Investigating the Effect of Volatiles on Sub-23 nm Particle Number Measurements for a Downsized GDI Engine with a Catalytic Stripper and Digital Filtering

Abstract

:1. Introduction

2. Experimental Section

2.1. Engine Setup

2.2. Gas Analyser

2.3. Particulate Measurement

3. Results and Discussion

3.1. Digital Filtering Functions for Sub-23 nm Measurements

3.2. Impact of Catalytic Stripper

3.3. Particulate Emissions across the Test Matrix

4. Conclusions

- -

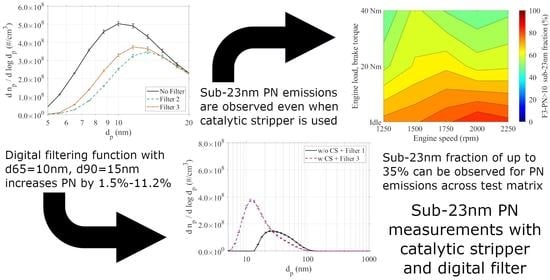

- An updated filtering function for SPN10-inspired counting efficiencies was applied to measurements acquired while using a catalytic stripper. The results show an increase of up to 11.2% for PN > 10 compared with the closest previous sub-23 nm digital filtering function. However, this increase is highly dependent on the underlying PSD, with conditions of a smaller GMD exhibiting a greater shift. These observations confirm the findings of a previous study in which the function was proposed based on DMS measurements without a catalytic stripper.

- -

- Directly comparing measurements with and without a catalytic stripper reveals that the catalytic stripper noticeably reduced variability in sub-23 nm particle concentration measurements. A significant portion of particles in this size regime remained that, thus, are assumed to be non-volatile solid particles. The shift from d50 = 23 nm/d90 = 41 nm digital filtering without the catalytic stripper (F1-PN > 23) to d65 = 10 nm/d90 = 15 nm digital filtering with the catalytic stripper (F3-PN > 10) leads to a considerable difference in the resulting PSD.

- -

- The measurements of the test matrix showed the highest PN emissions for fast-idle at 1250 rpm, regardless of using a catalytic stripper or the used digital filtering function. Specifically, the value doubled from F1-PN > 23 with to F3-PN > 10 of . The number of particulates generally increases when comparing the F3-PN > 10 with the F1-PN > 23, from as low as +27% at 1250 rpm with 40 Nm up to an almost four-fold +390% at 1750 rpm with 20 Nm.

- -

- Investigation of engine metrics revealed a similar trend between PN and THC emissions. The remaining included metrics; exhaust gas temperature, spark timing, 50% MFB position, injection timing, and pressure, could not conclusively explain the observed patterns in the PN and GMD measurements.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Health Organization. Ambient Air Pollution: A Global Assessment of Exposure and Burden of Disease; World Health Organization: Geneva, Switzerland, 2016; ISBN 9789241511353.

- U.S. Environmental Protection Agency Health and Environmental Effects of Particulate Matter (PM). 2021. Available online: https://www.epa.gov/pm-pollution/health-and-environmental-effects-particulate-matter-pm (accessed on 11 July 2021).

- Jansen, K.L.; Larson, T.V.; Koenig, J.Q.; Mar, T.F.; Fields, C.; Stewart, J.; Lippmann, M. Associations between health effects and particulate matter and black carbon in subjects with respiratory disease. Environ. Health Perspect. 2005, 113, 1741–1746. [Google Scholar] [CrossRef] [PubMed]

- Bond, T.C.; Doherty, S.J.; Fahey, D.W.; Forster, P.M.; Berntsen, T.; DeAngelo, B.J.; Flanner, M.G.; Ghan, S.; Kärcher, B.; Koch, D.; et al. Bounding the role of black carbon in the climate system: A scientific assessment. J. Geophys. Res. Atmos. 2013, 118, 5380–5552. [Google Scholar] [CrossRef]

- Shindell, D.; Kuylenstierna, J.C.I.; Vignati, E.; van Dingenen, R.; Amann, M.; Klimont, Z.; Anenberg, S.C.; Muller, N.; Janssens-Maenhout, G.; Raes, F.; et al. Simultaneously mitigating near-term climate change and improving human health and food security. Science 2012, 335, 183–189. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- European Environment Agency Exceedance of Air Quality Standards in Urban Areas. 2019. Available online: https://www.eea.europa.eu/data-and-maps/indicators/exceedance-of-air-quality-limit-3/assessment-5 (accessed on 11 July 2021).

- La Rocca, A.; Bonatesta, F.; Fay, M.W.; Campanella, F. Characterisation of soot in oil from a gasoline direct injection engine using transmission electron microscopy. Tribol. Int. 2015, 86, 77–84. [Google Scholar] [CrossRef]

- Maricq, M.M.; Podsiadlik, D.H.; Brehob, D.D.; Haghgooie, M. Particulate emissions from a direct-injection spark-ignition (DISI) engine 1999-01-1530. SAE Tech. Pap. 1999. [Google Scholar] [CrossRef]

- Zhao, H. (Ed.) Advanced Direct Injection Combustion Engine Technologies and Development: Diesel Engines; Woodhead Publishing: Cambridge, UK, 2009; ISBN 9781845697440. [Google Scholar]

- Piock, W.; Hoffmann, G.; Berndorfer, A.; Salemi, P.; Fusshoeller, B. Strategies towards meeting future particulate matter emission requirements in homogeneous gasoline direct injection engines. SAE Int. J. Engines 2011, 4, 1455–1468. [Google Scholar] [CrossRef] [Green Version]

- Peckham, M.S.; Finch, A.; Campbell, B.; Price, P.; Davies, M.T. Study of particle number emissions from a turbocharged gasoline direct injection (GDI) Engine including data from a fast-response particle size spectrometer 2011-01-1224. SAE Tech. Pap. 2011. [Google Scholar] [CrossRef]

- European Union. Council Directive 91/441/EEC of 26 June 1991 amending Directive 70/220/EEC on the approximation of the laws of the Member States relating to measures to be taken against air pollution by emissions from motor vehicles. Off. J. Eur. Communities 1991, L242, 1–106. [Google Scholar]

- European Union. Regulation (EC) No 715/2007 of the European Parliament and of the Council of 20 June 2007 on type approval of motor vehicles with respect to emissions from light passenger and commercial vehicles (Euro 5 and Euro 6) [...]. Off. J. Eur. Union 2007, L171, 1–16. [Google Scholar]

- Burtscher, H. Physical characterization of particulate emissions from diesel engines: A review. J. Aerosol Sci. 2005, 36, 896–932. [Google Scholar] [CrossRef]

- European Union. Commission Regulation (EC) No 692/2008 of 18 July 2008 implementing and amending Regulation (EC) No 715/2007 of the European Parliament and of the Council on type-approval of motor vehicles with respect to emissions [...]. Off. J. Eur. Union 2008, L199, 1–136. [Google Scholar]

- Andersson, J.; Giechaskiel, B.; Muñoz-Bueno, R.; Sandbach, E.; Dilara, P. Particle Measurement Programme (PMP) Light-Duty Inter-Laboratory Correlation Exercise (ILCE_LD) Final Report; European Commission: Ispra, Italy, 2007.

- Giechaskiel, B.; Dilara, P.; Andersson, J. Particle measurement programme (PMP) light-duty inter-laboratory exercise: Repeatability and reproducibility of the particle number method. Aerosol Sci. Technol. 2008, 42, 528–543. [Google Scholar] [CrossRef]

- Martini, G.; Giechaskiel, B.; Dilara, P. Future European emission standards for vehicles: The importance of the UN-ECE particle measurement programme. Biomarkers 2009, 14, 29–33. [Google Scholar] [CrossRef] [PubMed]

- Giechaskiel, B.; Manfredi, U.; Martini, G. Engine exhaust solid sub-23 nm particles: I. Literature survey. SAE Int. J. Fuels Lubr. 2014, 7, 950–964. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Joshi, A.; Ntziachristos, L.; Dilara, P. European regulatory framework and particulate matter emissions of gasoline light-duty vehicles: A review. Catalysts 2019, 9, 586. [Google Scholar] [CrossRef] [Green Version]

- United Nations Economic Commission for Europe PMP 52th Session [sic]. 2020. Available online: https://wiki.unece.org/display/trans/PMP+52th+Session (accessed on 11 July 2021).

- United Nations Economic Commission for Europe Final Report on the Development of Amendment 6 to Global Technical Regulation No. 15 on Worldwide Harmonized Light Vehicles Test Procedures (WLTP), Informal document GRPE-81-15. 2020. Available online: https://unece.org/DAM/trans/doc/2020/wp29grpe/GRPE-81-15e.pdf (accessed on 11 July 2021).

- Samaras, Z.; Rieker, M.; Papaioannou, E.; van Dorp, W.F.; Kousoulidou, M.; Ntziachristos, L.; Andersson, J.; Bergmann, A.; Hausberger, S.; Keskinen, J.; et al. Perspectives for regulating 10 nm particle number emissions based on novel measurement methodologies. J. Aerosol Sci. 2022, 162, 105957. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.; Martini, G.; Dilara, P. Overview of vehicle exhaust particle number regulations. Processes 2021, 9, 2216. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.; Martini, G.; Dilara, P.; Ntziachristos, L. Revisiting total particle number measurements for vehicle exhaust regulations. Atmosphere 2022, 13, 155. [Google Scholar] [CrossRef]

- Kulkarni, P.; Baron, P.A.; Willeke, K. (Eds.) Aerosol Measurement: Principles, Techniques, and Applications, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 9781118001684. [Google Scholar]

- Braisher, M.; Stone, R.; Price, P. Particle number emissions from a range of European vehicles 2010-01-0786. SAE Tech. Pap. 2010. [Google Scholar] [CrossRef]

- Pfau, S.A.; Haffner-Staton, E.; La Rocca, A. Measurement of sub-23 nm particulate emissions from GDI engines: A comparison of processing methods 2021-01-0626. SAE Tech. Pap. 2021. [Google Scholar] [CrossRef]

- Leach, F.C.P. Particulate Emissions from Gasoline Direct Injection Engines. Ph.D. Thesis, University of Oxford, Oxford, UK, 2014. [Google Scholar]

- Leach, F.; Stone, R.; Richardson, D.; Lewis, A.; Akehurst, S.; Turner, J.; Remmert, S.; Campbell, S.; Cracknell, R.F. Particulate emissions from a highly boosted gasoline direct injection engine. Int. J. Engine Res. 2018, 19, 347–359. [Google Scholar] [CrossRef]

- Leach, F.C.P.; Stone, R.; Richardson, D.; Turner, J.W.G.; Lewis, A.; Akehurst, S.; Remmert, S.; Campbell, S.; Cracknell, R. The effect of oxygenate fuels on PN emissions from a highly boosted GDI engine. Fuel 2018, 225, 277–286. [Google Scholar] [CrossRef]

- Leach, F.C.P.; Stone, R.; Richardson, D.; Lewis, A.G.J.; Akehurst, S.; Turner, J.W.G.; Shankar, V.; Chahal, J.; Cracknell, R.F.; Aradi, A. The effect of fuel composition on particulate emissions from a highly boosted GDI engine—An evaluation of three particulate indices. Fuel 2019, 252, 598–611. [Google Scholar] [CrossRef]

- Leach, F.; Lewis, A.; Akehurst, S.; Turner, J.; Richardson, D. Sub-23 nm particulate emissions from a highly boosted GDI engine 2019-24-0153. SAE Tech. Pap. 2019. [Google Scholar] [CrossRef] [Green Version]

- Giechaskiel, B.; Lähde, T.; Suarez-Bertoa, R.; Clairotte, M.; Grigoratos, T.; Zardini, A.; Perujo, A.; Martini, G. Particle number measurements in the European legislation and future JRC activities. Combust. Engines 2018, 174, 3–16. [Google Scholar] [CrossRef]

- Horn, H.G. PEMs4Nano Report: Calibrated CPC with D50 <= 10 nm for Laboratory Use—Together with the Documented Calibration Procedure. 2017. Available online: https://www.pems4nano.eu/download/public_reports/reports_of_project_results_deliverables/PEMs4Nano-D2.05-Calibrated-CPC-with-D50-10nm-for-PEMS-use-PU-2018-03-30.pdf (accessed on 11 July 2021).

- Pfau, S.A. Nanoscale Characterisation of Soot Particulates from Gasoline Direct Injection Engines. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2021. [Google Scholar]

- Kumar, P.; Fennell, P.; Symonds, J.; Britter, R. Treatment of losses of ultrafine aerosol particles in long sampling tubes during ambient measurements. Atmos. Environ. 2008, 42, 8819–8826. [Google Scholar] [CrossRef] [Green Version]

- Duca, D.; Rahman, M.; Carpentier, Y.; Pirim, C.; Boies, A.; Focsa, C. Chemical characterization of size-selected nanoparticles emitted by a gasoline direct injection engine: Impact of a catalytic stripper. Fuel 2021, 294, 120317. [Google Scholar] [CrossRef]

- Bokor, C.; Rohani, B.; Humphries, C.; Morrey, D.; Bonatesta, F. Investigating the impact of gasoline composition on PN in GDI engines using an improved measurement method. Int. J. Engine Res. 2021, 22, 3391–3406. [Google Scholar] [CrossRef]

- Di Iorio, S.; Catapano, F.; Magno, A.; Sementa, P.; Vaglieco, B.M. Investigation on sub-23 nm particles and their volatile organic fraction (VOF) in PFI/DI spark ignition engine fueled with gasoline, ethanol and a 30 %v/v ethanol blend. J. Aerosol Sci. 2021, 153, 105723. [Google Scholar] [CrossRef]

- Catapano, F.; Di Iorio, S.; Magno, A.; Vaglieco, B.M. Effect of fuel quality on combustion evolution and particle emissions from PFI and GDI engines fueled with gasoline, ethanol and blend, with focus on 10–23 nm particles. Energy 2022, 239, 122198. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Woodburn, J.; Szczotka, A.; Bielaczyc, P. Particulate matter (PM) emissions of Euro 5 and Euro 6 vehicles using systems with evaporation tube or catalytic stripper and 23 nm or 10 nm counters 2020-01-2203. SAE Tech. Pap. 2020. [Google Scholar] [CrossRef]

- Catapano, F.; Di Iorio, S.; Magno, A.; Sementa, P.; Vaglieco, B.M. Effect of ethanol blends, E10, E25 and E85 on sub-23 nm particle emissions and their volatile fraction at exhaust of a high-performance GDI engine over the WLTC. Fuel 2022, 327, 125184. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Max. Power | 92 kW @ 6000 rpm |

| Max. Torque | 170 Nm @ 1400–4500 rpm |

| Bore | 71.9 mm |

| Stroke | 82.0 mm |

| Total Capacity | 999 cm3 |

| Compression Ratio | 10.5:1 |

| Injector | 5-hole solenoid |

| Max. Injection Pressure | 200 bar (common rail) |

| Parameter | Value |

|---|---|

| RON | 98.4 |

| MON | 87.1 |

| DVPE | 62.7 kPa |

| FBP | 198.3 °C |

| Ethanol | 0% |

| Sulfur | 3.4 mg/kg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pfau, S.A.; Haffner-Staton, E.; La Rocca, A.; Cairns, A. Investigating the Effect of Volatiles on Sub-23 nm Particle Number Measurements for a Downsized GDI Engine with a Catalytic Stripper and Digital Filtering. Fuels 2022, 3, 682-697. https://doi.org/10.3390/fuels3040041

Pfau SA, Haffner-Staton E, La Rocca A, Cairns A. Investigating the Effect of Volatiles on Sub-23 nm Particle Number Measurements for a Downsized GDI Engine with a Catalytic Stripper and Digital Filtering. Fuels. 2022; 3(4):682-697. https://doi.org/10.3390/fuels3040041

Chicago/Turabian StylePfau, Sebastian A., Ephraim Haffner-Staton, Antonino La Rocca, and Alasdair Cairns. 2022. "Investigating the Effect of Volatiles on Sub-23 nm Particle Number Measurements for a Downsized GDI Engine with a Catalytic Stripper and Digital Filtering" Fuels 3, no. 4: 682-697. https://doi.org/10.3390/fuels3040041