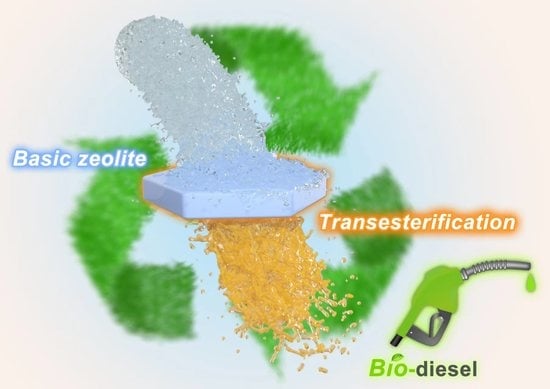

Advancements in Basic Zeolites for Biodiesel Production via Transesterification

Abstract

:1. Introduction

2. Synthesis of Basic Zeolite Catalysts

2.1. Origin of Basicity in Zeolites

2.2. Synthetic Strategies of Basic Zeolites

2.2.1. Ion Exchange Synthesis

2.2.2. Impregnation Method

2.2.3. One-Pot Synthesis

3. Characterization of Basic Zeolites

3.1. TPD of Carbon Dioxide (CO2-TPD)

3.2. Infrared Spectroscopy

3.3. NMR

3.4. XPS

4. Transesterification Reactions Utilizing Basic Zeolites

4.1. Conventional Microporous Basic Zeolites

4.2. Nanoscale and Hierarchical Basic Zeolites

4.3. Two-Dimensional (2D) Basic Zeolites

5. Challenges and Outlooks

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Izadyar, N.; Ong, H.C.; Chong, W.T.; Leong, K.Y. Resource assessment of the renewable energy potential for a remote area: A review. Renew. Sustain. Energy Rev. 2016, 62, 908–923. [Google Scholar] [CrossRef]

- Luque, R.; Lovett, J.C.; Datta, B.; Clancy, J.; Campelo, J.M.; Romero, A.A. Biodiesel as feasible petrol fuel replacement: A multidisciplinary overview. Energy Environ. Sci. 2010, 3, 1706–1721. [Google Scholar] [CrossRef]

- Demirbas, A. Political, economic and environmental impacts of biofuels: A review. Appl. Energy 2009, 86, S108–S117. [Google Scholar] [CrossRef]

- Yusuf, N.N.A.N.; Kamarudin, S.K.; Yaakub, Z. Overview on the current trends in biodiesel production. Energy Convers. Manag. 2011, 52, 2741–2751. [Google Scholar] [CrossRef]

- Demirbas, A. Progress and recent trends in biodiesel fuels. Energy Convers. Manag. 2009, 50, 14–34. [Google Scholar] [CrossRef]

- Pang, H.; Yang, G.; Li, L.; Yu, J. Esterification of Oleic Acid to Produce Biodiesel over 12-Tungstophosphoric Acid Anchored Two-dimensional Zeolite. Chem. Res. Chin. Univ. 2021, 37, 1072–1078. [Google Scholar] [CrossRef]

- Su, F.; Guo, Y.H. Advancements in solid acid catalysts for biodiesel production. Green Chem. 2014, 16, 2934–2957. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y. Chapter 21—Biodiesel Production: Status and Perspectives. In Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels (Second Edition); Pandey, A., Larroche, C., Dussap, C.-G., Gnansounou, E., Khanal, S.K., Ricke, S., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 503–522. [Google Scholar]

- Ishak, Z.I.; Sairi, N.A.; Alias, Y.; Aroua, M.K.T.; Yusoff, R. A review of ionic liquids as catalysts for transesterification reactions of biodiesel and glycerol carbonate production. Catal. Rev. 2017, 59, 44–93. [Google Scholar] [CrossRef]

- Gog, A.; Roman, M.; Tosa, M.; Paizs, C.; Irimie, F.D. Biodiesel production using enzymatic transesterification - Current state and perspectives. Renew. Energy 2012, 39, 10–16. [Google Scholar] [CrossRef]

- Amini, Z.; Ilham, Z.; Ong, H.C.; Mazaheri, H.; Chen, W.-H. State of the art and prospective of lipase-catalyzed transesterification reaction for biodiesel production. Energy Convers. Manag. 2017, 141, 339–353. [Google Scholar] [CrossRef]

- Melero, J.A.; Iglesias, J.; Morales, G. Heterogeneous acid catalysts for biodiesel production: Current status and future challenges. Green Chem. 2009, 11, 1285–1308. [Google Scholar] [CrossRef]

- Lee, A.F.; Bennett, J.A.; Manayil, J.C.; Wilson, K. Heterogeneous catalysis for sustainable biodiesel production via esterification and transesterification. Chem. Soc. Rev. 2014, 43, 7887–7916. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Girish, N.; Niju, S.P.; Meera Sheriffa Begum, K.M.; Anantharaman, N. Utilization of a cost effective solid catalyst derived from natural white bivalve clam shell for transesterification of waste frying oil. Fuel 2013, 111, 653–658. [Google Scholar] [CrossRef]

- Wen, L.; Wang, Y.; Lu, D.; Hu, S.; Han, H. Preparation of KF/CaO nanocatalyst and its application in biodiesel production from Chinese tallow seed oil. Fuel 2010, 89, 2267–2271. [Google Scholar] [CrossRef]

- Alonso, D.M.; Mariscal, R.; Granados, M.L.; Maireles-Torres, P. Biodiesel preparation using Li/CaO catalysts: Activation process and homogeneous contribution. Catal. Today 2009, 143, 167–171. [Google Scholar] [CrossRef]

- Baroutian, S.; Aroua, M.K.; Raman, A.A.A.; Sulaiman, N.M.N. Potassium hydroxide catalyst supported on palm shell activated carbon for transesterification of palm oil. Fuel Process. Technol. 2010, 91, 1378–1385. [Google Scholar] [CrossRef]

- Hattori, H. Heterogeneous Basic Catalysis. Chem. Rev. 1995, 95, 537–558. [Google Scholar] [CrossRef]

- Sun, L.-B.; Liu, X.-Q.; Zhou, H.-C. Design and fabrication of mesoporous heterogeneous basic catalysts. Chem. Soc. Rev. 2015, 44, 5092–5147. [Google Scholar] [CrossRef]

- Li, J.; Corma, A.; Yu, J. Synthesis of new zeolite structures. Chem. Soc. Rev. 2015, 44, 7112–7127. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Yu, J.; Xu, R. Needs and trends in rational synthesis of zeolitic materials. Chem. Soc. Rev. 2012, 41, 1729–1741. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, M.; Tian, P.; Liu, Z. Progress in Seed-assisted Synthesis of (Silico)Aluminophosphate Molecular Sieves. Chem. Res. Chin. Univ. 2022, 38, 1–8. [Google Scholar] [CrossRef]

- Li, J.; Rong, H.; Chen, C.; Li, Z.; Zuo, J.; Wang, W.; Liu, X.; Guan, Y.; Yang, X.; Liu, Y.; et al. Synthesis Optimization of SSZ-13 Zeolite Membranes by Dual Templates for N2/NO2 Separation. Chem. Res. Chin. Univ. 2022, 38, 250–256. [Google Scholar] [CrossRef]

- Lin, S.; Zhi, Y.; Liu, Z.; Yuan, J.; Liu, W.; Zhang, W.; Xu, Z.; Zheng, A.; Wei, Y.; Liu, Z. Multiscale dynamical cross-talk in zeolite-catalyzed methanol and dimethyl ether conversions. Natl. Sci. Rev. 2022, 9. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Wu, P. New progress in zeolite synthesis and catalysis. Natl. Sci. Rev. 2022, 9. [Google Scholar] [CrossRef]

- Sudarsanam, P.; Peeters, E.; Makshina, E.V.; Parvulescu, V.I.; Sels, B.F. Advances in porous and nanoscale catalysts for viable biomass conversion. Chem. Soc. Rev. 2019, 48, 2366–2421. [Google Scholar] [CrossRef]

- Luo, W.; Cao, W.; Bruijnincx, P.C.A.; Lin, L.; Wang, A.; Zhang, T. Zeolite-supported metal catalysts for selective hydrodeoxygenation of biomass-derived platform molecules. Green Chem. 2019, 21, 3744–3768. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J. New stories of zeolite structures: Their descriptions, determinations, predictions, and evaluations. Chem. Rev. 2014, 114, 7268–7316. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Yu, J. Applications of zeolites in sustainable chemistry. Chem 2017, 3, 928–949. [Google Scholar] [CrossRef] [Green Version]

- Bai, R.; Song, Y.; Li, Y.; Yu, J. Creating hierarchical pores in zeolite catalysts. Trends Chem. 2019, 1, 601–611. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.; Sun, Q.; Yu, J. Ultrasmall metal nanoparticles confined within crystalline nanoporous materials: A fascinating class of nanocatalysts. Adv. Mater. 2019, 31, 1803966. [Google Scholar] [CrossRef] [Green Version]

- Endalew, A.K.; Kiros, Y.; Zanzi, R. Inorganic heterogeneous catalysts for biodiesel production from vegetable oils. Biomass Bioenergy 2011, 35, 3787–3809. [Google Scholar] [CrossRef]

- Alaba, P.A.; Sani, Y.M.; Mohammed, I.Y.; Abakr, Y.A.; Daud, W.M.A.W. Synthesis and characterization of sulfated hierarchical nanoporous faujasite zeolite for efficient transesterification of shea butter. J. Clean. Prod. 2017, 142, 1987–1993. [Google Scholar] [CrossRef]

- MacArio, A.; Giordano, G.; Setti, L.; Parise, A.; Campelo, J.M.; Marinas, J.M.; Luna, D. Study of lipase immobilization on zeolitic support and transesterification reaction in a solvent free-system. Biocatal. Biotransform. 2007, 25, 328–335. [Google Scholar] [CrossRef]

- Wang, Y.; Chou, H.; Chen, B.; Lee, D. Optimization of sodium loading on zeolite support for catalyzed transesterification of triolein with methanol. Bioresour. Technol. 2013, 145, 248–253. [Google Scholar] [CrossRef]

- Wang, Y.; Dang, T.; Chen, B.; Lee, D. Transesterification of Triolein to Biodiesel Using Sodium-Loaded Catalysts Prepared from Zeolites. Ind. Eng. Chem. Res. 2012, 51, 9959–9965. [Google Scholar] [CrossRef]

- Suppes, G.J.; Dasari, M.A.; Doskocil, E.J.; Mankidy, P.J.; Goff, M.J. Transesterification of soybean oil with zeolite and metal catalysts. Appl. Catal. A 2004, 257, 213–223. [Google Scholar] [CrossRef]

- Li, Z.; Ding, S.; Chen, C.; Qu, S.; Du, L.; Lu, J.; Ding, J. Recyclable Li/NaY zeolite as a heterogeneous alkaline catalyst for biodiesel production: Process optimization and kinetics study. Energy Convers. Manag. 2019, 192, 335–345. [Google Scholar] [CrossRef]

- Du, L.; Ding, S.; Li, Z.; Lv, E.; Lu, J.; Ding, J. Transesterification of castor oil to biodiesel using NaY zeolite-supported La2O3 catalysts. Energy Convers. Manag. 2018, 173, 728–734. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, B. High-silica zeolite beta as a heterogeneous catalyst in transesterification of triolein for biodiesel production. Catal. Today 2016, 278, 335–343. [Google Scholar] [CrossRef]

- Barthomeuf, D. Basic Zeolites: Characterization and Uses in Adsorption and Catalysis. Catal. Rev. 1996, 38, 521–612. [Google Scholar] [CrossRef]

- Hathaway, P.E.; Davis, M.E. Base catalysis by alkali modified zeolites: III. Alkylation with methanol. J. Catal. 1989, 119, 497–507. [Google Scholar] [CrossRef]

- Barthomeuf, D. Acidity and Basicity in Zeolites. In Studies in Surface Science and Catalysis; Öhlmann, G., Pfeifer, H., Fricke, R., Eds.; Elsevier: Amsterdam, The Netherlands, 1991; Volume 65, pp. 157–169. [Google Scholar]

- Davis, R.J.; Doskocil, E.J.; Bordawekar, S. Structure/function relationships for basic zeolite catalysts containing occluded alkali species. Catal. Today 2000, 62, 241–247. [Google Scholar] [CrossRef]

- Sun, H.; Wu, D.; Liu, K.; Guo, X.; Navrotsky, A. Energetics of Alkali and Alkaline Earth Ion-Exchanged Zeolite A. J. Phys. Chem. C 2016, 120, 15251–15256. [Google Scholar] [CrossRef]

- Lawan, I.; Garba, Z.N.; Zhou, W.; Zhang, M.; Yuan, Z. Synergies between the microwave reactor and CaO/zeolite catalyst in waste lard biodiesel production. Renew. Energy 2020, 145, 2550–2560. [Google Scholar] [CrossRef]

- Al-Ani, A.; Darton, R.J.; Sneddon, S.; Zholobenko, V. Nanostructured Zeolites: The Introduction of Intracrystalline Mesoporosity in Basic Faujasite-type Catalysts. ACS Appl. Nano Mater. 2018, 1, 310–318. [Google Scholar] [CrossRef]

- Babajide, O.; Musyoka, N.; Petrik, L.; Ameer, F. Novel zeolite Na-X synthesized from fly ash as a heterogeneous catalyst in biodiesel production. Catal. Today 2012, 190, 54–60. [Google Scholar] [CrossRef] [Green Version]

- Al-Ani, A.; Mordvinova, N.E.; Lebedev, O.I.; Khodakov, A.Y.; Zholobenko, V. Ion-exchanged zeolite P as a nanostructured catalyst for biodiesel production. Energy Rep. 2019, 5, 357–363. [Google Scholar] [CrossRef]

- Pang, H.; Yang, G.; Li, L.; Yu, J. Efficient transesterification over two-dimensional zeolites for sustainable biodiesel production. Green Energy Environ. 2020, 5, 405–413. [Google Scholar] [CrossRef]

- Manadee, S.; Sophiphun, O.; Osakoo, N.; Supamathanon, N.; Kidkhunthod, P.; Chanlek, N.; Wittayakun, J.; Prayoonpokarach, S. Identification of potassium phase in catalysts supported on zeolite NaX and performance in transesterification of Jatropha seed oil. Fuel Process. Technol. 2017, 156, 62–67. [Google Scholar] [CrossRef]

- AbuKhadra, M.R.; Basyouny, M.G.; El-Sherbeeny, A.M.; El-Meligy, M.A.; Abd Elgawad, A.E.E. Transesterification of commercial waste cooking oil into biodiesel over innovative alkali trapped zeolite nanocomposite as green and environmental catalysts. Sustain. Chem. Pharm. 2020, 17, 100289. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, J.; Wei, Q.; Zheng, J.; Zhang, J. Transesterification of soybean oil to biodiesel using zeolite supported CaO as strong base catalysts. Fuel Process. Technol. 2013, 109, 13–18. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, N.; Xu, Q.; Yu, J. Nanopore-Supported Metal Nanocatalysts for Efficient Hydrogen Generation from Liquid-Phase Chemical Hydrogen Storage Materials. Adv. Mater. 2020, 32, 2001818. [Google Scholar] [CrossRef]

- Zhou, Y.; Jin, Y.; Wang, M.; Zhang, W.; Xie, J.; Gu, J.; Wen, H.; Wang, J.; Peng, L. One-Pot Synthesis of Zeolitic Strong Solid Bases: A Family of Alkaline-Earth Metal-Containing Silicalite-1. Chem. Eur. J. 2015, 21, 15412–15420. [Google Scholar] [CrossRef] [PubMed]

- Bordiga, S.; Lamberti, C.; Bonino, F.; Travert, A.; Thibault-Starzyk, F. Probing zeolites by vibrational spectroscopies. Chem. Soc. Rev. 2015, 44, 7262–7341. [Google Scholar] [CrossRef] [PubMed]

- Yagi, F.; Tsuji, H.; Hattori, H. IR and TPD (temperature-programmed desorption) studies of carbon dioxide on basic site active for 1-butene isomerization on alkali-added zeolite X. Microporous Mater. 1997, 9, 237–245. [Google Scholar] [CrossRef]

- Sánchez-Sánchez, M.; Blasco, T. Characterization of zeolite basicity using probe molecules by means of infrared and solid state NMR spectroscopies. Catal. Today 2009, 143, 293–301. [Google Scholar] [CrossRef]

- Bekhti, H.; Boucheffa, Y.; Blal, A.H.A.; Travert, A. In situ FTIR investigation of CO2 adsorption over MgO–Impregnated NaY zeolites. Vib. Spectrosc. 2021, 117, 103313. [Google Scholar] [CrossRef]

- Stevens, R.W.; Siriwardane, R.V.; Logan, J. In Situ Fourier Transform Infrared (FTIR) Investigation of CO2 Adsorption onto Zeolite Materials. Energy Fuels 2008, 22, 3070–3079. [Google Scholar] [CrossRef]

- Huang, M.; Kaliaguine, S. Zeolite basicity characterized by pyrrole chemisorption: An infrared study. J. Chem. Soc. Faraday Trans. 1992, 88, 751–758. [Google Scholar] [CrossRef]

- Wilson, J.N.; Idriss, H. Structure Sensitivity and Photocatalytic Reactions of Semiconductors. Effect of the Last Layer Atomic Arrangement. J. Am. Chem. Soc. 2002, 124, 11284–11285. [Google Scholar] [CrossRef]

- Sánchez-Sánchez, M.; Blasco, T. Investigation on the Nature of the Adsorption Sites of Pyrrole in Alkali-Exchanged Zeolite Y by Nuclear Magnetic Resonance in Combination with Infrared Spectroscopy. J. Am. Chem. Soc. 2002, 124, 3443–3456. [Google Scholar] [CrossRef] [PubMed]

- Vos, A.M.; Mignon, P.; Geerlings, P.; Thibault-Starzyk, F.; Schoonheydt, R.A. Probing the basicity of zeolite frameworks with N2O4: A DFT approach. Microporous Mesoporous Mater. 2006, 90, 370–376. [Google Scholar] [CrossRef]

- Mignon, P.; Pidko, E.A.; Van Santen, R.A.; Geerlings, P.; Schoonheydt, R.A. Understanding the Reactivity and Basicity of Zeolites: A Periodic DFT Study of the Disproportionation of N2O4 on Alkali-Cation-Exchanged Zeolite Y. Chem. Eur. J. 2008, 14, 5168–5177. [Google Scholar] [CrossRef] [PubMed]

- Plant, D.F.; Simperler, A.; Bell, R.G. Adsorption of Methanol on Zeolites X and Y. An Atomistic and Quantum Chemical Study. J. Phys. Chem. B 2006, 110, 6170–6178. [Google Scholar] [CrossRef]

- Schenkel, R.; Jentys, A.; Parker, S.F.; Lercher, J.A. INS and IR and NMR Spectroscopic Study of C1−C4 Alcohols Adsorbed on Alkali Metal-Exchanged Zeolite X. J. Phys. Chem. B 2004, 108, 15013–15026. [Google Scholar] [CrossRef]

- Sánchez-Sánchez, M.; Blasco, T. Pyrrole as an NMR probe molecule to characterise zeolite basicity. Chem. Commun. 2000, 6, 491–492. [Google Scholar] [CrossRef]

- Schoonheydt, R.A.; Geerlings, P.; Pidko, E.A.; van Santen, R.A. The framework basicity of zeolites. J. Mater. Chem. 2012, 22, 18705–18717. [Google Scholar] [CrossRef]

- Okamoto, Y.; Ogawa, M.; Maezawa, A.; Imanaka, T. Electronic structure of zeolites studied by X-Ray photoelectron spectroscopy. J. Catal. 1988, 112, 427–436. [Google Scholar] [CrossRef]

- Huang, M.; Adnot, A.; Kaliaguine, S. Characterization of basicity in alkaline cation faujasite zeolites—An XPS study using pyrrole as a probe molecule. J. Catal. 1992, 137, 322–332. [Google Scholar] [CrossRef]

- Han, J.; Yang, G.; Zou, Y.; Chen, X.; Valtchev, V. Hierarchical SAPO-34 Preparation Based on the Crystal Metastability in Mother Liquor Solution. Adv. Mater. Interfaces 2021, 8, 2002029. [Google Scholar] [CrossRef]

- Han, J.; Yang, G.; Ding, H.; Chen, X. Revealing inherent factors of SAPO-34 zeolites etching towards the fabrication of hierarchical structure. Microporous Mesoporous Mater. 2021, 319, 111067. [Google Scholar] [CrossRef]

- Yang, G.; Qiu, Z.; Han, J.; Chen, X.; Yu, J. Fluoride etching opens the access for bulky molecules to active sites in microporous Ti-Beta zeolite. Mater. Chem. Front. 2020, 4, 2982–2989. [Google Scholar] [CrossRef]

- Yang, G.; Han, J.; Qiu, Z.; Chen, X.; Feng, Z.; Yu, J. An amino acid-assisted approach to fabricate nanosized hierarchical TS-1 zeolites for efficient oxidative desulfurization. Inorg. Chem. Front. 2020, 7, 1975–1980. [Google Scholar] [CrossRef]

- Yang, G.; Han, J.; Liu, Y.; Qiu, Z.; Chen, X. The synthetic strategies of hierarchical TS-1 zeolites for the oxidative desulfurization reactions. Chin. J. Chem. Eng. 2020, 28, 2227–2234. [Google Scholar] [CrossRef]

- Yang, G.; Han, J.; Huang, Y.; Chen, X.; Valtchev, V. Busting the efficiency of SAPO-34 catalysts for the methanol-to-olefin conversion by post-synthesis methods. Chin. J. Chem. Eng. 2020, 28, 2022–2027. [Google Scholar] [CrossRef]

- Chen, X.; Yang, G.; Valtchev, V. Environmentally benign synthesis of crystalline nanosized molecular sieves. Green Energy Environ. 2020, 5, 394–404. [Google Scholar] [CrossRef]

- Opanasenko, M.V.; Roth, W.J.; Čejka, J. Two-dimensional zeolites in catalysis: Current status and perspectives. Catal. Sci. Technol. 2016, 6, 2467–2484. [Google Scholar] [CrossRef]

- Roth, W.J.; Nachtigall, P.; Morris, R.E.; Čejka, J. Two-Dimensional Zeolites: Current Status and Perspectives. Chem. Rev. 2014, 114, 4807–4837. [Google Scholar] [CrossRef]

- Xu, L.; Sun, J. Recent Advances in the Synthesis and Application of Two-Dimensional Zeolites. Adv. Energy Mater. 2016, 6, 1600441. [Google Scholar] [CrossRef]

- Corma, A. State of the art and future challenges of zeolites as catalysts. J. Catal. 2003, 216, 298–312. [Google Scholar] [CrossRef]

- Grirrane, A.; Corma, A.; García, H. Gold-Catalyzed Synthesis of Aromatic Azo Compounds from Anilines and Nitroaromatics. Science 2008, 322, 1661–1664. [Google Scholar] [CrossRef] [PubMed]

- Simancas, R.; Dari, D.; Velamazan, N.; Navarro, M.T.; Cantin, A.; Jorda, J.L.; Sastre, G.; Corma, A.; Rey, F. Modular Organic Structure-Directing Agents for the Synthesis of Zeolites. Science 2010, 330, 1219–1222. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Jorda, J.L.; Yu, J.; Baumes, L.A.; Mugnaioli, E.; Diaz-Cabanas, M.J.; Kolb, U.; Corma, A. Synthesis and Structure Determination of the Hierarchical Meso-Microporous Zeolite ITQ-43. Science 2011, 333, 1131–1134. [Google Scholar] [CrossRef] [PubMed]

- Bereciartua, P.J.; Cantín, Á.; Corma, A.; Jordá, J.L.; Palomino, M.; Rey, F.; Valencia, S.; Corcoran, E.W.; Kortunov, P.; Ravikovitch, P.I.; et al. Control of zeolite framework flexibility and pore topology for separation of ethane and ethylene. Science 2017, 358, 1068–1071. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Paris, C.; Martínez-Triguero, J.; Boronat, M.; Moliner, M.; Corma, A. Synthesis of reaction-adapted zeolites as methanol-to-olefins catalysts with mimics of reaction intermediates as organic structure-directing agents. Nat. Catal. 2018, 1, 547–554. [Google Scholar] [CrossRef]

- Liu, L.; Corma, A. Metal catalysts for heterogeneous catalysis: From single atoms to nanoclusters and nanoparticles. Chem. Rev. 2018, 118, 4981–5079. [Google Scholar] [CrossRef] [Green Version]

- Gallego, E.M.; Portilla, M.T.; Paris, C.; Leon-Escamilla, A.; Boronat, M.; Moliner, M.; Corma, A. “Ab initio” synthesis of zeolites for preestablished catalytic reactions. Science 2017, 355, 1051–1054. [Google Scholar] [CrossRef] [Green Version]

- Corma, A.; Fornes, V.; Pergher, S.B.; Maesen, T.L.M.; Buglass, J.G. Delaminated zeolite precursors as selective acidic catalysts. Nature 1998, 396, 353. [Google Scholar] [CrossRef]

- Corma, A.; Fornés, V.; Guil, J.M.; Pergher, S.; Maesen, T.L.M.; Buglass, J.G. Preparation, characterisation and catalytic activity of ITQ-2, a delaminated zeolite. Microporous Mesoporous Mater. 2000, 38, 301–309. [Google Scholar] [CrossRef]

- Corma, A.; Diaz, U.; Domine, M.E.; Fornés, V. New Aluminosilicate and Titanosilicate Delaminated Materials Active for Acid Catalysis, and Oxidation Reactions Using H2O2. J. Am. Chem. Soc. 2000, 122, 2804–2809. [Google Scholar] [CrossRef]

- Margarit, V.J.; Martínez-Armero, M.E.; Navarro, M.T.; Martínez, C.; Corma, A. Direct Dual-Template Synthesis of MWW Zeolite Monolayers. Angew. Chem. Int. Ed. 2015, 54, 13724–13728. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Macario, A.; Giordano, G.; Onida, B.; Cocina, D.; Tagarelli, A.; Giuffrè, A.M. Biodiesel production process by homogeneous/heterogeneous catalytic system using an acid–base catalyst. Appl. Catal. A 2010, 378, 160–168. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, G.; Yu, J. Advancements in Basic Zeolites for Biodiesel Production via Transesterification. Chemistry 2023, 5, 438-451. https://doi.org/10.3390/chemistry5010032

Yang G, Yu J. Advancements in Basic Zeolites for Biodiesel Production via Transesterification. Chemistry. 2023; 5(1):438-451. https://doi.org/10.3390/chemistry5010032

Chicago/Turabian StyleYang, Guoju, and Jihong Yu. 2023. "Advancements in Basic Zeolites for Biodiesel Production via Transesterification" Chemistry 5, no. 1: 438-451. https://doi.org/10.3390/chemistry5010032