Women in Thermal Management

A topical collection in Energies (ISSN 1996-1073). This collection belongs to the section "J: Thermal Management".

Viewed by 10356Editors

2. KU Leuven, Department of Mechanical Engineering, B-3000 Leuven, Belgium

Interests: demand side management; heat pumps; energy efficiency; renewable energy; energy transition; energy flexibility

Special Issues, Collections and Topics in MDPI journals

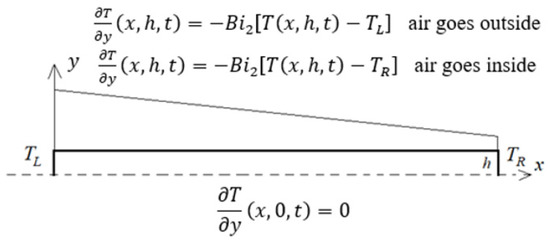

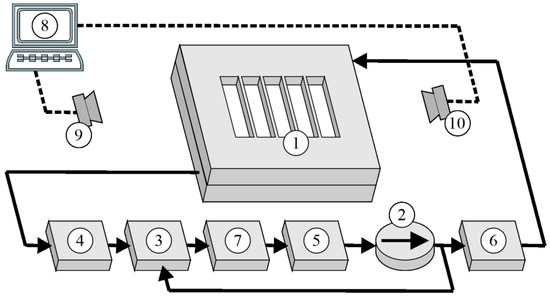

Interests: heat transfer; minichannels; minigaps; compact heat exchangers; two-phase flow; heat transfer enhancement; temperature measurement; computational methods for solving inverse heat transfer problems; thermal and production engineering; quality management tools

Special Issues, Collections and Topics in MDPI journals

Interests: thermal investigation of ICs and MEMS; thermal sensors; thermal testing; thermal simulation; thermal model generation; electro-thermal simulation; CPS systems

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

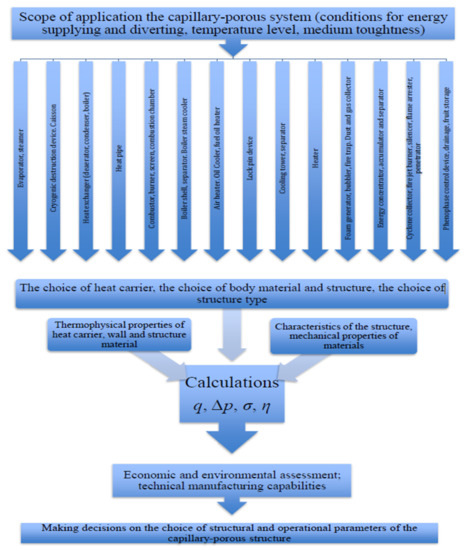

Topical Collection "Women in Thermal Management" is dedicated to scientists who deal with thermal engineering topics such as energy efficiency, renewable energy, heat transfer processes (especially in small channels, including mathematical modeling and computational methods for solving heat transfer problems), production engineering and management, electro-thermal testing, as well as simulation and model generation using cyber-physical systems. We strongly encourage the submission of papers that focus on these issues and understand the importance of innovation and creative approaches in science.

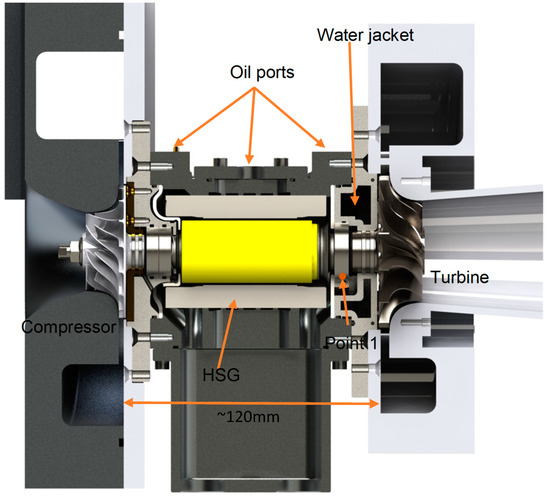

One essential interest of this issue is energy efficiency regarding heat transfer during fluid flow in channels of small dimensions. The combination of stricter energy performance requirements with the continuing trend towards miniaturization (e.g., for refrigerant charge reduction in heat pumps and chillers) has made thermal management a key issue in engineering research. As a result, increasingly advanced methods are being employed to intensify heat transfer. One of the key aspects is heat transfer with phase change, which is known to increase the efficacy of the process. Various solutions can be applied to support heat transfer during fluid flow, such as changing the geometrical parameters, the use of nanofluids, or the application of enhanced heating surfaces. We invite papers discussing engineering design in this field, in combination with production engineering (e.g., additive manufacturing) and management.

Prof. Dr. Alessia Arteconi

Prof. Dr. Magdalena Piasecka

Prof. Dr. Márta Rencz

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Energies is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- heat pumps

- minigaps

- minichannels

- compact heat exchangers

- heat transfer enhancement

- two-phase flow

- computational methods for solving heat transfer problems

- thermal management

- refrigerant charge reduction

- additive manufacturing

- production engineering

- renewable energy

- energy efficiency

- quality management tools

- quality function deployment (QFD)