Advances in Binders for Construction Materials (Second Volume)

A special issue of Materials (ISSN 1996-1944). This special issue belongs to the section "Construction and Building Materials".

Deadline for manuscript submissions: 20 July 2024 | Viewed by 3133

Special Issue Editor

Interests: binders; construction building materials; historic mortars; heritage conservation; nanolime; deterioration; inorganic porous building materials; monument repair

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

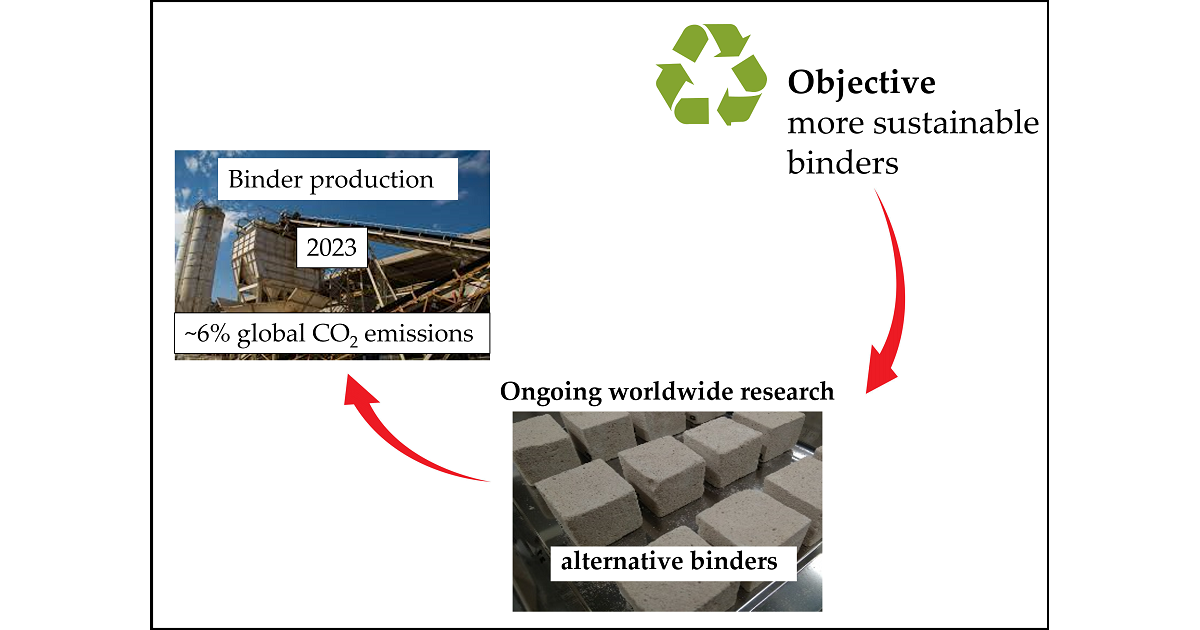

The global binder production for construction materials is approximately 7.5 billion tons per year, contributing ~6% to the global anthropogenic atmospheric CO2 emissions. Reducing this carbon footprint is a key aim of the construction industry, and current research focuses on developing new innovative ways to attain more sustainable binders and concrete/mortars as a real alternative to the current global demand for Portland cement.

With this aim, several potential alternative binders are currently being investigated by scientists worldwide, based on calcium aluminate cement, calcium sulfoaluminate cement, alkali-activated binders, calcined clay limestone cements, nanomaterials, or supersulfated cements. This Special Issue welcomes contributions that address research and practical advances in i) alternative binder manufacturing processes; ii) chemical, microstructural, and structural characterization of unhydrated binders and of hydrated systems; iii) the properties and modelling of concrete and mortars; iv) applications and durability of concrete and mortars; and v) the conservation and repair of historic concrete/mortar structures using alternative binders.

This Special Issue volume II will focus on papers with a broad interest in the binder industry and construction community, based upon the novelty and quality of the results and the real potential application of the findings to the practice and industry.

Dr. Jorge Otero

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- binders

- mortars

- renders

- grouts

- building materials

- lime

- cement

- concrete

- alkali-activated materials

- alternative binders

- high-performance concrete

- geopolymers

- gypsum

- calcium aluminate cement

- nanolime

- supersulfated cements

- calcium sulfoaluminate binders

- mortar additives

- Roman fly ash

- cementitious composites

- calcined clay limestone cements

- natural pozzolans

- hybrid binders

- nanomaterials

- durability

- life cycle assessment

- recycled materials

- waste management

- environmental assessment

- repair of historic construction materials

- concrete conservation

- case studies