Lignin

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Biomacromolecules, Biobased and Biodegradable Polymers".

Viewed by 3255Editors

Interests: biomaterial; bio-based polymer; bioplastics; biodegradable polymer; biopolymer; composite material comprising a polymer matrix

Special Issues, Collections and Topics in MDPI journals

Interests: biomass; biopolymer and bio-based materials and chemicals; natural and fiber composites and nanocomposites; cellulose, lignin and extractives; polymer modification and functionalization; polymer adhesives; resins and coatings; smart and functional sensors and devices

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

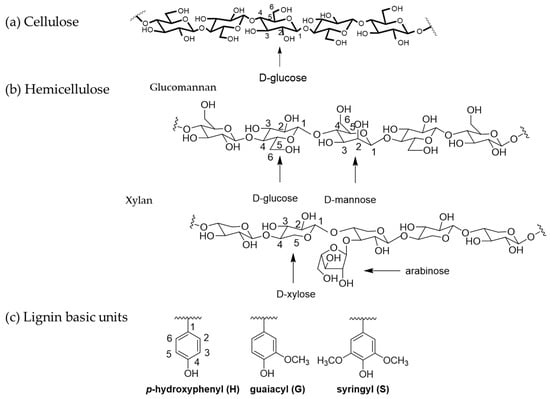

Lignin is one of main components of ligneous biomass and is mainly obtained from forestry resources. Lignin is biologically produced, mainly from three monomers, p-coumaryl alcohol, coniferyl alcohol, and sinapyl alcohol; however, their polymerized structure is very complicated. The content of aliphatic hydroxyl groups, phenolic hydroxy groups, methoxy groups, and carbonyl groups depends on the source plant. The whole molecular structure of lignin in its original state has not been fully determined yet, since lignin is covalently bound to cell wall polysaccharides and is insoluble in solvents because of its network structure. Therefore, the structural model of lignin has been proposed via integration of partial structures determined from chemically degraded lignin.

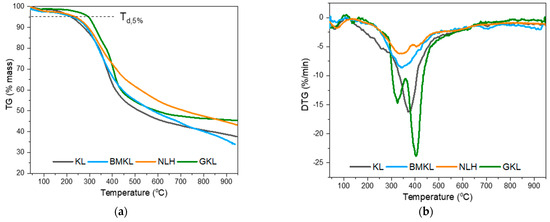

More practically, industrial lignin (partially degraded lignin) is obtained from the pulping process in the pulp and paper industry as low utilization value ligneous waste, and is mainly used for recovering energy by burning. Therefore, high-value utilization of industrial lignin has become a very important issue; it is not only required by the paper industry but also required to develop applications of cellulose nanofibers. Recent progress in polymer sciences and technologies has prompted several newly proposed methods of lignin utilization in material applications: (1) lignin-based thermosets, (2) lignin-based thermoplastics, (3) lignin-based additives for plastics such as plasticizers and antioxidants, and (4) lignin-based functional materials such as foams, films, and composites. However, many issues must be resolved before industrial output is possible; for example, we sometimes do not expect reproducibility of research results, because the chemical properties of lignin significantly vary, not only with the diversity of plant species but also according to the methods used to obtain it. Indeed, there are many methods to prepare lignin sources if minor modification is included. Generally, four methods are employed industrially: (1) sulfite pulping, (2) kraft pulping, (3) soda pulping and (4) organosolv pulping. The chemical properties of lignin obtained from each process varied with the quantity of functional groups such as phenolic hydroxy groups, sulfonate groups, and thiol groups. The solubility of lignin in water or organic solvents is also influenced by the extraction method. Though there exist a lot of obstacles to material applications, lignin is an attractive chemical due to its abundance and versatility. Therefore, we can expect steady development of lignin-based materials in future research.

In this collection, studies on the synthesis, physical and chemical properties, and novel functionality of lignin-based polymeric materials are welcome. Studies on the extraction, modification, and characterization of natural lignin and its applications are also welcome.

Dr. Naozumi Teramoto

Prof. Dr. Ning Yan

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- lignin extraction and conversion

- lignin-based chemicals and materials

- biosynthesis of lignin

- chemical structure and characterization of lignin

- applications of lignin