Nanomaterials and Textiles

A special issue of Nanomaterials (ISSN 2079-4991). This special issue belongs to the section "Nanocomposite Materials".

Deadline for manuscript submissions: 10 May 2024 | Viewed by 9024

Special Issue Editors

Interests: functi onal textiles; high performance fibers; textile mate rials; dyeing; printing; spectroscopy; sol gel technology; polymers; coatings; radiation protection; pigments; particles; natural materials; material science; chemistry

Interests: biopolymers; electrospinning; magnetism; spintronics; optics; dye-sensitized solar cells (DSSCs); smart textiles

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

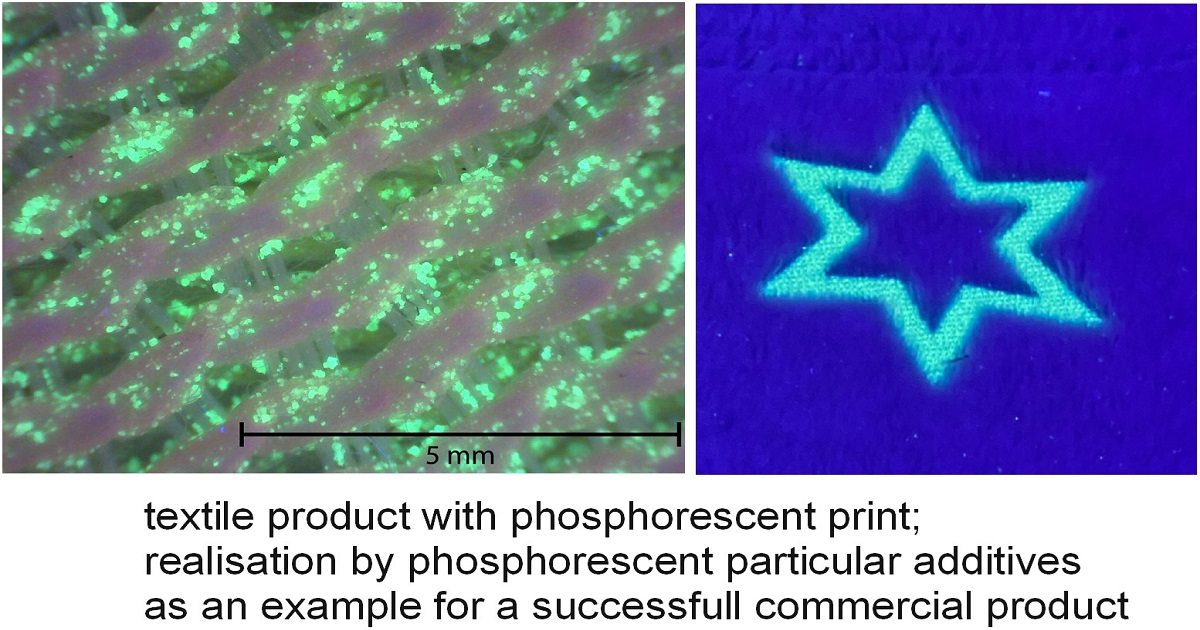

When nanomaterials meet textiles, innovative new materials meet successful conventional fiber-based materials. This Special Issue will give an overview on all kinds of nanomaterials and their advantageous applications on textile-based materials for the realization of new materials with advanced or completely new properties. Prominent examples in this field are related to nanoparticular (sol-gel based) finishing agents for antimicrobial or flame-retardant functionalization; embedding particles in fibers during spinning processes to reach radiation protective properties; phosphorescence inorganic particles or fluorescent carbon quantum dots for the realization of luminescent effects. A broad field for nanomaterials and textiles is as well electrospinning, opening up e.g., the chance for the creation of new functional filter materials.

In summary, this Special Issue will present comprehensive research outlining progress in the field of nanomaterials and textiles - the application of nanomaterials to improve the performance of textiles or initiate even new functional properties. This includes the utilization of nanoparticular finishing agents, new printing technology, fiber modification by spin-doping or electrospinning techniques, and similar techniques. We invite authors to contribute original research articles and review articles covering the current progress on nanomaterials and textiles. Potential topics include, but are not limited to:

- Nanoparticular finishing agents

- Sol-gel technology

- Surface structuring of textiles (nanostructuring)

- Photoactive materials

- Printing processes and nanoparticular additives

- Functional textiles – in the area of antimicrobial, flame-retardant, UV-protective textiles, etc.

- Application of graphene, graphene-oxide, or carbon quantum dot materials

- Fiber modification by spin-doping

- Electrospinning

- Nanomaterials in composites and fiber-reinforced materials

Prof. Dr. Boris Mahltig

Prof. Dr. Andrea Ehrmann

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Nanomaterials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2900 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- nanomaterials

- textiles

- fibers

- non-woven

- sol-gel technology

- electrospinning

- nanostructuring, functional textiles