Polymer Composite Processing

(Closed)

Share This Topical Collection

Editor

Prof. Dr. Seong Yun Kim

Prof. Dr. Seong Yun Kim

Prof. Dr. Seong Yun Kim

Prof. Dr. Seong Yun Kim

E-Mail

Website

Guest Editor

Division of Polymer-Nano & Textile Engineering, Chonbuk National University, Jeonju-si 54896, Republic of Korea

Interests: composites; polymer processing

Topical Collection Information

Dear Colleagues,

The regulation of carbon dioxide emissions under the Paris Climate Agreement is the future to come. These irreversible changes have created a new economic system called carbon dioxide credits, and technically, it is bringing about the era of electric vehicles with lightweight materials. Various structural composite materials such as carbon-fibre-reinforced plastics, which can reduce the weights of vehicles and improve stability at the same time, are being developed. Research on functional composite materials such as nano-carbon composite materials that can be applied to various and complex electronic systems are also actively progressing. Various results have been reported on the conductive and mechanical properties of the newly developed composite materials, as well as their active properties such as sensing, self-healing, and actuation. In addition, various polymer processes such as 3D printing and plasma-assisted processes have been proposed for the fabrication of new types of composite materials. Various structural modelling, process modelling, numerical analysis and non-destructive analysis techniques are applied to characterize these new composite materials and optimize processes. We hope to share new concepts related to a wide range of properties and the processing of newly developed polymer composites. In this way, we seek to confer new insights into polymer composite processing. Both original research papers and review articles are welcome.

Dr. Seong Yun Kim

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- Polymer composites

- Functional composites

- Structural composites

- Carbon fibers

- Nanocarbons

- Conductive properties

- Mechanical properties

- Self-healing

- Sensing

- Actuating

- Structural capacitor

- Processing

- Plasma-assisted processing

- Structural modeling

- Process modeling

- Computational analysis

- Non-destructive analysis.

Published Papers (3 papers)

Open AccessArticle

Effect of Carbon Nanofibers on the Viscoelastic Response of Epoxy Resins

by

Paulo Santos, Abílio P. Silva and Paulo N. B. Reis

Cited by 3 | Viewed by 1476

Abstract

Two epoxy resins with different viscosities were enhanced up to 1 wt.%, applying a simple method with carbon nanofibers (CNFs). These were characterized in terms of static bending stress, stress relaxation, and creep tests. In bending, the contents of 0.5 wt.% and 0.75

[...] Read more.

Two epoxy resins with different viscosities were enhanced up to 1 wt.%, applying a simple method with carbon nanofibers (CNFs). These were characterized in terms of static bending stress, stress relaxation, and creep tests. In bending, the contents of 0.5 wt.% and 0.75 wt.% of CNFs on Ebalta and Sicomin epoxies, respectively, promote higher relative bending stress (above 11.5% for both) and elastic modulus (13.1% for Sicomin and 16.2% for Ebalta). This highest bending stress and modulus occurs for the lower viscosity resin (Ebalta) due to its interfacial strength and dispersibility of the fillers. Creep behaviour and stress relaxation for three stress levels (20, 50, and 80 MPa) show the benefits obtained with the addition of CNFs, which act as a network that contributes to the immobility of the polymer chains. A long-term experiment of up to 100 h was successfully applied to fit the Kohlrausch–Williams–Watts (KWW) and Findley models to stress relaxation and creep behaviour with very good accuracy.

Full article

►▼

Show Figures

Open AccessArticle

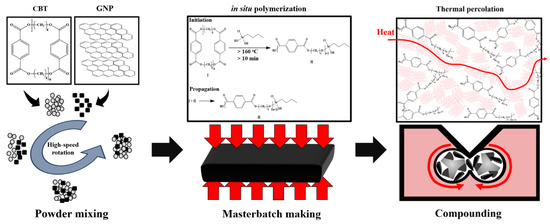

Thermal Percolation Behavior in Thermal Conductivity of Polymer Nanocomposite with Lateral Size of Graphene Nanoplatelet

by

Ji-un Jang, Hae Eun Nam, Soon Oh So, Hyeseong Lee, Geon Su Kim, Seong Yun Kim and Seong Hun Kim

Cited by 15 | Viewed by 2897

Abstract

In this study, the thermal percolation behavior for the thermal conductivity of nanocomposites according to the lateral size of graphene nanoplatelets (GNPs) was studied. When the amount of GNPs reached the critical concentration, a rapid increase in thermal conductivity and thermal percolation behavior

[...] Read more.

In this study, the thermal percolation behavior for the thermal conductivity of nanocomposites according to the lateral size of graphene nanoplatelets (GNPs) was studied. When the amount of GNPs reached the critical concentration, a rapid increase in thermal conductivity and thermal percolation behavior of the nanocomposites were induced by the GNP network. Interestingly, as the size of GNPs increased, higher thermal conductivity and a lower percolation threshold were observed. The in-plane thermal conductivity of the nanocomposite containing 30 wt.% M25 GNP (the largest size) was 8.094 W/m·K, and it was improved by 1518.8% compared to the polymer matrix. These experimentally obtained thermal conductivity results for below and above the critical content were theoretically explained by applying Nan’s model and the percolation model, respectively, in relation to the GNP size. The thermal percolation behavior according to the GNP size identified in this study can provide insight into the design of nanocomposite materials with excellent heat dissipation properties.

Full article

►▼

Show Figures

Open AccessArticle

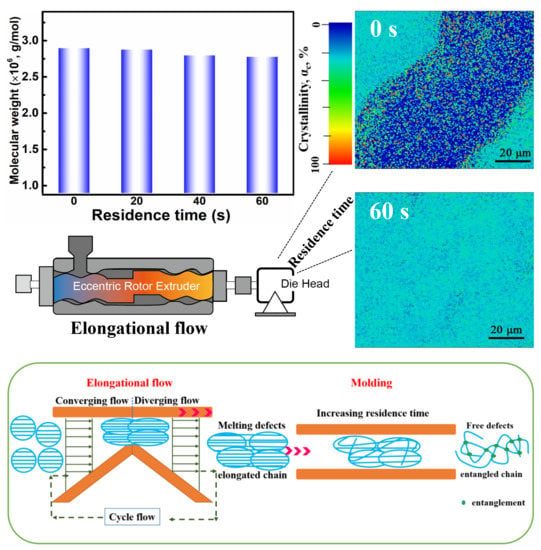

Enhancing Chain Mobility of Ultrahigh Molecular Weight Polyethylene by Regulating Residence Time under a Consecutive Elongational Flow for Improved Processability

by

Xiaochuan Chen, Xiaotong Wang, Yanhong Feng, Jinping Qu, Dingshan Yu, Changlin Cao and Xudong Chen

Cited by 2 | Viewed by 2622

Abstract

Improving the processability of ultrahigh molecular weight polyethylene (UHMWPE) and understanding the effect of the polymeric chain mobility has long been a challenging task. Herein, we show that UHMWPE without any processing aids can be processed at a lower temperature of 180 °C

[...] Read more.

Improving the processability of ultrahigh molecular weight polyethylene (UHMWPE) and understanding the effect of the polymeric chain mobility has long been a challenging task. Herein, we show that UHMWPE without any processing aids can be processed at a lower temperature of 180 °C compared to conventional processing temperatures (~250 °C) under a continuous elongational flow (CEF) by using an eccentric rotor extruder (ERE). By probing the effect of the residence time of UHMWPE samples under a CEF on the morphology, rheological behavior and molecular orientation, we find that the long polymer chains of UHMWPE are apt to orientate under a consecutive volume elongational deformation, thereby leading to a higher residual stress for the extruded sample. Meanwhile, the residence time of samples can regulate the polymeric chain mobility, giving rise to the simultaneous decrease of the melting defects and residual stress as well as Hermans orientation function with increasing residence time from 0 to 60 s. This also engenders the enhanced diffusion of UHMWPE segments, resulting in a defect-free morphology and higher entanglement with lower crystallinity but without causing obvious thermal oxidative degradation of UHMWPE. This interesting result could originate from the fast chain entanglement and particle welding enabled by a desirably short residence time, which could be explained by the empirical, entropy-driven melting explosion mechanism.

Full article

►▼

Show Figures