Enhancing Structural Stability of Oil-Shell Microbubbles via Incorporation of a Gold Nanoparticle Protective Shell for Theranostic Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microfluidic Device Preparation

2.2. Material

2.3. Phospholipid Formulation

2.4. Experiment Setup and Bubble Production

2.5. Imaging Setup

2.6. Image-Processing Pipeline

2.6.1. Statistical Analysis Pipeline

2.6.2. Fluorescent Intensity Measurement

2.6.3. Segmentation for Identification of Dewetting Using Machine-Learning Techniques

2.7. Microbubble Concentration Detection

3. Results and Discussion

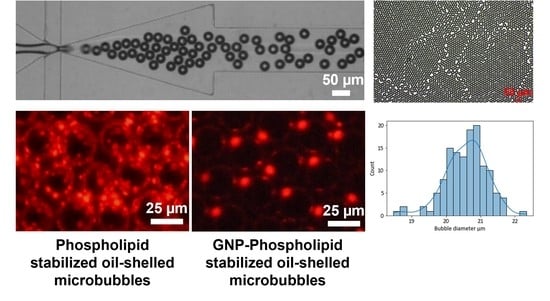

3.1. Formation of phospholipid-shell DEBs

3.2. Morphology and Stability of Phospholipid-Shell DEBs

3.3. GNP-Functionalized Phospholipid-Shell DEBs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- American Cancer Society. Cancer Facts and Figures 2022; American Cancer Society: Atlanta, GA, USA, 2022. [Google Scholar]

- Krzyszczyk, P.; Acevedo, A.; Davidoff, E.J.; Timmins, L.M.; Marrero-Berrios, I.; Patel, M.; White, C.; Lowe, C.; Sherba, J.J.; Hartmanshenn, C.; et al. The growing role of precision and personalized medicine for cancer treatment. Technology 2018, 6, 79–100. [Google Scholar] [CrossRef]

- Shapiro, C.L.; Recht, A. Side effects of adjuvant treatment of breast cancer. N. Engl. J. Med. 2001, 344, 1997–2008. [Google Scholar] [CrossRef]

- Nurgali, K.; Jagoe, R.T.; Abalo, R. Adverse effects of cancer chemotherapy: Anything new to improve tolerance and reduce sequelae? Front. Pharmacol. 2018, 9, 245. [Google Scholar] [CrossRef]

- Ma, H.; He, C.; Cheng, Y.; Yang, Z.; Zang, J.; Liu, J.; Chen, X. Localized co-delivery of doxorubicin, cisplatin, and methotrexate by thermosensitive hydrogels for enhanced osteosarcoma treatment. ACS Appl. Mater. Interfaces 2015, 7, 27040–27048. [Google Scholar] [CrossRef]

- Pucci, C.; Martinelli, C.; Ciofani, G. Innovative approaches for cancer treatment: Current perspectives and new challenges. Ecancermedicalscience 2019, 13, 961. [Google Scholar] [CrossRef] [PubMed]

- May, J.P.; Li, S.D. Hyperthermia-induced drug targeting. Expert Opin. Drug Deliv. 2013, 10, 511–527. [Google Scholar] [CrossRef] [PubMed]

- Klibanov, A.L.; Shevchenko, T.I.; Raju, B.I.; Seip, R.; Chin, C.T. Ultrasound-triggered release of materials entrapped in microbubble–liposome constructs: A tool for targeted drug delivery. J. Control. Release 2010, 148, 13–17. [Google Scholar] [CrossRef]

- Wu, G.; Mikhailovsky, A.; Khant, H.A.; Fu, C.; Chiu, W.; Zasadzinski, J.A. Remotely triggered liposome release by near-infrared light absorption via hollow gold nanoshells. J. Am. Chem. Soc. 2008, 130, 8175–8177. [Google Scholar] [CrossRef] [PubMed]

- Stride, E.; Segers, T.; Lajoinie, G.; Cherkaoui, S.; Bettinger, T.; Versluis, M.; Borden, M. Microbubble agents: New directions. Ultrasound Med. Biol. 2020, 46, 1326–1343. [Google Scholar] [CrossRef]

- Batchelor, D.V.; Abou-Saleh, R.H.; Coletta, P.L.; McLaughlan, J.R.; Peyman, S.A.; Evans, S.D. Nested nanobubbles for ultrasound-triggered drug release. ACS Appl. Mater. Interfaces 2020, 12, 29085–29093. [Google Scholar] [CrossRef]

- Unger, E.; Fritz, T.; Shen, D.K.; Lund, P.; Sahn, D.; Ramaswami, R.; Matsunaga, T.; Yellowhair, D.; Kulik, B. Gas fIIIed lipid bilayers as imaging contrast agents. J. Liposome Res. 1994, 4, 861–874. [Google Scholar] [CrossRef]

- Capece, S.; Domenici, F.; Brasili, F.; Oddo, L.; Cerroni, B.; Bedini, A.; Bordi, F.; Chiessi, E.; Paradossi, G. Complex interfaces in “phase-change” contrast agents. Phys. Chem. Chem. Phys. 2016, 18, 8378–8388. [Google Scholar] [CrossRef]

- Straub, J.A.; Chickering, D.E.; Church, C.C.; Shah, B.; Hanlon, T.; Bernstein, H. Porous PLGA microparticles: AI-700, an intravenously administered ultrasound contrast agent for use in echocardiography. J. Control. Release 2005, 108, 21–32. [Google Scholar] [CrossRef] [PubMed]

- Angile, F.E.; Vargo, K.B.; Sehgal, C.M.; Hammer, D.A.; Lee, D. Recombinant protein-stabilized monodisperse microbubbles with tunable size using a valve-based microfluidic device. Langmuir 2014, 30, 12610–12618. [Google Scholar] [CrossRef] [PubMed]

- Nesbitt, H.; Sheng, Y.; Kamila, S.; Logan, K.; Thomas, K.; Callan, B.; Taylor, M.A.; Love, M.; O’Rourke, D.; Kelly, P.; et al. Gemcitabine loaded microbubbles for targeted chemo-sonodynamic therapy of pancreatic cancer. J. Control. Release 2018, 279, 8–16. [Google Scholar] [CrossRef]

- Yan, F.; Li, L.; Deng, Z.; Jin, Q.; Chen, J.; Yang, W.; Yeh, C.K.; Wu, J.; Shandas, R.; Liu, X.; et al. Paclitaxel-liposome–microbubble complexes as ultrasound-triggered therapeutic drug delivery carriers. J. Control. Release 2013, 166, 246–255. [Google Scholar] [CrossRef]

- Peyman, S.A.; Abou-Saleh, R.H.; McLaughlan, J.R.; Ingram, N.; Johnson, B.R.; Critchley, K.; Freear, S.; Evans, J.A.; Markham, A.F.; Coletta, P.L.; et al. Expanding 3D geometry for enhanced on-chip microbubble production and single step formation of liposome modified microbubbles. Lab Chip 2012, 12, 4544–4552. [Google Scholar] [CrossRef]

- Bourn, M.D.; Mohajerani, S.Z.; Mavria, G.; Ingram, N.; Coletta, P.L.; Evans, S.; Peyman, S.A. Tumour associated vasculature-on-a-chip for the evaluation of microbubble-mediated delivery of targeted liposomes. Lab Chip 2023, 23, 1674–1693. [Google Scholar] [CrossRef]

- Hettiarachchi, K.; Zhang, S.; Feingold, S.; Lee, A.P.; Dayton, P.A. Controllable microfluidic synthesis of multiphase drug-carrying lipospheres for site-targeted therapy. Biotechnol. Prog. 2009, 25, 938–945. [Google Scholar] [CrossRef] [PubMed]

- Postema, M.; Gilja, O.H. Ultrasound-directed drug delivery. Curr. Pharm. Biotechnol. 2007, 8, 355–361. [Google Scholar] [CrossRef]

- Sanwal, R.; Joshi, K.; Ditmans, M.; Tsai, S.S.; Lee, W.L. Ultrasound and Microbubbles for Targeted Drug Delivery to the Lung Endothelium in ARDS: Cellular Mechanisms and Therapeutic Opportunities. Biomedicines 2021, 9, 803. [Google Scholar] [CrossRef] [PubMed]

- Domenici, F.; Capocefalo, A.; Brasili, F.; Bedini, A.; Giliberti, C.; Palomba, R.; Silvestri, I.; Scarpa, S.; Morrone, S.; Paradossi, G.; et al. Ultrasound delivery of Surface Enhanced InfraRed Absorption active gold-nanoprobes into fibroblast cells: A biological study via Synchrotron-based InfraRed microanalysis at single cell level. Sci. Rep. 2019, 9, 11845. [Google Scholar] [CrossRef]

- Domenici, F.; Brasili, F.; Giantulli, S.; Cerroni, B.; Bedini, A.; Giliberti, C.; Palomba, R.; Silvestri, I.; Morrone, S.; Paradossi, G.; et al. Differential effects on membrane permeability and viability of human keratinocyte cells undergoing very low intensity megasonic fields. Sci. Rep. 2017, 7, 16536. [Google Scholar] [CrossRef]

- Gao, Y.; Chan, C.U.; Gu, Q.; Lin, X.; Zhang, W.; Yeo, D.C.L.; Alsema, A.M.; Arora, M.; Chong, M.S.K.; Shi, P.; et al. Controlled nanoparticle release from stable magnetic microbubble oscillations. NPG Asia Mater. 2016, 8, e260. [Google Scholar] [CrossRef]

- Dove, J.D.; Murray, T.W.; Borden, M.A. Enhanced photoacoustic response with plasmonic nanoparticle-templated microbubbles. Soft Matter 2013, 9, 7743–7750. [Google Scholar] [CrossRef]

- Meng, Z.; Zhou, X.; She, J.; Zhang, Y.; Feng, L.; Liu, Z. Ultrasound-responsive conversion of microbubbles to nanoparticles to enable background-free in vivo photoacoustic imaging. Nano Lett. 2019, 19, 8109–8117. [Google Scholar] [CrossRef] [PubMed]

- Talu, E.; Hettiarachchi, K.; Powell, R.L.; Lee, A.P.; Dayton, P.A.; Longo, M.L. Maintaining monodispersity in a microbubble population formed by flow-focusing. Langmuir 2008, 24, 1745–1749. [Google Scholar] [CrossRef]

- Hettiarachchi, K.; Talu, E.; Longo, M.L.; Dayton, P.A.; Lee, A.P. On-chip generation of microbubbles as a practical technology for manufacturing contrast agents for ultrasonic imaging. Lab Chip 2007, 7, 463–468. [Google Scholar] [CrossRef] [PubMed]

- Shih, R.; Bardin, D.; Martz, T.D.; Sheeran, P.S.; Dayton, P.A.; Lee, A.P. Flow-focusing regimes for accelerated production of monodisperse drug-loadable microbubbles toward clinical-scale applications. Lab Chip 2013, 13, 4816–4826. [Google Scholar] [CrossRef]

- Churchman, A.H.; Mico, V.; De Pablo, J.G.; Peyman, S.A.; Freear, S.; Evans, S.D. Combined flow-focus and self-assembly routes for the formation of lipid stabilized oil-shell microbubbles. Microsystems Nanoeng. 2018, 4, 17087. [Google Scholar] [CrossRef]

- Hayward, R.C.; Utada, A.S.; Dan, N.; Weitz, D.A. Dewetting instability during the formation of polymersomes from block-copolymer-stabilized double emulsions. Langmuir 2006, 22, 4457–4461. [Google Scholar] [CrossRef] [PubMed]

- McDonald, J.C.; Duffy, D.C.; Anderson, J.R.; Chiu, D.T.; Wu, H.; Schueller, O.J.; Whitesides, G.M. Fabrication of microfluidic systems in poly (dimethylsiloxane). Electrophoresis 2000, 21, 27–40. [Google Scholar] [CrossRef]

- Vallejo, D.; Lee, S.; Lee, D.; Zhang, C.; Rapier, C.; Chessler, S.; Lee, A. Cell-sized lipid vesicles for cell–cell synaptic therapies. Technology 2017, 5, 201–213. [Google Scholar] [CrossRef]

- Segers, T.; Lassus, A.; Bussat, P.; Gaud, E.; Frinking, P. Improved coalescence stability of monodisperse phospholipid-coated microbubbles formed by flow-focusing at elevated temperatures. Lab Chip 2019, 19, 158–167. [Google Scholar] [CrossRef] [PubMed]

- Segers, T.; Lohse, D.; Versluis, M.; Frinking, P. Universal equations for the coalescence probability and long-term size stability of phospholipid-coated monodisperse microbubbles formed by flow focusing. Langmuir 2017, 33, 10329–10339. [Google Scholar] [CrossRef]

- Kwan, J.J.; Borden, M.A. Microbubble dissolution in a multigas environment. Langmuir 2010, 26, 6542–6548. [Google Scholar] [CrossRef]

- Pham, D.L.; Xu, C.; Prince, J.L. Current methods in medical image segmentation. Annu. Rev. Biomed. Eng. 2000, 2, 315–337. [Google Scholar] [CrossRef]

- Pal, N.R.; Pal, S.K. A review on image segmentation techniques. Pattern Recognit. 1993, 26, 1277–1294. [Google Scholar] [CrossRef]

- Seo, H.; Badiei Khuzani, M.; Vasudevan, V.; Huang, C.; Ren, H.; Xiao, R.; Jia, X.; Xing, L. Machine learning techniques for biomedical image segmentation: An overview of technical aspects and introduction to state-of-art applications. Med Phys. 2020, 47, e148–e167. [Google Scholar] [CrossRef]

- Arzt, M.; Deschamps, J.; Schmied, C.; Pietzsch, T.; Schmidt, D.; Tomancak, P.; Haase, R.; Jug, F. LABKIT: Labeling and segmentation toolkit for big image data. Front. Comput. Sci. 2022, 4, 10. [Google Scholar] [CrossRef]

- Schroff, F.; Criminisi, A.; Zisserman, A. Object Class Segmentation using Random Forests. In Proceedings of the BMVC, Leeds, UK, 1–4 September 2008; pp. 1–10. [Google Scholar]

- Shum, H.C.; Santanach-Carreras, E.; Kim, J.W.; Ehrlicher, A.; Bibette, J.; Weitz, D.A. Dewetting-induced membrane formation by adhesion of amphiphile-laden interfaces. J. Am. Chem. Soc. 2011, 133, 4420–4426. [Google Scholar] [CrossRef] [PubMed]

- Deng, N.N.; Yelleswarapu, M.; Huck, W.T. Monodisperse uni-and multicompartment liposomes. J. Am. Chem. Soc. 2016, 138, 7584–7591. [Google Scholar] [CrossRef] [PubMed]

- Segers, T.; De Rond, L.; De Jong, N.; Borden, M.; Versluis, M. Stability of monodisperse phospholipid-coated microbubbles formed by flow-focusing at high production rates. Langmuir 2016, 32, 3937–3944. [Google Scholar] [CrossRef]

- Segers, T.; Gaud, E.; Casqueiro, G.; Lassus, A.; Versluis, M.; Frinking, P. Foam-free monodisperse lipid-coated ultrasound contrast agent synthesis by flow-focusing through multi-gas-component microbubble stabilization. Appl. Phys. Lett. 2020, 116, 173701. [Google Scholar] [CrossRef]

- Zalloum, I.O.; Paknahad, A.A.; Kolios, M.C.; Karshafian, R.; Tsai, S.S. Controlled Shrinkage of Microfluidically Generated Microbubbles by Tuning Lipid Concentration. Langmuir 2022, 38, 13021–13029. [Google Scholar] [CrossRef]

- Cerezo, J.; Zuniga, J.; Bastida, A.; Requena, A.; Ceron-Carrasco, J.P. Atomistic molecular dynamics simulations of the interactions of oleic and 2-hydroxyoleic acids with phosphatidylcholine bilayers. J. Phys. Chem. B 2011, 115, 11727–11738. [Google Scholar] [CrossRef] [PubMed]

- Kurniawan, J.; Suga, K.; Kuhl, T.L. Interaction forces and membrane charge tunability: Oleic acid containing membranes in different pH conditions. Biochim. Biophys. Acta-(BBA)-Biomembr. 2017, 1859, 211–217. [Google Scholar] [CrossRef]

- Fredrick, E.; Walstra, P.; Dewettinck, K. Factors governing partial coalescence in oil-in-water emulsions. Adv. Colloid Interface Sci. 2010, 153, 30–42. [Google Scholar] [CrossRef]

- Chen, W.; Yu, B.; Wei, Z.; Mao, S.; Li, T. The creation of raspberry-like droplets and their coalescence dynamics: An ideal model for certain biological processes. J. Colloid Interface Sci. 2022, 615, 752–758. [Google Scholar] [CrossRef]

- Pickering, S.U. Cxcvi.—Emulsions. J. Chem. Soc. Trans. 1907, 91, 2001–2021. [Google Scholar] [CrossRef]

- Pan, M.; Rosenfeld, L.; Kim, M.; Xu, M.; Lin, E.; Derda, R.; Tang, S.K. Fluorinated pickering emulsions impede interfacial transport and form rigid interface for the growth of anchorage-dependent cells. ACS Appl. Mater. Interfaces 2014, 6, 21446–21453. [Google Scholar] [CrossRef] [PubMed]

- Azmin, M.; Mohamedi, G.; Edirisinghe, M.; Stride, E. Dissolution of coated microbubbles: The effect of nanoparticles and surfactant concentration. Mater. Sci. Eng. C 2012, 32, 2654–2658. [Google Scholar] [CrossRef]

- Yang, Y.; Fang, Z.; Chen, X.; Zhang, W.; Xie, Y.; Chen, Y.; Liu, Z.; Yuan, W. An overview of Pickering emulsions: Solid-particle materials, classification, morphology, and applications. Front. Pharmacol. 2017, 8, 287. [Google Scholar] [CrossRef] [PubMed]

- Mohamedi, G.; Azmin, M.; Pastoriza-Santos, I.; Huang, V.; Perez-Juste, J.; Liz-Marzan, L.M.; Edirisinghe, M.; Stride, E. Effects of gold nanoparticles on the stability of microbubbles. Langmuir 2012, 28, 13808–13815. [Google Scholar] [CrossRef]

- Yoon, Y.I.; Pang, X.; Jung, S.; Zhang, G.; Kong, M.; Liu, G.; Chen, X. Smart gold nanoparticle-stabilized ultrasound microbubbles as cancer theranostics. J. Mater. Chem. B 2018, 6, 3235–3239. [Google Scholar] [CrossRef] [PubMed]

- Tay, L.M.; Xu, C. Coating microbubbles with nanoparticles for medical imaging and drug delivery. Nanomedicine 2017, 12, 91–94. [Google Scholar] [CrossRef]

- Palmieri, D.; Brasili, F.; Capocefalo, A.; Bizien, T.; Angelini, I.; Oddo, L.; Toumia, Y.; Paradossi, G.; Domenici, F. Improved hybrid-shell perfluorocarbon microdroplets as ultrasound-and laser-activated phase-change platform. Colloids Surfaces A Physicochem. Eng. Asp. 2022, 641, 128522. [Google Scholar] [CrossRef]

| Formulation Reference | Total Lipid Concentration | GNP Concentration |

|---|---|---|

| F1 | 0.83 mg/mL | 0 Particles/mL |

| F2 | 1.19 mg/mL | 0 Particles/mL |

| F3 | 1.19 mg/mL | 1013 Particles/mL |

| F4 | 1.56 mg/mL | 0 Particles/mL |

| F5 | 1.56 mg/mL | 1013 Particles/mL |

| F6 | 2.45 mg/mL | 0 Particles/mL |

| F7 | 2.45 mg/mL | 1013 Particles/mL |

| Solution | Pressure/Flow Rate |

|---|---|

| Lipid phase | 40–45 µL/min |

| Gas phase | 27.5–34.5 KPa |

| Oil phase | 0.1 µL/min |

| Fluorophore Type | Fluorophore Purpose | Excitation/Emission Wavelength (nm) |

|---|---|---|

| Nile red | Visualization of the oil layer, Wavelength and DEB structural integrity | 559/635 |

| CY3 | Visualization of the GNP protective Wavelength shell on the GNP-DEBs | 555/570 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ataei, M.; Yi, H.-P.; Taravatfard, A.Z.; Lin, K.Y.; Lee, A.P. Enhancing Structural Stability of Oil-Shell Microbubbles via Incorporation of a Gold Nanoparticle Protective Shell for Theranostic Applications. Colloids Interfaces 2023, 7, 34. https://doi.org/10.3390/colloids7020034

Ataei M, Yi H-P, Taravatfard AZ, Lin KY, Lee AP. Enhancing Structural Stability of Oil-Shell Microbubbles via Incorporation of a Gold Nanoparticle Protective Shell for Theranostic Applications. Colloids and Interfaces. 2023; 7(2):34. https://doi.org/10.3390/colloids7020034

Chicago/Turabian StyleAtaei, Marzieh, Hsiu-Ping Yi, Aida Zahra Taravatfard, Ken Young Lin, and Abraham Phillip Lee. 2023. "Enhancing Structural Stability of Oil-Shell Microbubbles via Incorporation of a Gold Nanoparticle Protective Shell for Theranostic Applications" Colloids and Interfaces 7, no. 2: 34. https://doi.org/10.3390/colloids7020034