Polymeric Coatings

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Polymer Chemistry".

Viewed by 42928Editor

Interests: bioinspired surfaces; wetting; biopolymers; polymer nanocomposites

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

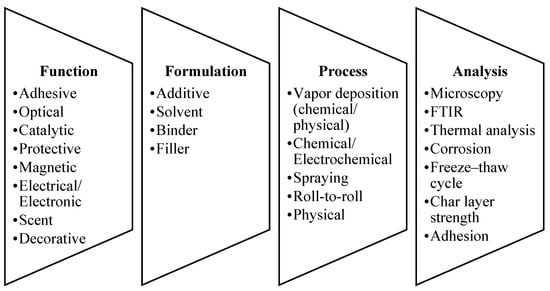

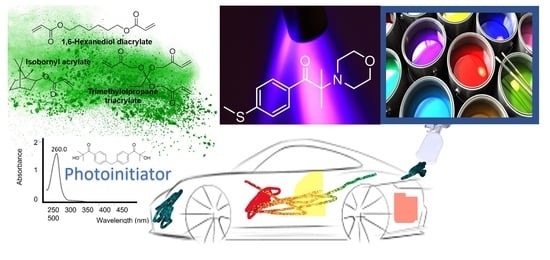

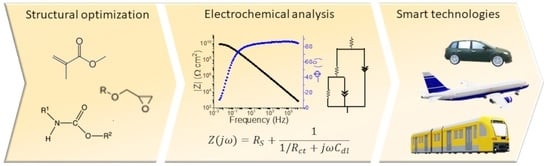

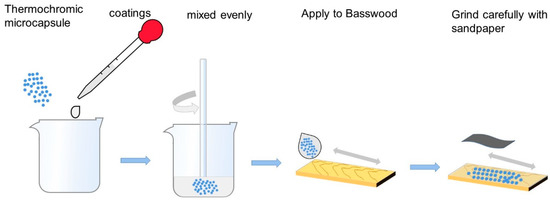

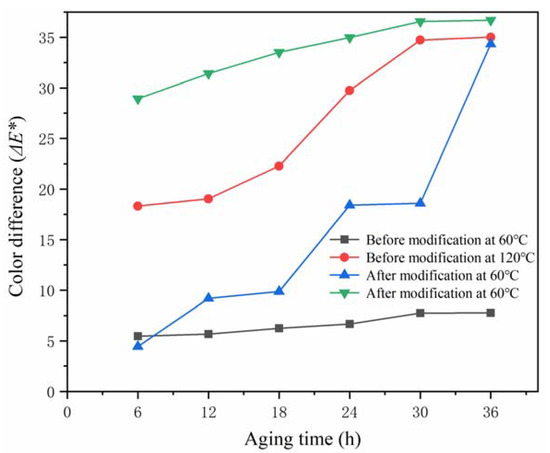

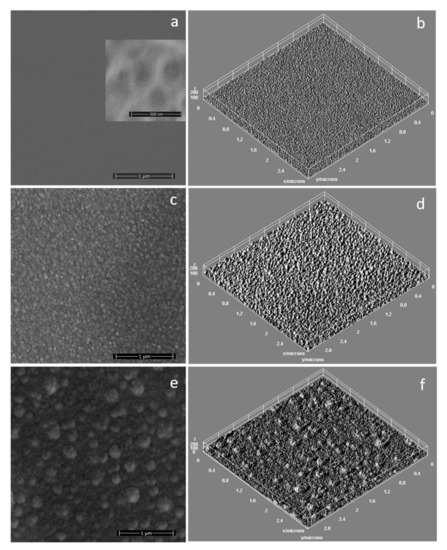

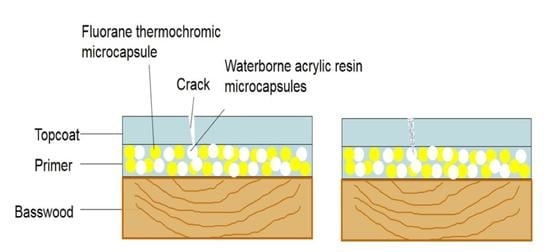

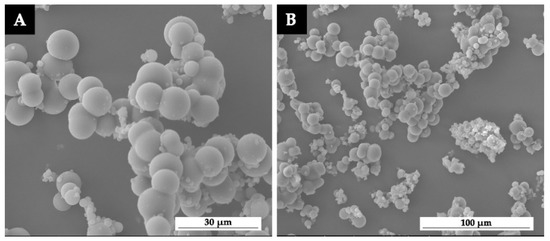

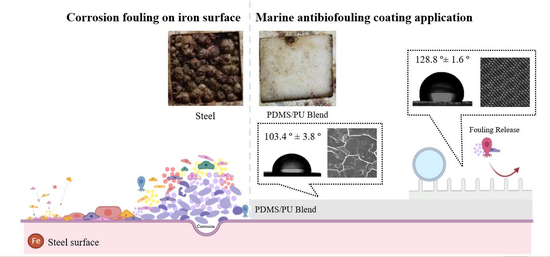

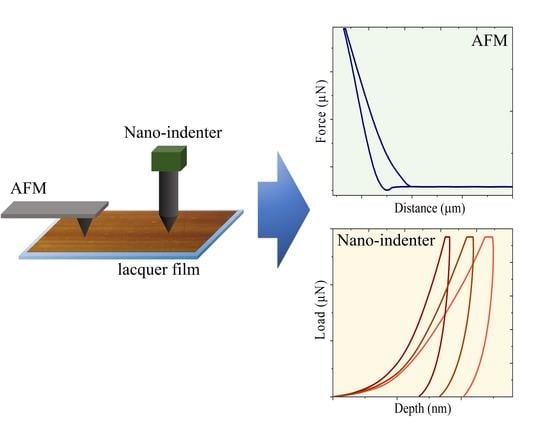

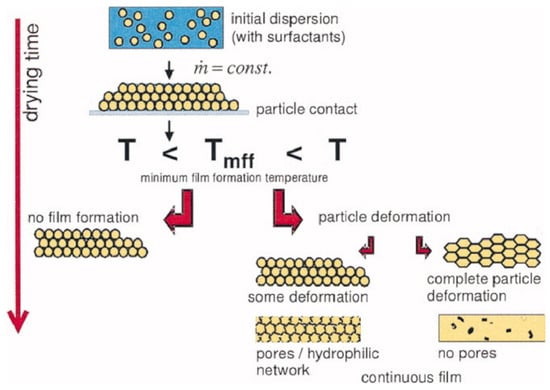

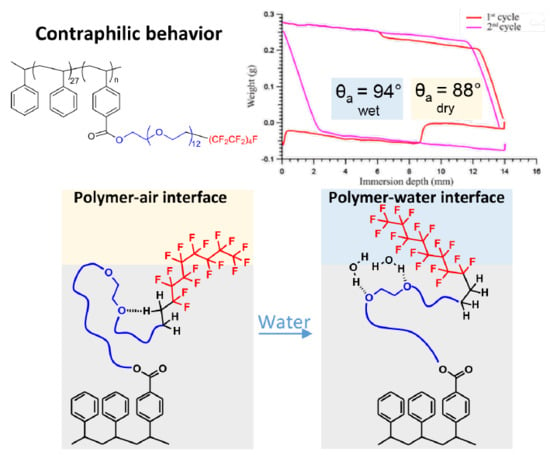

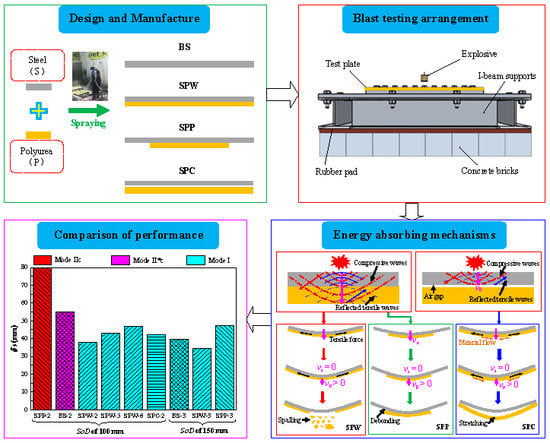

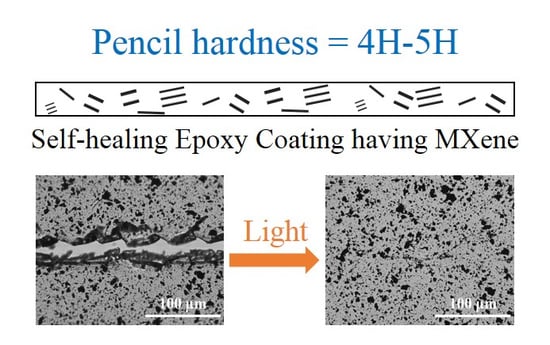

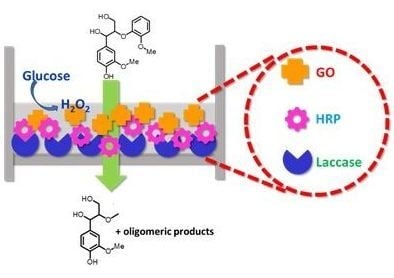

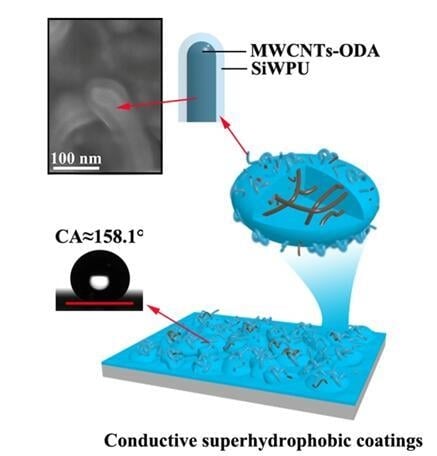

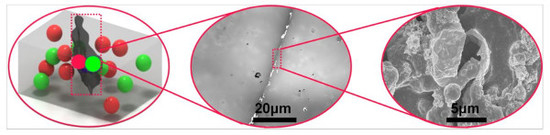

Coatings are an essential part of all surfaces, including “living surfaces” such as our skin. Coatings have been developed to offer decoration, protection, and different special functions. A major portion of coating science and technology relies on advances in polymer science and polymer composites. To this end, polymers in coatings will need to respond to major technological trends, such as ecofriendly materials that require synthesis of novel resins for waterborne, solvent‐free, thermal‐insulating, and air‐purifying coatings. Moreover, polymeric coatings should be made more robust, including better scratch and mar resistance, enhanced corrosion resistance, aging and heat resistance, and anti‐fingerprint performance, to name a few. Polymer composites properly integrated into coatings can lead to multifunctional and smart coatings, having special properties such as self‐cleaning, latent heat storing, bionic anti‐fouling, self‐healing, light/heat/electricity conducting, and regulating and sensory coatings. Incorporating one or more of these functions into polymer coatings is not an easy task. However, advances in polymerization methods, emulsion science and technology, new organic–inorganic hybrid systems, as well as principles of nanotechnology and self‐assembly can lead to robust multifunctional polymer coatings with strong technological implications. This Special Issue mainly focuses on any one of these polymeric materials, composites, and functionalities that can be used to make or render coatings “special” and will be of interest to all professionals, industrial practitioners, as well as researchers and graduate students in the fields of polymers chemistry and engineering, coatings materials science, and chemical engineering that need to know the most recent advances in functional polymer coatings.

Prof. Dr. Ilker S. Bayer

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- non-wettable coatings

- conductive coatings

- biodegradable coatings

- self-healing coatings

- anti-fouling coatings

- sensory coatings

- stretchable and bendable conformal coatings

Related Special Issues

- Surface Modification and Functional Coatings for Polymers in Polymers (15 articles - displayed below)

- Functional Polymer Coatings in Polymers (11 articles - displayed below)

- Functional Polymer Coatings II in Polymers (9 articles - displayed below)

- Advances in Polymer Based Composite Coatings in Polymers (10 articles - displayed below)

- Advances in Polymer Based Composite Coatings II in Polymers (5 articles - displayed below)