Advanced Functional Nanostructured Films and Coatings for Energy Applications

A special issue of Coatings (ISSN 2079-6412). This special issue belongs to the section "Thin Films".

Deadline for manuscript submissions: closed (31 March 2024) | Viewed by 18641

Special Issue Editor

Interests: functional materials; graphene; nanocomposites; polymer-embedded nanostructures

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

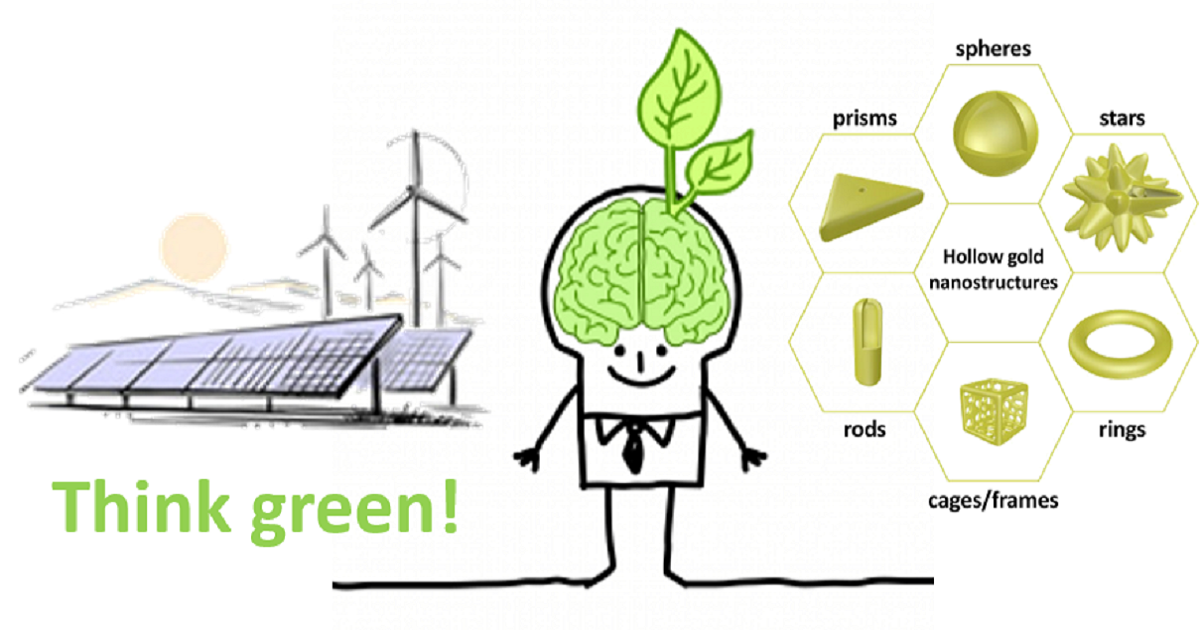

Advanced functional nanomaterials could have a fundamental role in the building of a novel sustainable world. Devices for energy production, conversion and storage (solar cells, batteries, supercapacitors, thermoelectric materials, phase-change materials, advanced thermal insulators, etc.) combine a number of highly specialized components (i.e., solid or liquid phases having highly specific characteristics) and each of these elements can be conveniently made of hybrid/composite nanostructured materials in order to allow the device to reach optimal performance in service. To reduce raw material use and manufacturing costs, complex natural nanostructured substances and/or their chemically modified forms could be very relevant for such challenging innovation targets. However, it is essential to be able to develop adequate artificial substances with properties coming from the mesoscopic world. Chemical synthesis and material engineering act together in this novel exciting research field of nanomaterial science, which will play a decisive role for the comfort of our future lives. This Special Issue aims to collect state-of-the-art papers on any topics related to nanomaterials for energy applications in the form of films or coatings, such as nanostructured materials that allow transition from combustion engines to electrified vehicles, the development of emission-free energy sources for home and industry, nanostructured materials highly capable of storing heat and solar energy, highly efficient thermal insulators, etc. In particular, among the different available classes of nanostructured films and coatings for energy applications, special attention will be addressed to very uncommon and niche solutions.

Dr. Gianfranco Carotenuto

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Coatings is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- nanostructured films and coatings

- functional nanomaterials

- nanomaterials for energy applications

- mesoscopic properties

- nanoparticles

- nanocomposites

- natural nanostructures