Manufacturing Engineering and Mechanical Properties of Composite Materials

A topical collection in Materials (ISSN 1996-1944). This collection belongs to the section "Advanced Composites".

Viewed by 120465Editor

Interests: advanced material processing; multi-material micro manufacturing; additive manufacturing; composite materials; smart materials; interconnect devices; micro mechanical systems

Topical Collection Information

Dear Colleagues,

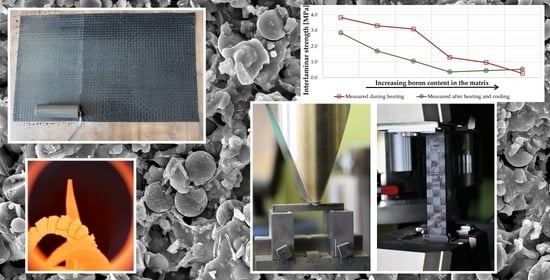

Composite materials play a significant role in the development of modern science and technology. They have a broad and proven range of applications in various engineering fields, including aerospace, architecture, automotive, energy, military, and sports, and are replacing traditional materials at a growing pace. Recent advances in materials and manufacturing technologies have provided possibilities for many novel applications of composite materials in highly demanding engineering fields. Multifunctional properties, possibilities to tailor the properties, and the potential to manufacture the materials into precise and complex shapes have made composites very lucrative at the present state of technology.

However, we still face many challenges in the manufacturing and processing of composites. The price of the raw materials, the complex manufacturing process, difficulties with the process physics, complex synergistic relations with the process variables, and difficulties with quality control are but a few. The widespread application of composites calls for low-cost, low-defect, industrially adaptive, and automated manufacturing processes. A clear understanding of the processing fundamentals and the properties of the final parts is required for successful applications of composite materials. Continuous research into the subject area is essential to enriching our understanding and helping us to overcome design and manufacturing challenges in the present and future industrial scenarios.

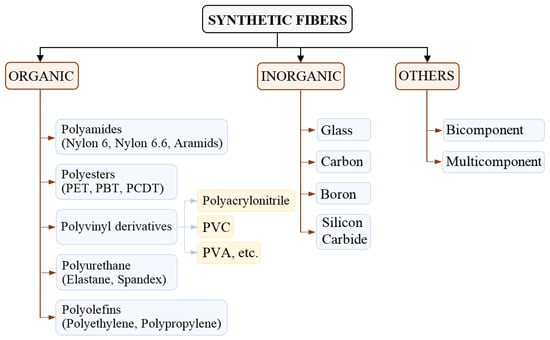

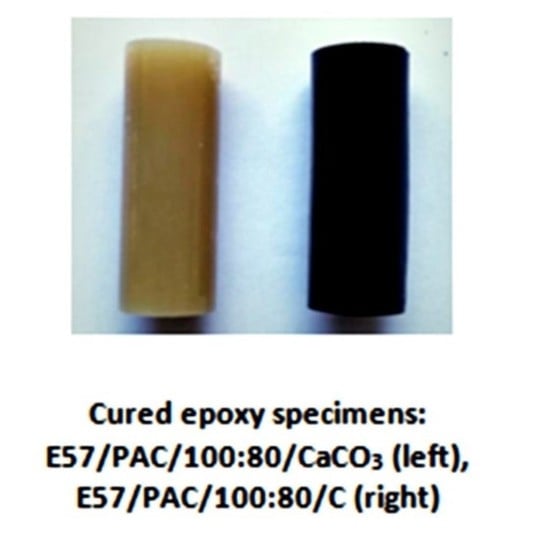

This Special Issue of Materials focuses on all aspects of current scientific and technological progress related to the manufacturing of composite materials and products. Topics of interest include mechanical and structural properties of composites as well as their constituent materials; experimental and theoretical studies relating to composites; manipulation of properties through manufacturing and processing; modeling and simulations; microscopic to macroscopic behavior; and performance verification techniques. This Special Issue places emphasis on more novel areas of composites, such as nanocomposites, hybrid composites, biomedical composites, intelligent and autonomic composites (e.g., self-healing, self-sensing, and self-reinforcing composites), ultra-high-performance composites, sustainability in composite material processing, the recyclability of composites, digital manufacturing, and virtual testing.

It is my pleasure to invite you to submit a manuscript for this Special Issue. Full papers, communications, and reviews that address advances in the manufacturing and performance of composite materials are welcome.

Prof. Dr. Aminul IslamGuest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- composites

- hybrid composites

- nanocomposites

- autonomic composites

- mechanical properties

- tensile and compressive loads

- manufacturing technology

- additive manufacturing

- automated manufacturing

- process optimization

- modeling and simulation

- defects and damage

- destructive and nondestructive testing

- applications of composites.