Sustainable Use of Construction and Structural Materials (to Meet the United Nations Sustainable Development Goals-SDG)

Share This Topical Collection

Editor

Prof. Dr. Jamal Khatib

Prof. Dr. Jamal Khatib

Prof. Dr. Jamal Khatib

Prof. Dr. Jamal Khatib

E-Mail

Website

Collection Editor

1. Civil Engineering, University of Wolverhampton, Wulfruna Street, Wolverhampton WV1 1LY, UK

2. Faculty of Engineering, Beirut Arab University, Beirut 11 5020, Lebanon

Interests: construction and structural materials

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

Climate change, the increase in human population and the decrease in natural resources have alerted many governments in the world to start taking serious actions towards a sustainable future. This is demonstrated by the 2030 agenda for sustainable development set by the United Nations in order to meet the various challenges facing the world. Construction is often necessary in order to meet the need for the growing population. This includes building, road, bridges and tunnels. This collection will focus on producing building and construction materials in a sustainable manner. Utilisation of waste, recycled, local and natural materials will serve the purpose of this collection. It is expected the research submitted to this issue will consist of efficient production process materials and efficient design through the use lightweight materials. This will include an economic way to produce the materials and the reduction in the quantities of materials used. Papers related to the innovative use and production of construction and building materials will be welcome.

Prof. Dr. Jamal Khatib

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Buildings is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- building and construction materials

- waste in construction

- materials production

- lightweight materials

- structural materials

- natural materials

- sustainable construction

- recycling

Published Papers (4 papers)

Open AccessArticle

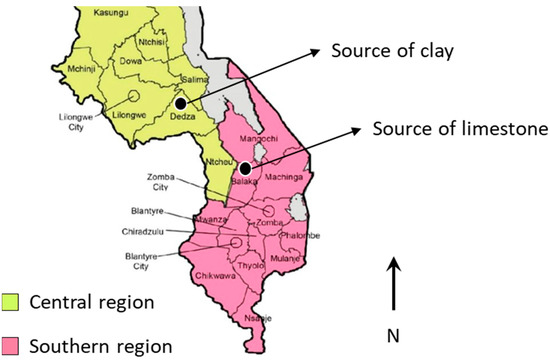

Mechanical Performance and Physico-Chemical Properties of Limestone Calcined Clay Cement (LC3) in Malawi

by

Innocent Kafodya, Debojyoti Basuroy, Joseph Mwiti Marangu, Grant Kululanga, Riccardo Maddalena and Viviana Iris Novelli

Cited by 4 | Viewed by 2427

Abstract

Malawi is one of the least-developed countries in Sub-Saharan Africa with disaster-prone housing infrastructure characterized by poor construction materials. Therefore, there is a need to provide resilient and cost-effective materials, such as limestone calcined clay cement (LC3). However, the exploitation of LC3 in

[...] Read more.

Malawi is one of the least-developed countries in Sub-Saharan Africa with disaster-prone housing infrastructure characterized by poor construction materials. Therefore, there is a need to provide resilient and cost-effective materials, such as limestone calcined clay cement (LC3). However, the exploitation of LC3 in Malawi is limited due to a lack of mineralogical information about the clays and limestone and related strength and durability when used as a cementitious material. In this study, the strength and physico-chemical properties of LC3 systems with 50% and 40% clinker contents (LC3-50 and LC3-40) were investigated. Cement mortar specimens were prepared at water to cement (w/c) ratios of 0.45, 0.5, and 0.6 with varying calcined clay (CC) to limestone (CC/LS) ratios (1:1, 2:1, and 3:1). The effects of CC/LS ratio on the fresh properties, strength, and durability were investigated. The results showed that specimens with 40% Portland cement replacement levels (LC3-40) exhibited higher standard consistency (up to 45%) than LC3-50, porosity in the range of 8.3–13.3%, and maximum water uptake in the range of 3.8–10.9%. On the other hand, LC3-50 samples offered the highest strength of approximately 40 MPa, complying with requirements for pozzolanic cementitious materials, whereas LC3-40 conforms to the strength requirements for masonry cements. This work shows that LC3 systems can be manufactured with local clays and limestone available in Malawi, and used as a sustainable construction material to mitigate carbon emissions as well as boost the local economy.

Full article

►▼

Show Figures

Open AccessArticle

MSWIBA Formation and Geopolymerisation to Meet the United Nations Sustainable Development Goals (SDGs) and Climate Mitigation

by

Nikolina Poranek, Beata Łaźniewska-Piekarczyk, Adrian Czajkowski and Krzysztof Pikoń

Cited by 9 | Viewed by 1664

Abstract

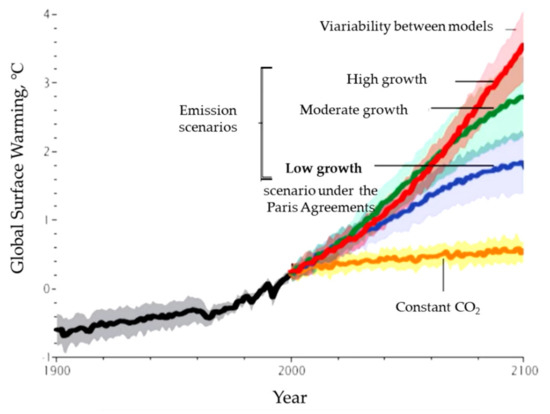

Sustainable Development Goals (SDGs) constitute an action plan for the environment and people. One of the main goals is to limit the increase in global average temperature to 2 °C and aim for a stop at 1.5 °C. The goals of the circular

[...] Read more.

Sustainable Development Goals (SDGs) constitute an action plan for the environment and people. One of the main goals is to limit the increase in global average temperature to 2 °C and aim for a stop at 1.5 °C. The goals of the circular economy (CE) are in line with the SDGs. In the waste management chain, the last CE element is a recovery in the municipal solid waste incineration plant (MSWIP). However, during recovery, municipal solid waste bottom ash (MSWIBA) is created (in about 30% of the bunch). The development of MSWIBA in the construction industry is a possibility of closing the cycle. This article shows the MSWIBA formation process, alkali pre-treatment of MSWIBA, and its geopolymerisation. Studies have determined the mechanical properties of geopolymer with MSWIBA and leachability from crushed and from monolith geopolymer. Alkali pre-treatment improves MSWIBA mechanical properties and upgrades immobilisation. Moreover, geopolymerisation is a better solution than concreting, because of the lack or low consumption of high-emission and energy-intensive cement. A SWOT analysis was carried out for the proposed solution.

Full article

►▼

Show Figures

Open AccessArticle

Cost Factor Analysis for Timber–Concrete Composite with a Lightweight Plywood Rib Floor Panel

by

Karina Buka-Vaivade, Dmitrijs Serdjuks and Leonids Pakrastins

Cited by 8 | Viewed by 2454

Abstract

With the growing importance of the principle of sustainability, there is an increasing interest in the use of timber–concrete composite for floors, especially for medium and large span buildings. Timber–concrete composite combines the better properties of both materials and reduces their disadvantages. The

[...] Read more.

With the growing importance of the principle of sustainability, there is an increasing interest in the use of timber–concrete composite for floors, especially for medium and large span buildings. Timber–concrete composite combines the better properties of both materials and reduces their disadvantages. The most common choice is to use a cross-laminated timber panel as a base for a timber–concrete composite. But a timber–concrete composite solution with plywood rib panels with an adhesive connection between the timber base and fibre reinforced concrete layer is offered as the more cost-effective constructive solution. An algorithm for determining the rational parameters of the panel cross-section has been developed. The software was written based on the proposed algorithm to compare timber–concrete composite panels with cross-laminated timber and plywood rib panel bases. The developed algorithm includes recommendations of forthcoming Eurocode 5 for timber–concrete composite design and an innovative approach to vibration calculations. The obtained data conclude that the proposed structural solution has up to 73% lower cost and up to 71% smaller self-weight. Thus, the proposed timber–concrete composite construction can meet the needs of society for cost-effective and sustainable innovative floor solutions.

Full article

►▼

Show Figures

Open AccessArticle

The Effect of Adding Phragmites australis Fibers on the Properties of Concrete

by

Meheddene Machaka, Jamal Khatib, Safaa Baydoun, Adel Elkordi and Joseph J. Assaad

Cited by 11 | Viewed by 2997

Abstract

Nowadays, the increasing demand for concrete is causing serious environmental impact including pollution and waste generation, rapid depletion of natural resources, and increased CO

2 emission. Incorporating natural fibers in concrete can contribute toward environmental sustainability. This paper is concerned with the use

[...] Read more.

Nowadays, the increasing demand for concrete is causing serious environmental impact including pollution and waste generation, rapid depletion of natural resources, and increased CO

2 emission. Incorporating natural fibers in concrete can contribute toward environmental sustainability. This paper is concerned with the use of natural fibers obtained from the plant species

Phragmites australis (PA). The plant is invasive, and rapidly grows abundantly along rivers and waterways, causing major ecological problems. This research is part of a wide range investigation on the use of natural fibers produced from the stem of PA plants in concrete. Using a machine, plant stems were crushed into fibers measuring 40 mm in length and 2 mm in width, and treated with 4% NaOH solution for 24 h. A total of four concrete mixes were prepared with varying additions of treated fibers, ranging from 0% to 1.5% (by volume) with water to cement ratio of 0.5% (by volume). Concrete specimens were tested at 3, 7, and 28 days. Testing included compressive strength, density, total water absorption, and capillary water absorption. The results show that incorporating PA natural fibers reduces the water absorption by total immersion and capillary action by up to 45%. Moreover, there is a negligible decrease in concrete density and strength when fibers were added. It is concluded that adding up to 1.5% natural PA fibers to concrete is a feasible strategy to produce an eco-friendly material which can be used in the production of sustainable building material with adequate mechanical and durability performance.

Full article

►▼

Show Figures