On Classification of Water-in-Oil and Oil-in-Water Droplet Generation Regimes in Flow-Focusing Microfluidic Devices

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Equipment

2.3. Microfluidic Device Design

2.4. Silicon Master Mold Fabrication

2.5. Microfluidic Device Fabrication and Surface Modification

2.6. Experimental Setup

2.7. Experimental Data from Previous Works of Several Research Groups

2.8. Droplet Generation Regime Identification and Classification

3. Results and Discussion

3.1. Water-in-Oil Droplet Generation

3.2. Oil-in-Water Droplet Generation

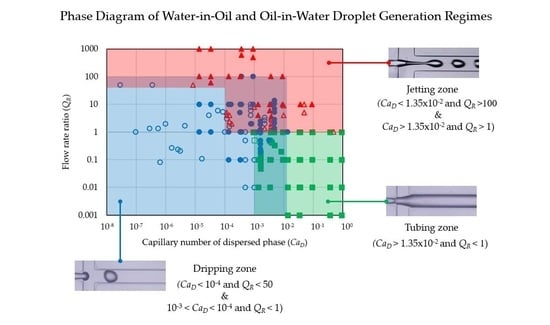

3.3. Droplet Generation Regimes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vasiljevic, D.; Parojcic, J.; Primorac, M.; Vuleta, G. An investigation into the characteristics and drug release properties of multiple W/O/W emulsion systems containing low concentration of lipophilic polymeric emulsifier. Int. J. Pharm. 2006, 309, 171–177. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Peng, S.; Wen, W.; Sheng, P.; Li, W. Design and fabrication of magnetically functionalized core/shell microspheres for smart drug delivery. Adv. Funct. Mater. 2009, 19, 292–297. [Google Scholar] [CrossRef]

- Brower, K.K.; Crumpton, C.C.; Klemm, S.; Cruz, B.; Kim, G.; Calhoun, S.G.K.; Nichols, L.; Fordyce, P.M. Double emulsion flow cytometry with high throughput single droplet isolation and nucleic acid recovery. Lab Chip 2020, 20, 2062–2074. [Google Scholar] [CrossRef] [PubMed]

- Hettiarachchi, K.; Kim, H.; Faris, G.W. Optical manipulation and control of real-time PCR in cell encapsulating microdroplets by IR laser. Microfluid. Nanofluid. 2012, 13, 967–975. [Google Scholar] [CrossRef]

- Liu, K.; Deng, Y.; Zhang, N.; Li, S.; Ding, H.; Guo, F.; Liu, W.; Guo, S.; Zhao, X.Z. Generation of disk-like hydrogel beads for cell encapsulation and manipulation using a droplet-based microfluidic device. Microfluid. Nanofluid. 2012, 13, 761–767. [Google Scholar] [CrossRef]

- Ding, Y.; Choo, J.; DeMello, A.J. From single-molecule detection to next-generation sequencing: Microfluidic droplets for high-throughput nucleic acid analysis. Microfluid. Nanofluid. 2017, 21, 58. [Google Scholar] [CrossRef]

- Guo, R.; Yang, C.G.; Xu, Z.R. A superposable double-gradient droplet array chip for preparation of PEGDA microspheres containing concentration-gradient drugs. Microfluid. Nanofluid. 2017, 21, 157. [Google Scholar] [CrossRef]

- Vaezi, Z.; Sedghi, M.; Ghorbani, M.; Shojaeilangari, S.; Allahverdi, A.; Manesh, H.N. Investigation of the programmed cell death by encapsulated cytoskeleton drug liposomes using a microfluidic platform. Microfluid. Nanofluid. 2020, 24, 48. [Google Scholar] [CrossRef]

- Wang, K.; Qin, K.; Wang, T.; Luo, G. Ultra-thin liquid film extraction based on a gas–liquid–liquid double emulsion in a microchannel device. RSC Adv. 2015, 5, 6470–6474. [Google Scholar] [CrossRef]

- Doonan, S.R.; Lin, M.; Lee, D.; Lee, J.; Bailey, R.C. C3PE: Counter-current continuous phase extraction for improved precision of in-droplet chemical reactions. Microfluid. Nanofluid. 2020, 24, 50. [Google Scholar] [CrossRef]

- Shum, H.C.; Lee, D.; Yoon, I.; Kodger, T.; Weitz, D.A. Double emulsion templated monodisperse phospholipid vesicles. Langmuir 2008, 24, 7651–7653. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Yu, Z.; Parker, R.M.; Wu, Y.; Abell, C.; Scherman, O.A. Interfacial assembly of dendritic microcapsules with host–guest chemistry. Nat. Commun. 2014, 5, 5772. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, B.; Jeon, T.Y.; Oh, Y.K.; Kim, S.H. Microfluidic production of semipermeable microcapsules by polymerization-induced phase separation. Langmuir 2015, 31, 6027–6034. [Google Scholar]

- Deshpande, S.; Caspi, Y.; Meijering, A.E.C.; Dekker, C. Octanol-assisted liposome assembly on chip. Nat. Commun. 2016, 7, 10447. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Choi, C.H.; Abbaspourrad, A.; Wesner, C.; Caggioni, M.; Zhu, T.; Weitz, D.A. Encapsulation and enhanced retention of fragrance in polymer microcapsules. ACS Appl. Mater. 2016, 8, 4007–4013. [Google Scholar] [CrossRef]

- Wang, K.; Lu, Y.C.; Xu, J.H.; Tan, J.; Luo, G.S. Liquid–liquid micro-dispersion in a double-pore T-shaped microfluidic device. Microfluid. Nanofluid. 2009, 6, 557–564. [Google Scholar]

- Wang, K.; Lu, Y.C.; Xu, J.H.; Tan, J.; Luo, G.S. Generation of Micromonodispersed droplets and bubbles in the capillary embedded T-Junction microfluidic devices. AIChE J. 2011, 57, 2. [Google Scholar] [CrossRef]

- Wang, X.; Yong, Y.; Yang, C.; Mao, Z.S.; Li, D. Investigation on pressure drop characteristic and mass transfer performance of gas–liquid flow in micro-channels. Microfluid. Nanofluid. 2014, 16, 413–423. [Google Scholar]

- Seo, M.; Paquet, C.; Nie, Z.; Xua, S.; Kumacheva, E. Microfluidic consecutive flow-focusing droplet generators. Soft Matter 2007, 3, 986–992. [Google Scholar]

- Pannacci, N.; Bruus, H.; Bartolo, D.; Etchart, I.; Lockhart, T.; Hennequin, Y.; Willaime, H.; Tabeling, P. Equilibrium and Nonequilibrium States in Microfluidic Double Emulsions. PRL 2008, 101, 164502. [Google Scholar]

- Abate, A.R.; Thiele, J.; Weinhart, M.; Weitz, D.A. Patterning microfluidic device wettability using flow confinement. Lab Chip 2010, 10, 1774–1776. [Google Scholar] [CrossRef]

- Bauer, W.C.; Fischlechner, M.; Abell, C.; Huck, W.T.S. Hydrophilic PDMS microchannels for high-throughput formation of oil-in-water microdroplets and water-in-oil-in-water double emulsions. Lab Chip 2010, 10, 1814–1819. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, H.H.; Chang, S.C.; Su, Y.C. On-demand double emulsification utilizing pneumatically actuated, selectively surface-modified PDMS micro-devices. Microfluid. Nanofluid. 2010, 9, 1091–1102. [Google Scholar] [CrossRef]

- Abate, A.R.; Thiele, J.; Weitz, D.A. One-step formation of multiple emulsions in microfluidics. Lab Chip 2011, 11, 253–258. [Google Scholar] [CrossRef] [PubMed]

- Deng, N.N.; Meng, Z.J.; Xie, R.; Ju, X.J.; Mou, C.L.; Wang, W.; Chu, L.Y. Simple and cheap microfluidic devices for the preparation of monodisperse emulsions. Lab Chip 2011, 11, 3963. [Google Scholar] [CrossRef] [PubMed]

- Thiele, J.; Seiffert, S. Double emulsions with controlled morphology by microgel scaffolding. Lab Chip 2011, 11, 3188. [Google Scholar] [CrossRef]

- Hwang, S.; Choi, C.H.; Lee, C.S. Regioselective surface modification of PDMS microfluidic device for the generation of monodisperse double emulsions. Macromol. Res. 2012, 20, 4. [Google Scholar] [CrossRef]

- Jankowski, P.; Ogonczyk, D.; Derzsi, L.; Lisowski, W.; Garstecki, P. Hydrophilic polycarbonate chips for generation of oil-in-water (O/W) and water-in-oil-in-water (W/O/W) emulsions. Microfluid. Nanofluid. 2013, 14, 767–774. [Google Scholar] [CrossRef] [Green Version]

- Wu, B.; Gong, H.Q.; Zhang, R. Maskless formation of chromatic-pattern barcodes in two-component microcapsules. Microfluid. Nanofluid. 2014, 16, 1069–1074. [Google Scholar] [CrossRef]

- Deng, N.N.; Mou, C.L.; Wang, W.; Ju, X.J.; Xie, R.; Chu, L.Y. Multiple emulsion formation from controllable drop pairs in microfluidics. Microfluid. Nanofluid. 2014, 17, 967–972. [Google Scholar] [CrossRef]

- Li, S.; Gong, X.; Mc Nally, C.S.; Zeng, M.; Gaule, T.; Anduix-Canto, C.; Kulak, A.N.; Bawazer, L.A.; McPherson, M.J.; Meldrum, F.C. Rapid preparation of highly reliable PDMS double emulsion microfluidic devices. RSC Adv. 2016, 6, 25927–25933. [Google Scholar] [CrossRef]

- Hirama, H.; Wada, S.; Shimamura, J.; Komazaki, Y.; Inoue, T.; Torii, T. Surface modification of a glass microchannel for the formation of multiple emulsion droplets. Microfluid. Nanofluid. 2017, 21, 91. [Google Scholar] [CrossRef]

- Cai, B.; Ji, T.T.; Wang, N.; Li, X.B.; He, R.X.; Liu, W.; Wang, G.; Zhao, X.Z.; Wang, L.; Wang, Z. A microfluidic platform utilizing anchored water-in-oil-in-water double emulsions to create a niche for analyzing single non-adherent cells. Lab Chip 2019, 19, 422–431. [Google Scholar] [CrossRef] [PubMed]

- Liao, Q.Q.; Zhao, S.K.; Cai, B.; He, R.X.; Rao, L.; Wu, Y.; Guo, S.S.; Liu, Q.Y.; Lui, W.; Zhao, X.Z. Biocompatible fabrication of cell-laden calcium alginate microbeads using microfluidic double flow-focusing device. Sens. Actuators A 2018, 279, 313–320. [Google Scholar] [CrossRef]

- Nawar, S.; Stolaroff, J.K.; Ye, C.; Wu, H.; Nguyen, D.T.; Xin, F.; Weitz, D.A. Parallelizable microfluidic dropmakers with multilayer geometry for the generation of double emulsions. Lab Chip 2020, 20, 147. [Google Scholar] [CrossRef] [PubMed]

- Nan, L.; Cao, Y.; Yuan, S.; Shum, H.C. Oil-mediated high-throughput generation and sorting of water-in-water droplets. Microsyst. Nanoeng. 2020, 6, 70. [Google Scholar] [CrossRef]

- Song, R.; Abbasi, M.S.; Lee, J. Fabrication of 3D printed modular microfluidic system for generating and manipulating complex emulsion droplets. Microfluid. Nanofluid. 2019, 23, 92. [Google Scholar] [CrossRef]

- Schmit, A.; Courbin, L.; Marquis, M.; Renard, D.; Panizza, P. A pendant drop method for the production of calibrated double emulsions and emulsion gels. RSC Adv. 2014, 4, 28504. [Google Scholar] [CrossRef]

- Si, T.; Feng, H.; Luo, X.; Xu, R.X. Formation of steady compound cone-jet modes and multilayered droplets in a tri-axial capillary flow focusing device. Microfluid. Nanofluid. 2015, 18, 967–977. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, M.J.; Chu, L.Y. Microfluidic approach for encapsulation via double emulsions. Curr. Opin. Pharmacol. 2014, 18, 35–41. [Google Scholar] [CrossRef]

- Levenstein, M.A.; Bawazer, L.A.; Nally, C.S.; Marchant, W.J.; Gong, X.; Meldrum, F.C.; Kapur, N. A reproducible approach to the assembly of microcapillaries for double emulsion production. Microfluid. Nanofluid. 2016, 20, 143. [Google Scholar] [CrossRef] [Green Version]

- Che, Z.; Wong, T.N.; Nguyen, N.T. A simple method for the formation of water-in-oil-in-water (W/O/W) double emulsions. Microfluid. Nanofluid. 2017, 21, 8. [Google Scholar] [CrossRef] [Green Version]

- Hou, L.; Ren, Y.; Jia, Y.; Chen, X.; Deng, X.; Tang, Z.; Hu, Q.; Tao, Y.; Jiang, H. Osmolarity-controlled swelling behaviors of dual-cored double-emulsion drops. Microfluid. Nanofluid. 2017, 21, 60. [Google Scholar] [CrossRef]

- Michelona, M.; Huang, Y.; Torrec, L.G.; Weitz, D.A.; Cunha, R.L. Single-step microfluidic production of W/O/W double emulsions as templates for β-carotene-loaded giant liposomes formation. Chem. Eng. J. 2019, 366, 27–32. [Google Scholar] [CrossRef]

- Ngo, I.L.; Joo, S.W.; Byon, C. Effect of junction angle and viscosity ratio on droplet formation in microfluidic cross-junction. J. Fluids Eng. 2016, 138, 051202. [Google Scholar] [CrossRef]

- Gu, H.; Duits, M.H.G.; Mugele, F. Droplets formation and merging in two-phase flow microfluidics. Int. J. Mol. Sci. 2011, 12, 2572–2597. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, T.J.; Hidrovo, C. Pressure and partial wetting effects on superhydrophobic friction reduction in microchannel flow. Phys. Fluids 2012, 24, 112003. [Google Scholar] [CrossRef] [Green Version]

- Woolford, B.; Maynes, D.; Webb, B.W. Liquid flow through microchannels with grooved walls under wetting and superhydrophobic conditions. Microfluid. Nanofluid. 2009, 7, 121–135. [Google Scholar] [CrossRef]

- Zhang, Y.; Ho, Y.; Chiu, Y.; Chan, H.F.; Chlebina, B.; Schuhmann, T.; You, L.; Leong, K.W. A programmable microenvironment for cellular studies via microfluidics-generated double emulsions. Biomaterials 2013, 34, 4564–4572. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chiu, Y.; Chan, H.F.; Phua, K.L.; Zhang, Y.; Juul, S.; Knudsen, B.R.; Ho, Y.; Leong, K.W. Synthesis of fluorosurfactants for emulsion-based biological applications. ACS Nano 2014, 8, 3913–3920. [Google Scholar] [CrossRef] [PubMed]

- Dreyfus, R.; Tabeling, P.; Willaime, H. Ordered and disordered patterns in two-phase flows in microchannels. Phys. Rev. Lett. 2003, 90, 144505. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Glawdel, T.; Elbuken, C.; Ren, C.L. Droplet formation in microfluidic T-junction generators operating in the transitional regime. II. Model. Phys. Rev. 2012, 85, 016323. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anna, S.L.; Mayer, H.C. Microscale tipstreaming in a microfluidic flow focusing device. Phys. Fluids 2006, 18, 121512. [Google Scholar] [CrossRef] [Green Version]

- Utada, A.S.; Nieves, A.F.; Stone, H.A.; Weitz, D.A. Dripping to jetting transitions in coflowing liquid streams. Phys. Rev. Lett. 2007, 99, 094502. [Google Scholar] [CrossRef] [PubMed]

- Cubaud, T. and Mason, T.G. Capillary threads and viscous droplets in square microchannels. Phys. Rev. Lett. 2008, 20, 053302. [Google Scholar]

- Derzsi, L.; Kasprzyk, M.; Plog, J.P.; Garstecki, P. Flow focusing with viscoelastic liquids. Phys. Rev. Lett. 2013, 25, 092001. [Google Scholar] [CrossRef] [Green Version]

- Loo, S.; Stoukatch, S.; Kraft, M.; Gilet, T. Droplet formation by squeezing in a microfluidic cross-junction. Microfluid. Nanofluid. 2016, 20, 146. [Google Scholar]

- Palogan, B.; Kumar, R.; Bhattacharya, S. Effect of surface coating on droplet generation in flow-focusing microchannels. Microfluid. Nanofluid. 2020, 24, 72. [Google Scholar] [CrossRef]

- Nie, Z.; Seo, M.; Xu, S.; Lewis, P.C.; Mok, M.; Kumacheva, E.; Whitesides, G.M.; Garstecki, P.; Stone, H.A. Emulsification in a microfluidic flow-focusing device: Effect of the viscosities of the liquids. Microfluid. Nanofluid. 2008, 5, 585–594. [Google Scholar] [CrossRef]

- Fu, T.; Wu, Y.; Ma, Y.; Li, H.Z. Droplet formation and breakup dynamics in microfluidic flow-focusing devices: From dripping to jetting. Chem. Eng. Sci. 2012, 84, 207–217. [Google Scholar] [CrossRef]

- Mastiani, M.; Seo, S.; Jimenez, S.M.; Petrozzi, N.; Kim, M.M. Flow regime mapping of aqueous two-phase system droplets in flow-focusing geometries. Colloids Surf. A Physicochem. Eng. Asp. 2017, 531, 111–120. [Google Scholar] [CrossRef]

- Wu, S.; Chen, J.; Lui, X.; Yao, F. Experimental study of droplet formation in the cross-junction. J. Dispers. Sci. Technol. 2020, 42, 1–8. [Google Scholar] [CrossRef]

- Liu, Z.h.; Chai, M.; Chen, X.; Hejazi, S.H.; Li, Y. Emulsification in a microfluidic flow-focusing device: Effect of the dispersed phase viscosity. Fuel 2021, 283, 119229. [Google Scholar] [CrossRef]

- Kalli, M.; Angeli, P. Effect of surfactants on drop formation flow patterns in a flow-focusing microchannel. Chem. Eng. Sci. 2022, 253, 117517. [Google Scholar] [CrossRef]

- Kamnerdsook, K.; Juntasaro, E.; Khemthongcharoen, N.; Chanasakulniyom, M.; Sripumkhai, W.; Pattamang, P.; Promptmas, C.; Atthi, N.; Jeamsaksiri, W. Formation of double emulsion micro-droplets in a microfluidic device using a partially hydrophilic-hydrophobic surface. RSC Adv. 2021, 11, 35653–35662. [Google Scholar] [CrossRef]

| Reference Paper | Droplet Type | Dispersed Phase | Continuous Phase | Phase Diagram Parameter | |

|---|---|---|---|---|---|

| x-Axis | y-Axis | ||||

| Anna and Mayer (2006) [53] | W/O | DI water | Mineral oil | CaD | QR |

| Utada et al. [54] | W/O | DI water | PDMS oil | CaC | WeD |

| Cubaud and Mason (2008) [55] | W/O | Glycerol | PDMS oil | CaC | CaD |

| Nie et al. (2008) [59] | O/W | TPGDA | SDS | CaD | VD/VC |

| Fu et al. (2012) [60] | O/W | Silicone oil | DI water | CaC | WeD |

| Derzsi et al. (2012) [56] | O/W | Silicone oil | Glycerol | CaD | CaC |

| Van Loo et al. (2016) [57] | W/O | DI water | Silicone oil | CaD | QR |

| Mastiani et al. (2017) [61] | W/O | DEG | PEG solution | PD | CaC |

| Palagan et al. (2020) [58] | W/O | DI water | Silicone oil | CaD | QR |

| Wu et al. (2020) [62] | O/W | Silicon oil | PVA | CaD | CaC |

| Liu et al. (2021) [63] | O/W | Mineral oil | Glycerol | QC | QD |

| Kalli and Angeli (2022) [64] | W/O | Glycerol | Silicone oil | CaC | CaD |

| Droplet Type | WD | WC | H | Surface Property | Surface Modification Method |

|---|---|---|---|---|---|

| W/O | 25 | 100 | 100 | hydrophobic | not modified |

| 50 | 125 | 100 | hydrophobic | not modified | |

| 50 | 150 | 100 | hydrophobic | not modified | |

| 25 | 100 | 100 | partially | permanent chemical coating | |

| 20 | 20 | 50 | partially | permanent chemical coating | |

| O/W | 25 | 100 | 100 | hydrophilic | chemical coating |

| 50 | 125 | 100 | hydrophilic | chemical coating | |

| 50 | 150 | 100 | hydrophilic | chemical coating | |

| 25 | 100 | 100 | partially | permanent chemical coating | |

| 20 | 20 | 50 | partially | permanent chemical coating |

| Reference Paper | Regime | CaD | CaC | QR | WeD |

|---|---|---|---|---|---|

| Bauer et al. (2010) [22] | Dripping | 2.85 × 10−7 | 1.45 × 10−6 | 1.33 | 2.66 × 10−7 |

| Abate et al. (2011) [24] | Dripping | 3.04 × 10−6 | 3.40 × 10−5 | 0.21 | 1.89 × 10−5 |

| Li et al. (2016) [31] | Dripping | 2.33 × 10−11 | 1.21 × 10−9 | 1.67 | 2.61 × 10−12 |

| Cai et al. (2019) [33] | Dripping | 9.50 × 10−8 | 3.20 × 10−7 | 1.00 | 5.91 × 10−8 |

| Liao et al. (2018) [34] | Dripping | 5.42 × 10−7 | 9.66 × 10−6 | 1.33 | 8.09 × 10−8 |

| Nan et al. (2020) [36] | Dripping | 1.57 × 10−6 | 5.08 × 10−6 | 0.27 | 4.21 × 10−6 |

| Van Loo et al. (2016) [57] | Dripping | 5.00 × 10−4 | n/a | 0.01 | n/a |

| Dripping | 5.00 × 10−4 | n/a | 0.10 | n/a | |

| Dripping | 5.00 × 10−4 | n/a | 0.50 | n/a | |

| Dripping | 1.00 × 10−4 | n/a | 1.00 | n/a | |

| Jetting | 1.00 × 10−3 | n/a | 8.00 | n/a | |

| Jetting | 5.00 × 10−2 | n/a | 5.00 | n/a | |

| Jetting | 1.00 × 10−2 | n/a | 4.00 | n/a | |

| Jetting | 5.00 × 10−1 | n/a | 1.00 | n/a | |

| Palagan et al. (2020) [58] | Dripping | 1.00 × 10−3 | n/a | 0.01 | n/a |

| Dripping | 1.00 × 10−3 | n/a | 0.10 | n/a | |

| Dripping | 5.00 × 10−4 | n/a | 1.00 | n/a | |

| Jetting | 5.00 × 10−2 | n/a | 10.00 | n/a | |

| Jetting | 1.00 × 10−2 | n/a | 9.00 | n/a | |

| Jetting | 1.00 × 10−1 | n/a | 1.00 | n/a | |

| Liu et al. (2021) [63] | Dripping | 2.86 × 10−5 | 1.93 × 10−4 | 4.00 | 3.58 × 10−10 |

| Dripping | 5.72 × 10−5 | 5.79 × 10−4 | 6.00 | 1.43 × 10−10 | |

| Dripping | 8.59 × 10−5 | 7.72 × 10−4 | 5.33 | 3.22 × 10−9 | |

| Dripping | 1.14 × 10−4 | 5.79 × 10−4 | 3.00 | 5.72 × 10−9 | |

| Dripping | 1.43 × 10−4 | 3.86 × 10−4 | 1.60 | 8.94 × 10−9 | |

| Jetting | 1.14 × 10−4 | 7.72 × 10−4 | 4.00 | 5.72 × 10−9 | |

| Jetting | 1.14 × 10−4 | 9.65 × 10−4 | 5.00 | 5.72 × 10−9 | |

| Jetting | 1.43 × 10−4 | 5.79 × 10−4 | 2.40 | 8.94 × 10−9 | |

| Jetting | 1.43 × 10−4 | 9.65 × 10−4 | 4.00 | 8.94 × 10−9 | |

| Jetting | 1.72 × 10−4 | 5.79 × 10−4 | 2.00 | 1.29 × 10−8 | |

| Kalli and Angeli (2022) [64] | Tubing | 1.02 × 10−3 | 2.51 × 10−4 | 0.50 | 4.19 × 10−8 |

| Tubing | 1.01 × 10−3 | 4.96 × 10−4 | 1.00 | 4.19 × 10−8 | |

| Dripping | 7.63 × 10−4 | 1.00 × 10−3 | 2.00 | 4.19 × 10−8 | |

| Dripping | 7.63 × 10−4 | 2.00 × 10−3 | 4.00 | 4.19 × 10−8 | |

| Dripping | 7.63 × 10−4 | 3.01 × 10−3 | 6.00 | 4.19 × 10−8 | |

| Dripping | 7.63 × 10−4 | 4.01 × 10−3 | 8.00 | 4.19 × 10−8 | |

| Dripping | 7.63 × 10−4 | 5.01 × 10−3 | 10.00 | 4.19 × 10−8 | |

| Dripping | 2.29 × 10−3 | 3.01 × 10−3 | 2.00 | 3.77 × 10−7 | |

| Dripping | 2.29 × 10−3 | 4.01 × 10−3 | 2.67 | 3.77 × 10−7 | |

| Dripping | 2.29 × 10−3 | 5.01 × 10−3 | 3.33 | 3.77 × 10−7 | |

| Jetting | 2.29 × 10−3 | 2.00 × 10−3 | 1.33 | 3.77 × 10−7 | |

| Jetting | 3.81 × 10−3 | 3.01 × 10−3 | 1.20 | 1.05 × 10−6 | |

| Jetting | 3.81 × 10−3 | 4.01 × 10−3 | 1.60 | 1.05 × 10−6 | |

| Jetting | 3.81 × 10−3 | 5.01 × 10−3 | 2.00 | 1.05 × 10−6 | |

| Jetting | 3.81 × 10−3 | 7.02 × 10−3 | 2.80 | 1.05 × 10−6 | |

| Jetting | 3.81 × 10−3 | 8.02 × 10−3 | 3.20 | 1.05 × 10−6 | |

| Jetting | 3.81 × 10−3 | 9.02 × 10−3 | 3.60 | 1.05 × 10−6 |

| Device | Regime | CaD | CaC | QR | WeD |

|---|---|---|---|---|---|

| WD25WC100H100 | Dripping | 1.63 × 10−4 | 1.43 × 10−2 | 10.00 | 1.18 × 10−9 |

| Dripping | 3.25 × 10−4 | 1.43 × 10−2 | 5.00 | 4.74 × 10−9 | |

| Dripping | 8.13 × 10−4 | 1.43 × 10−2 | 2.00 | 2.96 × 10−8 | |

| Dripping | 1.63 × 10−3 | 1.43 × 10−2 | 1.00 | 1.18 × 10−7 | |

| Dripping | 3.14 × 10−3 | 1.43 × 10−2 | 0.52 | 4.43 × 10−7 | |

| Tubing | 3.25 × 10−3 | 1.43 × 10−2 | 0.50 | 4.74 × 10−7 | |

| Tubing | 3.58 × 10−3 | 1.43 × 10−2 | 0.45 | 5.73 × 10−3 | |

| Tubing | 3.90 × 10−3 | 1.43 × 10−2 | 0.42 | 6.82 × 10−7 | |

| Tubing | 4.88 × 10−3 | 1.43 × 10−2 | 0.33 | 1.07 × 10−6 | |

| Tubing | 8.13 × 10−3 | 1.43 × 10−2 | 0.20 | 2.96 × 10−6 | |

| WD50WC125H100 | Tubing | 1.63 × 10−3 | 1.09 × 10−3 | 0.05 | 1.97 × 10−7 |

| Tubing | 1.63 × 10−3 | 2.12 × 10−3 | 0.09 | 1.97 × 10−7 | |

| Tubing | 1.63 × 10−3 | 3.19 × 10−3 | 0.14 | 1.97 × 10−7 | |

| Dripping | 1.63 × 10−3 | 4.28 × 10−3 | 0.19 | 1.97 × 10−7 | |

| Dripping | 1.63 × 10−3 | 8.54 × 10−3 | 0.37 | 1.97 × 10−7 | |

| Dripping | 1.63 × 10−3 | 2.14 × 10−2 | 0.93 | 1.97 × 10−7 | |

| Dripping | 1.63 × 10−3 | 4.27 × 10−2 | 1.86 | 1.97 × 10−7 | |

| WD50WC150H100 | Tubing | 1.63 × 10−3 | 1.19 × 10−3 | 0.06 | 1.97 × 10−7 |

| Tubing | 1.63 × 10−3 | 2.34 × 10−3 | 0.12 | 1.97 × 10−7 | |

| Tubing | 1.63 × 10−3 | 3.56 × 10−3 | 0.19 | 1.97 × 10−7 | |

| Dripping | 1.63 × 10−3 | 4.73 × 10−3 | 0.25 | 1.97 × 10−7 | |

| Dripping | 1.63 × 10−3 | 9.46 × 10−3 | 0.50 | 1.97 × 10−7 | |

| Dripping | 1.63 × 10−3 | 2.36 × 10−2 | 1.24 | 1.97 × 10−7 | |

| Dripping | 1.63 × 10−3 | 4.72 × 10−2 | 2.47 | 1.97 × 10−7 |

| Device | Regime | CaD | CaC | QR | WeD |

|---|---|---|---|---|---|

| WD25WC100H100 | Dripping | 1.35 × 10−5 | 1.19 × 10−4 | 1.00 | 3.37 × 10−8 |

| Dripping | 1.35 × 10−5 | 1.19 × 10−3 | 10.00 | 3.37 × 10−8 | |

| Jetting | 1.35 × 10−5 | 1.19 × 10−2 | 100.00 | 3.37 × 10−8 | |

| Jetting | 1.35 × 10−5 | 1.19 × 10−1 | 1000.00 | 3.37 × 10−8 | |

| Dripping | 1.35 × 10−4 | 1.19 × 10−4 | 0.10 | 3.37 × 10−6 | |

| Dripping | 1.35 × 10−4 | 1.19 × 10−3 | 1.00 | 3.37 × 10−6 | |

| Dripping | 1.35 × 10−4 | 1.19 × 10−2 | 10.00 | 3.37 × 10−6 | |

| Jetting | 1.35 × 10−4 | 1.19 × 10−1 | 100.00 | 3.37 × 10−6 | |

| Tubing | 1.35 × 10−3 | 1.19 × 10−4 | 0.01 | 3.37 × 10−4 | |

| Tubing | 1.35 × 10−3 | 1.19 × 10−3 | 0.10 | 3.37 × 10−4 | |

| Dripping | 1.35 × 10−3 | 1.19 × 10−2 | 1.00 | 3.37 × 10−4 | |

| Jetting | 1.35 × 10−3 | 4.78 × 10−2 | 4.00 | 3.37 × 10−4 | |

| Jetting | 1.35 × 10−3 | 1.19 × 10−1 | 10.00 | 3.37 × 10−4 | |

| Tubing | 1.35 × 10−2 | 1.19 × 10−4 | 0.00 | 3.37 × 10−2 | |

| Tubing | 1.35 × 10−2 | 1.19 × 10−3 | 0.01 | 3.37 × 10−2 | |

| Tubing | 1.35 × 10−2 | 1.19 × 10−2 | 0.10 | 3.37 × 10−2 | |

| Dripping | 1.35 × 10−2 | 1.19 × 10−1 | 1.00 | 3.37 × 10−2 | |

| WD20WC20H50 | Dripping | 3.39 × 10−5 | 1.19 × 10−3 | 1.00 | 1.51 × 10−7 |

| Dripping | 3.39 × 10−5 | 1.19 × 10−2 | 10.00 | 1.51 × 10−7 | |

| Jetting | 3.39 × 10−5 | 7.16 × 10−2 | 60.00 | 1.51 × 10−7 | |

| Jetting | 3.39 × 10−5 | 1.19 × 10−1 | 100.00 | 1.51 × 10−7 | |

| Jetting | 3.39 × 10−5 | 1.19 × 100 | 1000.00 | 1.51 × 10−7 | |

| Dripping | 3.39 × 10−4 | 1.19 × 10−3 | 0.10 | 1.51 × 10−5 | |

| Dripping | 3.39 × 10−4 | 1.19 × 10−2 | 1.00 | 1.51 × 10−5 | |

| Dripping | 3.39 × 10−4 | 1.19 × 10−1 | 10.00 | 1.51 × 10−5 | |

| Jetting | 3.39 × 10−4 | 1.19 × 100 | 100.00 | 1.51 × 10−5 | |

| Tubing | 3.39 × 10−3 | 1.19 × 10−3 | 0.01 | 1.51 × 10−3 | |

| Tubing | 3.39 × 10−3 | 1.19 × 10−2 | 0.10 | 1.51 × 10−3 | |

| Dripping | 3.39 × 10−3 | 1.19 × 10−1 | 1.00 | 1.51 × 10−3 | |

| Dripping | 3.39 × 10−3 | 4.78 × 10−1 | 4.00 | 1.51 × 10−3 | |

| Jetting | 3.39 × 10−3 | 7.16 × 10−1 | 6.00 | 1.51 × 10−3 | |

| Jetting | 3.39 × 10−3 | 1.19 × 100 | 10.00 | 1.51 × 10−3 | |

| Tubing | 3.39 × 10−2 | 1.19 × 10−3 | 0.001 | 1.51 × 10−1 | |

| Tubing | 3.39 × 10−2 | 1.19 × 10−2 | 0.01 | 1.51 × 10−1 | |

| Tubing | 3.39 × 10−2 | 1.19 × 10−1 | 0.10 | 1.51 × 10−1 | |

| Tubing | 3.39 × 10−2 | 1.19 × 100 | 1.00 | 1.51 × 10−1 |

| Reference Paper | Regime | CaD | CaC | QR | WeD |

|---|---|---|---|---|---|

| Bauer et al. (2010) [22] | Dripping | 9.60 × 10−7 | 1.42 × 10−7 | 2.00 | 6.05 × 10−7 |

| Abate et al. (2011) [24] | Dripping | 2.54 × 10−6 | 7.12 × 10−7 | 0.23 | 3.09 × 10−7 |

| Li et al. (2016) [31] | Dripping | 4.35 × 10−6 | 1.90 × 10−6 | 1.67 | 3.63 × 10−6 |

| Cai et al. (2019) [33] | Dripping | 1.69 × 10−5 | 2.94 × 10−6 | 0.11 | 4.71 × 10−8 |

| Liao et al. (2018) [34] | Dripping | 1.90 × 10−9 | 1.30 × 10−10 | 0.16 | 2.61 × 10−12 |

| Nan et al. (2020) [36] | Dripping | 6.40 × 10−7 | 2.37 × 10−6 | 0.08 | 2.02 × 10−7 |

| Nie et al. (2008) [59] | Dripping | 2.78 × 10−8 | 7.94 × 10−8 | 50.00 | 1.38 × 10−15 |

| Dripping | 3.47 × 10−7 | 9.92 × 10−7 | 50.00 | 2.15 × 10−13 | |

| Jetting | 8.33 × 10−6 | 2.38 × 10−5 | 50.00 | 1.24 × 10−10 | |

| Fu et al. (2012) [60] | Tubing | n/a | 2.00 × 10−4 | n/a | 1.00 × 10−7 |

| Tubing | n/a | 2.00 × 10−4 | n/a | 1.00 × 10−6 | |

| Tubing | n/a | 2.00 × 10−4 | n/a | 1.00 × 10−5 | |

| Tubing | n/a | 2.00 × 10−4 | n/a | 1.00 × 10−4 | |

| Tubing | n/a | 2.00 × 10−4 | n/a | 1.00 × 10−3 | |

| Dripping | n/a | 1.00 × 10−3 | n/a | 1.00 × 10−7 | |

| Dripping | n/a | 1.00 × 10−3 | n/a | 1.00 × 10−5 | |

| Dripping | n/a | 1.00 × 10−3 | n/a | 1.00 × 10−3 | |

| Dripping | n/a | 1.00 × 10−2 | n/a | 1.00 × 10−4 | |

| Dripping | n/a | 1.00 × 10−2 | n/a | 1.00 × 10−2 | |

| Jetting | n/a | 4.00 × 10−2 | n/a | 1.00 × 10−3 | |

| Jetting | n/a | 4.00 × 10−2 | n/a | 1.00 × 10−2 | |

| Jetting | n/a | 4.00 × 10−2 | n/a | 1.00 × 10−1 | |

| Wu et al. (2020) [62] | Tubing | 2.00 × 10−4 | 1.00 × 10−3 | n/a | n/a |

| Tubing | 1.00 × 10−4 | 5.00 × 10−4 | n/a | n/a | |

| Tubing | 7.00 × 10−4 | 3.00 × 10−4 | n/a | n/a | |

| Tubing | 5.00 × 10−4 | 2.00 × 10−4 | n/a | n/a | |

| Tubing | 4.00 × 10−4 | 1.00 × 10−4 | n/a | n/a | |

| Dripping | 1.00 × 10−5 | 2.00 × 10−3 | n/a | n/a | |

| Dripping | 2.00 × 10−5 | 4.00 × 10−3 | n/a | n/a | |

| Dripping | 3.00 × 10−5 | 5.00 × 10−3 | n/a | n/a | |

| Dripping | 5.00 × 10−5 | 7.00 × 10−3 | n/a | n/a | |

| Dripping | 1.00 × 10−4 | 7.00 × 10−3 | n/a | n/a |

| Device | Regime | CaD | CaC | QR | WeD |

|---|---|---|---|---|---|

| WD50WC125H100 | Tubing | 4.78 × 10−3 | 5.42 × 10−5 | 1.00 | 4.12 × 10−8 |

| Dripping | 4.78 × 10−3 | 1.14 × 10−4 | 2.10 | 4.12 × 10−8 | |

| Dripping | 4.78 × 10−3 | 2.82 × 10−4 | 5.20 | 4.12 × 10−8 | |

| Dripping | 4.78 × 10−3 | 5.69 × 10−4 | 10.50 | 4.12 × 10−8 | |

| WD50WC150H100 | Tubing | 4.78 × 10−3 | 6.32 × 10−5 | 1.40 | 4.12 × 10−8 |

| Dripping | 4.78 × 10−3 | 1.26 × 10−4 | 2.80 | 4.12 × 10−8 | |

| Dripping | 4.78 × 10−3 | 3.16 × 10−4 | 7.00 | 4.12 × 10−8 | |

| Dripping | 4.78 × 10−3 | 6.28 × 10−4 | 13.90 | 4.12 × 10−8 |

| Device | Regime | CaD | CaC | QR | WeD |

|---|---|---|---|---|---|

| WD25WC100H100 | Tubing | 3.65 × 10−4 | 2.16 × 10−5 | 1.00 | 3.01 × 10−8 |

| Dripping | 3.65 × 10−4 | 2.16 × 10−4 | 10.00 | 3.01 × 10−8 | |

| Dripping | 3.65 × 10−4 | 2.16 × 10−3 | 100.00 | 3.01 × 10−8 | |

| Jetting | 3.65 × 10−4 | 1.29 × 10−2 | 600.00 | 3.01 × 10−8 | |

| Jetting | 3.65 × 10−4 | 2.16 × 10−2 | 1000.00 | 3.01 × 10−8 | |

| Tubing | 3.65 × 10−3 | 2.16 × 10−5 | 0.10 | 3.01 × 10−6 | |

| Tubing | 3.65 × 10−3 | 2.16 × 10−4 | 1.00 | 3.01 × 10−6 | |

| Dripping | 3.65 × 10−3 | 2.16 × 10−3 | 10.00 | 3.01 × 10−6 | |

| Jetting | 3.65 × 10−3 | 2.16 × 10−2 | 100.00 | 3.01 × 10−6 | |

| Tubing | 3.65 × 10−2 | 2.16 × 10−5 | 0.01 | 3.01 × 10−4 | |

| Tubing | 3.65 × 10−2 | 2.16 × 10−4 | 0.10 | 3.01 × 10−4 | |

| Tubing | 3.65 × 10−2 | 2.16 × 10−3 | 1.00 | 3.01 × 10−4 | |

| Jetting | 3.65 × 10−2 | 2.16 × 10−2 | 10.00 | 3.01 × 10−4 | |

| Tubing | 3.65 × 10−1 | 2.16 × 10−5 | 0.00 | 3.01 × 10−2 | |

| Tubing | 3.65 × 10−1 | 2.16 × 10−4 | 0.01 | 3.01 × 10−2 | |

| Tubing | 3.65 × 10−1 | 2.16 × 10−3 | 0.10 | 3.01 × 10−2 | |

| Tubing | 3.65 × 10−1 | 2.16 × 10−2 | 1.00 | 3.01 × 10−2 | |

| WD20WC20H50 | Tubing | 9.13 × 10−4 | 2.16 × 10−4 | 1.00 | 1.34 × 10−7 |

| Dripping | 9.13 × 10−4 | 2.16 × 10−3 | 10.00 | 1.34 × 10−7 | |

| Dripping | 9.13 × 10−4 | 2.16 × 10−2 | 100.00 | 1.34 × 10−7 | |

| Jetting | 9.13 × 10−4 | 1.08 × 10−1 | 500.00 | 1.34 × 10−7 | |

| Jetting | 9.13 × 10−4 | 2.16 × 10−1 | 1000.00 | 1.34 × 10−7 | |

| Tubing | 9.13 × 10−3 | 2.16 × 10−4 | 0.10 | 1.34 × 10−5 | |

| Tubing | 9.13 × 10−3 | 2.16 × 10−3 | 1.00 | 1.34 × 10−5 | |

| Jetting | 9.13 × 10−3 | 2.16 × 10−2 | 10.00 | 1.34 × 10−5 | |

| Jetting | 9.13 × 10−3 | 2.16 × 10−1 | 100.00 | 1.34 × 10−5 | |

| Tubing | 9.13 × 10−2 | 2.16 × 10−4 | 0.01 | 1.34 × 10−3 | |

| Tubing | 9.13 × 10−2 | 2.16 × 10−3 | 0.10 | 1.34 × 10−3 | |

| Tubing | 9.13 × 10−2 | 2.16 × 10−2 | 1.00 | 1.34 × 10−3 | |

| Jetting | 9.13 × 10−2 | 2.16 × 10−1 | 10.00 | 1.34 × 10−3 | |

| Tubing | 9.13 × 10−1 | 2.16 × 10−4 | 0.001 | 1.34 × 10−1 | |

| Tubing | 9.13 × 10−1 | 2.16 × 10−3 | 0.01 | 1.34 × 10−1 | |

| Tubing | 9.13 × 10−1 | 2.16 × 10−2 | 0.10 | 1.34 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamnerdsook, A.; Juntasaro, E.; Khemthongcharoen, N.; Chanasakulniyom, M.; Sripumkhai, W.; Pattamang, P.; Promptmas, C.; Atthi, N.; Jeamsaksiri, W. On Classification of Water-in-Oil and Oil-in-Water Droplet Generation Regimes in Flow-Focusing Microfluidic Devices. Colloids Interfaces 2023, 7, 17. https://doi.org/10.3390/colloids7010017

Kamnerdsook A, Juntasaro E, Khemthongcharoen N, Chanasakulniyom M, Sripumkhai W, Pattamang P, Promptmas C, Atthi N, Jeamsaksiri W. On Classification of Water-in-Oil and Oil-in-Water Droplet Generation Regimes in Flow-Focusing Microfluidic Devices. Colloids and Interfaces. 2023; 7(1):17. https://doi.org/10.3390/colloids7010017

Chicago/Turabian StyleKamnerdsook, Ampol, Ekachai Juntasaro, Numfon Khemthongcharoen, Mayuree Chanasakulniyom, Witsaroot Sripumkhai, Pattaraluck Pattamang, Chamras Promptmas, Nithi Atthi, and Wutthinan Jeamsaksiri. 2023. "On Classification of Water-in-Oil and Oil-in-Water Droplet Generation Regimes in Flow-Focusing Microfluidic Devices" Colloids and Interfaces 7, no. 1: 17. https://doi.org/10.3390/colloids7010017