Reinforced Polymer Composites (Closed)

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Polymer Composites and Nanocomposites".

Viewed by 50847Editor

Interests: polymers; composites; graphite; nanotubes; nanoclay

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

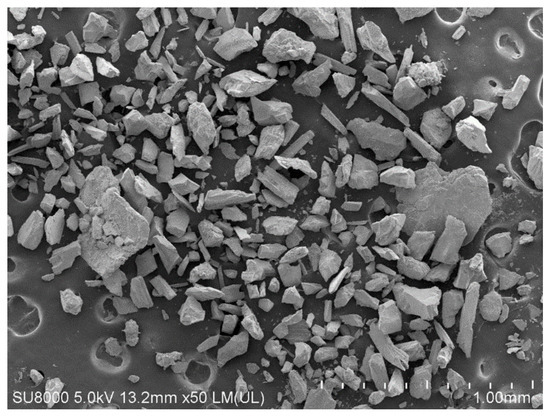

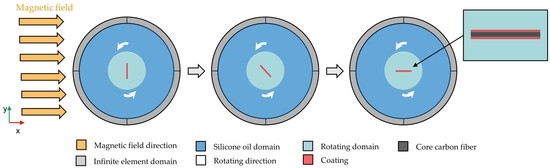

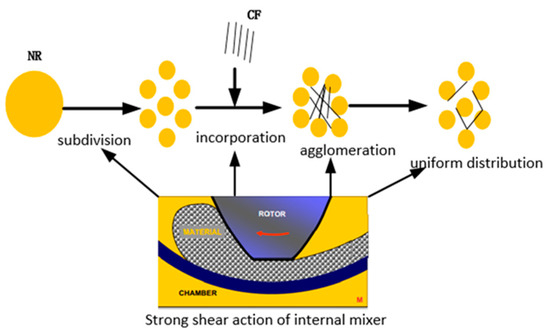

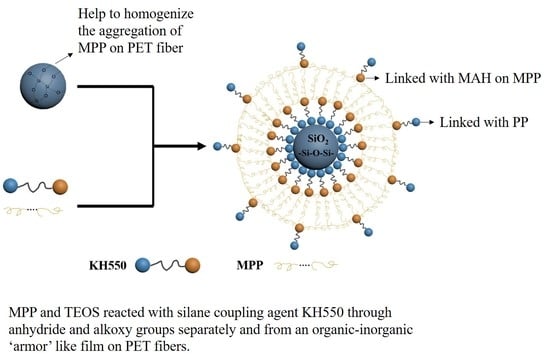

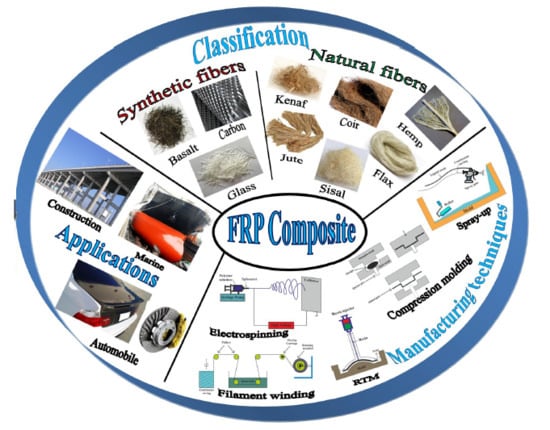

This Topic Collection focuses on recent advances in reinforced polymer composites. Polymer materials are widely used today, for example, in human life, medicine, and industry. Despite their popularity, polymers have numerous disadvantages, such as insufficient strength, stiffness, creep, and low usage temperature. That is why reinforcing fillers are widely used to improve polymer properties. The following factors should be taken into account to achieve high mechanical properties: (a) uniform distribution of the filler in the polymer matrix of a bulk sample will result in a composite physical and chemical property uniformity over its volume; (b) the filler should not agglomerate inside the polymer bulk sample because it might act as a stress concentrator; and (c) the interaction between fillers and polymer matrix should result in composite supramolecular structure improvement. Strong interfacial interaction between polymer matrix and filler surface can improve load transfer from the matrix to the reinforcing filler.

This Topic Collection covers all the fields related to reinforced polymer composites, but special attention will be given to the following aspects:

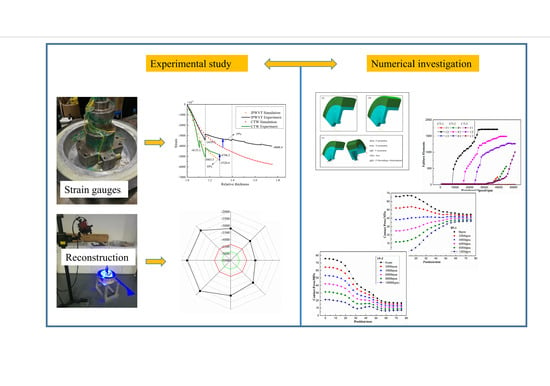

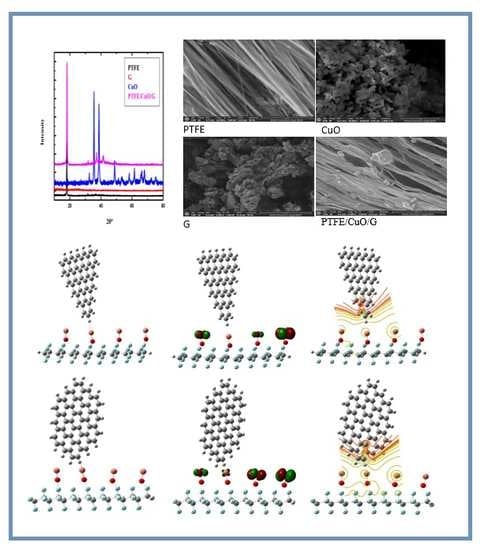

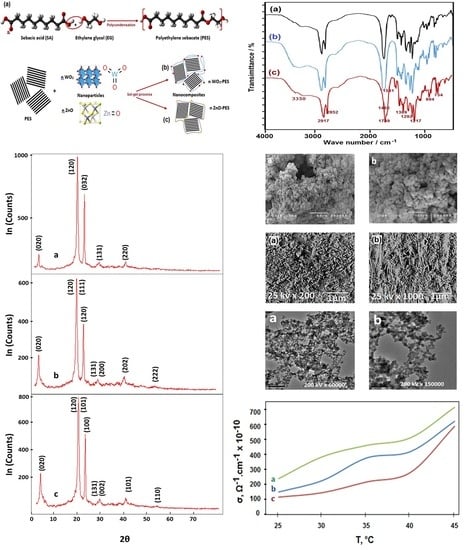

- Effect of polymer–filler interface interactions on composite properties;

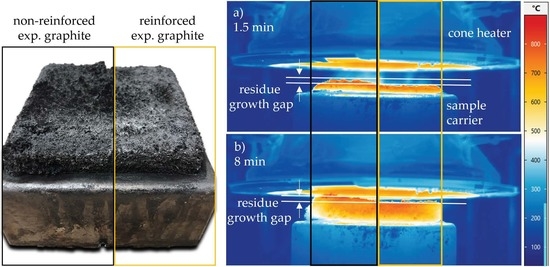

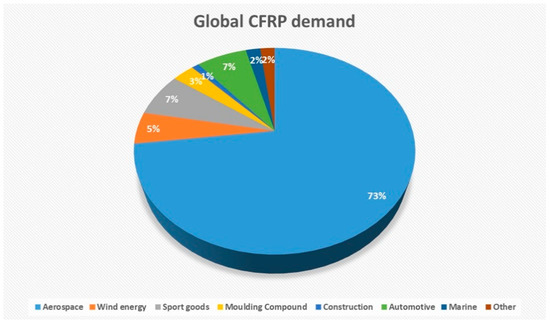

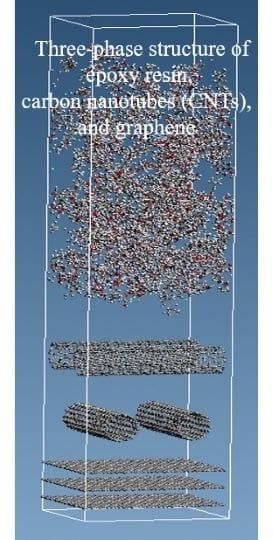

- Carbon fillers for polymers, including fibers, nanotubes, graphene, etc.;

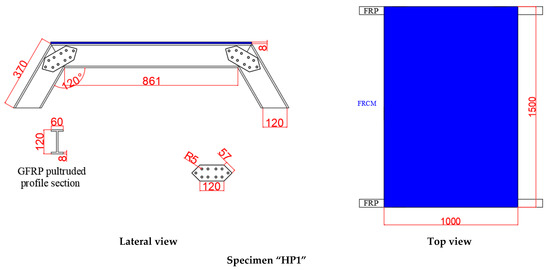

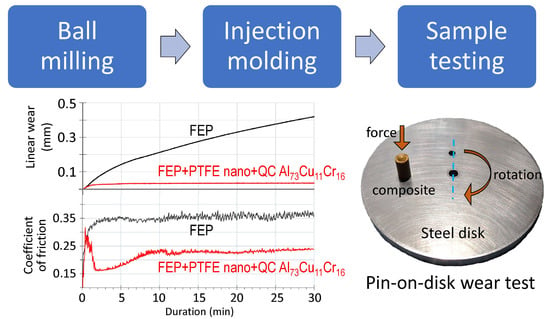

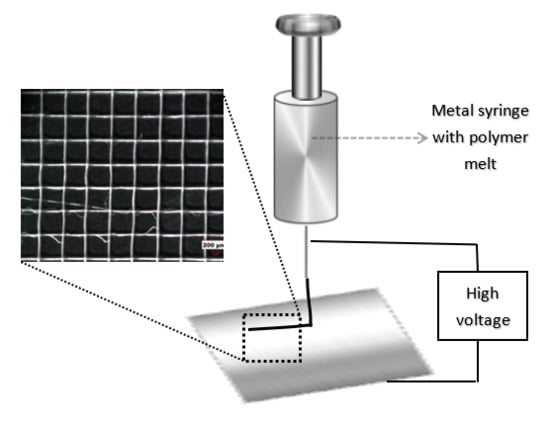

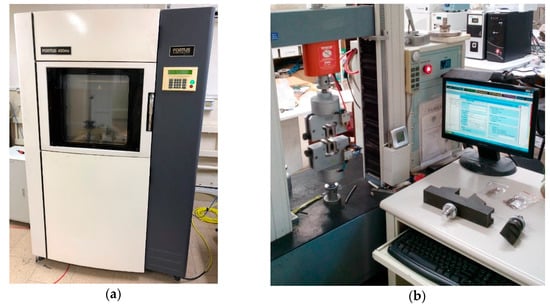

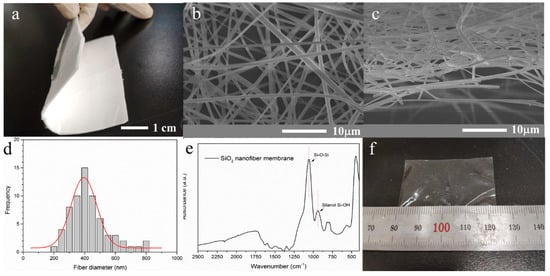

- Solid-state techniques for polymer composite formation, such as ball-milling, extrusion, molding, etc.;

- Polymer composites produced by additive manufacturing;

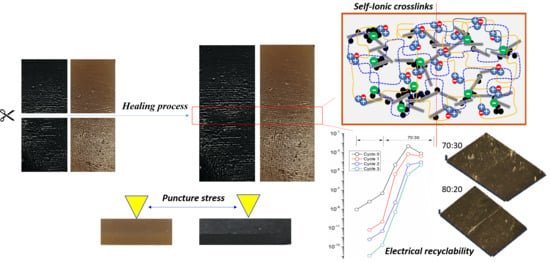

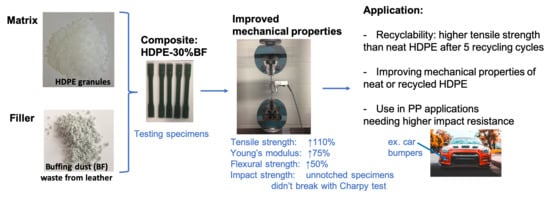

- Use of recycling materials in polymer composites;

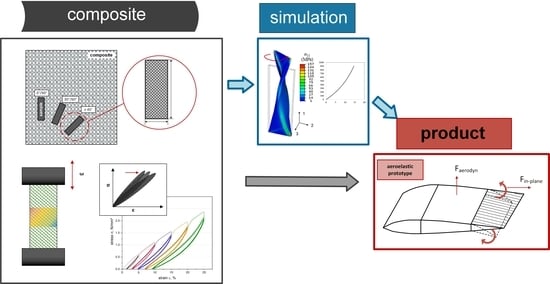

- Structure of reinforced polymer composites, including structure of interfaces;

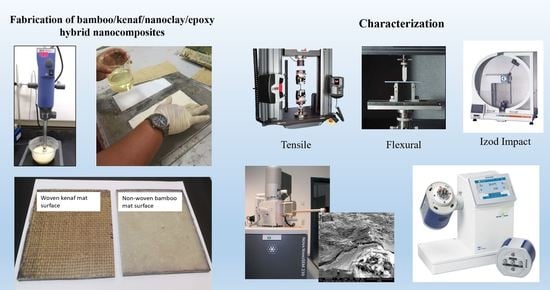

- Thermal, mechanical, and tribological properties of reinforced polymer composites;

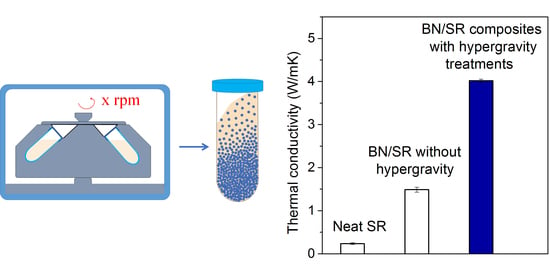

- Thermal and electrical conductivity of reinforced polymer composites.

Authors are welcome to submit their latest research in the form of original full articles, communications, or reviews on this topic.

Prof. Dr. Victor Tcherdyntsev

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- composites

- reinforcers

- interfaces

- surfactants

- carbon

- thermoplastics

- thermosets

- agglomeration

- orientation

- additive manufacturing

- recycling

Related Special Issues

- Reinforced Polymer Composites in Polymers (23 articles - displayed below)

- Reinforced Polymer Composites II in Polymers (23 articles - displayed below)

- Reinforced Polymer Composites III in Polymers (18 articles - displayed below)