Journal Description

Alloys

Alloys

is an international, peer-reviewed, open access journal on all aspects of alloys science and engineering, published quarterly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- Rapid Publication: first decisions in 16 days; acceptance to publication in 5.8 days (median values for MDPI journals in the second half of 2023).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

- Alloys is a companion journal of Metals.

Latest Articles

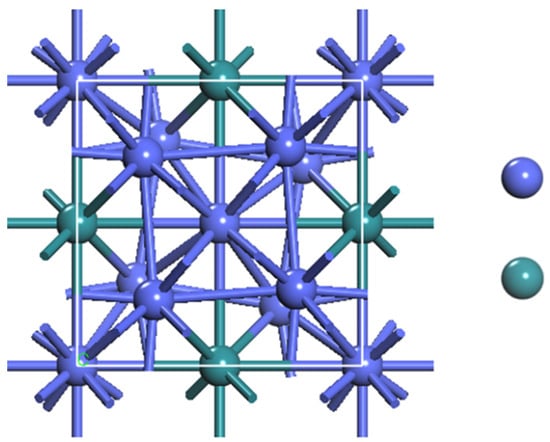

First-Principles Study on Thermodynamic, Structural, Mechanical, Electronic, and Phonon Properties of tP16 Ru-Based Alloys

Alloys 2024, 3(2), 126-139; https://doi.org/10.3390/alloys3020007 - 15 Apr 2024

Abstract

►

Show Figures

Transition metal-ruthenium alloys are promising candidates for ultra-high-temperature structural applications. However, the mechanical and electronic characteristics of these alloys are not well understood in the literature. This study uses first-principles density functional theory calculations to explore the structural, electronic, mechanical, and phonon properties

[...] Read more.

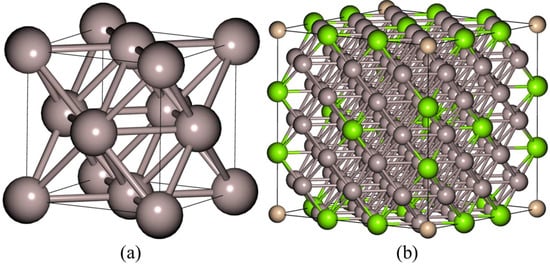

Transition metal-ruthenium alloys are promising candidates for ultra-high-temperature structural applications. However, the mechanical and electronic characteristics of these alloys are not well understood in the literature. This study uses first-principles density functional theory calculations to explore the structural, electronic, mechanical, and phonon properties of X3Ru (X = Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, and Zn) binary alloys in the tP16 crystallographic phase. We find that Mn3Ru, Sc3Ru, Ti3Ru, V3Ru, and Zn3Ru have negative heats of formation and hence are thermodynamically stable. Mechanical analysis (Cij) indicates that all tP16-X3Ru alloys are mechanically stable except, Fe3Ru and Cr3Ru. Moreover, these compounds exhibit ductility and possess high melting temperatures. Furthermore, phonon dispersion curves indicate that Cr3Ru, Co3Ru, Ni3Ru, and Cu3Ru are dynamically stable, while the electronic density of states reveals all the X3Ru alloys are metallic, with a significant overlap between the valence and conduction bands at the Fermi energy. These findings offer insights into the novel properties of the tP16 X3Ru intermetallic alloys for the exploration of high-temperature structural applications.

Full article

Open AccessReview

Mechanism of Electropulsing Treatment Technology for Flow Stress of Metal Material: A Review

by

Bobo Lu, Kai Tang, Mingxia Wu, Yi Yang and Gang Yang

Alloys 2024, 3(1), 96-125; https://doi.org/10.3390/alloys3010006 - 21 Mar 2024

Abstract

►▼

Show Figures

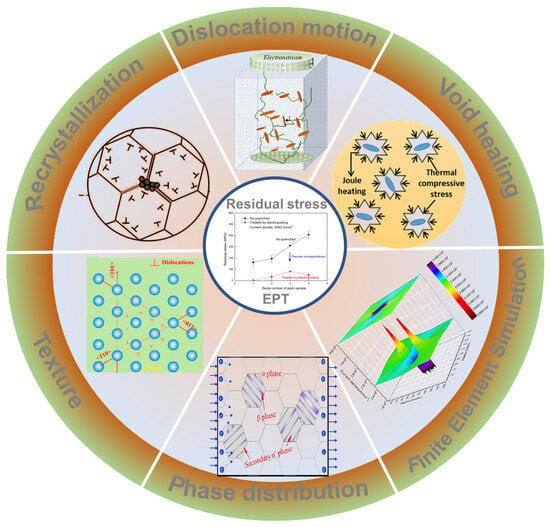

Residual stress is caused by non–uniform deformation caused by non–uniform force, heat and composition, which is of great significance in engineering applications. It is assumed that the residual stress is always the upper limit of the elastic limit, so the reduction of the

[...] Read more.

Residual stress is caused by non–uniform deformation caused by non–uniform force, heat and composition, which is of great significance in engineering applications. It is assumed that the residual stress is always the upper limit of the elastic limit, so the reduction of the flow stress will reduce the residual elastic stress. It is particularly important to control the flow stress in metal materials. Compared with traditional methods, the use of electropulsing treatment (EPT) technology stands out due to its energy–efficient, highly effective, straightforward and pollution–free characteristics. However, there are different opinions about the mechanism of reducing flow stress through EPT due to the conflation of the effects from pulsed currents. Herein, a clear correlation is identified between induced stress levels and the application of pulsed electrical current. It was found that the decrease in flow stress is positively correlated with the current density and the duration of electrical contact and current action time. We first systematically and comprehensively summarize the influence mechanisms of EPT on dislocations, phase, textures and recrystallization. An analysis of Joule heating, electron wind effect, and thermal–induced stress within metal frameworks under the influence of pulsed currents was conducted. And the distribution of electric, thermal and stress fields under EPT are discussed in detail based on a finite element simulation (FES). Finally, some new insights into the issues and challenges of flow stress drops caused by EPT are proposed, which is critically important for advancing related mechanism research and the revision of theories and models.

Full article

Figure 1

Open AccessFeature PaperArticle

On the Microstructure and Properties of Complex Concentrated bcc Solid Solution and Tetragonal D8m M5Si3 Silicide Phases in a Refractory Complex Concentrated Alloy

by

Nik Tankov, Claire Utton and Panos Tsakiropoulos

Alloys 2024, 3(1), 59-95; https://doi.org/10.3390/alloys3010005 - 07 Mar 2024

Abstract

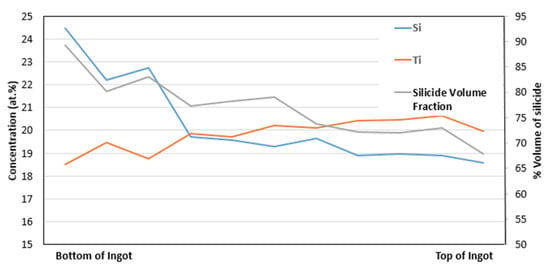

In this work, the refractory complex concentrated alloy (RCCA) 3.5Al–4Cr–6Ge–1Hf–5Mo–36Nb–22Si–1.5Sn–20Ti–1W (at.%) was studied in the as cast and heat treated conditions (100 h or 200 h at 1500 °C). There was strong macrosegregation of Si in the 0.6 kg button/ingot of the cast

[...] Read more.

In this work, the refractory complex concentrated alloy (RCCA) 3.5Al–4Cr–6Ge–1Hf–5Mo–36Nb–22Si–1.5Sn–20Ti–1W (at.%) was studied in the as cast and heat treated conditions (100 h or 200 h at 1500 °C). There was strong macrosegregation of Si in the 0.6 kg button/ingot of the cast alloy, in which A2 solid solution, D8m βNb5Si3, C14-NbCr2 Laves phase and Tiss and a ternary eutectic of the A2, D8m and C14 phases were formed. The partitioning of Ti in the as cast and heat treated microstructure and its relationships with other solutes was shown to be important for the properties of the A2 solid solution and the D8m βNb5Si3, which were the stable phases at 1500 °C. The near surface microstructure of the alloy was contaminated with oxygen after heat treatment under flowing Ar. For the aforementioned phases, it was shown, for the first time, that there are relationships between solutes, between solutes and the parameters VEC, Δχ and δ, between the said parameters, and between parameters and phase properties. For the contaminated with oxygen solid solution and silicide, trends in relationships between solutes, between solutes and oxygen content and between the aforementioned parameters and oxygen content also were shown for the first time. The nano-hardness and Young’s modulus of the A2 solid solution and the D8m βNb5Si3 of the as cast and heat-treated alloy were measured using nanoindentation. Changes of nano-hardness and Young’s modulus of the A2 solid solution and D8m βNb5Si3 per solute addition for this multiphase RCCA were discussed. The nano-hardness and Young’s modulus of the solid solution and the βNb5Si3, respectively, were 9.5 ± 0.2 GPa and 177.4 ± 5.5 GPa, and 17.55 ± 0.5 GPa and 250.27 ± 6.3 GPa after 200 h at 1500 °C. The aforementioned relationships and properties of the two phases demonstrated the importance of synergy and entanglement of solutes, parameters and phases in the microstructure and properties of the RCCA. Implications of synergy and entanglement for the design of metallic ultra-high temperature materials were emphasised.

Full article

(This article belongs to the Collection Feature Paper Collection of Advanced Research on Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Oxidation of Fe35Mn21Ni20Cr12Al12 High Entropy Alloy in Dry Air

by

Lamiaa Z. Mohamed, Sanaa S. Abd ElMoamen, Seung Jo Yoo and Mohamed Abdel-Hady Gepreel

Alloys 2024, 3(1), 43-58; https://doi.org/10.3390/alloys3010004 - 23 Feb 2024

Abstract

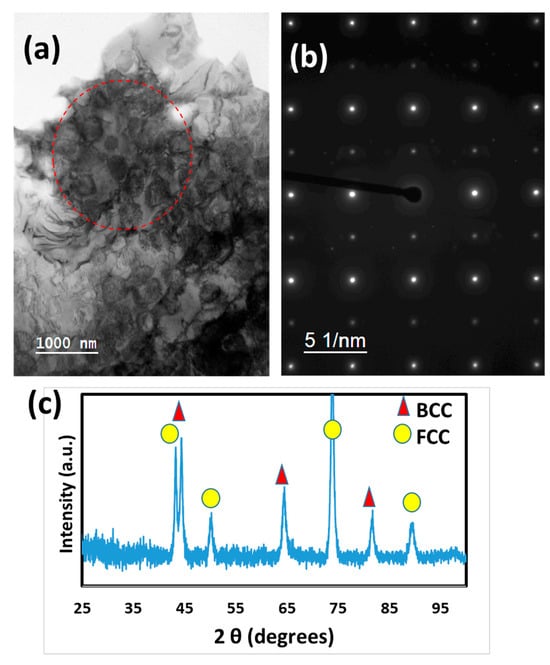

The isothermal oxidation of a Fe35Mn21Ni20Cr12Al12 high entropy alloy (HEA) was investigated in dry air for 50 h at 500, 600, and 700 °C after 90% cold rolling. The Fe35Mn21Ni

[...] Read more.

The isothermal oxidation of a Fe35Mn21Ni20Cr12Al12 high entropy alloy (HEA) was investigated in dry air for 50 h at 500, 600, and 700 °C after 90% cold rolling. The Fe35Mn21Ni20Cr12Al12 HEA behaves according to the linear oxidation rate with rate constants of 1 × 10−6, 3 × 10−6, and 7 × 10−6 g/(cm2·s) for oxidation at 500 °C, 600 °C, and 700 °C, respectively. The activation energy for oxidation of the HEA was calculated to be 60.866 KJ/mole in the 500–700 °C temperature range. The surface morphology and phase identification of the oxide layers were characterized. The formation of MnO2, Mn2O3, Mn3O4, Cr2O3, and Al2O3 in the oxide layers along with Fe2O3 is the key to the oxidation mechanism. The elemental mapping and line EDX scans were performed to identify the oxidation mechanisms.

Full article

(This article belongs to the Collection Feature Paper Collection of Advanced Research on Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Optical Properties of AgAu Alloy Clusters: Effect of Chemical Configuration along a Rearrangement Pathway

by

Hans-Christian Weissker and Florent Calvo

Alloys 2024, 3(1), 31-42; https://doi.org/10.3390/alloys3010003 - 20 Feb 2024

Abstract

Gold and silver are, for all their chemical similarities, optically very different. Small Ag clusters show a localized surface-plasmon resonance (LSPR), whereas in Au clusters smaller than about 300 atoms, the resonance is absent due to the coupling with the interband transitions from

[...] Read more.

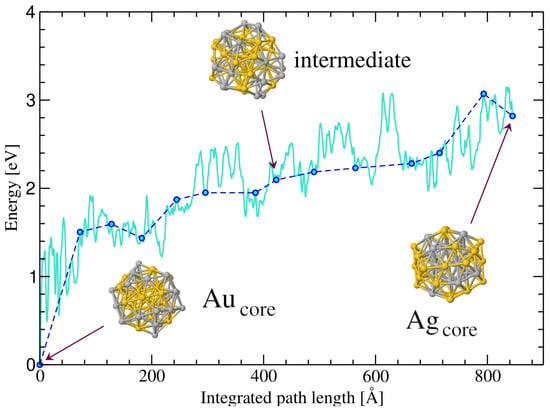

Gold and silver are, for all their chemical similarities, optically very different. Small Ag clusters show a localized surface-plasmon resonance (LSPR), whereas in Au clusters smaller than about 300 atoms, the resonance is absent due to the coupling with the interband transitions from the d electrons. This opens the possibility of tuning the cluster properties depending on their composition and chemical configuration. Earlier work on AgAu alloy clusters has shown that the outermost shell of atoms is crucial to their overall optical properties. In the present contribution, we consider the optical spectroscopic properties associated with the structural rearrangement in 55-atom AgAu alloy clusters in which the core transforms from pure silver to pure gold. Calculations using time-dependent density-functional theory are complemented by an in-depth study of the subtle effects that the chemical configuration has on the details of the materials’ d bands. Although the cluster surface remains alloyed, the geometrical changes translate into strong variations in the optical properties.

Full article

(This article belongs to the Collection Feature Paper Collection of Advanced Research on Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Exploring Synergistic Effect on the Stability of Ni-, Pd-, Ir-Doped TiN (N = 1–15) Nanoparticles

by

Tshegofatso Phaahla, Phuti Ngoepe and Hasani Chauke

Alloys 2024, 3(1), 15-30; https://doi.org/10.3390/alloys3010002 - 26 Jan 2024

Abstract

►▼

Show Figures

Bimetallic nanoclusters have attracted great interest due to their ability to enhance the catalytic properties of nanoclusters through synergetic effects that emerge from the combination of the metal nanocluster with different transition metal (TM) species. However, their indefinite composition and broad distribution hinder

[...] Read more.

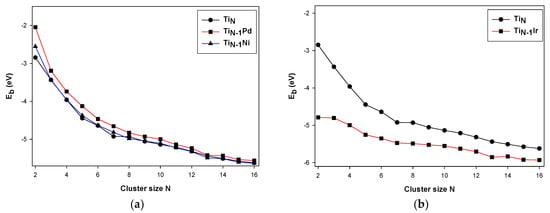

Bimetallic nanoclusters have attracted great interest due to their ability to enhance the catalytic properties of nanoclusters through synergetic effects that emerge from the combination of the metal nanocluster with different transition metal (TM) species. However, their indefinite composition and broad distribution hinder the insightful understanding of the interaction between these invasive metals in bimetallic doped nanoalloys. In this study, we report a density functional theory calculation with the PBEsol exchange-correlation functional for 16-atom TiN−1TM (TM = Ni, Ir, Pd) nanoalloys, which provides new insights into the synergetic effect of these invasive metals. The probe into the effect of these metal impurities revealed that the replacement of a Ti atom with Ni, Ir and Pd enhances the relative stability of the nanoalloys, and the maximum stability for a lower bimetallic composition is reached for Ti4Ir, Ti5Pd and Ti7Ni. The most stable nanoalloy is reached for the Ti12Ir cluster in comparison with the Ti12Pd and Ti12Ni clusters and pure Ti13 monoatomic nanocluster. This stability trend is as revealed well by both the binding energy and the dissociation energy. The average HOMO-LUMO gap for the bigger clusters revealed that the valence electrons in the HOMO can absorb lower energy, which is indicatory of a higher reactivity and lower stability. The quantum confinement is higher for the smaller clusters, which illustrates a higher stability and lower reactivity for those systems.

Full article

Figure 1

Open AccessArticle

The Effect of the Environment on the Case Hardening Characteristics of AISI 1018 Steel during Cassava Leaf Pack Cyaniding

by

Renee Erica Gordon, Egwu Eric Kalu, Adelana Rasak Adetunji, Dorr Campbell and Peter N. Kalu

Alloys 2024, 3(1), 1-14; https://doi.org/10.3390/alloys3010001 - 31 Dec 2023

Abstract

►▼

Show Figures

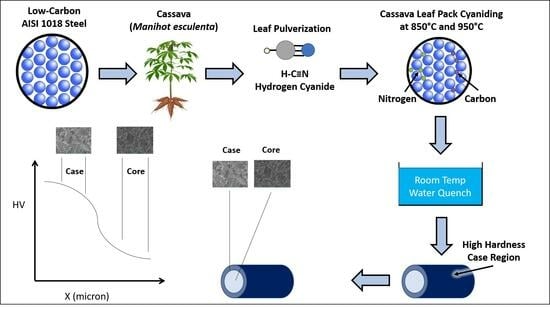

As part of a comprehensive study on eco-friendly processing techniques, the influence of the heat treatment environment on the case hardening of AISI 1018 steel using pulverized cassava leaf was studied. The process was carried out at two different temperatures (850 °C and

[...] Read more.

As part of a comprehensive study on eco-friendly processing techniques, the influence of the heat treatment environment on the case hardening of AISI 1018 steel using pulverized cassava leaf was studied. The process was carried out at two different temperatures (850 °C and 950 °C) and under three environmental conditions: Process 1, the control experiment, was carried out in air only; in Process 2, the medium comprised pulverized cassava leaves; and in Process 3 a combination of pulverized cassava leaves plus barium carbonate (BaCO3) was used as an energizer (CBC mixture). Vickers microhardness testing and scanning electron microscopy were used to evaluate the effect of the processing environment on the case hardening of the steel. As expected, regardless of the processing temperature, Process 1 resulted in little or no hardening of the steel surface. However, notable case hardening occurred when the steel specimens were subjected to either Process 2 or Process 3. Furthermore, the inclusion of barium carbonate in Process 3 significantly enhanced the case hardening effectiveness of the cassava leaf in terms of the rate of and maximum hardness achieved. A maximum enhancement was observed at 950 °C. After 1 h, the increase in hardness was 160% and 280% for Process 2 and Process 3, respectively. Upon increasing the processing time to 5 h, the increase in hardness due to Process 2 was raised to 254%, while that of Process 3 remained at approximately 280%. The diffusivity of AISI 1018 was calculated using the microhardness data. The diffusivity was highest in Process 2 samples with values of 1.568 × 10−9 m2/s at 850 °C and 1.893 × 10−9 m2/s at 950 °C. Effective case hardening of AISI 1018 steel was carried out using the medium of cassava leaf, without the addition of barium carbonate (BaCO3) as an energizer.

Full article

Graphical abstract

Open AccessFeature PaperArticle

Modelling Microstructure in Casting of Steel via CALPHAD-Based ICME Approach

by

Chunhui Luo, Karin Hansson, Zhili Song, Debbie Ågren, Ewa Sjöqvist Persson, Fredrik Cederholm and Changji Xuan

Alloys 2023, 2(4), 321-343; https://doi.org/10.3390/alloys2040021 - 28 Nov 2023

Abstract

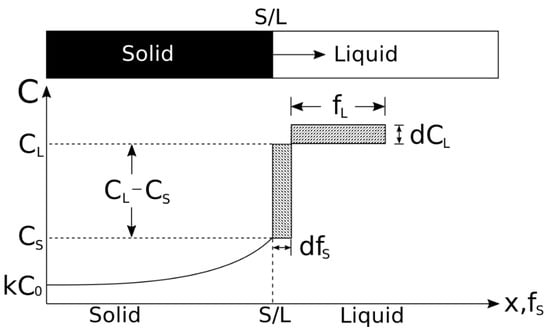

Integrated computational materials engineering (ICME) is emerging as an increasingly powerful approach to integrate computational materials science tools into a holistic system and address the multiscale modeling challenges in the processing of advanced steels. This work aims at incorporating macroscopic model (finite element-based

[...] Read more.

Integrated computational materials engineering (ICME) is emerging as an increasingly powerful approach to integrate computational materials science tools into a holistic system and address the multiscale modeling challenges in the processing of advanced steels. This work aims at incorporating macroscopic model (finite element-based thermal model) and microscopic model (CALPHAD-based microstructure model), building an industry-oriented computational tool (MICAST) for casting of steels. Two case studies were performed for solidification simulations of tool steel and stainless steel by using the CALPHAD approach (Thermo-Calc package and CALPHAD database). The predicted microsegregation results agree with the measured ones. In addition, two case studies were performed for continuous casting and ingot casting with selected steel grades, mold geometries and process conditions. The temperature distributions and histories in continuous casting and ingot casting process of steels were calculated using in-house finite-element code which is integrated in MICAST. The predicted temperature history from the casting process simulation was exported as input data for the DICTRA simulation of solidification. The resulting microsegregation by the DICTRA simulation can reflect the microstructure evolution in the real casting process. Current computational practice demonstrates that CALPHAD-based material models can be directly linked with casting process models to predict location-specific microstructures for smart material processing.

Full article

(This article belongs to the Collection Feature Paper Collection of Advanced Research on Alloys)

►▼

Show Figures

Figure 1

Open AccessFeature PaperArticle

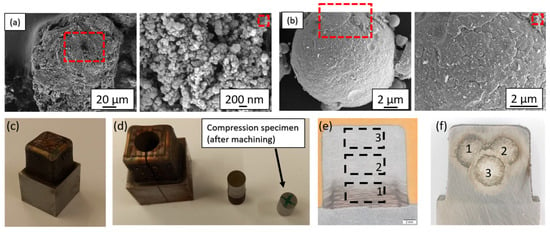

Processing of Carbon Nanoparticle-Enriched AISI H11 Tool Steel Powder Mixtures in DED-LB/M for the AM of Forging Tools with Tailored Properties (Part II): Influence of Nanoscale Carbon Additives on Microstructure and Mechanical Properties

by

Oliver Hentschel, Jan Kohlstruck, Pavel Krakhmalev, Dimitrios Nikas and Michael Schmidt

Alloys 2023, 2(4), 288-320; https://doi.org/10.3390/alloys2040020 - 14 Nov 2023

Cited by 1

Abstract

A promising approach for producing parts with outstanding properties in directed energy deposition (DED-LB/M) provides the application of tailored powder mixtures processed by applying in situ alloying strategies. In this work, DED-LB/M was used to manufacture multilayer specimens from AISI H11 steel powders

[...] Read more.

A promising approach for producing parts with outstanding properties in directed energy deposition (DED-LB/M) provides the application of tailored powder mixtures processed by applying in situ alloying strategies. In this work, DED-LB/M was used to manufacture multilayer specimens from AISI H11 steel powders enriched with carbon nanoparticles (C-np) in concentrations of 0.1 wt.-% and 0.2 wt.-%. The scientific aim was to investigate the impact of C-np on the microstructural (particularly retained austenite content (RA-c) and grain size) and mechanical properties (specifically hardness and compression yield strength) of the manufactured specimens. It was shown that the addition of C-np to the H11 powder leads to a stronger distortion of martensite as well as significantly enhancing the RA-c. Furthermore, the C-np seem to favor the formation of finer martensite, as can be verified with XRD and EBSD. Under as-built conditions, the mean hardness increases from 653 ± 10 HV1 for the H11 sample to 770 ± 14 HV1 for the sample reinforced with 0.2 wt.-% C-np. At the same time, Y0.2% rises up from 1839 ± 61 MPa to 2134 ± 68 MPa. The hardness- and strength-increasing effect of the added C-np is retained even after heat treatment, similarly to the industrial standard.

Full article

(This article belongs to the Special Issue Design of New Metallic Alloys for AM)

►▼

Show Figures

Figure 1

Open AccessArticle

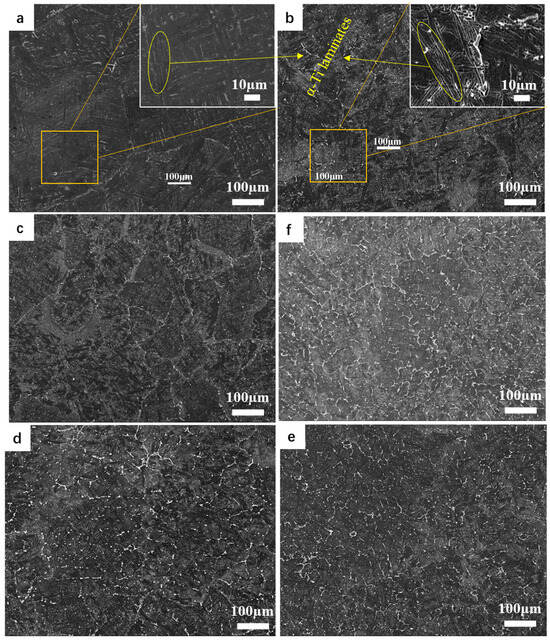

Investigation on the Optimal Amount of Y and B Elements in High-Temperature Titanium Alloy Ti-5.9Al-4Sn-3.9Zr-3.8Mo-0.4Si-xY-yB

by

Yingbo Zhang, Yuanhui Peng, Pu Zhang, Yunfeng Hu, Dongliang Wu and Xing Tu

Alloys 2023, 2(4), 271-287; https://doi.org/10.3390/alloys2040019 - 30 Oct 2023

Abstract

►▼

Show Figures

This article presents a novel and feasible approach for researching the quantity of the ceramic phase and component optimization in high-temperature titanium alloys with small trace amounts of ceramic phases. Different near-α titanium alloys with varying yttrium and boron contents were prepared through

[...] Read more.

This article presents a novel and feasible approach for researching the quantity of the ceramic phase and component optimization in high-temperature titanium alloys with small trace amounts of ceramic phases. Different near-α titanium alloys with varying yttrium and boron contents were prepared through the utilization of a vacuum non-consumable arc furnace melting method. The alloy used was a Ti-5.9Al-4Sn-3.9Zr-3.8Mo-0.4Si base. Its microstructure, texture, mechanical properties, and fracture behavior were studied. The observation of the as-cast structure shows that the addition of different doses of trace Y and B elements significantly refines both the original β grains and α grains. Moreover, the addition of the B element transforms the Widmanstätten structure in the titanium alloy structure into a basketweave structure. The addition of Y can refine the grain structure, improve the uniformity of the matrix structure, and act as a strong deoxidizer, which will take away the oxygen in the matrix and purify it. The TiB whiskers generated with the addition of B promotes dynamic recrystallization behavior and leads to more equiaxed α grains being precipitated around them, resulting in a significant refinement of the microstructure of the as-cast alloy. After adding a small amount of B, the texture strength of the α phase is significantly reduced, indicating that TiB whiskers inhibit the formation of texture. After conducting performance screening and structure analysis, the study supplements the analysis of Y’s regulation of the titanium alloy structure. The regulation is primarily explained by combining the results of the analysis of boron content, phase diagram analysis, mechanical properties, and fracture analysis. The mechanical analysis introduces the unique load transfer strengthening of TiB whiskers combined with an analysis of high-temperature mechanical properties, as the threshold for addition. The optimal amounts of Y and B additions are 0.6 wt% and 0.8 wt%, respectively. The optimized alloy obtained under this condition can achieve a tensile strength of 950 Mpa at 500 °C without any plastic deformation or heat treatment.

Full article

Figure 1

Open AccessArticle

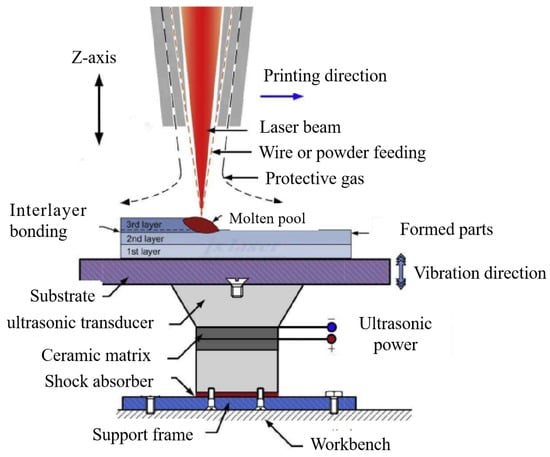

The Research on Ultrasonic Vibration Amplitudes in Ti6Al4V DED Additive Manufacturing

by

Wei Liu, Zhenchao Zhang, Suli Li and Chao Xu

Alloys 2023, 2(4), 256-270; https://doi.org/10.3390/alloys2040018 - 19 Oct 2023

Abstract

Ultrasonic-assisted Ti6Al4V Directed Energy Deposition (DED) additive manufacturing technology can improve the problem of uneven microstructure caused by laser heating and sudden cooling of the molten pool. In this paper, the numerical analysis and experimental verification methods were adopted. The influencing factors, such

[...] Read more.

Ultrasonic-assisted Ti6Al4V Directed Energy Deposition (DED) additive manufacturing technology can improve the problem of uneven microstructure caused by laser heating and sudden cooling of the molten pool. In this paper, the numerical analysis and experimental verification methods were adopted. The influencing factors, such as the cavitations’ effect, sound flow enhancement effect, and sound flow thermal effect related to the ultrasonic assistance in the molten pool, were analyzed. After equating the energy of the ultrasound, the model of additive manufacturing was introduced in the form of a heat source. The temperature gradient changes during the solidification process of the molten pool with the addition of ultrasound assistance and the effect of ultrasonic vibration during the manufacturing process on its deposited state and microstructure of solution-aged formed parts were studied. The results showed that when the wire feeding rate is 5 mm/s and the laser scanning speed is 5 mm/s, the optimal laser power is 1000 W~1100 W, corresponding to the optimal ultrasonic amplitude of 120 μm. Then, by comparing the temperature field with the same amplitude of 0 μm (i.e., no ultrasonic vibration) and the microstructure of the formed parts, it was verified that ultrasonic vibration facilitates fluid flow in the molten pool, which could lead to a more uniform temperature distribution. This optimized approach not only enhances the understanding of the process but also contributes significantly to the advancement of related research endeavors.

Full article

(This article belongs to the Topic Laser Welding of Metallic Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

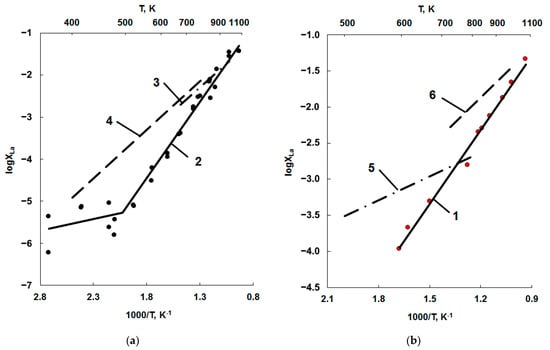

Solubility of Lanthanum in Liquid Alloys with Gallium and Indium

by

Alexander S. Dedyukhin, Andrey V. Shchetinskiy, Vladimir A. Volkovich and Leonid F. Yamschchikov

Alloys 2023, 2(4), 242-255; https://doi.org/10.3390/alloys2040017 - 10 Oct 2023

Abstract

The solubility of lanthanum in indium and Ga–In alloys containing 21.8, 40 and 70 wt. % In was determined experimentally at temperatures up to 1081 K. The low temperature limit depended on the melting point of the alloy. The solubility was measured using

[...] Read more.

The solubility of lanthanum in indium and Ga–In alloys containing 21.8, 40 and 70 wt. % In was determined experimentally at temperatures up to 1081 K. The low temperature limit depended on the melting point of the alloy. The solubility was measured using isothermal saturation and high-temperature filtration methods. The phase composition of solid intermetallic compounds formed in the ternary La–Ga–In systems of various compositions was determined by X-ray diffraction. Activity coefficients of lanthanum in the alloys based on gallium, indium and three Ga–In mixtures (21.8, 40 and 70 wt. % In) were calculated. Temperature dependencies of thermodynamically possible separation factors for the uranium/lanthanum couple in “LiCl–KCl–CsCl melt–liquid alloy” systems were derived for various gallium–indium alloys.

Full article

(This article belongs to the Collection Feature Paper Collection of Advanced Research on Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

Fretting Corrosion Performance Evaluation of Uncoated Cladding, Cr Coating Cladding and AlCrNbSiTi Coating Cladding

by

Xin Liu, Shen Li, Hui Wang, Menghe Tu, Bokai Zhou and Yong Hu

Alloys 2023, 2(4), 227-241; https://doi.org/10.3390/alloys2040016 - 28 Sep 2023

Abstract

In pressurized water reactors (PWRs), flow-induced vibration (FIV) induces the fretting wear of fuel rods and supporting grids, and the process is accompanied by corrosion, which is called fretting corrosion. In this paper, fretting corrosion experiments were carried out in a simulated cladding

[...] Read more.

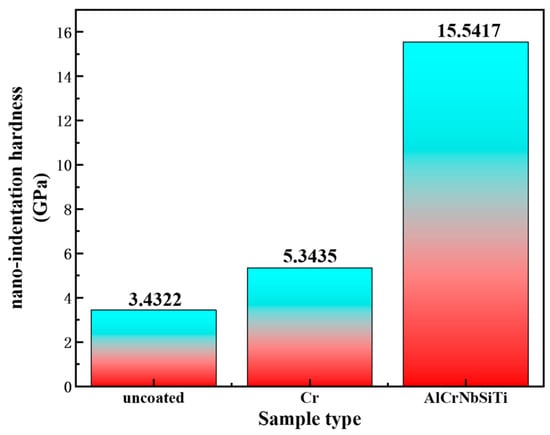

In pressurized water reactors (PWRs), flow-induced vibration (FIV) induces the fretting wear of fuel rods and supporting grids, and the process is accompanied by corrosion, which is called fretting corrosion. In this paper, fretting corrosion experiments were carried out in a simulated cladding service environment, and the fretting corrosion performance of AlCrNbSiTi coating cladding, Cr coating cladding and uncoated cladding with the supporting grids were investigated using a three-dimensional white light interferometer and a scanning electron microscope (SEM). The results showed that the AlCrNbSiTi coating cladding has the strongest fretting corrosion performance, the Cr coating cladding has the second best fretting corrosion performance and the uncoated cladding has the worst fretting corrosion performance. The coating also changes the wear mechanism of the cladding and improves the corrosion resistance of the cladding, which is responsible for the improvement in the fretting corrosion performance of the cladding. By comparing the AlCrNbSiTi coating with the Cr coating, it was found that the AlCrNbSiTi coating has a better fretting corrosion performance than the Cr coating due to its higher hardness and stronger corrosion resistance.

Full article

(This article belongs to the Special Issue New Alloys for Surface Engineered Coatings, Interfaces and Films)

►▼

Show Figures

Figure 1

Open AccessArticle

Mechanical Properties of Al–Mg–Si Alloys (6xxx Series): A DFT-Based Study

by

Kipkorir Kirui Pius, Nicholas O. Ongwen, Maxwell Mageto, Victor Odari and Francis Magiri Gaitho

Alloys 2023, 2(3), 213-226; https://doi.org/10.3390/alloys2030015 - 13 Sep 2023

Cited by 4

Abstract

►▼

Show Figures

Al–Mg–Si alloys are used in aircraft, train, and car manufacturing industries due to their advantages, which include non-corrosivity, low density, relatively low cost, high thermal and electrical conductivity, formability, and weldability. This study investigates the bulk mechanical properties of Al–Mg–Si alloys and the

[...] Read more.

Al–Mg–Si alloys are used in aircraft, train, and car manufacturing industries due to their advantages, which include non-corrosivity, low density, relatively low cost, high thermal and electrical conductivity, formability, and weldability. This study investigates the bulk mechanical properties of Al–Mg–Si alloys and the influence of the Si/Mg ratio on these properties. The Al cell was used as the starting structure, and then nine structures were modeled with varying percentages of aluminium, magnesium, and silicon. Elastic constant calculations were conducted using the stress–strain method as implemented in the quantum espresso code. This study found that the optimum properties obtained were a density of 2.762 g/cm3, a bulk modulus of 83.3 GPa, a shear modulus of 34.4 GPa, a Vickers hardness of 2.79 GPa, a Poisson’s ratio of 0.413, a Pugh’s ratio of 5.42, and a yield strength of 8.38 GPa. The optimum Si/Mg ratio was found to be 4.5 for most of the mechanical properties. The study successfully established that the Si/Mg ratio is a critical factor when dealing with the mechanical properties of the Al–Mg–Si alloys. The alloys with the optimum Si/Mg ratio can be used for industrial applications such as plane skins and mining equipment where these properties are required.

Full article

Figure 1

Open AccessReview

A Perspective of the Design and Development of Metallic Ultra-High Temperature Materials: Refractory Metal Intermetallic Composites, Refractory Complex Concentrated Alloys and Refractory High Entropy Alloys

by

Panos Tsakiropoulos

Alloys 2023, 2(3), 184-212; https://doi.org/10.3390/alloys2030014 - 30 Aug 2023

Cited by 1

Abstract

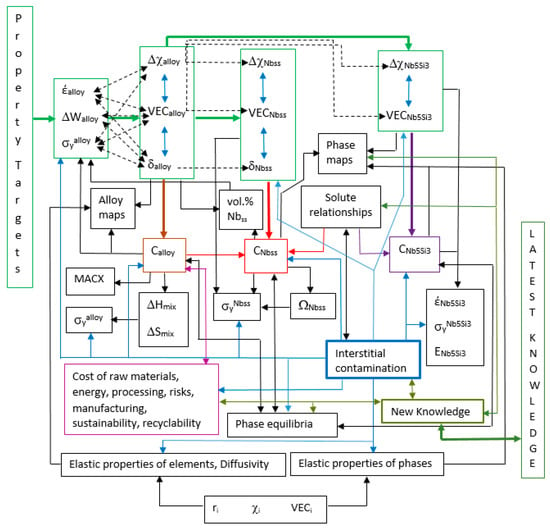

The paper is a personal perspective on the design of metallic ultra-high temperature materials (UHTMs). Specifically, the alloy design “landscape” of metallic UHTMs was considered from the viewpoint of the alloy design methodology NICE. The concepts of synergy, entanglement and self-regulation and their

[...] Read more.

The paper is a personal perspective on the design of metallic ultra-high temperature materials (UHTMs). Specifically, the alloy design “landscape” of metallic UHTMs was considered from the viewpoint of the alloy design methodology NICE. The concepts of synergy, entanglement and self-regulation and their significance for alloy design/development were discussed. The risks, ecological challenges and material-environment interactions associated with the development of metallic UHTMs were highlighted. The “landscape” showed that beneath the complexities of alloy design lies an elegant and powerful unity of specific parameters that link logically and that progress can be made by recognising those interrelationships between parameters that generate interesting, diverse, and complex alloys.

Full article

(This article belongs to the Collection Feature Paper Collection of Advanced Research on Alloys)

►▼

Show Figures

Figure 1

Open AccessFeature PaperArticle

On the Influence of Volumetric Energy Density and Inter-Layer Time on the Material Properties of Case-Hardening Steels

by

Dominic Bartels, Moritz Elias Albert, Florian Nahr and Michael Schmidt

Alloys 2023, 2(3), 168-183; https://doi.org/10.3390/alloys2030013 - 25 Aug 2023

Abstract

Case-hardening steels are gaining increasing interest in the field of laser powder bed fusion (PBF-LB/M) due to their excellent weldability. In combination with post-process carburization heat treatment, the surface properties can be improved to generate high-strength products. When manufacturing larger products by means

[...] Read more.

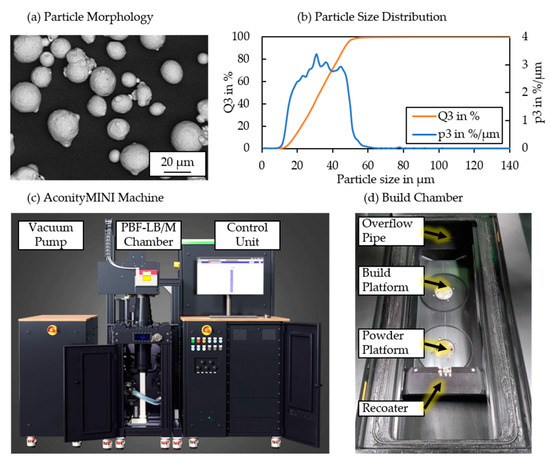

Case-hardening steels are gaining increasing interest in the field of laser powder bed fusion (PBF-LB/M) due to their excellent weldability. In combination with post-process carburization heat treatment, the surface properties can be improved to generate high-strength products. When manufacturing larger products by means of PBF-LB/M, the in situ heat accumulation and the altered cooling rates affect the resulting material properties. Therefore, the fabrication of larger products requires an understanding on the influencing factors that affect the material properties. This work investigates the effect of different volumetric energy densities (VED) on the resulting microstructural and mechanical properties. It is found that the hardness decreases continuously along the build direction. The gradient depends on the applied energy and is stronger for higher energy inputs due to heat accumulation and lowered cooling rates. Furthermore, countering strategies are investigated to avoid process-specific hardness reduction along the build direction. This includes a reduced number of parts within the build job as well as a modified inter-layer time (ILT) between consecutive layers of the specimen. Applying a moderate inter-layer time helps to counter process-specific overheating, which is indicated by an almost homogeneous material hardness and melt pool size along the build direction.

Full article

(This article belongs to the Special Issue Design of New Metallic Alloys for AM)

►▼

Show Figures

Figure 1

Open AccessArticle

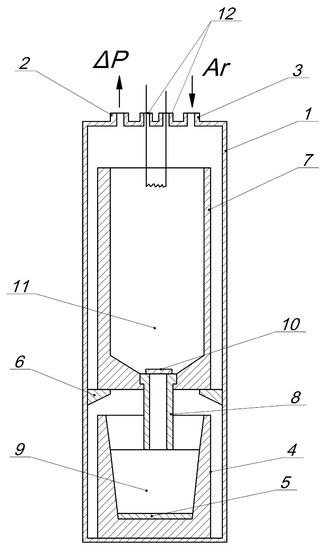

Production of Zirconium-Niobium Alloys for Nuclear Reactors Fuel Rods via SHS Process

by

Anatoly Mukhachev, Dmytro Yelatontsev and Olena Kharytonova

Alloys 2023, 2(3), 157-167; https://doi.org/10.3390/alloys2030012 - 02 Aug 2023

Abstract

This article presents the results of studies of the self-propagating high-temperature synthesis (SHS) for obtaining zirconium alloys with niobium by the method of calcium-thermal reduction of nuclear-grade zirconium tetrafluoride in the presence of niobium powder. The optimal heating temperature of the initial charge

[...] Read more.

This article presents the results of studies of the self-propagating high-temperature synthesis (SHS) for obtaining zirconium alloys with niobium by the method of calcium-thermal reduction of nuclear-grade zirconium tetrafluoride in the presence of niobium powder. The optimal heating temperature of the initial charge and the methods of charge mixture with different calcium content were determined. The safety of the SHS process is ensured by the formation of an optimal combustion front of the mixture to remove the released high-pressure gases. A setup for the furnace reduction of zirconium alloys with charge preheating, discharge of molten products into molds of various designs, and control of the time and rate of slag and alloy crystallization has been tested. The required performance of the installation, the degree of transition of zirconium from salt into the alloy, and the purity, structure, and uniformity of the alloy were achieved.

Full article

(This article belongs to the Collection Feature Paper Collection of Advanced Research on Alloys)

►▼

Show Figures

Figure 1

Open AccessArticle

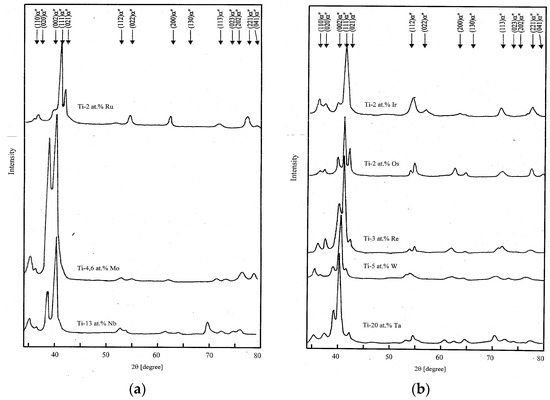

Nature and Regularities of the Orthorhombic α″-Phase Formation in Binary Titanium Alloys

by

Arkadiy V. Dobromyslov

Alloys 2023, 2(3), 148-156; https://doi.org/10.3390/alloys2030011 - 11 Jul 2023

Cited by 2

Abstract

►▼

Show Figures

A systematic study of the phase composition of quenched binary titanium alloys with d-metals of groups 5–11 from periods four to six was carried out using the methods of X-ray diffraction analysis. It was found that the formation of the orthorhombic α″-phase

[...] Read more.

A systematic study of the phase composition of quenched binary titanium alloys with d-metals of groups 5–11 from periods four to six was carried out using the methods of X-ray diffraction analysis. It was found that the formation of the orthorhombic α″-phase depends on the position of the alloying metal in the periodic table. The formation of the α″-phase occurs only in the systems Ti-V, Ti-Nb, Ti-Mo, Ti-Ru, Ti-Ta, Ti-W, Ti-Re, Ti-Os and Ti-Ir, and in other systems, it does not occur. It was found that the critical parameter for the formation of the α″-phase is the difference in the size of titanium atoms and those of the alloying metal {(rTi − rMe)/rTi 100%}. The formation of the α″-phase occurs only in systems where this value is lower than 9 at.%.

Full article

Figure 1

Open AccessArticle

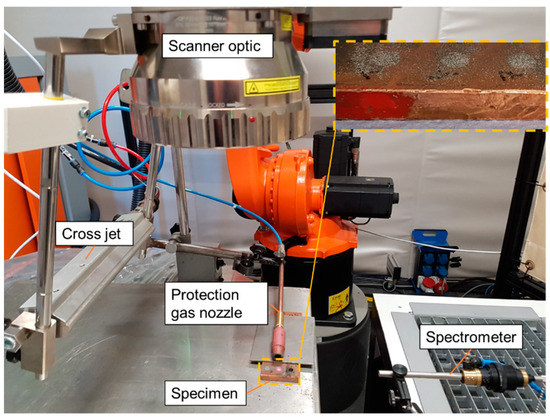

Spectral Visualization of Alloy Reactions during Laser Melting

by

Joerg Volpp, Himani Naesstroem, Lisanne Wockenfuss, Malte Schmidt and Knut Partes

Alloys 2023, 2(3), 140-147; https://doi.org/10.3390/alloys2030010 - 04 Jul 2023

Abstract

Laser materials processing includes rapid heating to possibly high temperatures and rapid cooling of the illuminated materials. The material reactions can show significant deviations from equilibrium processing. During processing of complex materials and material combinations, it is mainly unknown how the materials react

[...] Read more.

Laser materials processing includes rapid heating to possibly high temperatures and rapid cooling of the illuminated materials. The material reactions can show significant deviations from equilibrium processing. During processing of complex materials and material combinations, it is mainly unknown how the materials react and mix. However, it is important to know which chemical elements or compounds are present in the material to define the alloy. In addition, their distribution after rapid cooling needs to be better understood. Therefore, such alloy changes at rapid heating induced by laser illumination were created as pre-placed and pre-mixed powder nuggets. The energy input and the material ratio between the powder components were varied to identify characteristic responses. For the detection of reaction durations and mixing characteristics, the vapor plume content was assumed to contain the necessary information. Spectral measurements of the plume were used to identify indicators about process behaviors. It was seen that the spectral data give indications about the chemical reactions in the melt pool. The reactions of iron ore components with aluminum seem to require laser illumination to finish completely, although the thermite reaction should maintain the chemical reaction, likely due to the required melt mixing that enables the interaction of the reacting partners at all.

Full article

(This article belongs to the Special Issue Design of New Metallic Alloys for AM)

►▼

Show Figures

Figure 1

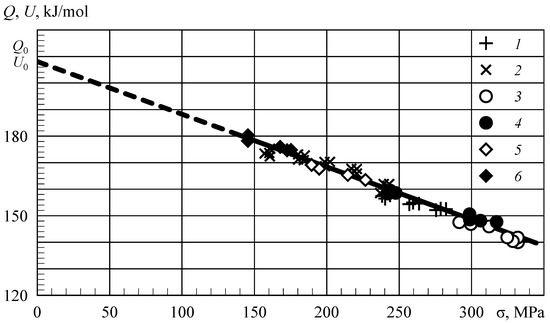

Open AccessArticle

Fracturing of Solids as a Thermodynamic Process

by

Mark Petrov

Alloys 2023, 2(3), 122-139; https://doi.org/10.3390/alloys2030009 - 30 Jun 2023

Abstract

►▼

Show Figures

Instead of a number of different approaches or a formal description of experimental data, a unified approach is proposed to consider failure and deformation as thermodynamic processes. Mathematical modeling of the processes is carried out using rheological models of the material. Parametric identification

[...] Read more.

Instead of a number of different approaches or a formal description of experimental data, a unified approach is proposed to consider failure and deformation as thermodynamic processes. Mathematical modeling of the processes is carried out using rheological models of the material. Parametric identification of structural models is carried out using minimal necessary experiments. Based on results of these experiments, the scope of applicability conditions for this material and test modes necessary for parametric identification of models are selected. One fracture criterion is used that formally corresponds to the achievement of a threshold concentration of micro-damage in any volume of the material. Calculations of durability under conditions of varying temperature and variable loads are based on the relationship of plastic flow and failure processes distributed over the volume of the material. They are performed numerically over time steps depending on the ratio of the rate of change of temperature and stresses.

Full article

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Alloys, Materials, Metals

Development of Light Alloys with Excellent Mechanical Properties

Topic Editors: Zhirou Zhang, Isaac ChangDeadline: 31 December 2025

Conferences

Special Issues

Special Issue in

Alloys

Design of New Metallic Alloys for AM

Guest Editor: Pavel KrakhmalevDeadline: 31 December 2024

Topical Collections

Topical Collection in

Alloys

Feature Paper Collection of Advanced Research on Alloys

Collection Editors: Nikki Stanford, Chamini L. Mendis, Peng Cao, Shashanka Rajendrachari