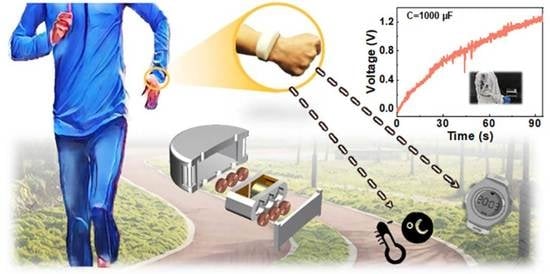

A Hybrid Triboelectric-Electromagnetic Nanogenerator Based on Arm Swing Energy Harvesting

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Devices Structure and Diagram of the HNG

3.2. Working Principle and Performance of the TENG

3.3. Working Principle and Performance of the EMG

3.4. Hybrid Generator and Energy Storage

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Reeder, B.; Chung, J.; Lyden, K.; Winters, J.; Jankowski, C.M. Older women’s perceptions of wearable and smart home activity sensors. Inform. Health Soc. Care 2020, 45, 96–109. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Zhou, H.; Sun, X.; Feng, T.; Zhao, X.; Wang, Z.; Liang, E.; Mao, Y. Cotton-based naturally wearable power source for self-powered personal electronics. J. Mater. Sci. 2020, 55, 2462–2470. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, D.; Seong, J.; Bak, B.; Choi, U.H.; Kim, J. Ionic liquid-based molecular design for transparent, flexible, and fire-retardant triboelectric nanogenerator (TENG) for wearable energy solutions. Nano Energy 2021, 84, 105925. [Google Scholar] [CrossRef]

- Walden, R.; Aazem, I.; Babu, A.; Pillai, S.C. Textile-Triboelectric nanogenerators (T-TENGs) for wearable energy harvesting devices. Chem. Eng. J. 2023, 451, 138741. [Google Scholar] [CrossRef]

- Wang, Z.L. Entropy theory of distributed energy for internet of things. Nano Energy 2019, 58, 669–672. [Google Scholar] [CrossRef]

- Zou, Y.; Raveendran, V.; Chen, J. Wearable triboelectric nanogenerators for biomechanical energy harvesting. Nano Energy 2020, 77, 105303. [Google Scholar] [CrossRef]

- Song, C.; Xia, K.; Xu, Z. A self-supported structure hybrid triboelectric/piezoelectric nanogenerator for bio-mechanical energy harvesting and pressure sensing. Microelectron. Eng. 2022, 256, 111723. [Google Scholar] [CrossRef]

- Vivekananthan, V.; Kim, W.J.; Alluri, N.R.; Purusothaman, Y.; Khandelwal, G.; Kim, S.-J. A highly reliable contact-separation based triboelectric nanogenerator for scavenging bio-mechanical energy and self-powered electronics. J. Mech. Sci. Technol. 2021, 35, 2131–2139. [Google Scholar] [CrossRef]

- Xia, K.; Xu, Z. Double-piezoelectric-layer-enhanced triboelectric nanogenerator for bio-mechanical energy harvesting and hot airflow monitoring. Smart Mater. Struct. 2020, 29, 095016. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.L.; Yang, Y. Hybridized nanogenerator for simultaneously scavenging mechanical and thermal energies by electromagnetic-triboelectric-thermoelectric effects. Nano Energy 2016, 26, 164–171. [Google Scholar] [CrossRef]

- Tang, X.; Lin, T.; Zuo, L. Design and Optimization of a Tubular Linear Electromagnetic Vibration Energy Harvester. IEEE/ASME Trans. Mechatron. 2014, 19, 615–622. [Google Scholar] [CrossRef]

- Wang, H.; Xu, C.; Pan, X.; Cheng, T. A triboelectric–electromagnetic hybrid generator for scavenging low-frequency oscillation energy from the environment and human body. J. Mater. Sci. 2022, 57, 21143–21155. [Google Scholar] [CrossRef]

- Qi, Y.; Liu, G.; Bu, T.; Zeng, J.; Zhang, Z.; Zhang, C. Ferromagnetic-Based Charge-Accumulation Triboelectric Nanogenerator With Ultrahigh Surface Charge Density. Small 2022, 18, 2201754. [Google Scholar] [CrossRef]

- Qi, Y.; Liu, G.; Gao, Y.; Bu, T.; Zhang, X.; Xu, C.; Lin, Y.; Zhang, C. Frequency Band Characteristics of a Triboelectric Nanogenerator and Ultra-Wide-Band Vibrational Energy Harvesting. ACS Appl. Mater. Interfaces 2021, 13, 26084–26092. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Liu, G.; Kuang, Y.; Wang, L.; Zeng, J.; Lin, Y.; Zhou, H.; Zhu, M.; Zhang, C. Frequency band broadening and charge density enhancement of a vibrational triboelectric nanogenerator with two stoppers. Nano Energy 2022, 99, 107427. [Google Scholar] [CrossRef]

- Zhao, J.; Zhen, G.; Liu, G.; Bu, T.; Liu, W.; Fu, X.; Zhang, P.; Zhang, C.; Wang, Z.L. Remarkable merits of triboelectric nanogenerator than electromagnetic generator for harvesting small-amplitude mechanical energy. Nano Energy 2019, 61, 111–118. [Google Scholar] [CrossRef]

- Ding, S.; Zhai, H.; Shao, Y.; Lei, R. Isometric Double-Layer Staggered Chain Teeth Triboelectric Nanogenerator. Micromachines 2022, 13, 421. [Google Scholar] [CrossRef]

- Mehamud, I.; Marklund, P.; Björling, M.; Shi, Y. Machine condition monitoring enabled by broad range vibration frequency detecting triboelectric nano-generator (TENG)-based vibration sensors. Nano Energy 2022, 98, 107292. [Google Scholar] [CrossRef]

- Hou, C.; Chen, T.; Li, Y.; Huang, M.; Shi, Q.; Liu, H.; Sun, L.; Lee, C. A rotational pendulum based electromagnetic/triboelectric hybrid-generator for ultra-low-frequency vibrations aiming at human motion and blue energy applications. Nano Energy 2019, 63, 103871. [Google Scholar] [CrossRef]

- Salauddin, M.; Toyabur, R.M.; Maharjan, P.; Rasel, M.S.; Kim, J.W.; Cho, H.; Park, J.Y. Miniaturized springless hybrid nanogenerator for powering portable and wearable electronic devices from human-body-induced vibration. Nano Energy 2018, 51, 61–72. [Google Scholar] [CrossRef]

- Li, T.; Pan, P.; Yang, Z.; Yang, X. Research on PDMS TENG of laser etch 3D structure. J. Mater. Sci. 2022, 57, 6723–6733. [Google Scholar] [CrossRef]

- Zhang, S.L.; Jiang, Q.; Wu, Z.; Ding, W.; Zhang, L.; Alshareef, H.N.; Wang, Z.L. Energy Harvesting-Storage Bracelet Incorporating Electrochemical Microsupercapacitors Self-Charged from a Single Hand Gesture. Adv. Energy Mater. 2019, 9, 1900152. [Google Scholar] [CrossRef]

- Bai, S.; Cui, J.; Zheng, Y.; Li, G.; Liu, T.; Liu, Y.; Hao, C.; Xue, C. Electromagnetic-triboelectric energy harvester based on vibration-to-rotation conversion for human motion energy exploitation. Appl. Energy 2023, 329, 120292. [Google Scholar] [CrossRef]

- Deng, Z.; Xu, L.; Qin, H.; Li, X.; Duan, J.; Hou, B.; Wang, Z.L. Rationally Structured Triboelectric Nanogenerator Arrays for Harvesting Water-Current Energy and Self-Powered Sensing. Adv. Mater. 2022, 34, 2205064. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, H.; Wu, H.; Lee, C. Self-powered triboelectric nanogenerator buoy ball for applications ranging from environment monitoring to water wave energy farm. Nano Energy 2017, 40, 203–213. [Google Scholar] [CrossRef]

- Han, C.; Cao, Z.; Yuan, Z.; Zhang, Z.; Huo, X.; Zhang, L.; Wu, Z.; Wang, Z.L. Hybrid Triboelectric-Electromagnetic Nanogenerator with a Double-Sided Fluff and Double Halbach Array for Wave Energy Harvesting. Adv. Funct. Mater. 2022, 32, 2205011. [Google Scholar] [CrossRef]

- Zhao, J.; Mu, J.; Cui, H.; He, W.; Zhang, L.; He, J.; Gao, X.; Li, Z.; Hou, X.; Chou, X. Hybridized Triboelectric-Electromagnetic Nanogenerator for Wind Energy Harvesting to Realize Real-Time Power Supply of Sensor Nodes. Adv. Mater. Technol. 2021, 6, 2001022. [Google Scholar] [CrossRef]

- Guo, H.; Leng, Q.; He, X.; Wang, M.; Chen, J.; Hu, C.; Xi, Y. A Triboelectric Generator Based on Checker-Like Interdigital Electrodes with a Sandwiched PET Thin Film for Harvesting Sliding Energy in All Directions. Adv. Energy Mater. 2015, 5, 1400790. [Google Scholar] [CrossRef]

- He, X.; Wen, Q.; Sun, Y.; Wen, Z. A low-frequency piezoelectric-electromagnetic-triboelectric hybrid broadband vibration energy harvester. Nano Energy 2017, 40, 300–307. [Google Scholar] [CrossRef]

- Wang, S.; Liao, W.; Zhang, Z.; Liao, Y.; Yan, M.; Kan, J. Development of a novel non-contact piezoelectric wind energy harvester excited by vortex-induced vibration. Energy Convers. Manag. 2021, 235, 113980. [Google Scholar] [CrossRef]

- Wu, Z.; Tang, J.; Zhang, X.; Yu, Z. An energy harvesting bracelet. Appl. Phys. Lett. 2017, 111, 013903. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, Y.; Ma, J.; Zhu, H.; Cao, X.; Wang, N.; Wang, Z.L. Harvesting wind energy: A hybridized design of pinwheel by coupling triboelectrification and electromagnetic induction effects. Nano Energy 2019, 60, 641–648. [Google Scholar] [CrossRef]

- Rana, S.M.S.; Rahman, M.T.; Salauddin, M.; Maharjan, P.; Bhatta, T.; Cho, H.; Park, J.Y. A human-machine interactive hybridized biomechanical nanogenerator as a self-sustainable power source for multifunctional smart electronics applications. Nano Energy 2020, 76, 105025. [Google Scholar] [CrossRef]

- Salauddin, M.; Toyabur, R.M.; Maharjan, P.; Rasel, M.S.; Cho, H.; Park, J.Y. Design and experimental analysis of a low-frequency resonant hybridized nanogenerator with a wide bandwidth and high output power density. Nano Energy 2019, 66, 104122. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, S.; Li, W.; Gao, Q.; Zhao, D.; Wang, Z.L.; Cheng, T. Self-Powered Sensing for Smart Agriculture by Electromagnetic-Triboelectric Hybrid Generator. ACS Nano 2021, 15, 20278–20286. [Google Scholar] [CrossRef]

- Zhong, X.; Yang, Y.; Wang, X.; Wang, Z.L. Rotating-disk-based hybridized electromagnetic-triboelectric nanogenerator for scavenging biomechanical energy as a mobile power source. Nano Energy 2015, 13, 771–780. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, X.; Yang, Y.; Wang, Z.L. Hybrid energy cell for harvesting mechanical energy from one motion using two approaches. Nano Energy 2015, 11, 162–170. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Cao, Z.; Han, C.; Wei, X.; Wang, L.; Wu, Z. A Hybrid Triboelectric-Electromagnetic Nanogenerator Based on Arm Swing Energy Harvesting. Nanoenergy Adv. 2023, 3, 126-137. https://doi.org/10.3390/nanoenergyadv3020007

Zheng J, Cao Z, Han C, Wei X, Wang L, Wu Z. A Hybrid Triboelectric-Electromagnetic Nanogenerator Based on Arm Swing Energy Harvesting. Nanoenergy Advances. 2023; 3(2):126-137. https://doi.org/10.3390/nanoenergyadv3020007

Chicago/Turabian StyleZheng, Jiayue, Zhi Cao, Chengcheng Han, Xuelian Wei, Linlin Wang, and Zhiyi Wu. 2023. "A Hybrid Triboelectric-Electromagnetic Nanogenerator Based on Arm Swing Energy Harvesting" Nanoenergy Advances 3, no. 2: 126-137. https://doi.org/10.3390/nanoenergyadv3020007