by polyacrylamide (PAM) of different molecular weights, charge densities, and functional groups was investigated via oscillatory rheology and unconfined compressive strength (UCS) analysis. Oscillatory rheology showed that the storage modulus G′ was approximately 10 times higher than the loss modulus G″, indicating a highly elastic CaCO3 sample upon consolidation via PAM. Both oscillatory rheology and UCS analysis exhibited similar trends, wherein the mechanical values (G′, G″, and UCS) first increased with increasing polymer dosage, until they reached a peak value (typically at 3 mgpol/gCaCO3), followed by a decrease in the mechanical values. This indicates that there is an optimum polymer dosage for the different PAM-CaCO3 colloidal systems, and that exceeding this value induces the re-stabilisation of the colloidal system, leading to a decreased degree of consolidation. Regarding the effect of the PAM molecular weight, the peak G′ and UCS values of CaCO3 consolidated by hydrolysed PAM (HPAM) of different molecular weights are very similar. This is likely due to the contour length of the HPAMs being either almost the same or longer than the average distance between two CaCO3 particles. The effect of the PAM charge density revealed that the peak G′ and UCS values decreased as the charge density of the PAM increased, while the optimum PAM dosage increased with decreasing PAM charge density. The higher likelihood of lower-charge PAM bridging between the particles contributes to higher elastic energy and mechanical strength. Finally, regarding the PAM functional group, CaCO3 consolidated by sulfonated polyacrylamide (SPAM) typically offers lower mechanical strength than that consolidated with HPAM. The bulky sulfonate side groups of SPAM interfere with the surface packing, reducing the number of polymers able to adsorb onto the surface and, eventually, reducing the degree of consolidation of CaCO3. The zeta potential of the PAM-CaCO3 samples became more negative with increasing PAM concentration due to the saturation of the particle surface. Good agreement between oscillatory rheology and UCS analysis could accelerate PAM screening for optimum CaCO3 consolidation.

Full article

(This article belongs to the Special Issue Feature Papers in Powders 2023)

►▼

Show Figures

Figure 1

Open AccessArticle

Dimensionless Number Group Analysis of Surface-Treated Powders

by

Bellamarie Ludwig

Powders 2023, 2(4), 749-762; https://doi.org/10.3390/powders2040047 - 13 Dec 2023

Abstract

►▼

Show Figures

Modeling powder properties remains a complex and difficult area of study because particulate materials can behave differently under variable conditions based on their bulk and surface-level properties. The research presented in this manuscript was designed to support the fundamental understanding of powder systems

[...] Read more.

Modeling powder properties remains a complex and difficult area of study because particulate materials can behave differently under variable conditions based on their bulk and surface-level properties. The research presented in this manuscript was designed to support the fundamental understanding of powder systems by joining experimental and theoretical calculations of dimensionless numbers groups for design purposes. In order to do so, this work focused on two critical variables to better understand fluidization design: physical and chemical surface properties. To better resolve the influence of surface properties, surface-treated powders were used. Five different powder samples of varying particle size distribution were characterized using physical property measurements, including pressure drop profiles to obtain the minimum fluidization velocity, density measurements, and particle sizing. Using theoretical equations, the minimum fluidization velocity was also calculated to compare with those obtained experimentally and determine typical dimensionless number groups used in bulk handling system design. The results showed that the theoretically determined values were lower than those calculated using the experimentally

Figure 1

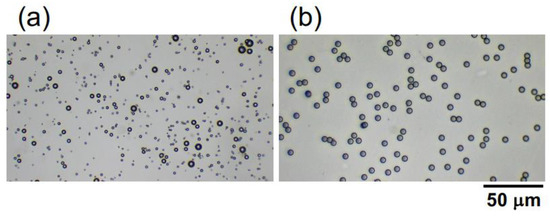

Open AccessCommunication

Rapid Ascent of Hollow Particles in Water Induced by an Electric Field

by

Hiroshi Kimura

Powders 2023, 2(4), 737-748; https://doi.org/10.3390/powders2040046 - 12 Dec 2023

Abstract

A novel method has been proposed to induce rapid upward movement of colloidal particles with a density lower than water by applying an electric field of several V/mm in water. This phenomenon, known as the Electrically Induced Rapid Sedimentation (ERS) effect, marks the

[...] Read more.

A novel method has been proposed to induce rapid upward movement of colloidal particles with a density lower than water by applying an electric field of several V/mm in water. This phenomenon, known as the Electrically Induced Rapid Sedimentation (ERS) effect, marks the first occurrence of ‘rapid upward movement of colloidal particles’ within the scope of this phenomenon. Focusing on hollow particles, an investigation of the ERS effect was conducted through transmittance measurement. The hollow particles in water showed a drastic increase in ascending velocity through the application of an electric field. The ascending velocity raised when increasing the electric field strength. Utilizing a quasi-DC electric field (an extremely low-frequency AC electric field), aggregate structures were captured for the first time.

Full article

(This article belongs to the Special Issue Feature Papers in Powders 2023)

►▼

Show Figures

Figure 1

Open AccessArticle

Solid Dispersions of Fenbendazole with Polymers and Succinic Acid Obtained via Methods of Mechanochemistry: Their Chemical Stability and Anthelmintic Efficiency

by

Salavat S. Khalikov, Ekaterina A. Khakina, Marat S. Khalikov and Anastasiya I. Varlamova

Powders 2023, 2(4), 727-736; https://doi.org/10.3390/powders2040045 - 30 Nov 2023

Cited by 1

Abstract

The substance fenbendazole is included in the composition of many anthelmintic drugs, in which the “chemical stability” parameter is one of the main characteristics when obtaining permission for the use of drugs in veterinary practice. Fenbendazole is characterized by low solubility in water

[...] Read more.

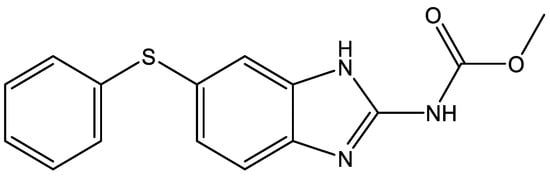

The substance fenbendazole is included in the composition of many anthelmintic drugs, in which the “chemical stability” parameter is one of the main characteristics when obtaining permission for the use of drugs in veterinary practice. Fenbendazole is characterized by low solubility in water and therefore the content of the substance is overestimated in its preparations, which increases the cost of the drug as well as the safety risks of pharmacotherapy. The possibilities of mechanochemical modification of fenbendazole were evaluated in order to improve the solubility index. During the mechanical processing treatment of the substance in the presence of polymeric substances, solid dispersions are formed, which have increased solubility and high anthelmintic activity. The inclusion in these dispersions of the third component, which is succinic acid, did not significantly change the solubility of fenbendazole. In all these dispersions, the substance remained unchanged both during the preparation of its solid dispersions and during their storage. When fenbendazole is modified in an organic solvent medium, the substance is partially converted into oxfendazole, which is one of its metabolites. The chemical stability of fenbendazole was confirmed via HPLC/MS and NMR spectroscopy. The anthelmintic activity of these compositions was evaluated and it was found that they have a high nematicidal activity.

Full article

(This article belongs to the Special Issue Particle Technologies)

►▼

Show Figures

Figure 1

Open AccessArticle

Injection Flow Rate Threshold Preventing Atypical In-Cavity Pressure during Low-Pressure Powder Injection Molding

by

Francis Arès, Dorian Delbergue and Vincent Demers

Powders 2023, 2(4), 709-726; https://doi.org/10.3390/powders2040044 - 07 Nov 2023

Abstract

►▼

Show Figures

Controlling injection parameters is paramount when it comes to producing high-quality green parts using powder injection molding. This work combines experimental and numerical approaches to study the impact of injection parameters on mold in-cavity pressure and on the overall quality of green parts

[...] Read more.

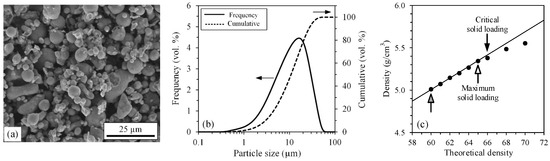

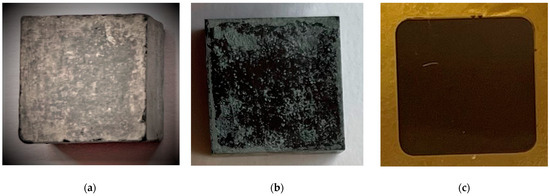

Controlling injection parameters is paramount when it comes to producing high-quality green parts using powder injection molding. This work combines experimental and numerical approaches to study the impact of injection parameters on mold in-cavity pressure and on the overall quality of green parts produced by low-pressure powder injection molding. The properties of two low-viscosity feedstocks (formulated from a water-atomized stainless-steel powder and wax-based binder system) were measured and implemented in an Autodesk Moldflow numerical model to quantify the molding pressures, which were finally validated using experimental real-scale injections. The results confirmed that an increase in mold temperature, an increase in feedstock temperature, and a decrease in solid loading decrease the mold in-cavity pressure, which was correlated with the feedstock viscosity. As a key result, real-scale injections confirmed that a minimum flow rate was required to avoid atypical high in-cavity pressure leading to several visual defects such as weld lines, flow marks, cracks, sinks, and incomplete filling. Due to differences in its thermal transfer properties, this flow rate threshold value decreases as the feedstock solid loading increases. For injection speeds higher than this value, the injection pressure measured experimentally was linearly correlated with the injection flow rate.

Full article

Figure 1

Open AccessArticle

Effect of Induction Heating on Surface Properties of Hot-Pressed Ceramics Based on Nanopowders Si3N4 and TiN

by

Lina L. Sartinska

Powders 2023, 2(4), 697-708; https://doi.org/10.3390/powders2040043 - 18 Oct 2023

Abstract

►▼

Show Figures

The effect of induction heating on the surface properties of hot-pressed ceramics based on plasma chemical nanopowders Si3N4 and TiN (additives: Al2O3, AlN, and Y2O3) has been studied. The research demonstrates the

[...] Read more.

The effect of induction heating on the surface properties of hot-pressed ceramics based on plasma chemical nanopowders Si3N4 and TiN (additives: Al2O3, AlN, and Y2O3) has been studied. The research demonstrates the formation of a modified layer on the surface of the hot-pressed material. The study examines the porosity, hardness, fracture toughness, brittleness, distribution of elements, and wear of hot-pressed ceramics on the surface before and after additional grinding. Removal of the surface porous layer results in increased density and hardness, leading to a higher number of acoustic emission signals during scratching with a Vickers indenter. A different response to scratching indicates a transgranular or intergranular fracture of the structure. The presence of porosity and carbon contamination on the surface layer of materials negatively impacts the properties of TiN-reinforced ceramics based on Si3N4-Al2O3-AlN (SIALON). However, the addition of Y2O3 effectively prevents carbon penetration and reduces the effect of grinding. Additionally, the dark-colored tone observed on the outer volume of the samples suggests a non-thermal microwave effect of the induction furnace.

Full article

Figure 1

Open AccessArticle

Cu-Substituted Hydroxyapatite Powder: Mechanochemical Synthesis Using Different Copper Sources and Thermal Stability

by

Natalya V. Eremina, Natalia V. Bulina, Mikhail A. Mikhailenko, Olga B. Vinokurova, Igor Y. Prosanov and Marina V. Chaikina

Powders 2023, 2(4), 678-696; https://doi.org/10.3390/powders2040042 - 08 Oct 2023

Abstract

In this paper, we present results of a study on the possibilities of the mechanochemical synthesis of copper-substituted hydroxyapatite with the replacement of calcium cations by copper cations. During the synthesis, various reagents—sources of copper cations—were used. It was found that the nature

[...] Read more.

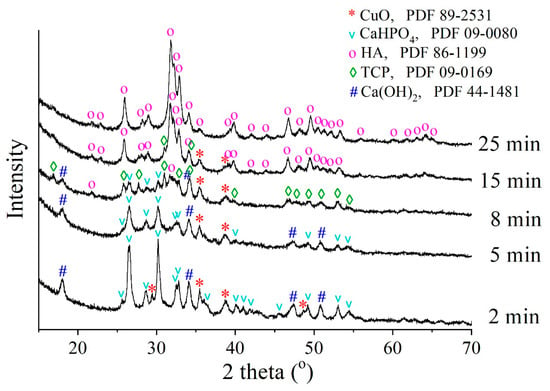

In this paper, we present results of a study on the possibilities of the mechanochemical synthesis of copper-substituted hydroxyapatite with the replacement of calcium cations by copper cations. During the synthesis, various reagents—sources of copper cations—were used. It was found that the nature of the carrier of the doping cation plays an important role in the formation of the structure of Cu-substituted apatite. It was established that a single-phase material forms most efficiently when copper (II) phosphate is employed; however, even this reagent did not allow the introduction of a large amount of copper into the hydroxyapatite crystal lattice. Out of 10 calcium cations in the unit cell of hydroxyapatite, no more than two could be replaced by copper cations. A further increase in the copper concentration led to the formation of an amorphous product. The degree of copper substitution in hydroxyapatite increases as the oxidation state of copper increases. The thermal stability of the hydroxyapatite with the highest degree of substitution was studied. It was shown that the presence of copper cations significantly decreases the stability of hydroxyapatite. In a temperature range of 550–750 °C, it is gradually decomposed to form a mixture of rhombohedral Ca2.57Cu0.43(PO4)2 and CuO. The FTIR spectrum of Ca2.57Cu0.43(PO4)2, which is a copper-substituted β-Ca3(PO4)2, was first studied.

Full article

(This article belongs to the Special Issue Particle Technologies)

►▼

Show Figures

Figure 1

Open AccessReview

The Optimization of Mechanochemical Processes toward Functional Nanocomposite Materials

by

Mamoru Senna

Powders 2023, 2(3), 659-677; https://doi.org/10.3390/powders2030041 - 20 Sep 2023

Cited by 1

Abstract

Mechanochemical technology is developing rapidly, judging by the scientific information in both basic and applied studies. However, many issues and points of view remain to be discussed. This review presents some new key issues for the optimization of mechanochemical processes in terms of

[...] Read more.

Mechanochemical technology is developing rapidly, judging by the scientific information in both basic and applied studies. However, many issues and points of view remain to be discussed. This review presents some new key issues for the optimization of mechanochemical processes in terms of theoretical and practical aspects. Emphasis is placed on powder technology aspects, which are not always discussed compared to functional or microscopic viewpoints. The transfer of chemical species across the interparticle interface between dissimilar species during the mechanosynthesis of nanocomposites offers many new opportunities. Since almost all material transport is preceded by charge transfer, its driving force has been sought using terminology beyond the well-established electrochemical terms. In particular, the valence state of the cationic species involved is of importance. The role of organic compounds throughout the process is emphasized, regardless of their survival in the final product. The similarity with pharmaceutical phenomena is pointed out, although its mentality is very different from that of the synthesis of nanocomposites. The rational amorphization and stabilization of molecular dispersion states with the participation of excipients are discussed. The effects of liquids, either added or formed by mechanochemical auto-liquefaction, are presented with reference to the comparison between wet and dry grinding. The mechanisms of the apparent stabilization of the mechanically activated states of the products are elucidated to investigate the practical applicability of these mechanochemically synthesized products. Finally, the most important aspects for the optimization of the mechanochemical processes of functional nanocomposites are listed.

Full article

(This article belongs to the Special Issue Feature Papers in Powders 2023)

►▼

Show Figures

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Conferences

Special Issues

Topical Collections

Topical Collection in

Powders

Multidimensional Particle Properties: Characterization, Description, Separation

Collection Editors: Alfred P. Weber, Einar Kruis, Doris Segets, Urs Alexander Peuker