Computational Product Design with Artificial Intelligence (Closed)

A topical collection in Machines (ISSN 2075-1702).

Viewed by 10031Editors

Interests: networked digital manufacturing; service-oriented manufacturing systems engineering; RFID/ IOT; logistics engineering; product family design theory; collaborative engineering

Special Issues, Collections and Topics in MDPI journals

Interests: distributed and sustainable manufacturing; circular economy; informatics; advanced manufacturing; artificial intelligence; design; engineering design

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

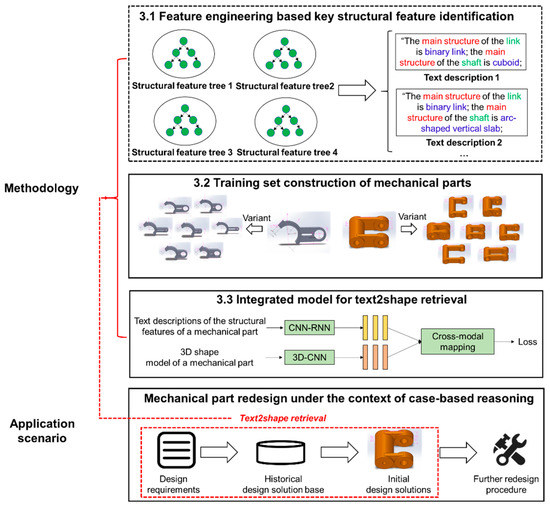

Computational product design (CPD) can be roughly separated into innovation categories of experience-driven, model-driven, and data-driven design. Experience-driven CPD usually applies methods such as case-based, ontology-based, and rule-based reasoning, knowledge graphs, etc., to reuse explicit design experience from experts. Model-driven CPD usually begins by building the geometrical, functional, or mechanistic models of the design targets and then conducting different kinds of simulations, optimization procedures, or design calculations. Data-driven CPD usually depends on extracting design-related information from historical data with machine learning algorithms to support different forms of design solution generation, optimization, evaluation, decision making, etc.

Rapid-developing artificial intelligence (AI) techniques have recently brought radical changes to the manufacturing industry in the fields of intelligent manufacturing and services. However, the application of AI in CPD is still in its infancy, and the exploitation of AI to realize improved innovation, efficiency, cost reduction, etc., in CPD still requires further exploration.

In this regard, this Topical Collection aims to share research related to AI and its application in CPD, from design requirement analysis to detailed design and design evaluation. Original research articles, reviews, communications and technical notes are welcome, and the topics covered may include, but are not limited to:

- Theory and framework on computational product design methodology with artificial intelligence;

- Computational geometry and graphics issues in product design;

- Datasets and deep learning for 3D shapes and product semantics;

- Representation learning for 3D shapes and product semantics;

- Intelligent generative and retrieval models for product design including text2shape, voice2shape, sketch2shape, image2shape, graph2shape, etc.;

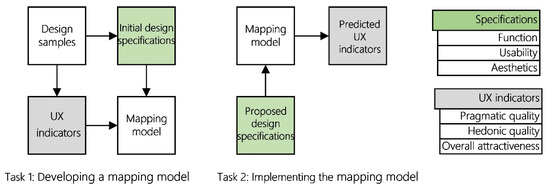

- AI-assisted UX design;

- AI-assisted design information and knowledge management;

- AI-assisted decision-making for design;

- Data-driven approaches for conceptual design;

- Design process modelling with artificial intelligence including knowledge graphs;

- Finite element analysis and optimization;

- Machine learning-based topology optimization;

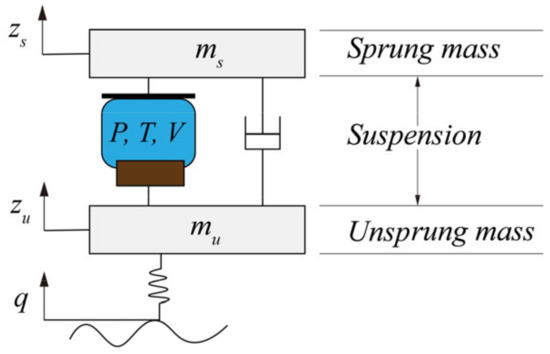

- Bond graphs and Modelica for dynamics issues in early-stage product design;

- Design optimizations with swarm intelligence;

- Intelligent parameterized CAD;

- Product design under the context of social manufacturing;

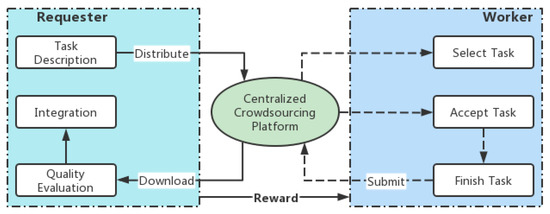

- Collaborative design with collective intelligence including crowdsourcing;

- Industrial Internet for open product design;

- Kansei engineering and emotional computing in product design;

- Smart generative design for additive manufacturing;

- Smart conceptual design methods;

- Design for smart products using AI and machine learning

- Smart product family and platform design;

- Intelligent design for product-service systems;

- Smart maintenance design for products;

- Computational layout design and digital simulation for manufacturing systems;

- Case studies for industrial applications.

Please notice that authors can submit their papers to the Topical Collection at any time. Papers will be published online immediately after their acceptance and without delay caused by whether all paper collections are ready. It is different from the policy of traditional special issue.

Prof. Dr. Pingyu Jiang

Prof. Dr. Ying Liu

Dr. Maolin Yang

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Machines is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.