1. Introduction

Biocatalysis or enzymatic catalysis is the application of active biological components in chemical reactions [

1,

2]. These biological components are known as enzymes. Enzymes can be proteins or amino acids. Primarily, enzymes catalyze biochemical reactions within the living system. There are six major classes of enzymes, namely oxidoreductases, transferases, hydrolases, lyases, isomerases and ligases [

1,

2]. Among these, hydrolases are a class of enzyme known for catalyzing relevant hydrolytic reactions in industry settings. Lipases (triacylglycerol hydrolases; E.C.3.1.1.3) belong to the hydrolase class. It is a digestive enzyme known for hydrolyzing fat into fatty acids and glycerol under physiological conditions. However, in the absence of natural media (water), i.e., in non-conventional media, lipases catalyze esterification, transeserification and interesterification reactions [

3,

4,

5].

Basic and applied research on enzymes is growing leaps and bounds, resulting in a number of landmark discoveries (

Figure 1) [

3,

4,

6,

7]. Nowadays, enzymes are used in several industrial sectors because of their specificity and selectivity, requirement of mild conditions during reactions and ability to eliminate toxicity associated with catalysts. Thus far, biocatalysis has been used as an important tool in fine chemicals, life sciences, cosmetics and skin care, food and energy industries to name a few (

Figure 2) [

6,

8,

9]. More recently, enzymes have been applied in the valorization of wastes and, in particular, in the treatment of food waste.

According to global estimates, one third of food fit for human consumption is lost or wasted every year [

10]. To put it simply, this is approximately 1.3 billion tons of food wasted worldwide per year [

10]. In economic terms, it costs about US

$ 1trillion. As per the World Resources Institute, considering food losses and wastes as an independent country, it would be the third largest green house gas emitter after the USA and China [

11]. This shows the immense negative impact of food waste on the economy and environment.

In the above context, it is important to resolve the ongoing food waste crisis [

12]. An ideal way to drastically minimize food waste is to avoid generating it through proper storage, consumption, and the implementation of best practices in restaurants. However, it is not possible to stop food waste generation completely since it is difficult to ensure the consumption of all produce. Along this line, the technical conversion of food waste into valuable products is becoming a priority research area [

13,

14]. Novel and efficient valorization technologies, such as material preparation, chemo-catalysis, bioconversion, extraction, thermochemical conversion and non-catalytic conversion, can provide sustainable solutions for the reduction of the amount of waste generated when compared with traditional waste management; this can be accomplished through composting, land filling, incineration and animal feeding (

Figure 3) [

15,

16,

17,

18,

19]. Among the reported technologies, bioconversion is used to synthesize biopolymers, succinic acid, carboxylic acids, alcohols, glycerol carbonate, dihydroxy acetone, diols, and biofuels from food waste.

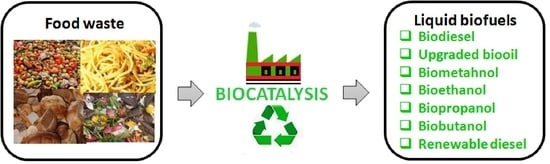

Given the intrinsic advantages of biocatalysis, this review paper presents an overview of various recent biocatalytic technologies being used for the conversion of food waste into liquid biofuels. The enzymatic preparation of biodiesel, upgraded bio-oil, methanol, ethanol, propanol, butanol and hydrocarbon-based fuels (renewable diesel) from food waste is evaluated. In addition, industrial scale ethanol production from food waste is also presented, which has tremendous market potential. Furthermore, limitations of the reported methods, societal and economic context and a perspective on the research topic are described, along with suitable examples for the benefit of researchers.

2. Food Waste—A Versatile Resource

Food waste is complex in nature and available in large quantities (

Figure 4). It is certainly possible to minimize food waste generation at the source by integrating awareness with technology. One of the reasons for food waste generation is the perceived consumer attitude about presentation and abundance, resulting in a throw-away culture. Raising awareness at the grassroots level and implementing simple action-oriented plans which consumers understand will prevent food from being wasted. The internet of things (IoT) can provide solutions for waste reduction in grocery stores and restaurant chains since it offers several benefits including (i) traceability, (ii) temperature as well as energy monitoring, and (iii) artificial intelligence. As an example, if all grocery stores are equipped with a temperature monitoring system (sensors), a large amount of food materials can be prevented from becoming waste.

Food waste can be classified as totally avoidable, probably avoidable and non-avoidable. Some amount of food waste generation is non-avoidable (

Figure 5) [

20]. The composition of food waste can vary depending on the place of origin and eating habits of inhabitants [

21].

Several research teams are using food waste as raw materials for the synthesis of valuable products. Before using it in chemical or biotechnological reactions, food waste needs to be characterized [

21]. Analyses of food wastes using different techniques, such as (a) elemental analysis (determination of CHNX, X = heteroatoms), (b) thermogravimetric analyis (TGA, determination of thermal stability and quantification of volatile components), (c) pH analysis, (d) Soxhlet extraction method (lipid content determination), (e) Kjeldahl method (quantification of protein and nitrogen), (f) biochemical methane potential test (BMP, to determine the methane potential and biodegradability), (g) acid digestion method (used for the dissolution of samples before elemental analysis) and (h) inductively coupled plasma optical emission spectroscopy (ICP-OES, quantification of elements such as K and P in the food waste sample), are essential to determine its suitability as the feedstock.

Food waste contains three major components, namely carbohydrates (41–85%), proteins (15–25%) and lipids (13–40%) (

Figure 6) [

21,

22]. Waste derived from rice, pasta, noodles and vegetables generally contain a significant amount of carbohydrates, whereas meat, fish market waste and poultry waste contain a high amount of protein and lipids. Even though food waste composition is dependent on the source of origin, time of generation and eating habits of people, some of the important properties, namely, moisture content (74–90%), volatile solids content (85–90%) and acidity (pH 4.5–5.5), are found to be similar across the world [

21,

22,

23].

Food waste is regarded as wealth. Traditional methods like incineration, open burning, sea dumping, and land filling are unviable options for food waste treatment. The advancement of chemical and biotechnological technologies in the past decades enables the sustainable valorization of food waste into building blocks, fuels, enzymes, and materials [

17,

23,

24,

25].

3. Towards a Food Waste-Based Biorefinery Using Biocatalysis

Food waste is a bigger threat (pollutant) to the environment than the aviation industry. Within the framework of the UN Sustainable Development Goals (SDGs), biorefineries are being developed for the sustainable utilization of food waste to prepare biofuels, chemicals, materials and high-value products [

15,

17,

20,

22,

23,

24,

25]. To develop a food waste–based biorefinery, different conversion routes can be followed: (i) chemical; (ii) thermochemical and (iii) bioconversion. In general, chemical catalysts are used in the chemical conversion route, whereas thermochemical methods can be carried out both catalytically and non-catalytically. Also, thermochemical conversion can be accomplished under subcritical and supercritical conditions. The bioconversion method employs purified/crude enzymes or micro-organisms (whole cells) to treat food waste. One important aspect of using enzymes for synthetic purposes is their specificity and selectivity and the reaction can be carried out under mild conditions [

26,

27,

28].

In the above context, several commercial enzymes are now available which can be employed as alternatives to conventional chemical catalysts [

28]. In addition, enzymes can be engineered in accordance with the requirements of a specific process. This enables the introduction of novel enzymes with new catalytic activities [

29,

30,

31]. Now it is a well-established fact that a large number of reactions can be completed using enzymes. Here, a food waste-based biorefinery is envisaged using biocatalysts.

Several enzymatic processes, such as hydrolysis, esterification, transesterification, interesterification, oxidation, reduction, decarboxylation, anaerobic digestion, fermentation, and epoxidation, can be performed efficiently to valorize waste (

Figure 7). Within this context, food waste is converted to biohythane and methane using anaerobic digestion (biogasification) (

Figure 7). The obtained methane can be enzymatically oxidized using methane mono-oxygenases (MMOs) to produce methanol. Thermochemical conversion technology is employed to prepare bio-oil from food waste, which is subsequently upgraded to a better quality fuel using lipase (

Figure 7). Furthermore, using bioconversion technologies, the lipid portion of food waste is converted into biodiesel, whereas the carbohydrate fraction is diverted to ethanol generating industries. Also, the carbohydrate fraction can be utilized as a nutrient to produce microalgae and enzymes. The resulting algae biomass is used for simultaneous lipid extraction (in situ) and enzymatic transesterification to yield biodiesel (

Figure 7). In addition, other liquid biofuels such as propanol and butanol are also synthesized biocatalytically (

Figure 7).

Various biofuels, namely biodiesel, upgraded bio-oil, methanol, ethanol, propanol, butanol, renewable diesel (hydrocarbon-based fuel), bio-oil, biohythane, methane and hydrogen, can be synthesized via a biorefinery approach (

Figure 7). Several chemical and biotechnological methods are employed to synthesize chemicals, namely glycerol carbonate, dihydroxy acetone, succinic acid, lactic acid, itaconic acid, 2,3-butanediol, levulinic acid, γ-valerolactone and hydroxymethyl furfural, from food waste (

Figure 7 and

Figure 8). In addition, other products, namely protein, animal feed, enzymes, small organic acids, flavors and colorants, biofertilizers and bioplastics, can be produced through a food waste-based biorefinery. The chemical building blocks prepared from food waste have important applications for fine chemical, biopolymer, cosmetics and life sciences industries. For example, glycerol carbonate is an important starting material in polyurethane and polycarbonate technology.

4. Biocatalysis for the Preparation of Liquid Biofuels

At present, petroleum-derived liquid fuels are used as the primary source of energy in the transport sector, which accounts for approximately a quarter of the global annual energy need. Also, it is responsible for emitting a quarter of the global energy-related CO

2 and other gaseous pollutants [

32]. In line with this, substituting petroleum-derived fuels with liquid biofuels will decarbonize the transport sector.

In particular, the ongoing research focus is on liquid biofuels since existing infrastructure for transportation is vast and readily available for their use. The production and availability of liquid biofuels is important to decarbonize the transport sector as global demand for transport services will continue to grow in the years to come. In this context, food waste—a no value resource—can be valorized through biocatalytic methods to produce liquid biofuels, which is significant from an environmental sustainability point of view (

Figure 9).

The micro-organism of interest can be picked from a natural habitat and, furthermore, it can be selected using screening methods. If found suitable, the whole cells can be employed in biotransformations. The whole cells tend to yield byproducts and exhibit a low yield of the desired products since it is a bag of mixed enzymes. Therefore, in accordance with the needs of the reaction, the required protein is purified and subsequently used in biocatalysis. The protein obtained as a powder is immobilized to make the enzyme recyclable and tolerant under the reaction conditions. To make the enzyme efficient and suitable for a specific reaction enzyme engineering/directed evolution is performed. The engineered enzymes are employed in biochemical reactions to achieve the product(s). Both the bioreactor design and solvent engineering are important tools to optimize the process parameters and ease downstream processing.

4.1. Biodiesel

Edible oils derived from food crops are largely used for biodiesel production (

Figure 10) [

33]. The feedstock accounts for 70–90% of the total cost of biodiesel production. Therefore, low-cost and non-edible feedstocks are potential candidates for biofuel production (

Table 1) [

34,

35]. As shown in

Table 1, food waste contains a significant amount of lipids/oil. The lipids from food waste are utilized for biodiesel production [

22,

23]. The advantages of biodiesel production using food waste lipids are that the feedstock is easily accessible and can provide an amicable solution to the waste disposal problem. To this effect, lipases are employed for biodiesel production from food waste since the reaction is performed under mild conditions and the catalyst (non-toxic) is known to cause less environmental pollution.

Karmee et al. investigated enzymatic biodiesel synthesis using lipid from food waste (

Figure 11, route I) [

36]. The lipid was obtained via enzymatic hydrolysis of food waste. The obtained lipid was reacted with methanol (lipid to methanol molar ratio: 1:5) using Novozym 435 as a catalyst. Under optimized reaction conditions, the immobilized lipase gave 90% biodiesel in 24 h at 40 °C [

36].

Noodles are available in packets in markets and they are a common staple food in many countries. In general, oil is used to fry noodles to preserve them and to increase the shelf life. The oil from noodle waste has been investigated for biodiesel synthesis [

37,

38,

39]. Yang et al. reported Novozym 435-catalyzed biodiesel preparation using oil isolated from noodle waste [

37]. The authors observed a 95.4% biodiesel conversion in 36 h [

37]. The optimum reaction parameters were an oil to methanol molar ratio of 1:9, enzyme amount of 15% (

w/

v), water amount of 2% (

w/

v) and temperature of 40 °C. Methanol was added in three potions to avoid deactivation of the lipases and loading times were at 0, 4 and 16 h [

37]. To circumvent the deactivation of lipases during biodiesel preparation, dimethyl carbonate can be used. For example, food waste lipids can potentially be used for the co-production of biodiesel and glycerol carbonate using lipase and dialkyl carbonates (e.g., dimethyl carbonate) (

Figure 11, route II). Such a method is attractive since it is glycerol-free and the resulting product (glycerol carbonate) has a wide range of applications as a solvent and starting material in polymer industries.

Food waste hydrolysate is used as a nutrient for the culture of lipid-producing micro-organisms. It is reported by Zeng et al. that when mixed cultures of

Rhodosporidium toruloides and

Chlorella vulgaris (yeast and microalgae) are used for food waste treatment, the experiments gave a higher amount of lipids in a short cultivation time as compared to a pure culture of

Rhodosporidium toruloides [

40]. The results indicate that yeast and microalgae mixed cultures can be used strategically for biofuel production from food waste.

Along the line, Zhang et al. reported the use of anaerobic-digested effluent from kitchen waste for microalgae cultivation [

41].The lipid content in

Chlorella sorokiniana SDEC-18 was 30.27–41.69%, whereas

Scenedesmus SDEC-8 gave 35.97–47.39% lipid content under optimum experimental conditions [

41]. The resulting biomass was harvested and the cell was disrupted to yield the oil, which was subsequently used for biodiesel production. To overcome the cost related to microalgae biomass drying and oil extraction, direct use of the harvested, lipid-enriched microalgae biomass via insitu transesterification is being investigated [

35]. During the insitu transesterification, oil extraction and conversion of lipids to biodiesel takes place simultaneously in one pot (

Figure 12) [

35]. Many researchers are also investigating single-step techniques for simultaneous celllysis and the extraction of lipid from microalgae using ultrasound-, microwave-, bead-beating-, surfactant- and pulsed electric field-assisted methods [

42].

4.2. Enzymatic Upgradation of Bio-Oil

Recently, considerable research has been going on to investigate how to convert food waste to liquid fuels and chemicals using thermochemical conversion technologies [

43,

44,

45]. The thermochemical treatment (pyrolysis and hydrothermal treatment) of food waste leads to the production of bio-oil, among other products. It is a widely acknowledged fact that any kind of food waste with a high or low moisture content can be treated thermochemically. The product (biooil) is a highly viscous tarry substance comprised of a mixture of reactive chemical compounds, such as organic acids, aldehydes and alcohols. Bio-oil is unstable in nature and degrades with time (e.g., aging). Furthermore, improper storage leads to uncontrolled decomposition, making it a jelly-like substance unworthy of further consumption as a fuel. This hinders the utilization of bio-oil as a potential biofuel. To overcome this problem, bio-oil can be upgraded to a more stable form of liquid fuel by esterification [

46,

47]. The upgraded bio-oil, which has a better shelf life, can be used in industrial burners as a replacement for conventional furnace oil (

Figure 13).

Several authors have upgraded crude bio-oil through catalytic esterification of the acids present in it before performing further hydrotreatment. Clearly, this process makes bio-oil less acidic and reduces the oxygen content in it. It also improves the stability of bio-oil and helps in decreasing the hydrogen utilization in the subsequent steps of refining. Enzymatic treatment of biooil obtained after hydrothermal treatment has also been investigated (

Figure 14) [

41]. As a first step, the hydrothermal liquefaction of wet spent coffee grounds was performed in a batch reactor. Subsequently, bio-oil prepared through hydrothermal liquefaction was upgraded using lipases to convert it into a higher quality fuel by bringing down the acid value (

Figure 14) [

48]. The results revealed that lipases are an effective biocatalyst for the upgradation of the highly acidic crude bio-oil.

4.3. Biomethanol

Biomethanol is a valuable product obtained from waste biomass. Methane prepared via the biomethanation/biogasification of food waste can be oxidized by methane mono-oxygenases (MMOs) (

Figure 15) [

49,

50]. MMOs, namely,

Bacillus methanicus and

Methylosinus trichosporium present in methanotrophs, are known for catalyzing the oxidation of methane to methanol [

49,

50,

51]. Immobilization of the enzyme using sodium alginate and silica gel can increase methanol production. Even though there are a few reports on the production of methanol from food waste, further research is required to achieve better understanding of the process for larger scale production.

4.4. Bioethanol

Bioethanol is in demand since it is blended with gasoline and used in vehicles without modifications to the existing engine. It is commercially available and can be synthesized from carbohydrate-rich organic wastes. It is one of the available alternatives to gasoline-based fuel. Ethanol is prepared through two bioconversion routes: (i) separate hydrolysis and fermentation (SHF) and (ii) simultaneous saccharification and fermentation (SSF) (

Figure 16) [

52].

It is also possible to contemplate the utilization of food waste as a nutrient for enzyme growth and, subsequently, the utilization of the enzyme for treating food waste in biorefinery systems (

Figure 17). Thereby, food waste can be used meaningfully as a substrate for both enzyme and biofuel production.

There are numerous reports in the literature pertaining to lab-scale preparation ofbioethanol from food waste [

53,

54,

55,

56,

57]. Here, the focus is on the production of bioethanol from food waste at a pilot scale. In Kitakyushu City, Japan, a pilot plant was established in 2007 to produce ethanol from food waste [

58]. It was built by Nippon Steel Engineering Co. and commissioned by the New Energy and Industrial Technology Development Organization (NEDO, Japan). The plant has the capacity to produce 400 L of ethanol per day by processing 10 tons of food waste [

58]. A public–private–academia partnership was initiated in Japan in 2011 between Kyoto city, Hitachi Zosen Corporation and Kumamoto University to develop a technology for bioethanol generation from office and household wastes [

59]. The results of the pilot scale experiments indicated that 60 L of ethanol can be obtained from one ton of municipal solid wastes [

59]. The remaining unutilized wastes were used for biogasification.

Yan et al. developed a bioconversion technology using

Saccharomyces cerevisiae H058 to produce ethanol from concentrated food waste hydrolysate at a pilot scale [

60]. Similarly, the source-separated food waste obtained from Greek Municipality was used as a feedstock. For SSF, the lowest production cost was 1.57 €/kg ethanol, with 20% loaded solids, whereas for SHF, the lowest production cost was 4.40 €/kg ethanol with 15% solid loading [

61]. Furthermore, the results from a pilot scale trial using source-separated municipal biowaste were found to be reproducible with an ethanol yield of 81–91% [

62]. In another independent study, a pilot scale system comprising two horizontal rotating bioreactors was designed and operated under non-isothermal simultaneous saccharification and fermentation (NSSF) conditions for bioethanol preparation from household food waste [

63]. The pilot scale system can yield 188 L of ethanol from one ton of dry household food waste [

56]. E-fuel developed a small system (E-Fuel MicroFueler) to convert sugar-rich liquid wastes into ethanol for domestic use [

64,

65].

4.5. Biopropanol

The biocatalytic productions of biodiesel, ethanol and butanol have been investigated extensively in industry and academia because of their applicability as liquid fuels. Other alcohols like propanol are used as a solvent and have applications for chemical synthesis. Also, propanol is used in cosmetic, sanitizer and flavor manufacturing industries. There is a review article by Walther and François on research performed on the biochemical production of propanol (

iso-propanaol and

n-propanol) [

66]. They state that even though the metabolic engineering and fermentation process contributed immensely to the biological production of propanol, the reported propanol yields and productivities are not enough to compete with the existing propanol synthesis using chemical catalysts [

66]. So far, there is no specific report on the use of food waste for propanol preparation.

4.6. Biobutanol

Butanol is an alcohol comprising four carbons. At present, several researcher groups have shown that it can be synthesized from biowaste. Generally, butanol derived from biomass sources is known as biobutanol. It is non-corrosive and non-hygroscopic in nature. It is a potential fuel that can be used in the already existing infrastructure without further modifications to engines. Additionally, the shelf life of fuels can be increased by blending it with butanol because of its non-hygroscopic properties.

The fermentation of cellulosic biomass is one of the available routes for the preparation of butanol. As a low-cost feedstock, food waste can be utilized to synthesize butanol since it contains significant quantities of carbohydrates. Furthermore, proteins, fatty acids, minerals and other molecules present in food waste could act as nutrients to help in the growth of micro-organisms. Huang et al. demonstrated that food waste is an ideal feedstock for producing propanol as compared to glucose. In line with this, food waste was used in the ABE process (Acetone, Butanol and Ethanol) using

Clostridium beijerinckii P260 [

67]. During the course of the investigation, the authors designed and developed an integrated vacuum stripping system to remove butanol from the fermentation broth to stop inhibition due to the presence of butanol (

Figure 18) [

67]. The fermentation results revealed that while using a higher concentration of food waste, the final ABE concentration decreased in the mixture. The decrease in ABE concentration could be because of a higher production of residual glucose and an incomplete utilization of glucose [

67]. There is also a report on the

n-butanol preparation from bakery waste [

68].

4.7. RenewableHydrocarbon Biofuels

Renewable diesel (hydrocarbon fuels) can be prepared from food waste. Akhtar et al. reported that a carboxylic acid reductase (CAR) from

Mycobacterium marinum converted aliphatic fatty acids (C6-C18) into corresponding alkanes and alcohols [

69]. Thework described by Akhtar et al. is significant since CAR can be applied to produce hydrocarbon-based fuels from lipids derived from food waste.

The algal photoenzyme fatty acid photodecarboxylase (FAP) from

Chlorella variabilis NC64A was discovered in 2017 by Sorigué et al. [

63]. The FAP uses blue light and a riboflavin (vitamin B2) cofactor to catalyze the decarboxylation of fatty acids [

70]. Using an in-house developed system, the first biocatalytic decarboxylation using FAP was reported by the Hollmann group [

71]. The authors successfully demonstrated the substrate scope of FAP by converting an array of free fatty acids into hydrocarbons (C1-shortened alkanes). Furthermore, FAP was used along with a lipase (

Candida rugosa) to facilitate a cascade reaction wherein triglyceride (triolein) was converted into hydrocarbons [

71]. In another study, the authors reported the synthesis of short chain alkanes from waste carboxylic acids catalyzed by FAP under light [

72]. More recently, the continuous flow photodecarboxylation of fatty acids using FAP has been investigated, making the biocatalytic process industrially relevant [

73,

74]. However, it remains to be seen whether FAP can be employed for the valorization of food wastes and other plentifully available, lipid-rich organic wastes for the sustainable production of biofuels (

Figure 19). This will further broaden the substrate scope of FAP, since lipid derived from food wastes/organic wastes are known to contain several impurities (contaminants).

5. Societal and Economic Aspects

5.1. Feckless Consumerism vs. Structural Fault

It is argued that households are not solely responsible for food waste generation; thus, consumers should not be singled out [

75]. Now, it is becoming clear that food waste is generated because of many factors resulting from structural faults, rather than individual [

75]. At a structural level, there is a failure to value the importance of food waste and an inability to keep food in the supply chain by distributing surplus food for human consumption.

5.2. Is Food Waste a Resource?

It is widely known and supported that several million tons of food can be prevented from being wasted. A huge amount of food waste is getting produced because of mistakes (including human) that need to be corrected. Terming the outcome of repeated mistakes as a resource is somewhat misleading. In fact, by calling food waste a resource, the scientific community is speaking only a half-truth, since it is suppressing multiple faults that are happening across the food supply chain. For instance, many countries do not have adequate cold storage facilities for food product storage; instead of advocating for the building of more facilities for storage, priority is given to food waste valorization by policymakers.

5.3. Edible vs. Inedible Food Wastes as Starting Materials

A number of research papers are reporting the use of food waste as a “valuable resource and starting material” for chemical and biochemical reactions. It should be stated in the scientific reports whether the food waste was derived from edible or inedible produce. Logically speaking, if 1kg of wasted meat or rice or any other edible products are used as the starting materials in a given reaction, there is no harm in putting a price tag on the starting material (food waste) similar to the procurement/purchase cost. Just because the meat/rice/edible product has become a waste does not take away from the fact that it had a price and someone paid for it. It is expected that at a minimum, re- searchers should report such facts while publishing their findings in journals, which will send a positive message to society in general and depict a larger picture of the economics of the process/biorefinery.

5.4. Converting Food Waste to Edibles without Catalysis

Can food waste derived from edibles be converted into other edible products without using catalysts and solvents? This will be more economical and sustainable than using catalytic processes for converting food waste into valuable products.

A large portion of food which is considered waste is still in the edible stage; the true economic value of such food can be harnessed by diverting them to community kitchens where food that was going to be thrown out can get converted into a meal at a lower cost [

76].

5.5. Converting Food Waste into Valuable Products—The Final Option

A thought process need to be developed among researchers from a circular economy, economical and societal viewpoint to consider converting food waste into value-added products as the final option only when it cannot be prevented from becoming a complete waste [

76]. Such food waste could be diverted to biorefineries for the preparation of bioenergy and bio-based products.

6. Limitations and Perspectives

6.1. Feedstock

The composition of food waste is not consistent. It is place- and time- dependent and diverse in nature. Even though food waste is regarded as a no-value or low-cost feedstock, the sorting and pre-treatment processes will add cost to the feedstock. The lipid and carbohydrate-rich portion from food waste contains a significant amount of water; thus, the choice of chemical/biochemical process should be such that water removal would not be a prerequisite since the removal and purification of contaminated water is costly.

6.2. Supply Chain Management

The storage and supply of food waste from the source of generation to industry is challenging since largely it is organic and perishable. To store the food waste properly, it needs to be dried to remove moisture, which adds an additional handling cost. In this case, the generated food waste is liquid/semi-solid requiring a pipeline for transportation [

77].

6.3. Decentralization of Small-Scale Biorefinery/Biofuel Plants

Installing small and medium scale plants in places where an adequate amount of food waste is generated will cut down the cost incurred by moisture removal, drying and transportation. Along this line, coffee shops, large eateries, restaurant chains, bakeries and dairy plants generating sizable wastes could evaluate integrated installation of treatment plants.

6.4. Off-Take Process

The market potential of biofuels and bio-based products from food waste needs to be surveyed and documented. An off-take arrangement between the producers and buyers to purchase or sell the products synthesized from food waste is essential (

Figure 20). It would be prudent for the manufacturer and buyer to negotiate and finalize all the price-related details and the market size of the products before the construction of the food waste biorefineries (

Figure 20).

6.5. Biocatalysts

Enzymes are costly compared to chemical catalysts. However, chemical catalysts are not suitable for converting low-quality feedstock. Novozym 435 (isolated and purified from

Candida antarctica and

Rhizopus oryzae) is widely used in oleochemistry and in biodiesel synthesis. The cost of Novozym 435 is US

$1000/kg compared to chemical catalysts at US

$0.62/kg [

78]. This issue can be tackled via directed evolution by producing low-cost and efficient enzymes. Recently, a low-cost liquid lipase formulation (Eversa Transform 2.0) is being used in the industry for the commercial production of biodiesel [

78,

79,

80].

Deactivation of enzymes in the presence of alcohols is a common phenomenon. During biodiesel production, lipases are deactivated in the presence of methanol, which can be circumvented to some extent by sequential addition of methanol and the regeneration of the lipase using tert-butanol, oils and other regeneration methods. Also, during the ABE process, to avoid inhibition due to butanol, it was constantly removed from the reaction mixture under vacuum.

Several authors observed the photochemical inactivation of FAP in the absence of the substrate in the binding pocket [

81,

82]. Also, in the presence of non-native substrates, illumination of blue light leads to the inactivation of FAP [

81,

82]. To make FAP relevant in chemical and life sciences industries, a solution would be needed to overcome the light-induced inactivation.

The food waste biorefinery may require optimization of several reactions in a cascade manner for the preparation of chemicals and fuels. Even though many commercial enzymes are already available in the market for applications in food waste biorefinery, more robust and efficient enzymes can be produced using enzyme engineering, keeping the process conditions in mind.

6.6. Solvents

Some of the enzymatic reactions require organic solvents. Such a system will require the purification of products and enzymes, which further complicates downstream processing. Different available options using supercritical carbon dioxide, deep eutectic solvents and bio-based solvents can be explored. In particular, supercritical carbon dioxide is promising since it can be employed as a solvent as well as for the purification of products by adjusting its solvent properties. Using supercritical fluids as solvents can yield less contaminated or pure products.

6.7. Microwave and Ultrasonic Technologies

Microwave and ultrasonic techniques are becoming more popular and have been investigated widely for the reduction of the time duration of reactions. The reactions performed under microwave conditions are limited to a small scale and scale-up is challenging. During ultrasonic process intensification, the recycling of lipases could be a problem as the enzymes show a decrease in activity during the reusability experiments. Further research on integration of microwave technology with continuous flow systems will facilitate industrial research.

6.8. Techno-Economic Analysis

Comparing biocatalytic methods for biofuel synthesis from food waste in a fair and informative manner is difficult since many of the reports do not include techno-economic analysis in the reported studies. Techno-economic assessment of different biofuels and bio-based product development methods will be useful for identifying bottlenecks for further improvements in these technologies [

83].

6.9. Life Cycle Assessment

Are the biofuels from food waste sustainable? To answer this question, life cycle assessment is useful since it deals with the environmental aspects associated with the product(s). Even though several life cycle assessment software packages (SimaPro, Amersfoort, Utrecht, The Netherlands; GaBi, San Francisco, CA, USA; Umberto, Reutlingen, Germany; and OpenLCA, Berlin, Germany) are available, such studies are limited.

6.10. Cross-Sectoral Initiatives

Food waste management policies should focus on the participation of all the relevant stakeholders. Incentivization of small- and medium-scale biofuel plants for the utilization of wastes can attract the participation of young entrepreneurs and better penetrate the waste management technologies in small towns or even in rural areas.

6.11. Beyond Biofuels

Hegde et al. argue that preparation of solvent-grade alcohols from food waste could be a better option since the production of biofuels from many food wastes is not feasible [

77]. Similarly, industrial preparation of biocomposites, polymers, polyurethane foams, hydroxy fatty acids, and packaging materials can be explored after consideration of the techno-economics of these processes (

Figure 21).

It is worthwhile to note that during the conversion of food waste to biofuels and value-added products, a number of nutrients are also lost (

Figure 22) [

84]. In this regard, a few research teams are working on nutrient recovery from food waste [

85].

7. Conclusions

It is wise to value food as food and prevent edible food items from becoming waste. Waste valorization using catalytic technologies should be the last option.

Hitherto, both chemical and enzymatic methods have been employed for food waste conversion. Given the intrinsic advantages of biocatalysts, they are used in the conversion of food waste into liquid biofuels. In this regard, many enzymes are available to perform hydrolysis, esterification, transesterification, interesterification, oxidation, reduction, epoxidation and decarboxylation reactions. The enzymes are immobilized for repeated recycling during biochemical processes. In addition, enzyme engineering can be carried out to produce new enzymes with novel catalytic activities compared to the wild types. These new biocatalysts will play crucial roles in the development of the food waste-based biorefinery.

Biocatalytic productions of liquid biofuels such as biodiesel and bioethanol have been reported at a pilot scale. A low-cost liquid lipase formulation (Eversa Transform 2.0) has been employed for the commercial production of biodiesel. Various microorganisms including Saccharomyces cerevisiae H058 have been used for the pilot scale production of bioethanol. Public–private–academia collaboration is now being established in several countries to build pilot scale bioethanol plants as part of clean and green city initiatives. A company (E-fuel, USA) has developed a small system (E-Fuel MicroFueler, Austin, TX, USA) to convert sugar-rich waste liquid into ethanol for domestic purposes. Such small-scale technologies should be developed and promoted since these can reach stakeholders at the grassroots level, including rural areas.

The production of methanol, propanol and butanol from food waste needs further extensive research for their production at a commercial scale. Renewable diesel (hydrocarbon fuels) can be prepared from fatty acids using carboxylic acid reductase (CAR). In line with this, an algal photoenzyme (fatty acid photodecarboxylase; FAP) from Chlorella variabilis NC64A was reported for the decarboxylation of fatty acids. The FAP, along with Candida rugosa (a lipase), was used in a cascade reaction to convert waste triglycerides to hydrocarbons. However, so far there are no reports on the use of either CAR or FAP for the synthesis of hydrocarbon fuels from food waste. Also, both CAR and FAP have yet to be commercialized.

To optimize the biocatalytic processes in a food waste biorefinery, solvent engineering, techno-economic analysis and life cycle assessment will play important roles. To ease downstream processing, tunable solvents can be used. Both techno-economic analysis and life cycle assessment will be needed to make the product market competitive and sustainable.

Finally, even though environmental pollution due to food waste requires the immediate attention of policymakers, scientists, entrepreneurs and all other stakeholders, the first priority must be the prevention of food waste. In alignment with the UN Sustainable Development Goals (SDGs), food which cannot be prevented from becoming waste can be used for the production of valuables through a biorefinery approach.