Sustainable Polymer/Biopolymer-Based Composites: Processing, Characterization, and Application

Share This Topical Collection

Editors

Dr. José Alberto Méndez

Dr. José Alberto Méndez

Dr. José Alberto Méndez

Dr. José Alberto Méndez

E-Mail

Website

Collection Editor

LEPAMAP Research Group, Department of Chemical Engineering, Agriculture and Food Technology, Universitat de Girona, Girona, Spain

Interests: biodegradable materials; biomaterials; natural fiber reinforced composites

Special Issues, Collections and Topics in MDPI journals

Dr. Helena Oliver-Ortega

Dr. Helena Oliver-Ortega

Dr. Helena Oliver-Ortega

Dr. Helena Oliver-Ortega

E-Mail

Website

Collection Editor

1. Department of Materials Science and Engineering, Universitat Politècnica de Catalunya, Colom 1, 08222 Terrassa, Spain

2. Institut d'Investigació Tèxtil i Cooperació Industrial de Terrassa (INTEXTER), Colom 15, 08222 Terrassa, Spain

Interests: polymers; bio-based polymers; biodegradable polymers; natural fibres; texitles; sustainability

Topical Collection Information

Dear Colleagues,

The ecological transition from a nonrenewable model of materials’ consumption to another based on materials derived from nature or with a biodegradable character requires new lines of research on the acquisition, performance, and characterization of the properties of materials to confirm the achievement of properties for materials/applications and for environment protection.

This Special Issue aims to highlight progress in the use of natural polymeric resources and reinforcements to produce sustainable composite materials that are competitive against those governing the current market based on non-renewable resources.

Dr. José Alberto Méndez

Dr. Helena Oliver-Ortega

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- sustainable polymers

- biopolymers

- cellulose fibers

- nano-fibrillated cellulose reinforcements

- biodegradable polyesters

- thermoplastic starch

- mechanical performance

- materials for automotive sector

Published Papers (6 papers)

2023

Open AccessArticle

Investigation on the Influence of Process Parameters on the Mechanical Properties of Extruded Bio-Based and Biodegradable Continuous Fiber-Reinforced Thermoplastic Sheets

by

Maximilian Lang, Benedikt Neitzel, Shiva MohammadKarimi and Florian Puch

Viewed by 848

Abstract

The use of bio-based and biodegradable matrix materials in fiber-reinforced polymers (FRPs) is an approach to reduce the consumption of fossil resources and the amount of polymer waste. This study aims to assess the influence of the process parameters on the resulting mechanical

[...] Read more.

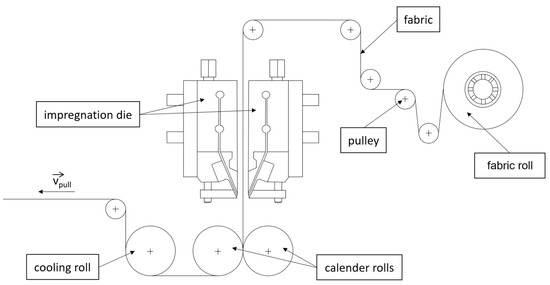

The use of bio-based and biodegradable matrix materials in fiber-reinforced polymers (FRPs) is an approach to reduce the consumption of fossil resources and the amount of polymer waste. This study aims to assess the influence of the process parameters on the resulting mechanical properties of extruded bio-based and biodegradable continuous fiber-reinforced thermoplastics (CFRTPs) in the form of sheets. Therefore, the impregnation temperature during the production of PLA/flax fiber composites is varied between 220 °C and 280 °C, and the consolidation pressure, between 50 bar and 90 bar. A design of experiments approach is used. Fiber contents of 28.8% to 34.8% and void contents of 6.8% to 15.5% are determined for the composites by optical measurements. To assess the mechanical properties, tensile tests are performed. Using the evaluation software Minitab, a strong negative influence of the consolidation pressure on the tensile modulus and the tensile strength is observed. Increasing the pressure from 50 bar to 90 bar results in a reduction in the tensile modulus of 50.7% and a reduction in the tensile strength of 54.8%, respectively. It is assumed that this is due to fibers being damaged by the external force exerted onto the materials during the consolidation process in the calender. The influence of the impregnation temperature on the mechanical properties cannot be verified.

Full article

►▼

Show Figures

Open AccessArticle

Mechanical Properties of Bio-Based Sandwich Composites Containing Recycled Polymer Textiles

by

Pooria Khalili, Mikael Skrifvars, Hom Nath Dhakal, Saeid Hosseinpour Dashatan, Mikael Danielsson and Alèxia Feiner Gràcia

Viewed by 939

Abstract

In this paper, sandwich composites were produced by compression moulding techniques, and they consisted of regenerated cellulose fabric (rayon) and bio-based polypropylene (PP) to form facings, while virgin and recycled polyamide (PA) textiles were used as core materials. To compare the mechanical performance

[...] Read more.

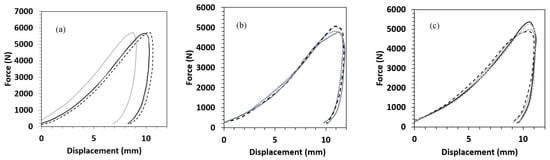

In this paper, sandwich composites were produced by compression moulding techniques, and they consisted of regenerated cellulose fabric (rayon) and bio-based polypropylene (PP) to form facings, while virgin and recycled polyamide (PA) textiles were used as core materials. To compare the mechanical performance between sandwich composites and typical composite designs, a control composite was produced to deliver the same weight and fiber mass fraction from rayon and PP. To evaluate the influence of recycled textile on the mechanical properties of the composites, a series of flexural, low velocity impact (LVI) and tensile tests were performed. It was found that the incorporation of thicker PA textile enhanced the bending stiffness by two times and the peak flexural force by 70% as compared to those of control. Substitution of a layer of recycled textile for two layers of rayon provided a good level of impact energy absorption capacity (~28 J) and maximum force (~4893–5229 N). The tensile strength of the four sandwich composites was reported to be in the range of 34.20 MPa and 46.80 MPa. This value was 91.90 for the control composite. The 2D cross-section slices of the composite specimens did not show any evidence of fiber tow debonding, fiber bundle splitting, or delamination.

Full article

►▼

Show Figures

Open AccessArticle

Advanced Plastic Waste Recycling—The Effect of Clay on the Morphological and Thermal Behavior of Recycled PET/PLA Sustainable Blends

by

Maria-Paraskevi Belioka, Georgia Markozanne, Kiriaki Chrissopoulou and Dimitrios S. Achilias

Cited by 5 | Viewed by 1316

Abstract

Bio-based polymers such as poly(lactic acid), PLA, are facing increased use in everyday plastic packaging, imposing challenges in the recycling process of its counterpart polyester poly(ethylene terephthalate), PET. This work presents the exploration of the properties of PET/PLA blends with raw materials obtained

[...] Read more.

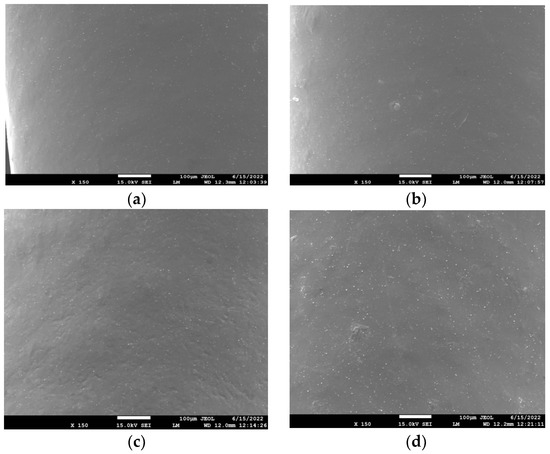

Bio-based polymers such as poly(lactic acid), PLA, are facing increased use in everyday plastic packaging, imposing challenges in the recycling process of its counterpart polyester poly(ethylene terephthalate), PET. This work presents the exploration of the properties of PET/PLA blends with raw materials obtained from recycled plastics. Several blends were prepared, containing 50 to 90% PET. Moreover, multiscale nanocomposite blends were formed via melt mixing using different amounts and types of nanoclay in order to study their effect on the morphology, surface properties, and thermal stability of the blends. The materials were characterized by X-ray diffraction analysis (XRD), thermo-gravimetric analysis (TGA), scanning electron microscopy (SEM), atomic force microscopy (AFM), and differential scanning calorimetry (DSC). The nanoclay was found to exhibit a uniform dispersion in the polymer matrix, presenting mainly intercalated structures with some exfoliated at low loading and some agglomerates at high loading (i.e., 10%). The addition of nanoclay to PET/PLA matrices increased the roughness of the blends and improved their thermal stability. Thermal degradation of the blends occurs in two steps following those of the individual polymers. Contamination of rPET with rPLA results in materials having poor thermal stability relative to rPET, presenting the onset of thermal degradation at nearly 100 °C lower. Therefore, important information was obtained concerning the recyclability of mixed PET and PLA waste. The perspective is to study the properties and find potential applications of sustainable blends of recycled PET and PLA by also examining the effect of different clays in different loadings. Therefore, useful products could be produced from blends of waste polyester.

Full article

►▼

Show Figures

Open AccessArticle

Antiviral Activity of Chitosan Nanoparticles and Chitosan Silver Nanocomposites against Alfalfa Mosaic Virus

by

Sherif Mohamed El-Ganainy, Ahmed M. Soliman, Ahmed Mahmoud Ismail, Muhammad Naeem Sattar, Khaled Yehia Farroh and Radwa M. Shafie

Cited by 3 | Viewed by 2181

Abstract

Plant viruses are a global concern for sustainable crop production. Among the currently available antiviral approaches, nanotechnology has been overwhelmingly playing an effective role in circumventing plant viruses. Alfalfa mosaic virus (AMV) was isolated and identified from symptomatic pepper plants in Egypt using

[...] Read more.

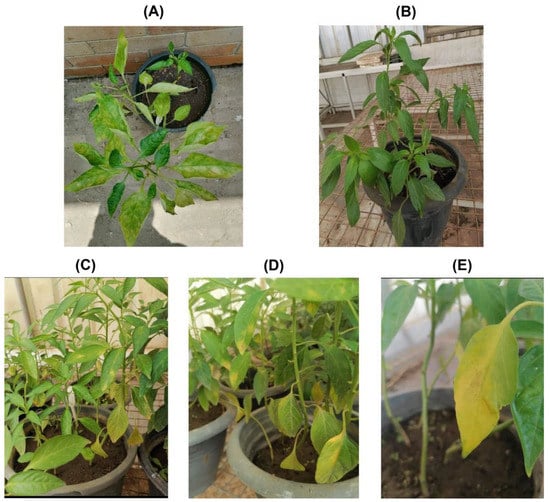

Plant viruses are a global concern for sustainable crop production. Among the currently available antiviral approaches, nanotechnology has been overwhelmingly playing an effective role in circumventing plant viruses. Alfalfa mosaic virus (AMV) was isolated and identified from symptomatic pepper plants in Egypt using symptomatology, serological tests using the direct ELISA technique, differential hosts and electron microscopy. The virus was biologically purified from a single local lesion that developed on

Chenopodium amaranticolor. The AMV infection was further confirmed using an AMV coat protein-specific primer RT-PCR. We further evaluated the antiviral potential of chitosan nanoparticles (CS-NPs) and chitosan silver nanocomposites (CS-Ag NC) in different concentrations against AMV infections in pepper plants. All tested concentrations of CS-NPs and CS-Ag NC induced the inhibition of AMV systemically infected pepper plants when applied 24 h after virus inoculation. The foliar application of 400 ppm CS-NPs or 200 ppm CS-Ag NC produced the highest AMV inhibitory effect (90 and 91%) when applied 24 h after virus inoculation. Treatment with CS-NPs and CS-Ag NC considerably increased the phenol, proline and capsaicin contents compared to the infected plants. Moreover, the agronomic metrics (plant height, fresh and dry pod weights and number of pods per plant) were also significantly improved. According to our results, the potential applications of CS-NPs and CS-Ag NC may provide an effective therapeutic measure for better AMV and other related plant virus management.

Full article

►▼

Show Figures

Open AccessArticle

Influence of Weathering on the Degradation of Cellulose Acetate Microplastics Obtained from Used Cigarette Butts

by

Branka Mušič, Anita Jemec Kokalj and Andrijana Sever Škapin

Cited by 1 | Viewed by 1651

Abstract

Cellulose acetate is used in many applications, including for cigarette filters. Unfortunately, unlike cellulose, its (bio)degradability is under question, yet it often ends up uncontrolled in the natural environment. The main purpose of this study is to compare the effects of weathering on

[...] Read more.

Cellulose acetate is used in many applications, including for cigarette filters. Unfortunately, unlike cellulose, its (bio)degradability is under question, yet it often ends up uncontrolled in the natural environment. The main purpose of this study is to compare the effects of weathering on two types of cigarette filter (classic filters and newer filters that have more recently arrived on the market) following their use and disposal in nature. Microplastics were prepared from polymer parts of used (classic and heated tobacco products—HTP) cigarettes and artificially aged. TG/DTA, FTIR, and SEM analyses were performed both before and after the aging process. Newer tobacco products contain an additional film made of a poly(lactic acid) polymer which, like cellulose acetate, burdens the environment and poses a risk to the ecosystem. Numerous studies have been conducted on the disposal and recycling of cigarette butts and cigarette butt extracts, revealing alarming data that have also influenced the decisions of the EU, who addressed the disposal of tobacco products in the EU Directive (EU) 2019/904. Despite this, there is still no systematic analysis in the literature evaluating the impact of weathering (i.e., accelerated aging) on the degradation of cellulose acetate in classic cigarettes compared with that in newer tobacco products that have recently appeared on the market. This is of particular interest given that the latter have been promoted as being healthier and environmentally friendly. The results show that in cellulose acetate cigarette filters the particle size decreased after accelerated aging. Also, the thermal analysis revealed differences in the behavior of the aged samples, while the FTIR spectra showed no shifts in the position of the peaks. Organic substances break down under UV light, which can be seen by measuring the color change. The PLA film was found to be more stable than cellulose acetate under the influence of UV light.

Full article

►▼

Show Figures

Open AccessArticle

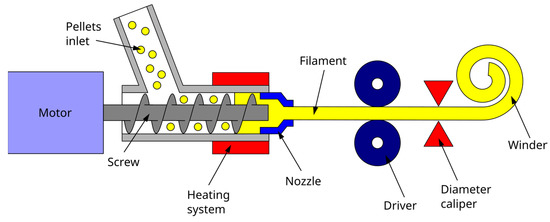

Effect of Extruder Type in the Interface of PLA Layers in FDM Printers: Filament Extruder Versus Direct Pellet Extruder

by

Antoni Pagés-Llobet, Francesc X. Espinach, Fernando Julián, Helena Oliver-Ortega and José Alberto Méndez

Cited by 1 | Viewed by 1965

Abstract

FDM (Fused Deposition Modeling) is one of the most used and industrially applied additive manufacturing processes due to its fast prototyping and manufacturing, simplicity, and low cost of the equipment. However, the mechanical properties of the printed products have a large dependence on

[...] Read more.

FDM (Fused Deposition Modeling) is one of the most used and industrially applied additive manufacturing processes due to its fast prototyping and manufacturing, simplicity, and low cost of the equipment. However, the mechanical properties of the printed products have a large dependence on orientation and interface strength between layers which is mainly related to the thermal union obtained. This thermal union has a large dependence on the melting and cooling down process. Additionally, the materials used must be extruded in a continuous filament before their use, which limits the materials used. However, a pellet extruder could be used directly in the printing equipment, avoiding filament extrusion. In this work, specimens of PLA (Poly(lactic acid)) with different bead orientations have been produced via filament or pellet extrusion to compare the effect of the different melting processes in the manufacturing methodology. Pellet extruded specimens showed higher infill and mechanical properties. These results were related to better adhesion between layers due to the longer melting and cooling process. The result was confirmed using DSC and XRD techniques, where a higher crystallinity was observed. A bicomponent specimen (50% pellet–50% filament) was prepared and tested, showing higher mechanical results than expected, which was, again, due to the better thermal union obtained in the pellet extruder.

Full article

►▼

Show Figures