Advanced Concrete Materials in Construction

A topical collection in Buildings (ISSN 2075-5309). This collection belongs to the section "Building Materials, and Repair & Renovation".

Viewed by 142171Editor

Interests: concrete durability; composite design; supplementary cement materials; self-healing technologies; anorganic binders; admixtures and additives; structure diagnosis

Topical Collection Information

Dear Colleagues,

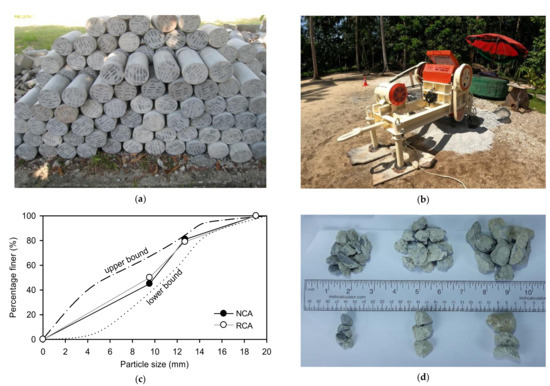

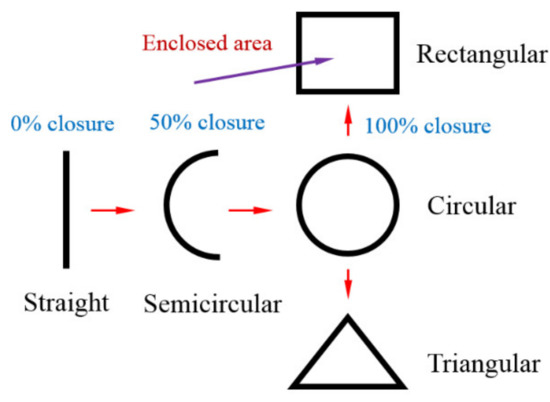

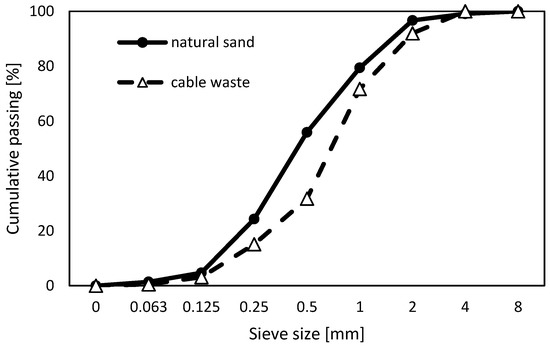

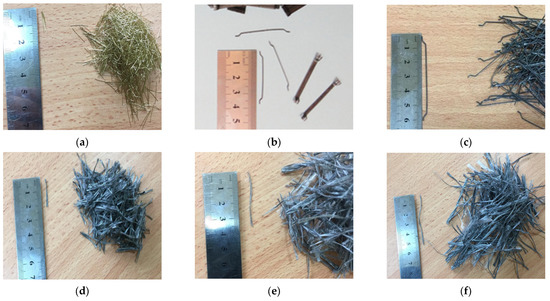

Advanced concrete materials used in building construction belong to the branch of composite engineering, which has exhibited dynamic development in last years. Various concrete materials have been used in civil engineering for thousands years using traditional—predominantly natural—resources. However, current changes of the climate and in the environment require a responsible approach to building design and the exploitation of natural resources. The development of advanced concrete composites which are “made to measure” is a main scientific interest. Hence, various waste materials are incorporated in concrete materials to meet this global effort. On the other hand, the preservation of the required properties and resistance to environmental action are necessary for the sustainability of our civilization. This Topical Collection deals with research and studies of the development of new advanced concrete materials; the incorporation of waste materials, techniques, and methodologies for the assessment of their specific properties; and the development of concrete materials for severe conditions. The protection of historical monuments requires advanced solutions, and hence related works are encouraged.

Original research (theoretical and experimental), case studies, and comprehensive review papers are invited for possible publication in this Topical Collection. Relevant topics to this Topical Collection include, but are not limited to, the following subjects:

- Advanced binder systems;

- Advanced design methods;

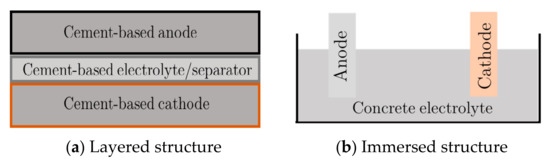

- Concrete materials in severe conditions;

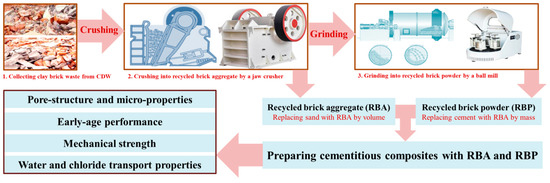

- Sustainability and recycling;

- High-performance composites;

- Experimental methods and techniques;

- Protection of cultural heritage.

Dr. Pavel Reiterman

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Buildings is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- composite engineering

- durability

- sustainability

- recycling

- waste materials

- binder systems

- cement supplementary materials

- admixtures

- additives