Reinforced Polymer Composites

(Closed)

A project collection of Polymers (ISSN 2073-4360). This project collection belongs to the section "Polymer Composites and Nanocomposites".

Papers displayed on this page all arise from the same project. Editorial decisions were made independently of project staff and handled by the Editor-in-Chief or qualified Editorial Board members.

Viewed by 132949

Printed Edition Available!

A printed edition of this Special Issue is available

here.

Share This Project Collection

Editor

Project Overview

Dear Colleagues,

This Special Issue focuses on the recent advances in reinforced polymer composites. Polymer materials are widely used in human life, medicine, industry, and so on. However, polymers have a lot of disadvantages, such as insufficient strength, stiffness, creep, and low usage temperature. That is why reinforcing fillers are widely used to improve polymer properties. The following factors should be taken into account to reach high mechanical properties when nanofillers are used: (a) Uniform distribution of the filler in the polymer matrix of a bulk sample will result in a composite physical and chemical properties uniformity over its volume; (b) filler should not agglomerate inside the polymer bulk sample because it might act as stress concentrator; and (c) interaction between fillers and polymer matrix should result in a composite supramolecular structure improvement. Strong interfacial interaction between polymer matrix and filler surface can improve load transfer from matrix to reinforcing filler.

This Special Issue covers all the fields related to the reinforced polymer composites, but special attention will be given to the following aspects:

- Effect of polymer-filler interfaces interaction on the composite properties;

- Carbon fillers for polymers, including fibers, nanotubes, graphene, etc.;

- Solid-state technique for polymer composite formation, such as ball-milling, extrusion, molding, etc.;

- Polymer composites by additive manufacturing;

- Using of recycling materials in polymer composites.

Authors are welcome to submit their latest research in the form of original full articles, communications, or reviews on this topic.

Prof. Dr. Victor Tcherdyntsev

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- composites

- reinforcers

- interfaces

- surfactants

- carbon

- thermoplastics

- thermosets

- agglomeration

- orientation

- additive manufacturing

- recycling

Related Special Issues

Published Papers (23 papers)

Open AccessArticle

Poly (Lactic Acid)/Ground Tire Rubber Blends Using Peroxide Vulcanization

by

Nicolas Candau, Oguzhan Oguz, Noel León Albiter, Gero Förster and Maria Lluïsa Maspoch

Cited by 13 | Viewed by 2844

Abstract

Poly (Lactic Acid) (PLA)/Ground Tire Rubber (GTR) blends using Dicumyl peroxide (DCP) as a crosslinking agent were prepared with the following aims: propose a new route to recycle wastes rubber from the automotive industry and improve the toughness and impact strength of the

[...] Read more.

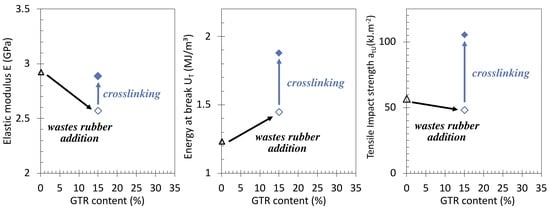

Poly (Lactic Acid) (PLA)/Ground Tire Rubber (GTR) blends using Dicumyl peroxide (DCP) as a crosslinking agent were prepared with the following aims: propose a new route to recycle wastes rubber from the automotive industry and improve the toughness and impact strength of the inherently brittle bio-based PLA. The GTR were subjected to two types of grinding process (cryo- and dry ambient grinding). Swelling measurements revealed the grinding to be associated with a mechanical damage of the rubber chains, independently on the type of grinding or on the GTR size (from <400 µm to <63 µm). Moreover, the finest GTR contains the largest amount of reinforcing elements (carbon black, clay) that can be advantageously used in PLA/GTR blends. Indeed, the use of the finest cryo-grinded GTR in the presence of DCP showed the least decrease of the tensile strength (−30%); maintenance of the tensile modulus and the largest improvement of the strain at break (+80%), energy at break (+60%) and impact strength (+90%) as compared to the neat PLA. The results were attributed to the good dispersion of both fine GTR and clay particles into the PLA matrix. Moreover, a possible re-crosslinking of the GTR particles and/or co-crosslinking at PLA/GTR interface in presence of DCP is expected to contribute to such improved ductility and impact strength.

Full article

►▼

Show Figures

Open AccessEditorial

Reinforced Polymer Composites

by

Victor V. Tcherdyntsev

Cited by 8 | Viewed by 1810

Abstract

The development of modern technology requires the elaboration of new materials with improved operational and technological properties [...]

Full article

Open AccessArticle

Experimental Evaluation of Low Velocity Impact Properties and Damage Progression on Bamboo/Glass Hybrid Composites Subjected to Different Impact Energy Levels

by

Ain Umaira Md Shah, Mohamed Thariq Hameed Sultan and Syafiqah Nur Azrie Safri

Cited by 12 | Viewed by 2480

Abstract

Six impact energy values, ranging from 2.5 J to 10 J, were applied to study the impact properties of neat epoxy and bamboo composites, while six impact energy values, ranging from 10 J to 35 J, were applied on bamboo/glass hybrid composites. Woven

[...] Read more.

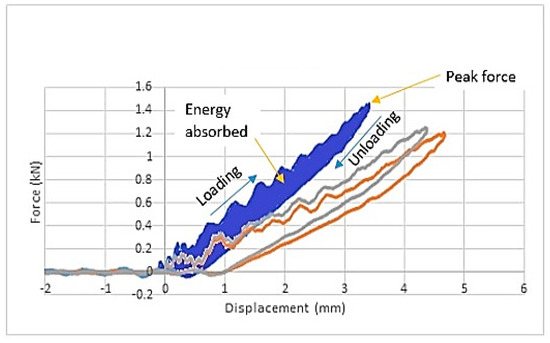

Six impact energy values, ranging from 2.5 J to 10 J, were applied to study the impact properties of neat epoxy and bamboo composites, while six impact energy values, ranging from 10 J to 35 J, were applied on bamboo/glass hybrid composites. Woven glass fibre was embedded at the outermost top and bottom layer of bamboo powder-filled epoxy composites, producing sandwich structured hybrid composites through lay-up and molding techniques. A drop weight impact test was performed to study the impact properties. A peak force analysis showed that neat epoxy has the stiffest projectile for targeting interaction, while inconsistent peak force data was collected for the non-hybrid composites. The non-hybrid composites could withstand up to 10 J, while the hybrid composites showed a total failure at 35 J. It can be concluded that increasing the filler loading lessened the severity of damages in non-hybrid composites, while introducing the woven glass fibre could slow down the penetration of the impactor, thus lowering the chances of a total failure of the composites.

Full article

►▼

Show Figures

Open AccessReview

A Review on the Kenaf/Glass Hybrid Composites with Limitations on Mechanical and Low Velocity Impact Properties

by

Seri Nur Zumaimi Ahmad Nadzri, Mohamed Thariq Hameed Sultan, Ain Umaira Md Shah, Syafiqah Nur Azrie Safri and Adi Azriff Basri

Cited by 20 | Viewed by 3939

Abstract

Environmental awareness and trends to develop sustainable resources have directed much research attention towards kenaf fibre as an alternative reinforcement in composite manufacturing. Numerous studies have been conducted on kenaf and its hybrid composites. Most studies were conducted on kenaf/glass hybrid composites compared

[...] Read more.

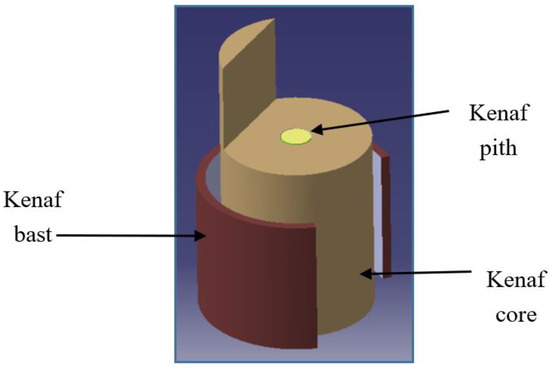

Environmental awareness and trends to develop sustainable resources have directed much research attention towards kenaf fibre as an alternative reinforcement in composite manufacturing. Numerous studies have been conducted on kenaf and its hybrid composites. Most studies were conducted on kenaf/glass hybrid composites compared to other kenaf/synthetic hybrid composites. Similar with other materials, mechanical properties were the fundamental knowledge identified by the researcher. Limited studies conducted on other properties have restricted the use of kenaf composites to non-structural applications. To extend the potential of kenaf composites to automotive exterior or other critical applications, studies on impact properties can be a valuable contribution in the material field. This review discusses the mechanical and low velocity impact properties of kenaf/glass hybrid composites reported previously. Percentage loading of fibre, the angle of orientation in woven fibres and the chemical treatment applied to the fibre before compounding are the three major parameters that affect the mechanical and impact properties of the composites. This review provides insights into the mechanical and impact properties of kenaf/glass hybrid composites for future research.

Full article

►▼

Show Figures

Open AccessArticle

The Effect of Modification on the Properties of Polyetherimide and Its Carbon-Filled Composite

by

Azamat Slonov, Ismel Musov, Azamat Zhansitov, Elena Rzhevskaya, Diana Khakulova and Svetlana Khashirova

Cited by 9 | Viewed by 3147

Abstract

The effect of oligophenylene sulfone (OPSU) and polycarbonate (PC) on the rheological, mechanical and thermal properties of polyetherimide (PEI) and a carbon-filled composite based on it was studied. It is shown that the introduction of OPSU and PC leads to a decrease in

[...] Read more.

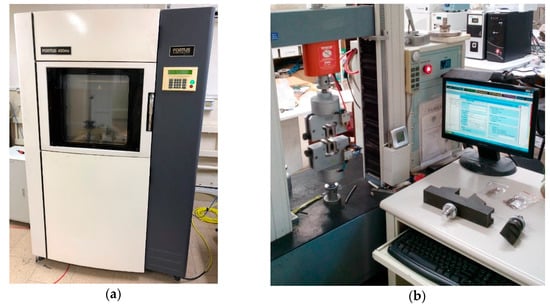

The effect of oligophenylene sulfone (OPSU) and polycarbonate (PC) on the rheological, mechanical and thermal properties of polyetherimide (PEI) and a carbon-filled composite based on it was studied. It is shown that the introduction of OPSU and PC leads to a decrease in the melt viscosity of PEI and a carbon-filled composite based on it with the preservation of their mechanical properties and heat resistance at a sufficiently high level. It was found that composites with OPSU have higher mechanical and thermal properties compared with composites with PC. Samples from modified carbon-filled PEI were printed by the fused deposit modeling (FDM) method. Three-dimensionally printed samples from carbon-filled PEI modified by OPSU showed significantly higher mechanical properties than composites with PC.

Full article

►▼

Show Figures

Open AccessArticle

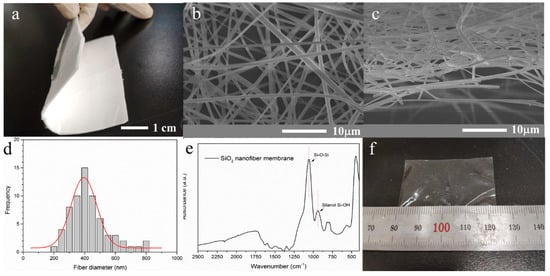

Bi-Functional Composting the Sulfonic Acid Based Proton Exchange Membrane for High Temperature Fuel Cell Application

by

Guoxiao Xu, Juan Zou, Zhu Guo, Jing Li, Liying Ma, Ying Li and Weiwei Cai

Cited by 7 | Viewed by 2701

Abstract

Although sulfonic acid (SA)-based proton-exchange membranes (PEMs) dominate fuel cell applications at low temperature, while sulfonation on polymers would strongly decay the mechanical stability limit the applicable at elevated temperatures due to the strong dependence of proton conduction of SA on water. For

[...] Read more.

Although sulfonic acid (SA)-based proton-exchange membranes (PEMs) dominate fuel cell applications at low temperature, while sulfonation on polymers would strongly decay the mechanical stability limit the applicable at elevated temperatures due to the strong dependence of proton conduction of SA on water. For the purpose of bifunctionally improving mechanical property and high-temperature performance, Nafion membrane, which is a commercial SA-based PEM, is composited with fabricated silica nanofibers with a three-dimensional network structure via electrospinning by considering the excellent water retention capacity of silica. The proton conductivity of the silica nanofiber–Nafion composite membrane at 110 °C is therefore almost doubled compared with that of a pristine Nafion membrane, while the mechanical stability of the composite Nafion membrane is enhanced by 44%. As a result, the fuel cell performance of the silica nanofiber-Nafion composite membrane measured at high temperature and low humidity is improved by 38%.

Full article

►▼

Show Figures

Open AccessArticle

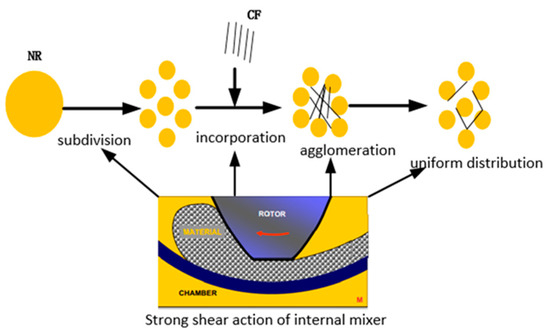

Surface Modification of Staple Carbon Fiber by Dopamine to Reinforce Natural Latex Composite

by

Xiaolong Tian, Shuang Han, Qianxiao Zhuang, Huiguang Bian, Shaoming Li, Changquan Zhang, Chuansheng Wang and Wenwen Han

Cited by 19 | Viewed by 3450

Abstract

Carbon fiber significantly enhances the mechanical, thermal and electrical properties of rubber composites, which are widely used in aerospace, military, national defense and other cutting-edge fields. The preparation of a high-performance carbon fiber rubber composite has been a research hotspot, because the surface

[...] Read more.

Carbon fiber significantly enhances the mechanical, thermal and electrical properties of rubber composites, which are widely used in aerospace, military, national defense and other cutting-edge fields. The preparation of a high-performance carbon fiber rubber composite has been a research hotspot, because the surface of carbon fiber is smooth, reactive inert and has a poor adhesion with rubber. In this paper, a high-performance rubber composite is prepared by mixing dopamine-modified staple carbon fiber with natural latex, and the mechanisms of modified carbon fiber-reinforced natural latex composite are explored. The experimental results show that the surface-modified staple carbon fiber forms uniform and widely covered polydopamine coatings, which significantly improve the interface adhesion between the carbon fiber and the rubber matrix. Meanwhile, when the concentration of dopamine is 1.5 g/L and the staple carbon fiber is modified for 6h, the carbon fiber rubber composite shows excellent conductivity, thermal conductivity, and dynamic mechanical properties, and its tensile strength is 10.6% higher than that of the unmodified sample.

Full article

►▼

Show Figures

Open AccessArticle

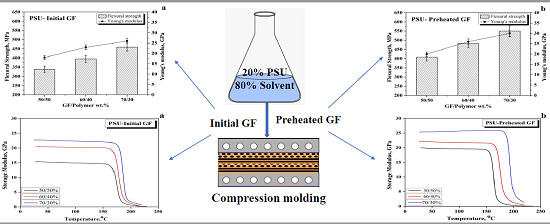

Effect of Glass Fibers Thermal Treatment on the Mechanical and Thermal Behavior of Polysulfone Based Composites

by

Galal Sherif, Dilyus I. Chukov, Victor V. Tcherdyntsev, Valerii G. Torokhov and Dmitry D. Zherebtsov

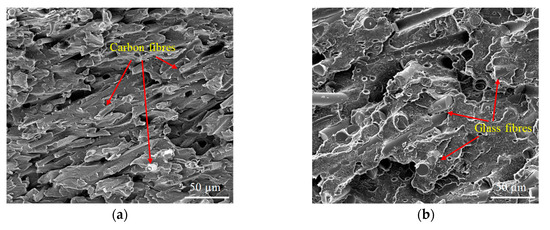

Cited by 17 | Viewed by 4120

Abstract

The effect of thermal treatment of glass fibers (GF) on the mechanical and thermo-mechanical properties of polysulfone (PSU) based composites reinforced with GF was investigated. Flexural and shear tests were used to study the composites’ mechanical properties. A dynamic mechanical analysis (DMA) and

[...] Read more.

The effect of thermal treatment of glass fibers (GF) on the mechanical and thermo-mechanical properties of polysulfone (PSU) based composites reinforced with GF was investigated. Flexural and shear tests were used to study the composites’ mechanical properties. A dynamic mechanical analysis (DMA) and a heat deflection temperature (HDT) test were used to study the thermo-mechanical properties of composites. The chemical structure of the composites was studied using IR-spectroscopy, and scanning electron microscopy (SEM) was used to illustrate the microstructure of the fracture surface. Three fiber to polymer ratios of initial and preheated GF composites (50/50, 60/40, 70/30 (wt.%)) were studied. The results showed that the mechanical and thermo-mechanical properties improved with an increase in the fiber to polymer ratio. The interfacial adhesion in the preheated composites enhanced as a result of removing the sizing coating during the thermal treatment of GF, which improved the properties of the preheated composites compared with the composites reinforced with initial untreated fibers. The SEM images showed a good distribution of the polymer on the GF surface in the preheated GF composites.

Full article

►▼

Show Figures

Open AccessArticle

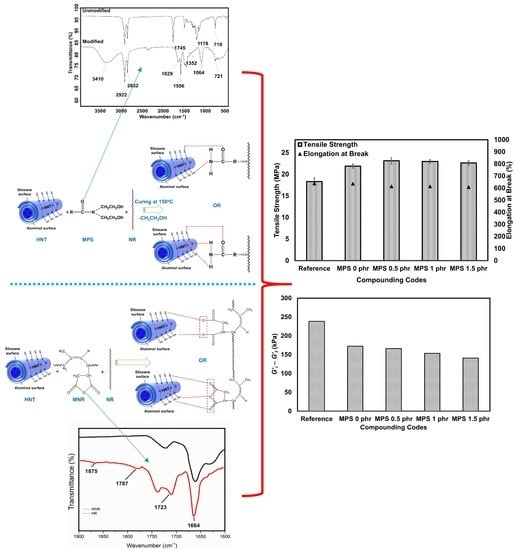

Synergistic Effect of Maleated Natural Rubber and Modified Palm Stearin as Dual Compatibilizers in Composites based on Natural Rubber and Halloysite Nanotubes

by

Nabil Hayeemasae, Zareedan Sensem, Indra Surya, Kannika Sahakaro and Hanafi Ismail

Cited by 20 | Viewed by 2865

Abstract

The performance of rubber composite relies on the compatibility between rubber and filler. This is specifically of concern when preparing composites with very different polarities of the rubber matrix and the filler. However, a suitable compatibilizer can mediate the interactions. In this study,

[...] Read more.

The performance of rubber composite relies on the compatibility between rubber and filler. This is specifically of concern when preparing composites with very different polarities of the rubber matrix and the filler. However, a suitable compatibilizer can mediate the interactions. In this study, composites of natural rubber (NR) with halloysite nanotubes (HNT) were prepared with maleated natural rubber (MNR) and modified palm stearin (MPS) as dual compatibilizers. The MPS dose ranged within 0.5–1.5 phr, while the MNR dose was fixed at 10 phr in all formulations. It was found that the mixed MNR/MPS significantly enhanced modulus, tensile strength, and tear strength of the composites. The improvements were mainly due to improved rubber-HNT interactions arising from hydrogen bonds formed in the presence of these two compatibilizers. This was clearly verified by observing the Payne effect. Apart from that, the MPS also acted as a plasticizer to provide improved dispersion of HNT. It was clearly demonstrated that MNR and MPS as dual compatibilizers improved rubber-HNT interactions and reduced filler-filler interactions, which then improved tensile and tear strengths, as well as dynamical properties. Therefore, the mix of MNR and MPS had a great potential to compatibilize non-polar rubber with HNT filler.

Full article

►▼

Show Figures

Open AccessReview

Fiber Reinforced Polymer Laminates for Strengthening of RC Slabs against Punching Shear: A Review

by

Osama Ahmed Mohamed, Manish Kewalramani and Rania Khattab

Cited by 20 | Viewed by 5304

Abstract

Reinforced concrete flat slabs or flat plates continue to be among the most popular floor systems due to speed of construction and inherent flexibility it offers in relation to locations of partitions. However, flat slab/plate floor systems that are deficient in two-way shear

[...] Read more.

Reinforced concrete flat slabs or flat plates continue to be among the most popular floor systems due to speed of construction and inherent flexibility it offers in relation to locations of partitions. However, flat slab/plate floor systems that are deficient in two-way shear strength are susceptible to brittle failure at a slab–column junction that may propagate and lead to progressive collapse of a larger segment of the structural system. Deficiency in two-way shear strength may be due to design/construction errors, material under-strength, or overload. Fiber reinforced polymer (FRP) composite laminates in the form of sheets and/or strips are used in structurally deficient flat slab systems to enhance the two-way shear capacity, flexural strength, stiffness, and ductility. Glass FRP (GFRP) has been used successfully but carbon FRP (CFRP) sheets/strips/laminates are more commonly used as a practical alternative to other expensive and/or challenging methods such column enlargement. This article reviews the literature on the methodology and effectiveness of utilizing FRP sheets/strips and laminates at the column/slab intersection to enhance punching shear strength of flat slabs.

Full article

►▼

Show Figures

Open AccessArticle

PEEK Composites as Self-Lubricating Bush Materials for Articulating Revolute Pin Joints

by

Juanjuan Zhu, Fang Xie and R S Dwyer-Joyce

Cited by 32 | Viewed by 4233

Abstract

In this study, bearing bushes made of polyetheretherketone (PEEK), 30 wt % carbon fibre reinforced PEEK, 30 wt % glass fibre reinforced PEEK, each 10 wt % of PTFE, graphite and carbon fibre modified PEEK were investigated on a purpose built pin joint

[...] Read more.

In this study, bearing bushes made of polyetheretherketone (PEEK), 30 wt % carbon fibre reinforced PEEK, 30 wt % glass fibre reinforced PEEK, each 10 wt % of PTFE, graphite and carbon fibre modified PEEK were investigated on a purpose built pin joint test rig. The unlubricated friction and wear behaviour was assessed in sliding contact with a 300M shaft, subjected to a nominal pressure of 93 MPa, articulating sliding speed of 45 °/s. The worn surface and the subsurface layer were studied using optical profilometry and scanning electron microscopy (SEM). Due to thermal sensitivity of PEEK composites, friction energy and temperature rise were analysed for determining the friction and wear mechanism. The bush made of PTFE, graphite and carbon fibre (each 10 wt %) modified PEEK presented the best performance for friction coefficient, wear loss, friction energy and temperature rise. Current work demonstrated that reinforcement modified PEEK composite possesses desirable properties to perform as a load bearing bush in certain tribological applications.

Full article

►▼

Show Figures

Open AccessArticle

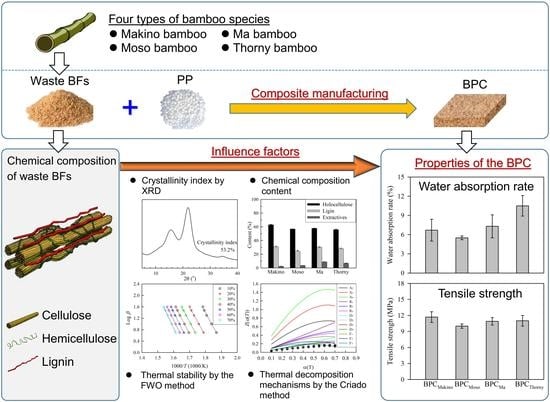

Utilization of Waste Bamboo Fibers in Thermoplastic Composites: Influence of the Chemical Composition and Thermal Decomposition Behavior

by

Chin-Hao Yeh and Teng-Chun Yang

Cited by 22 | Viewed by 4731

Abstract

In this study, four types of waste bamboo fibers (BFs), Makino bamboo (

Phyllostachys makinoi), Moso bamboo (

Phyllostachys pubescens), Ma bamboo (

Dendrocalamus latiflorus), and Thorny bamboo (

Bambusa stenostachya), were used as reinforcements and incorporated into polypropylene

[...] Read more.

In this study, four types of waste bamboo fibers (BFs), Makino bamboo (

Phyllostachys makinoi), Moso bamboo (

Phyllostachys pubescens), Ma bamboo (

Dendrocalamus latiflorus), and Thorny bamboo (

Bambusa stenostachya), were used as reinforcements and incorporated into polypropylene (PP) to manufacture bamboo–PP composites (BPCs). To investigate the effects of the fibers from these bamboo species on the properties of the BPCs, their chemical compositions were evaluated, and their thermal decomposition kinetics were analyzed by the Flynn–Wall–Ozawa (FWO) method and the Criado method. Thermogravimetric results indicated that the Makino BF was the most thermally stable since it showed the highest activation energy at various conversion rates that were calculated by the FWO method. Furthermore, using the Criado method, the thermal decomposition mechanisms of the BFs were revealed by diffusion when the conversion rates (α) were below 0.5. When the α values were above 0.5, their decomposition mechanisms trended to the random nucleation mechanism. Additionally, the results showed that the BPC with Thorny BFs exhibited the highest moisture content and water absorption rate due to this BF having high hemicellulose content, while the BPC with Makino BFs had high crystallinity and high lignin content, which gave the resulting BPC better tensile properties.

Full article

►▼

Show Figures

Open AccessCommunication

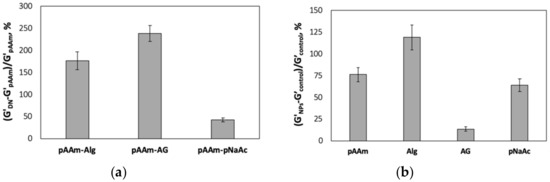

Role of Nanoparticle–Polymer Interactions on the Development of Double-Network Hydrogel Nanocomposites with High Mechanical Strength

by

Andrew Chang, Nasim Babhadiashar, Emma Barrett-Catton and Prashanth Asuri

Cited by 27 | Viewed by 3566

Abstract

Extensive experimental and theoretical research over the past several decades has pursued strategies to develop hydrogels with high mechanical strength. Our study investigated the effect of combining two approaches, addition of nanoparticles and crosslinking two different polymers (to create double-network hydrogels), on the

[...] Read more.

Extensive experimental and theoretical research over the past several decades has pursued strategies to develop hydrogels with high mechanical strength. Our study investigated the effect of combining two approaches, addition of nanoparticles and crosslinking two different polymers (to create double-network hydrogels), on the mechanical properties of hydrogels. Our experimental analyses revealed that these orthogonal approaches may be combined to synthesize hydrogel composites with enhanced mechanical properties. However, the enhancement in double network hydrogel elastic modulus due to incorporation of nanoparticles is limited by the ability of the nanoparticles to strongly interact with the polymers in the network. Moreover, double-network hydrogel nanocomposites prepared using lower monomer concentrations showed higher enhancements in elastic moduli compared to those prepared using high monomer concentrations, thus indicating that the concentration of hydrogel monomers used for the preparation of the nanocomposites had a significant effect on the extent of nanoparticle-mediated enhancements. Collectively, these results demonstrate that the hypotheses previously developed to understand the role of nanoparticles on the mechanical properties of hydrogel nanocomposites may be extended to double-network hydrogel systems and guide the development of next-generation hydrogels with extraordinary mechanical properties through a combination of different approaches.

Full article

►▼

Show Figures

Open AccessArticle

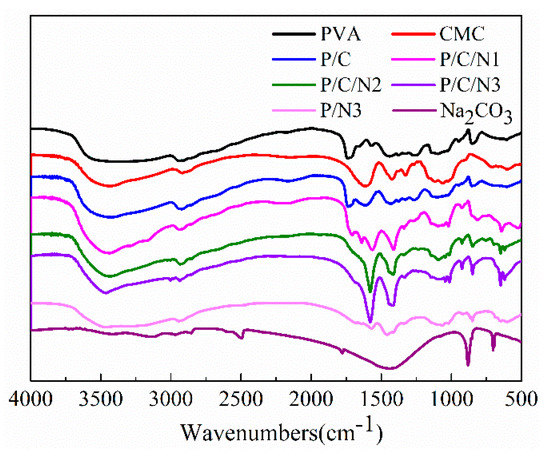

Effect of Na2CO3 on the Microstructure and Macroscopic Properties and Mechanism Analysis of PVA/CMC Composite Film

by

Jufang Zhu, Qiuying Li, Yanchao Che, Xingchen Liu, Chengcheng Dong, Xinyu Chen and Chao Wang

Cited by 43 | Viewed by 4822

Abstract

Polyvinyl alcohol (PVA)/carboxyl methyl cellulose sodium (CMC)/Na

2CO

3 composite films with different contents of Na

2CO

3 were prepared by blending and solution-casting. The effect of Na

2CO

3 on the microstructure of PVA/CMC composite film was analyzed by

[...] Read more.

Polyvinyl alcohol (PVA)/carboxyl methyl cellulose sodium (CMC)/Na

2CO

3 composite films with different contents of Na

2CO

3 were prepared by blending and solution-casting. The effect of Na

2CO

3 on the microstructure of PVA/CMC composite film was analyzed by Fourier-transform infrared (FTIR) spectroscopy, X-ray diffraction (XRD), differential scanning calorimetry (DSC), and atomic force microscopy (AFM). Its macroscopic properties were analyzed by water sorption, solubility, and dielectric constant tests. The results show that the microstructure of PVA/CMC/Na

2CO

3 composite films was different from that of PVA and PVA/CMC composite films. In addition, compared to PVA and PVA/CMC composite films, the water sorption of PVA/CMC/Na

2CO

3 composite films relatively increased, the solubility in water significantly decreased, and the dielectric properties significantly improved. All these results indicate that the hydrogen bonding interaction between PVA and CMC increased and the crystallinity of PVA decreased after the addition of Na

2CO

3. This was also a direct factor leading to increased water sorption, decreased solubility, and enhanced dielectric properties. The reaction mechanism of PVA, CMC, and Na

2CO

3 is proposed to further evaluate the effect of Na

2CO

3 on the microstructure and macroscopic properties of PVA/CMC/Na

2CO

3 composite films.

Full article

►▼

Show Figures

Open AccessArticle

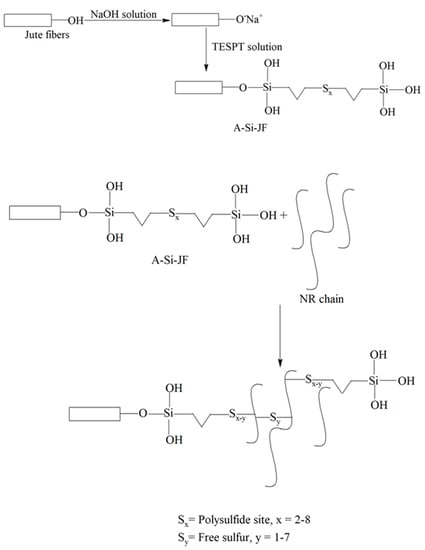

Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber (NR) Composites

by

Kumarjyoti Roy, Subhas Chandra Debnath, Lazaros Tzounis, Aphiwat Pongwisuthiruchte and Pranut Potiyaraj

Cited by 44 | Viewed by 3553

Abstract

In the present study, the suitability of various chemical treatments to improve the performance of jute fibers (JFs) filled natural rubber (NR) composites was explored. The surface of JFs was modified by three different surface treatments, namely, alkali treatment, combined alkali/stearic acid treatment

[...] Read more.

In the present study, the suitability of various chemical treatments to improve the performance of jute fibers (JFs) filled natural rubber (NR) composites was explored. The surface of JFs was modified by three different surface treatments, namely, alkali treatment, combined alkali/stearic acid treatment and combined alkali/silane treatment. Surface modified JFs were characterized by X-ray diffraction (XRD) pattern, Fourier transform infrared (FTIR) spectroscopy and field emission scanning electron microscopy (FESEM). The reinforcing effect of untreated and surface treated JFs in NR composites was comparatively evaluated in terms of cure, mechanical, morphological and thermal properties. Combined alkali/silane treated JFs filled NR composite showed considerably higher torque difference, tensile modulus, hardness and tensile strength as compared to either untreated or other surface treated JFs filled NR systems. A crosslink density measurement suggested effective rubber-fibers interaction in combined alkali/silane treated JFs filled NR composite. Morphological analysis confirmed the improvement in the interfacial bonding between NR matrix and JFs due to combined alkali/silane treatment allowing an efficient “stress-transfer” mechanism. As a whole, combined alkali/silane treatment was found to be most efficient surface treatment method to develop strong interfacial adhesion between NR matrix and JFs.

Full article

►▼

Show Figures

Open AccessArticle

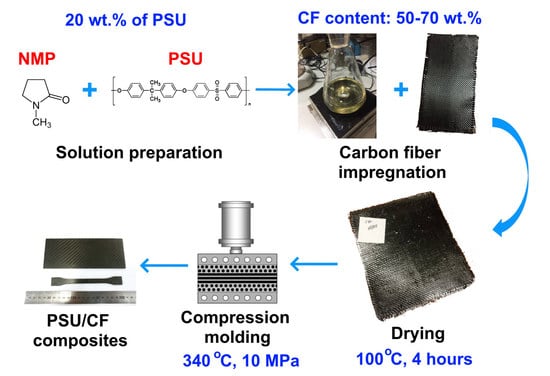

Structure and Properties of Polysulfone Filled with Modified Twill Weave Carbon Fabrics

by

Dilyus I. Chukov, Sarvarkhodza G. Nematulloev, Viсtor V. Tсherdyntsev, Valerii G. Torokhov, Andrey A. Stepashkin, Mikhail Y. Zadorozhnyy, Dmitry D. Zherebtsov and Galal Sherif

Cited by 13 | Viewed by 3842

Abstract

Carbon fabrics are widely used in polymer based composites. Nowadays, most of the advanced high-performance composites are based on thermosetting polymer matrices such as epoxy resin. Thermoplastics have received high attention as polymer matrices due to their low curing duration, high chemical resistance,

[...] Read more.

Carbon fabrics are widely used in polymer based composites. Nowadays, most of the advanced high-performance composites are based on thermosetting polymer matrices such as epoxy resin. Thermoplastics have received high attention as polymer matrices due to their low curing duration, high chemical resistance, high recyclability, and mass production capability in comparison with thermosetting polymers. In this paper, we suggest thermoplastic based composite materials reinforced with carbon fibers. Composites based on polysulfone reinforced with carbon fabrics using polymer solvent impregnation were studied. It is well known that despite the excellent mechanical properties, carbon fibers possess poor wettability and adhesion to polymers because of the fiber surface chemical inertness and smoothness. Therefore, to improve the fiber–matrix interfacial interaction, the surface modification of the carbon fibers by thermal oxidation was used. It was shown that the surface modification resulted in a noticeable change in the functional composition of the carbon fibers’ surface and increased the mechanical properties of the polysulfone based composites. Significant increase in composites mechanical properties and thermal stability as a result of carbon fiber surface modification was observed.

Full article

►▼

Show Figures

Open AccessArticle

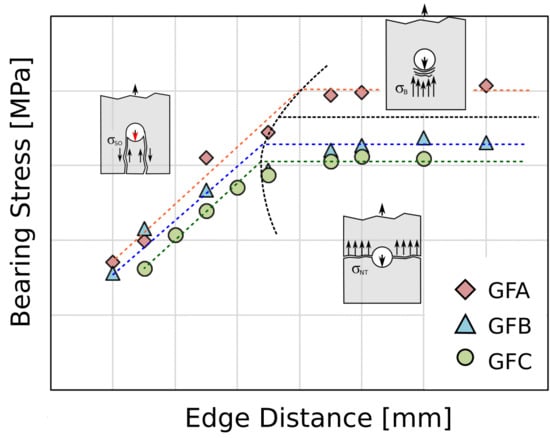

Pinned Hybrid Glass-Flax Composite Laminates Aged in Salt-Fog Environment: Mechanical Durability

by

Luigi Calabrese, Vincenzo Fiore, Paolo Bruzzaniti, Tommaso Scalici and Antonino Valenza

Cited by 20 | Viewed by 3638

Abstract

The aim of the present paper is to study the mechanical performance evolution of pinned hybrid glass-flax composite laminates under environment aging conditions. Hybrid glass-flax fibers/epoxy pinned laminates were exposed to salt-spray fog environmental conditions up to 60 days. With the purpose of

[...] Read more.

The aim of the present paper is to study the mechanical performance evolution of pinned hybrid glass-flax composite laminates under environment aging conditions. Hybrid glass-flax fibers/epoxy pinned laminates were exposed to salt-spray fog environmental conditions up to 60 days. With the purpose of assessing the relationship between mechanical performances and failure mechanisms at increasing aging time, single lap joints at varying joint geometry (i.e., hole diameter D and hole distance E from free edge) were characterized after 0 days (i.e., unaged samples), 30 days, and 60 days of salt-fog exposition. Based on this approach, the property–structure relationship of the composite laminates was assessed on these critical environmental conditions. In particular, a reduction of failure strength for long-aging-time-aged samples was observed in the range 20–30% compared to unaged one. Due to the natural fiber degradation in a salt-fog environment, premature catastrophic fractures mode due to shear-out and net-tension were found, related to reduced joint fracture strength. This behavior identifies that this type of joint requires a careful design in order to guarantee an effective mechanical stability of the composite hybrid joint under long-term operating conditions in an aggressive environment.

Full article

►▼

Show Figures

Open AccessArticle

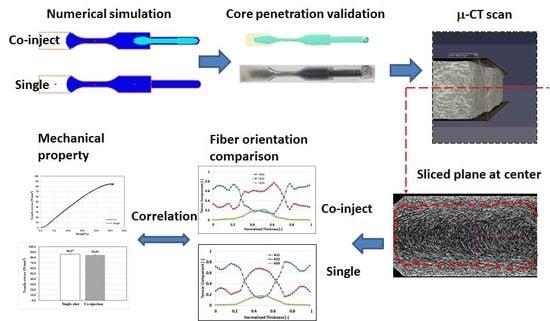

Investigation on the Fiber Orientation Distributions and Their Influence on the Mechanical Property of the Co-Injection Molding Products

by

Chao-Tsai Huang, Xuan-Wei Chen and Wei-Wen Fu

Cited by 20 | Viewed by 4206

Abstract

In recent years, due to the rapid development of industrial lightweight technology, composite materials based on fiber reinforced plastics (FRP) have been widely used in the industry. However, the environmental impact of the FRPs is higher each year. To overcome this impact, co-injection

[...] Read more.

In recent years, due to the rapid development of industrial lightweight technology, composite materials based on fiber reinforced plastics (FRP) have been widely used in the industry. However, the environmental impact of the FRPs is higher each year. To overcome this impact, co-injection molding could be one of the good solutions. But how to make the suitable control on the skin/core ratio and how to manage the glass fiber orientation features are still significant challenges. In this study, we have applied both computer-aided engineering (CAE) simulation and experimental methods to investigate the fiber feature in a co-injection system. Specifically, the fiber orientation distributions and their influence on the tensile properties for the single-shot and co-injection molding have been discovered. Results show that based on the 60:40 of skin/core ratio and same materials, the tensile properties of the co-injection system, including tensile stress and modulus, are a little weaker than that of the single-shot system. This is due to the overall fiber orientation tensor at flow direction (A

11) of the co-injection system being lower than that of the single-shot system. Moreover, to discover and verify the influence of the fiber orientation features, the fiber orientation distributions (FOD) of both the co-injection and single-shot systems have been observed using micro-computerized tomography (μ-CT) technology to scan the internal structures. The scanned images were further utilizing Avizo software to perform image analyses to rebuild the fiber structure. Specifically, the fiber orientation tensor at flow direction (A

11) of the co-injection system is about 89% of that of the single-shot system in the testing conditions. This is because the co-injection part has lower tensile properties. Furthermore, the difference of the fiber orientation tensor at flow direction (A

11) between the co-injection and the single-shot systems is further verified based on the fiber morphology of the μ-CT scanned image. The observed result is consistent with that of the FOD estimation using μ-CT scan plus image analysis.

Full article

►▼

Show Figures

Open AccessArticle

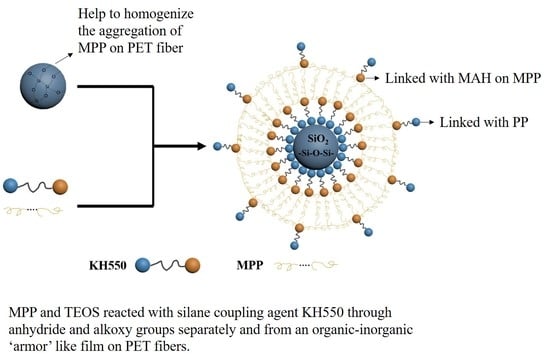

Surface Modification of PET Fiber with Hybrid Coating and Its Effect on the Properties of PP Composites

by

Yapeng Mao, Qiuying Li and Chifei Wu

Cited by 12 | Viewed by 5194

Abstract

Surface modification fundamentally influences the morphology of polyethylene terephthalate (PET) fibers produced from abandoned polyester textiles and improve the compatibility between the fiber and the matrix. In this study, PET fiber was modified through solution dip-coating using a novel synthesized tetraethyl orthosilicate (TEOS)/KH550/

[...] Read more.

Surface modification fundamentally influences the morphology of polyethylene terephthalate (PET) fibers produced from abandoned polyester textiles and improve the compatibility between the fiber and the matrix. In this study, PET fiber was modified through solution dip-coating using a novel synthesized tetraethyl orthosilicate (TEOS)/KH550/ polypropylene (PP)-g-MAH (MPP) hybrid (TMPP). The PET fiber with TMPP modifier was exposed to the air. SiO

2 particles would be hydrolyzed from TEOS and become the crystalline cores of MPP. Then, the membrane formed by MPP, SiO

2 and KH550 covered the surface of the PET fiber. TMPP powder was investigated and characterized by fourier transform infrared spectroscopy, scanning electron microscope (SEM) and thermogravimetric analysis (TGA). TMPP-modified PET fiber was researched by X-ray diffraction and SEM. Furthermore, tensile strength of single fiber was also tested. PET fiber/PP composites were studied through dynamic mechanical analysis and SEM. Flexural properties of composites were also measured. The interfacial properties of PET fiber and PP matrix were indirectly represented by contact angle analysis. Results showed that the addition of TEOS is helpful in homogenizing the distribution of PP-g-MAH. Furthermore, TMPP generates an organic-inorganic ‘armor’ structure on PET fiber, which can make up for the damage areas on the surface of PET fiber and strengthen each single-fiber by 14.4%. Besides, bending strength and modulus of TMPP-modified PET fiber-reinforced PP composite respectively, increase by 10 and 800 MPa. The compatibility between PET fiber and PP was also confirmed to be increased by TMPP. Predictably, this work supplied a new way for PET fiber modification and exploited its potential applications in composites.

Full article

►▼

Show Figures

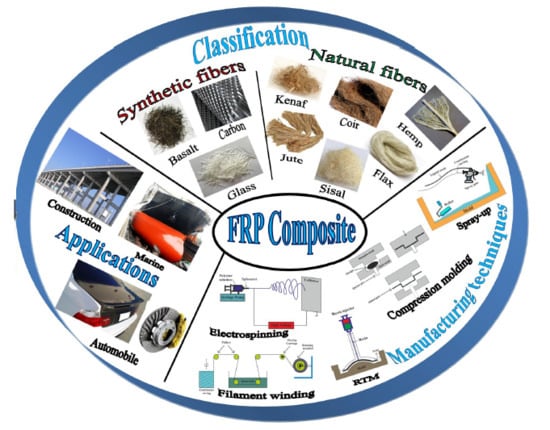

Open AccessEditor’s ChoiceReview

Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications

by

Dipen Kumar Rajak, Durgesh D. Pagar, Pradeep L. Menezes and Emanoil Linul

Cited by 817 | Viewed by 45072

Abstract

Composites have been found to be the most promising and discerning material available in this century. Presently, composites reinforced with fibers of synthetic or natural materials are gaining more importance as demands for lightweight materials with high strength for specific applications are growing

[...] Read more.

Composites have been found to be the most promising and discerning material available in this century. Presently, composites reinforced with fibers of synthetic or natural materials are gaining more importance as demands for lightweight materials with high strength for specific applications are growing in the market. Fiber-reinforced polymer composite offers not only high strength to weight ratio, but also reveals exceptional properties such as high durability; stiffness; damping property; flexural strength; and resistance to corrosion, wear, impact, and fire. These wide ranges of diverse features have led composite materials to find applications in mechanical, construction, aerospace, automobile, biomedical, marine, and many other manufacturing industries. Performance of composite materials predominantly depends on their constituent elements and manufacturing techniques, therefore, functional properties of various fibers available worldwide, their classifications, and the manufacturing techniques used to fabricate the composite materials need to be studied in order to figure out the optimized characteristic of the material for the desired application. An overview of a diverse range of fibers, their properties, functionality, classification, and various fiber composite manufacturing techniques is presented to discover the optimized fiber-reinforced composite material for significant applications. Their exceptional performance in the numerous fields of applications have made fiber-reinforced composite materials a promising alternative over solitary metals or alloys.

Full article

►▼

Show Figures

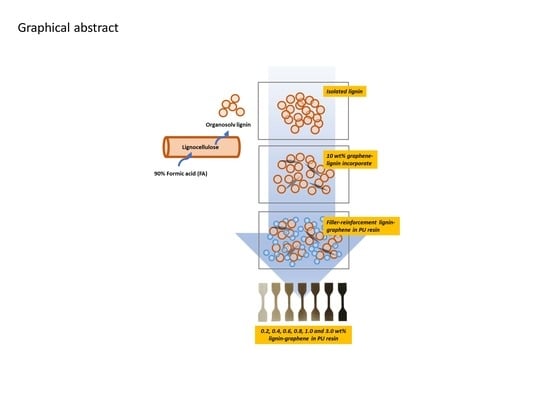

Open AccessArticle

Evaluation of the Compatibility of Organosolv Lignin-Graphene Nanoplatelets with Photo-Curable Polyurethane in Stereolithography 3D Printing

by

Fathirrahman Ibrahim, Denesh Mohan, Mohd Shaiful Sajab, Saiful Bahari Bakarudin and Hatika Kaco

Cited by 48 | Viewed by 4630

Abstract

In this study, lignin has been extracted from oil palm empty fruit bunch (EFB) fibers via an organosolv process. The organosolv lignin obtained was defined by the presence of hydroxyl-containing molecules, such as guaiacyl and syringyl, and by the presence of phenolic molecules

[...] Read more.

In this study, lignin has been extracted from oil palm empty fruit bunch (EFB) fibers via an organosolv process. The organosolv lignin obtained was defined by the presence of hydroxyl-containing molecules, such as guaiacyl and syringyl, and by the presence of phenolic molecules in lignin. Subsequently, the extracted organosolv lignin and graphene nanoplatelets (GNP) were utilized as filler and reinforcement in photo-curable polyurethane (PU), which is used in stereolithography 3D printing. The compatibility as well as the characteristic and structural changes of the composite were identified through the mechanical properties of the 3D-printed composites. Furthermore, the tensile strength of the composited lignin and graphene shows significant improvement as high as 27%. The hardness of the photo-curable PU composites measured by nanoindentation exhibited an enormous improvement for 0.6% of lignin-graphene at 92.49 MPa with 238% increment when compared with unmodified PU.

Full article

►▼

Show Figures

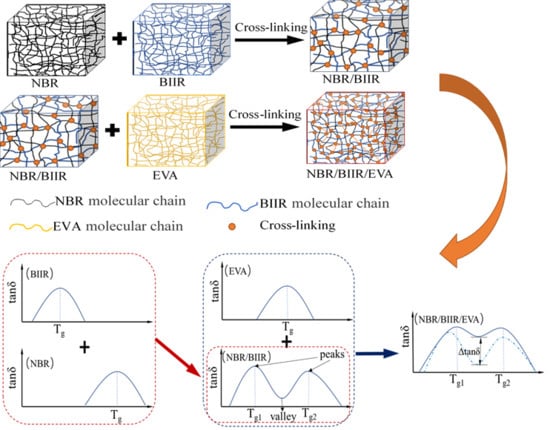

Open AccessArticle

Preparation and Properties of Rubber Blends for High-Damping-Isolation Bearings

by

Tuo Lei, Yong-Wang Zhang, Dong-Liang Kuang and Yong-Rui Yang

Cited by 22 | Viewed by 7268

Abstract

To improve the energy dissipation capacity of rubber isolation bearings, it is important to find a new rubber material with good applicability and high damping properties. Two types of blends were prepared using nitrile rubber (NBR), brominated butyl rubber (BIIR) and ethylene-vinyl acetate

[...] Read more.

To improve the energy dissipation capacity of rubber isolation bearings, it is important to find a new rubber material with good applicability and high damping properties. Two types of blends were prepared using nitrile rubber (NBR), brominated butyl rubber (BIIR) and ethylene-vinyl acetate copolymer (EVA): NBR/BIIR and NBR/BIIR/EVA. The vulcanization, mechanical and damping properties of the blends were analyzed. The results show that both blends exhibit excellent vulcanization plateaus and mechanical properties. For NBR/BIIR, as the BIIR content increases, the complementary effects of NBR and BIIR afforded by blending are enhanced. Two damping peaks appeared in the tanδ-T curve and shifted toward lower and higher temperatures, respectively, which clearly widened the effective damping temperature range. However, the damping value in the valley of the tanδ-T curve was as low as 0.39. For NBR/BIIR/EVA, the addition of EVA greatly increased damping in the valley of the tanδ-T curve to approximately 0.54. EVA was observed to be the optimal polymer for improving the compatibility of the NBR/BIIR blend. Moreover, hot air thermal aging tests showed that both blends demonstrated good stability.

Full article

►▼

Show Figures

Open AccessArticle

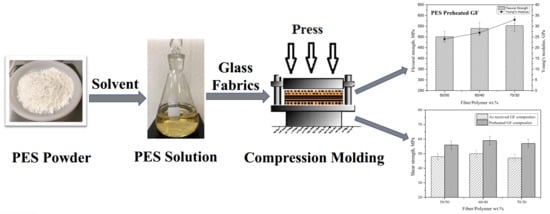

Effect of Formation Route on the Mechanical Properties of the Polyethersulfone Composites Reinforced with Glass Fibers

by

Galal Sherif, Dilyus Chukov, Victor Tcherdyntsev and Valerii Torokhov

Cited by 37 | Viewed by 4315

Abstract

Interfacial interaction is one of the most important factors that affect the mechanical properties of the fiber reinforced composites. The effect of fabrics′ sizing removal from glass fibers’ surface by thermal treatment on the mechanical characteristics of polyethersulfone based composites at different fiber

[...] Read more.

Interfacial interaction is one of the most important factors that affect the mechanical properties of the fiber reinforced composites. The effect of fabrics′ sizing removal from glass fibers’ surface by thermal treatment on the mechanical characteristics of polyethersulfone based composites at different fiber to polymer weight ratios was investigated. Three fiber to polymer weight ratios of 50/50, 60/40, and 70/30 were studied. Flexural and shear tests were carried out to illustrate the mechanical properties of the composites; the structure was studied using Fourier-transform infrared spectroscopy and scanning electron microscopy. It was shown that solution impregnation of glass fabrics with polyethersulfone before compression molding allows to achieve good mechanical properties of composites. The thermal treatment of glass fabrics before impregnation results in an increase in flexural and shear strength for all the composites due to the improvement of fiber–matrix interaction.

Full article

►▼

Show Figures