Morphology-Controlled WO3 for the Photocatalytic Oxidation of Methane to Methanol in Mild Conditions

Abstract

:1. Introduction

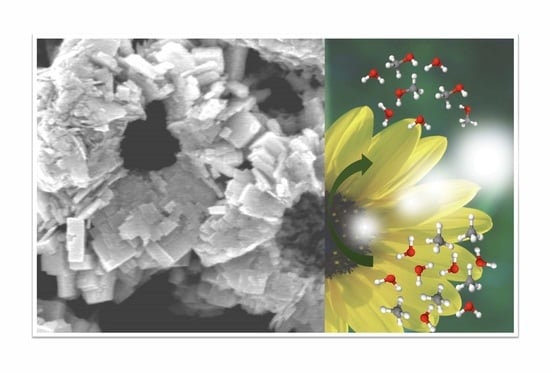

2. Results and Discussion

3. Experimental

3.1. Chemicals and Materials

3.2. Synthesis of WO3 Rods

3.3. Synthesis of WO3 Flowers

3.4. Photocatalytic Semiconductor Characterization

3.5. Photocatalytic Experiment and Setup

3.6. Analytical Determination

4. Conclusions and Future Directions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tian, Y.; Piao, L.; Chen, X. Research Progress on the Photocatalytic Activation of Methane to Methanol. Green Chem. 2021, 23, 3526–3541. [Google Scholar]

- Cortie, D.; Yi, Z.; Chen, X.; Li, Y.; Pan, X.; Huang, X. Photocatalytic Oxidation of Methane over Silver Decorated Zinc Oxide Nanocatalysts. Nat. Commun. 2016, 7, 1–8. [Google Scholar]

- Yang, J.; Hao, J.; Wei, J.; Dai, J.; Li, Y. Visible-Light-Driven Selective Oxidation of Methane to Methanol on Amorphous FeOOH Coupled m-WO3. Fuel 2020, 266, 117104. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, X.; Liu, J.-W.; Lee, Y.; Li, X. Natural Gas Hydrate Resources and Hydrate Technologies: A Review and Analysis of the Associated Energy and Global Warming Challenges. Energy Environ. Sci. 2021, 14, 5611–5668. [Google Scholar] [CrossRef]

- Hashiguchi, B.G.; Hövelmann, C.H.; Bischof, S.M.; Lokare, K.S.; Leung, C.H.; Periana, R.A. Methane-to-Methanol Conversion. Energy Production and Storage: Inorganic Chemical Strategies for a Warming World; Wiley: Hoboken, NJ, USA, 2010; pp. 101–142. [Google Scholar]

- Arminio-Ravelo, J.A.; Escudero-Escribano, M. Strategies toward the Sustainable Electrochemical Oxidation of Methane to Methanol. Curr. Opin. Green Sustain. Chem. 2021, 30, 100489. [Google Scholar] [CrossRef]

- de Klerk, A. Engineering Evaluation of Direct Methane to Methanol Conversion. Energy Sci. Eng. 2015, 3, 60–70. [Google Scholar] [CrossRef]

- Hao, J.; Schwach, P.; Fang, G.; Guo, X.; Zhang, H.; Shen, H.; Huang, X.; Eggart, D.; Pan, X.; Bao, X. Enhanced Methane Conversion to Olefins and Aromatics by H-Donor Molecules under Nonoxidative Condition. ACS Catal. 2019, 9, 9045–9050. [Google Scholar] [CrossRef]

- Cai, X.; Fang, S.; Hu, Y.H. Unprecedentedly High Efficiency for Photocatalytic Conversion of Methane to Methanol over Au–Pd/TiO2–What Is the Role of Each Component in the System? J. Mater. Chem. A 2021, 9, 10796–10802. [Google Scholar] [CrossRef]

- Olah, G.A. Beyond Oil and Gas: The Methanol Economy. Angew. Chemie Int. Ed. 2005, 44, 2636–2639. [Google Scholar] [CrossRef]

- Negishi, Y.; Watanabe, S.; Aoki, M.; Hossain, S.; Kurashige, W. Toward the Creation of Highly Active Photocatalysts That Convert Methane into Methanol. In Concepts of Semiconductor Photocatalysis; IntechOpen: London, UK, 2019; pp. 85–97. [Google Scholar]

- Liu, Y.; Wang, L.; Xiao, F.-S. Selective Oxidation of Methane into Methanol Under Mild Conditions. Chem. Res. Chinese Univ. 2022, 38, 671–676. [Google Scholar] [CrossRef]

- Song, H.; Meng, X.; Wang, S.; Zhou, W.; Song, S.; Kako, T.; Ye, J. Selective Photo-Oxidation of Methane to Methanol with Oxygen over Dual-Cocatalyst-Modified Titanium Dioxide. ACS Catal. 2020, 10, 14318–14326. [Google Scholar] [CrossRef]

- Gondal, M.A.; Hameed, A.; Yamani, Z.H.; Arfaj, A. Photocatalytic Transformation of Methane into Methanol under UV Laser Irradiation over WO3, TiO2 and NiO Catalysts. Chem. Phys. Lett. 2004, 392, 372–377. [Google Scholar] [CrossRef]

- Villa, K.; Murcia-López, S.; Andreu, T.; Morante, J.R. Mesoporous WO3 Photocatalyst for the Partial Oxidation of Methane to Methanol Using Electron Scavengers. Appl. Catal. B Environ. 2015, 163, 150–155. [Google Scholar] [CrossRef]

- Villa, K.; Murcia-López, S.; Morante, J.R.; Andreu, T. An Insight on the Role of La in Mesoporous WO3 for the Photocatalytic Conversion of Methane into Methanol. Appl. Catal. B Environ. 2016, 187, 30–36. [Google Scholar] [CrossRef]

- Hameed, A.; Ismail, I.M.I.; Aslam, M.; Gondal, M.A. Photocatalytic Conversion of Methane into Methanol: Performance of Silver Impregnated WO3. Appl. Catal. A Gen. 2014, 470, 327–335. [Google Scholar] [CrossRef]

- Noceti, R.P.; Taylor, C.E.; D’Este, J.R. Photocatalytic Conversion of Methane. Catal. Today 1997, 33, 199–204. [Google Scholar] [CrossRef]

- Gondal, M.A.; Hameed, A.; Suwaiyan, A. Photo-Catalytic Conversion of Methane into Methanol Using Visible Laser. Appl. Catal. A Gen. 2003, 243, 165–174. [Google Scholar] [CrossRef]

- Murcia-López, S.; Villa, K.; Andreu, T.; Morante, J.R. Partial Oxidation of Methane to Methanol Using Bismuth-Based Photocatalysts. ACS Catal. 2014, 4, 3013–3019. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, D.; Li, N.; Xu, Q.; Li, H.; He, J.; Lu, J. Pt-Co Nanoparticles Supported on Hollow Multi-Shelled CeO2 as a Catalyst for Highly Efficient Toluene Oxidation: Morphology Control and the Role of Bimetal Synergism. J. Colloid Interface Sci. 2022, 608, 48–59. [Google Scholar] [CrossRef]

- Khalifeh, R.; Karimi, M.; Rajabzadeh, M.; Hafizi, A.; Nogorani, F.S. Synthesis and Morphology Control of Nano CuAl2O4 Hollow Spheres and Their Application as an Efficient and Sustainable Catalyst for CO2 Fixation. J. CO2 Util. 2020, 41, 101233. [Google Scholar] [CrossRef]

- Dong, P.; Hou, G.; Xi, X.; Shao, R.; Dong, F. WO3-Based Photocatalysts: Morphology Control, Activity Enhancement and Multifunctional Applications. Environ. Sci. Nano 2017, 4, 539–557. [Google Scholar] [CrossRef]

- Pan, H.; Risley, V.A.; Martindale, K.R.; Heagy, M.D. Photocatalytic Reduction of Bicarbonate to Formic Acid Using Hierarchical ZnO Nanostructures. ACS Sustain. Chem. Eng. 2018, 7, 1210–1219. [Google Scholar] [CrossRef]

- Murillo-Sierra, J.C.; Hernández-Ramírez, A.; Hinojosa-Reyes, L.; Guzmán-Mar, J.L. A Review on the Development of Visible Light-Responsive WO3-Based Photocatalysts for Environmental Applications. Chem. Eng. J. Adv. 2021, 5, 100070. [Google Scholar] [CrossRef]

- Farhadian, M.; Sangpout, P.; Hosseinzadeh, G. Morphology Dependent Photocatalytic Activity of WO3 Nanostructures. J. Energy Chem. 2015, 24, 171–177. [Google Scholar] [CrossRef]

- Xu, D.; Jiang, T.; Wang, D.; Chen, L.; Zhang, L.; Fu, Z.; Wang, L.; Xie, T. PH-Dependent Assembly of Tungsten Oxide Three-Dimensional Architectures and Their Application in Photocatalysis. ACS Appl. Mater. Interfaces 2014, 6, 9321–9327. [Google Scholar] [CrossRef] [PubMed]

- Shandilya, P.; Sambyal, S.; Sharma, R.; Mandyal, P.; Fang, B. Properties, Optimized Morphologies, and Advanced Strategies for Photocatalytic Applications of WO3 Based Photocatalysts. J. Hazard. Mater. 2022, 428, 128218. [Google Scholar] [CrossRef]

- Pan, H.; Martindale, K.R.; Heagy, M.D. Iron Oxide Nanostructures for the Reduction of Bicarbonate to Solar Fuels. Top. Catal. 2018, 61, 601–609. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Q.; Li, X.; Bai, H.; Li, W.; Zeng, T.; Xi, G. Ligand-Free and Size-Controlled Synthesis of Oxygen Vacancy-Rich WO3−x Quantum Dots for Efficient Room-Temperature Formaldehyde Gas Sensing. RSC Adv. 2016, 6, 95747–95752. [Google Scholar] [CrossRef]

- Jeyapaul, T.; Prakash, K.; Harikengaram, S.; Chellamani, A.; Selvam, V. Synthesis of WO3 Nanorods and Their Photocatalytic Degradation of Organic Contaminants. Rasayan J. Chem 2018, 11, 1405–1414. [Google Scholar] [CrossRef]

- Kong, L.; Guo, X.; Xu, J.; Mo, Z.; Li, L. Morphology Control of WO3 Nanoplate Film on W Foil by Oxalic Acid for Photocatalytic Gaseous Acetaldehyde Degradation. J. Photochem. Photobiol. A Chem. 2020, 401, 112760. [Google Scholar] [CrossRef]

- Acharyya, S.S.; Ghosh, S.; Bal, R. Fabrication of Three Dimensional (3D) Hierarchical Ag/WO3 Flower-like Catalyst Materials for the Selective Oxidation of m-Xylene to Isophthalic Acid. Chem. Commun. 2015, 51, 5998–6001. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; Xing, Y.; Li, Y.; Zhao, Y.; Du, W.; Zhou, M. Preparation and Gas Sensing Properties of Flower-like WO3 Hierarchical Architecture. Vacuum 2016, 129, 13–19. [Google Scholar] [CrossRef]

- Zeng, W.; Zhang, H.; Wang, Z. Effects of Different Petal Thickness on Gas Sensing Properties of Flower-like WO3·H2O Hierarchical Architectures. Appl. Surf. Sci. 2015, 347, 73–78. [Google Scholar] [CrossRef]

- Li, Y.; Tang, Z.; Zhang, J.; Zhang, Z. Fabrication of Vertical Orthorhombic/Hexagonal Tungsten Oxide Phase Junction with High Photocatalytic Performance. Appl. Catal. B Environ. 2017, 207, 207–217. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zhang, P.; Wang, T.; Gong, J. Monoclinic WO3 Nanomultilayers with Preferentially Exposed (002) Facets for Photoelectrochemical Water Splitting. Nano Energy 2015, 11, 189–195. [Google Scholar] [CrossRef]

- Sharon, M.; Sharan, M.K.; Jawalekar, S.R. Preparation and Characterisation of Oxygen Deficient WO3 Film-1. Sol. Energy Mater. 1984, 10, 329–334. [Google Scholar] [CrossRef]

- Huang, J.; Xu, X.; Gu, C.; Fu, G.; Wang, W.; Liu, J. Flower-like and Hollow Sphere-like WO3 Porous Nanostructures: Selective Synthesis and Their Photocatalysis Property. Mater. Res. Bull. 2012, 47, 3224–3232. [Google Scholar] [CrossRef]

- Wei, S.; Li, S.; Wei, R.; Liu, S.; Du, W. Different Morphologies of WO3 and Their Exposed Facets-Dependent Acetone Sensing Properties. Sens. Actuators B Chem. 2021, 329, 129188. [Google Scholar] [CrossRef]

- Weng, B.; Wu, J.; Zhang, N.; Xu, Y.-J. Observing the Role of Graphene in Boosting the Two-Electron Reduction of Oxygen in Graphene–WO3 Nanorod Photocatalysts. Langmuir 2014, 30, 5574–5584. [Google Scholar] [CrossRef]

- Ji, R.; Zheng, D.; Zhou, C.; Cheng, J.; Yu, J.; Li, L. Low-Temperature Preparation of Tungsten Oxide Anode Buffer Layer via Ultrasonic Spray Pyrolysis Method for Large-Area Organic Solar Cells. Materials 2017, 10, 820. [Google Scholar] [CrossRef]

- Villa, K.; Murcia-López, S.; Andreu, T.; Morante, J.R. On the Role of WO3 Surface Hydroxyl Groups for the Photocatalytic Partial Oxidation of Methane to Methanol. Catal. Commun. 2015, 58, 200–203. [Google Scholar] [CrossRef]

- Wang, J.; Khoo, E.; Lee, P.S.; Ma, J. Synthesis, Assembly, and Electrochromic Properties of Uniform Crystalline WO3 Nanorods. J. Phys. Chem. C 2008, 112, 14306–14312. [Google Scholar] [CrossRef]

| WO3 Architecture | Crystal Modification | Bandgap (eV) | BET Surface Area (m2/g) |

|---|---|---|---|

| micron | monoclinic | 2.48 ± 0.06 | 4.3 |

| nanopowder | monoclinic | 2.58 ± 0.05 | 7.1 |

| rods | hexagonal | 2.71 ± 0.08 | 19.6 |

| wires | hexagonal | 2.75 ± 0.05 | 17.0 |

| flowers | orthorhombic | 2.59 ± 0.09 | 16.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Premachandra, D.; Heagy, M.D. Morphology-Controlled WO3 for the Photocatalytic Oxidation of Methane to Methanol in Mild Conditions. Methane 2023, 2, 103-112. https://doi.org/10.3390/methane2010008

Premachandra D, Heagy MD. Morphology-Controlled WO3 for the Photocatalytic Oxidation of Methane to Methanol in Mild Conditions. Methane. 2023; 2(1):103-112. https://doi.org/10.3390/methane2010008

Chicago/Turabian StylePremachandra, Dumindu, and Michael D. Heagy. 2023. "Morphology-Controlled WO3 for the Photocatalytic Oxidation of Methane to Methanol in Mild Conditions" Methane 2, no. 1: 103-112. https://doi.org/10.3390/methane2010008