The Effects of Processing and Preservation Technologies on Meat Quality: Sensory and Nutritional Aspects

Abstract

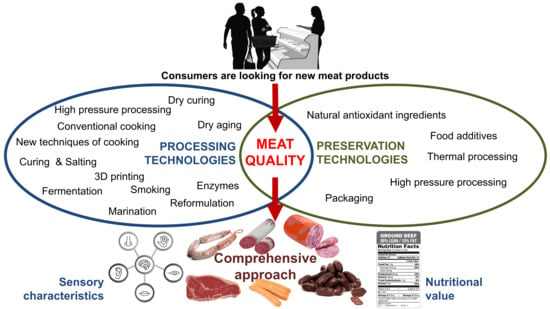

:1. Introduction

2. Processing

2.1. Physical Methods

2.1.1. Dry Aging

2.1.2. Dry Curing

2.1.3. High Pressure Processing

2.1.4. Conventional Cooking

2.1.5. New Techniques of Cooking: Low-Temperature Long-Time (LTLT) and Sous Vide Cooking

2.1.6. 3D Printing

2.2. Chemical and Biochemical Methods

2.2.1. Fermentation

2.2.2. Smoking

2.2.3. Curing and Salting

2.2.4. Marination

2.2.5. Reformulation

Reduced Salt Content

Fat Content Modification

Nitrite Content Reduction

Incorporation of Protein and Dietary Fiber

2.2.6. Enzymes

Enzymes Used for Meat Tenderization

Enzymes Used for Meat Restructuring

Enzymes Used to Produce Flavor and Aromas in Meat

3. Preservation

3.1. Physical Methods

3.1.1. Thermal Processing

3.1.2. Packaging

Vacuum Packing and Modified Atmosphere Packaging

Active Packaging

Intelligent Packaging

Edible Films and Coatings

3.1.3. High Pressure Processing

3.2. Chemical and Biochemical Methods

3.2.1. Food Additives

3.2.2. Natural Antioxidant Ingredients

Essential Oils and Spices

Plant Extracts

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Beriain, M.J.; Gómez, I.; Petri, E.; Insausti, K.; Sarriés, M.V. The effects of olive oil emulsified alginate on the physico-chemical, sensory, microbial, and fatty acid profiles of low-salt, inulin-enriched sausages. Meat Sci. 2011, 88, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Diéguez, P.M.; Beriain, M.J.; Insausti, K.; Arrizubieta, M.J. Thermal analysis of meat emulsion cooking process by computer simulation and experimental measurement. Int. J. Food Eng. 2010, 6, 1–21. [Google Scholar] [CrossRef]

- Naveena, B.M.; Sen, A.R.; Vaithiyanathan, S.; Babji, Y.; Kondaiah, N. Comparative efficacy of pomegranate juice, pomegranate rind powder extract and BHT as antioxidants in cooked chicken patties. Meat Sci. 2008, 80, 1304–1308. [Google Scholar] [CrossRef]

- Beriain, M.J.; Gómez, I.; Ibanez, F.C.; Sarries, V.; Ordonez, A.I. Improvement of the functional and healthy properties of meat products. In Food Quality: Balancing Health and Disease; Grumezescu, A., Holban, A.M., Eds.; Handbook of Food Bioengineering; Academic Press: London, UK, 2018; Volume 13, pp. 1–74. ISBN 978-0-12-811442-1. [Google Scholar]

- Warren, K.E.; Kastner, C.L. A comparison of dry-aged and vacuum-aged beef strip loins. J. Muscle Foods 1992, 3, 151–157. [Google Scholar] [CrossRef]

- Campbell, R.E.; Hunt, M.C.; Levis, P.; Chambers, E. Dry-aging effects on palatability of beef longissimus muscle. J. Food Sci. 2001, 66, 196–199. [Google Scholar] [CrossRef]

- Hwang, Y.H.; Sabikun, N.; Ismail, I.; Joo, S.T. Changes in sensory compounds during dry aging of pork cuts. Food Sci. Anim. Resour. 2019, 39, 379–387. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.H.B.; Kemp, R.; Samuelsson, L.M. Effects of dry-aging on meat quality attributes and metabolite profiles of beef loins. Meat Sci. 2016, 111, 168–176. [Google Scholar] [CrossRef]

- Li, X.; Babol, J.; Bredie, W.L.P.; Nielsen, B.; Tománková, J.; Lundström, K. A comparative study of beef quality after ageing longissimus muscle using a dry ageing bag, traditional dry ageing or vacuum package ageing. Meat Sci. 2014, 97, 433–442. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Wang, N.; Raghavan, G.S.V.; Pei, Y.; Song, C.; Zhu, G. Novel sensing technologies during the food drying process. Food Eng. Rev. 2020, 12, 121–148. [Google Scholar] [CrossRef]

- Wang, H.; Doty, D.M.; Beard, F.J.; Pierce, J.C.; Hankins, O.G. Extensibility of single beef muscle fibers. J. Anim. Sci. 1956, 15, 97–108. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Wang, S.; Wang, N.; Nie, P.; He, Y.; Sun, D.W.; Yao, J. Application of time series hyperspectral imaging (TS-HSI) for determining water distribution within beef and spectral kinetic analysis during dehydration. Food Bioprocess. Technol. 2013, 6, 2943–2958. [Google Scholar] [CrossRef]

- Hoagland, R.; Snider, G.G. Nutritive value of protein in dehydrated meat. Food Res. 1946, 11, 494–500. [Google Scholar] [CrossRef] [PubMed]

- Rice, E.E.; Robinson, H.E. Nutritive value of canned and dehydrated meat and meat products. Am. J. Public Health Nations Health 1944, 34, 587–592. [Google Scholar] [CrossRef] [PubMed]

- Santchurn, S.J.; Arnaud, E.; Zakhia-Rozis, N.; Collignan, A.; Hui, H.Y. Drying: Principles and applications. In Handbook of Meat and Meat Processing; CRC Press: Boca Raton, FL, USA, 2012; pp. 505–521. [Google Scholar]

- Flores, M. Understanding the implications of current health trends on the aroma of wet and dry cured meat products. Meat Sci. 2018, 144, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Tume, R.K.; Xiong, Y.; Xu, X.; Zhou, G.; Chen, C.; Nishiumi, T. Structural modification of myofibrillar proteins by high-pressure processing for functionally improved, value-added, and healthy muscle gelled foods. Crit. Rev. Food Sci. Nutr. 2018, 58, 2981–3003. [Google Scholar] [CrossRef] [PubMed]

- Rastogi, N.K.; Raghavarao, K.S.M.S.; Niranjan, K. Opportunities and challenges in high pressure processing of foods. Crit. Rev. Food Sci. Nutr. 2007, 47, 69–112. [Google Scholar] [CrossRef] [PubMed]

- Kaur, L.; Astruc, T.; Vénien, A.; Loison, O.; Cui, J.; Irastorza, M.; Boland, M. High pressure processing of meat: Effects on ultrastructure and protein digestibility. Food Funct. 2016, 7, 2389–2397. [Google Scholar] [CrossRef]

- Xue, S.; Wang, C.; Kim, Y.H.B.; Bian, G.; Han, M.; Xu, X.; Zhou, G. Application of high-pressure treatment improves the in vitro protein digestibility of gel-based meat product. Food Chem. 2020, 306, 125602. [Google Scholar] [CrossRef]

- Orlien, V. High pressure treatment and the effects on meat proteins. Med. Res. Arch. 2017, 5, 1–10. [Google Scholar]

- Bajovic, B.; Bolumar, T.; Heinz, V. Quality considerations with high pressure processing of fresh and value added meat products. Meat Sci. 2012, 92, 280–289. [Google Scholar] [CrossRef]

- Gao, H.; Zeng, J.; Ma, H.; Wang, Z.; Pan, R. Improving tenderness of goose breast by ultra-high pressure. Int. J. Food Prop. 2015, 18, 1693–1701. [Google Scholar] [CrossRef]

- Chen, X.; Xu, X.; Han, M.; Zhou, G.; Chen, C.; Li, P. Conformational changes induced by high-pressure homogenization inhibit myosin filament formation in low ionic strength solutions. Food Res. Int. 2016, 85, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Hamid, N.; Oey, I.; Kantono, K.; Farouk, M. The impact of high-pressure processing on physicochemical properties and sensory characteristics of three different lamb meat cuts. Molecules 2020, 25, 2665. [Google Scholar] [CrossRef] [PubMed]

- Rakotondramavo, A.; Ribourg, L.; Meynier, A.; Guyon, C.; de Lamballerie, M.; Pottier, L. Monitoring oxidation during the storage of pressure-treated cooked ham and impact on technological attributes. Heliyon 2019, 5, e02285. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Sullivan, G.; Stratton, J.; Bower, C.; Cavender, G. Effect of HPP treatment on the safety and quality of beef steak intended for sous vide cooking. LWT Food Sci. Technol. 2017, 86, 185–192. [Google Scholar] [CrossRef]

- Rakotondramavo, A.; Rabesona, H.; Brou, C.; de Lamballerie, M.; Pottier, L. Ham processing: Effects of tumbling, cooking and high pressure on proteins. Eur. Food Res. Technol. 2019, 245, 273–284. [Google Scholar] [CrossRef]

- Hayman, M.M.; Baxter, I.; O’Riordan, P.J.; Stewart, C.M. Effects of high-pressure processing on the safety, quality, and shelf life of ready-to-eat meats. J. Food Prot. 2004, 67, 1709–1718. [Google Scholar] [CrossRef]

- Yeh, Y.; Thippareddi, H.; De Mello, A. High pressure processing (HPP) does not affect texture and sensory attributes of smoked hams cured by conventional and alternative methods. Meat Muscle Biol. 2017, 1, 29. [Google Scholar] [CrossRef]

- Pingen, S.; Sudhaus, N.; Becker, A.; Krischek, C.; Klein, G. High pressure as an alternative processing step for ham production. Meat Sci. 2016, 118, 22–27. [Google Scholar] [CrossRef]

- Xiong, Y.L. The storage and preservation of meat: I—Thermal technologies. In Lawrie’s Meat Science, 8th ed.; Toldrá, F., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2017; pp. 205–230. ISBN 978-0-08-100694-8. [Google Scholar]

- Murphy, R.Y.; Marks, B.P.; Marcy, J.A. Apparent specific heat of chicken breast patties and their constituent proteins by differential scanning calorimetry. J. Food Sci. 1998, 63, 88–91. [Google Scholar] [CrossRef]

- Ngadi, M.O.; Ikediala, J.N. Heat transfer properties of chicken-drum muscle. J. Sci. Food Agric. 1998, 78, 12–18. [Google Scholar] [CrossRef]

- Beriain, M.J.; Ibáñez, F.C.; Baleztena, J.; Oria, E. The effect of a modified meat product on nutritional status in institutionalized elderly people. Nutr. Hosp. 2011, 26, 907–915. [Google Scholar] [PubMed]

- Dominguez-Hernandez, E.; Salaseviciene, A.; Ertbjerg, P. Low-temperature long-time cooking of meat: Eating quality and underlying mechanisms. Meat Sci. 2018, 143, 104–113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roldán, M.; Ruiz, J.; del Pulgar, J.S.; Pérez-Palacios, T.; Antequera, T. Volatile compound profile of sous-vide cooked lamb loins at different temperature–time combinations. Meat Sci. 2015, 100, 52–57. [Google Scholar] [CrossRef] [PubMed]

- Sánchez del Pulgar, J.; Roldan, M.; Ruiz-Carrascal, J. Volatile compounds profile of sous-vide cooked pork cheeks as affected by cooking conditions (vacuum packaging, temperature and time). Molecules 2013, 18, 12538–12547. [Google Scholar] [CrossRef] [Green Version]

- Davey, C.L.; Niederer, A.F.; Graafhuis, A.E. Effects of ageing and cooking on the tenderness of beef muscle. J. Sci. Food Agric. 1976, 27, 251–256. [Google Scholar] [CrossRef]

- Davey, C.L.; Niederer, A.F. Cooking tenderizing in beef. Meat Sci. 1977, 1, 271–276. [Google Scholar] [CrossRef]

- Schellekens, M. New research issues in sous-vide cooking. Trends Food Sci. Technol. 1996, 7, 256–262. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, B.; Oh, E.; Kim, Y.S.; Choi, Y.M. Combined effects of sous-vide cooking conditions on meat and sensory quality characteristics of chicken breast meat. Poult. Sci. 2020, 99, 3286–3291. [Google Scholar] [CrossRef]

- Botinestean, C.; Keenan, D.F.; Kerry, J.P.; Hamill, R.M. The effect of thermal treatments including sous-vide, blast freezing and their combinations on beef tenderness of M. semitendinosus steaks targeted at elderly consumers. LWT Food Sci. Technol. 2016, 74, 154–159. [Google Scholar] [CrossRef]

- Supaphon, P.; Astruc, T.; Kerdpiboon, S. Physical characteristics and surface-physical properties relationship of Thai local beef during sous-vide processing. Agric. Nat. Resour. 2020, 54, 25–32. [Google Scholar] [CrossRef] [Green Version]

- García-Segovia, P.; Andrés-Bello, A.; Martínez-Monzó, J. Effect of cooking method on mechanical properties, color and structure of beef muscle (M. pectoralis). J. Food Eng. 2007, 80, 813–821. [Google Scholar] [CrossRef]

- Armstrong, G.A.; McIlveen, H. Effects of prolonged storage on the sensory quality and consumer acceptance of sous vide meat-based recipe dishes. Food Qual. Prefer. 2000, 11, 377–385. [Google Scholar] [CrossRef]

- Kehlet, U.; Mitra, B.; Ruiz Carrascal, J.; Raben, A.; Aaslyng, M.D. The satiating properties of pork are not affected by cooking methods, sousvide holding time or mincing in healthy men—A randomized cross-over meal test study. Nutrients 2017, 9, 941. [Google Scholar] [CrossRef] [Green Version]

- Prodhan, U.K.; Pundir, S.; Chiang, V.S.C.; Milan, A.M.; Barnett, M.P.G.; Smith, G.C.; Markworth, J.F.; Knowles, S.O.; Cameron-Smith, D. Comparable postprandial amino acid and gastrointestinal hormone responses to beef steak cooked using different methods: A randomised crossover trial. Nutrients 2020, 12, 380. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rinaldi, M.; Dall’Asta, C.; Paciulli, M.; Cirlini, M.; Manzi, C.; Chiavaro, E. A novel time/temperature approach to sous vide cooking of beef muscle. Food Bioprocess. Technol. 2014, 7, 2969–2977. [Google Scholar] [CrossRef]

- Sánchez del Pulgar, J.; Gázquez, A.; Ruiz-Carrascal, J. Physico-chemical, textural and structural characteristics of sous-vide cooked pork cheeks as affected by vacuum, cooking temperature, and cooking time. Meat Sci. 2012, 90, 828–835. [Google Scholar] [CrossRef]

- Gómez, I.; Ibañez, F.C.; Beriain, M.J. Physicochemical and sensory properties of sous vide meat and meat analog products marinated and cooked at different temperature-time combinations. Int. J. Food Prop. 2019, 22, 1693–1708. [Google Scholar] [CrossRef] [Green Version]

- Voon, S.L.; An, J.; Wong, G.; Zhang, Y.; Chua, C.K. 3D food printing: A categorised review of inks and their development. Virtual Phys. Prototyp. 2019, 14, 203–218. [Google Scholar] [CrossRef]

- Portanguen, S.; Tournayre, P.; Sicard, J.; Astruc, T.; Mirade, P.S. Toward the design of functional foods and biobased products by 3D printing: A review. Trends Food Sci. Technol. 2019, 86, 188–198. [Google Scholar] [CrossRef] [Green Version]

- Lipton, J.; Arnold, D.; Nigl, F.; Lopez, N.; Cohen, D.; Norén, N.; Lipson, H. Multi-material food printing with complex internal structure suitable for conventional post-processing. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 2010; pp. 809–815. [Google Scholar]

- Liu, C.; Ho, C.; Wang, J. The development of 3D food printer for printing fibrous meat materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 284, 012019. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Prakash, S. Post-processing feasibility of composite-layer 3D printed beef. Meat Sci. 2019, 153, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Leroy, F.; De Vuyst, L. Fermented foods: Fermented meat products. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 656–660. ISBN 978-0-12-384953-3. [Google Scholar]

- Dierick, N.; Vandekerckhove, P.; Demeyer, O. Changes in nonprotein nitrogen compounds during dry sausage ripening. J. Food Sci. 1974, 39, 301–304. [Google Scholar] [CrossRef]

- DeMasi, T.W.; Wardlaw, F.B.; Dick, R.L.; Acton, J.C. Nonprotein nitrogen (NPN) and free amino acid contents of dry, fermented and nonfermented sausages. Meat Sci. 1990, 27, 1–12. [Google Scholar] [CrossRef]

- García de Fernando, G.D.; Fox, P.F. Study of proteolysis during the processing of a dry fermented pork sausage. Meat Sci. 1991, 30, 367–383. [Google Scholar] [CrossRef]

- Beriain, M.J.; Lizaso, G.; Chasco, J. Free amino acids and proteolysis involved in ‘salchichon’ processing. Food Control. 2000, 11, 41–47. [Google Scholar] [CrossRef]

- Toldrá, F.; Aristoy, M.C.; Part, C.; Cerveró, C.; Rico, E.; Motilva, M.J.; Flores, J. Muscle and adipose tissue aminopeptidase activities in raw and dry-cured ham. J. Food Sci. 1992, 57, 816–818. [Google Scholar] [CrossRef]

- Toldrá, F. The role of muscle enzymes in dry-cured meat products with different drying conditions. Trends Food Sci. Technol. 2006, 17, 164–168. [Google Scholar] [CrossRef]

- Zhang, X.; Kong, B.; Xiong, Y.L. Production of cured meat color in nitrite-free Harbin red sausage by Lactobacillus fermentum fermentation. Meat Sci. 2007, 77, 593–598. [Google Scholar] [CrossRef]

- Zhou, G.H.; Zhao, G.M. Biochemical changes during processing of traditional Jinhua ham. Meat Sci. 2007, 77, 114–120. [Google Scholar] [CrossRef]

- Bolzoni, L.; Barbieri, G.; Virgili, R. Changes in volatile compounds of Parma ham during maturation. Meat Sci. 1996, 43, 301–310. [Google Scholar] [CrossRef]

- Ruiz, J.; Ventanas, J.; Cava, R.; Andrés, A.; García, C. Volatile compounds of dry-cured Iberian ham as affected by the length of the curing process. Meat Sci. 1999, 52, 19–27. [Google Scholar] [CrossRef]

- Puchalska, P.; Alegre, M.L.M.; López, M.C.G. Isolation and characterization of peptides with antihypertensive activity in foodstuffs. Crit. Rev. Food Sci. Nutr. 2015, 55, 521–551. [Google Scholar] [CrossRef] [PubMed]

- Cintas, L.M.; Rodriguez, J.M.; Fernandez, M.F.; Sletten, K.; Nes, I.F.; Hernandez, P.E.; Holo, H. Isolation and characterization of pediocin L50, a new bacteriocin from Pediococcus acidilactici with a broad inhibitory spectrum. Appl. Env. Microbiol. 1995, 61, 2643–2648. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Drider, D.; Fimland, G.; Héchard, Y.; McMullen, L.M.; Prévost, H. The continuing story of class IIa bacteriocins. Microbiol. Mol. Biol. Rev. 2006, 70, 564–582. [Google Scholar] [CrossRef] [Green Version]

- Suleman, R.; Wang, Z.; Aadil, R.M.; Hui, T.; Hopkins, D.L.; Zhang, D. Effect of cooking on the nutritive quality, sensory properties and safety of lamb meat: Current challenges and future prospects. Meat Sci. 2020, 167, 108172. [Google Scholar] [CrossRef]

- Pöhlmann, M.; Hitzel, A.; Schwägele, F.; Speer, K.; Jira, W. Influence of different smoke generation methods on the contents of polycyclic aromatic hydrocarbons (PAH) and phenolic substances in Frankfurter-type sausages. Food Control. 2013, 34, 347–355. [Google Scholar] [CrossRef]

- Toldrá, F.; Hui, Y.H. Handbook of Fermented Meat and Poultry, 1st ed.; Toldrá, F., Hui, Y.H., Eds.; Blackwell Publishing Ltd.: Ames, AI, USA, 2007; ISBN 978-0-8138-1477-3. [Google Scholar]

- Bertram, H.C.; Kohler, A.; Böcker, U.; Ofstad, R.; Andersen, H.J. Heat-induced changes in myofibrillar protein structures and myowater of two pork qualities. A combined FT-IR spectroscopy and low-field NMR relaxometry study. J. Agric. Food Chem. 2006, 54, 1740–1746. [Google Scholar] [CrossRef]

- Stabursvik, E.; Martens, H. Thermal denaturation of proteins in post rigor muscle tissue as studied by differential scanning calorimetry. J. Sci. Food Agric. 1980, 31, 1034–1042. [Google Scholar] [CrossRef]

- Lingbeck, J.M.; Cordero, P.; O’Bryan, C.A.; Johnson, M.G.; Ricke, S.C.; Crandall, P.G. Functionality of liquid smoke as an all-natural antimicrobial in food preservation. Meat Sci. 2014, 97, 197–206. [Google Scholar] [CrossRef]

- Estrada-Muñoz, R.; Boyle, E.a.E.; Marsden, J.L. Liquid smoke effects on Escherichia coli O157:H7, and its antioxidant properties in beef products. J. Food Sci. 1998, 63, 150–153. [Google Scholar] [CrossRef]

- Incze, K. European products. In Handbook of Fermented Meat and Poultry; Toldrá, F., Ed.; Blackwell Publishing Ltd.: Oxford, UK, 2007; pp. 307–318. ISBN 978-0-470-37643-0. [Google Scholar]

- Jantawat, P.; Carpenter, J.A. Salt preblending and incorporation of mechanically deboned chicken meat in smoked sausage. J. Food Qual. 1989, 12, 393–401. [Google Scholar] [CrossRef]

- Anandh, M.A.; Lakshmanan, V. Storage stability of smoked buffalo rumen meat product treated with ginger extract. J. Food Sci. Technol. 2014, 51, 1191–1196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hou, C.; Wang, Z.; Wu, L.; Chai, J.; Song, X.; Wang, W.; Zhang, D. Effects of breeds on the formation of heterocyclic aromatic amines in smoked lamb. Int. J. Food Sci. Technol. 2017, 52, 2661–2669. [Google Scholar] [CrossRef]

- Sugimura, T.; Wakabayashi, K.; Nakagama, H.; Nagao, M. Heterocyclic amines: Mutagens/carcinogens produced during cooking of meat and fish. Cancer Sci. 2004, 95, 290–299. [Google Scholar] [CrossRef]

- Bailey, H.M.; Berg, E.P.; Stein, H.H. Protein quality evaluation in processed human foods by the digestible indispensable amino acid score methodology. In Energy and Protein Metabolism and Nutrition; EAAP Scientific Series: Rome, Italy, 2019; Volume 138, pp. 423–424. ISBN 978-90-8686-340-2. [Google Scholar]

- Ahmad, S.; Anzar, A.; Srivastava, A.K.; Srivastava, P.K. Effect of curing, antioxidant treatment, and smoking of buffalo meat on ph, total plate count, sensory characteristics, and shelf life during refrigerated storage. Int. J. Food Prop. 2005, 8, 139–150. [Google Scholar] [CrossRef]

- Janiszewski, P.; Grześkowiak, E.; Lisiak, D.; Borys, B.; Borzuta, K.; Pospiech, E.; Poławska, E. The influence of thermal processing on the fatty acid profile of pork and lamb meat fed diet with increased levels of unsaturated fatty acids. Meat Sci. 2016, 111, 161–167. [Google Scholar] [CrossRef]

- Sindelar, J.J.; Milkowski, A.L. Human safety controversies surrounding nitrate and nitrite in the diet. Nitric Oxide Biol. Chem. 2012, 26, 259–266. [Google Scholar] [CrossRef]

- Jakszyn, P.; Gonzalez, C.A. Nitrosamine and related food intake and gastric and oesophageal cancer risk: A systematic review of the epidemiological evidence. World J. Gastroenterol. 2006, 12, 4296–4303. [Google Scholar] [CrossRef]

- Gassara, F.; Kouassi, A.P.; Brar, S.K.; Belkacemi, K. Green alternatives to nitrates and nitrites in meat-based products—A review. Crit. Rev. Food Sci. Nutr. 2016, 56, 2133–2148. [Google Scholar] [CrossRef] [Green Version]

- Sindelar, J. Investigating uncured no nitrate or nitrite added processed meat products. AI State University: Ames, AI, USA, 2006. [Google Scholar]

- Vega-Warner, V.; Merkel, R.A.; Smith, D.M. Composition, solubility and gel properties of salt soluble proteins from two bovine muscle types. Meat Sci. 1999, 51, 197–203. [Google Scholar] [CrossRef]

- Gómez, M.; Lorenzo, J.M. Effect of fat level on physicochemical, volatile compounds and sensory characteristics of dry-ripened “chorizo” from Celta pig breed. Meat Sci. 2013, 95, 658–666. [Google Scholar] [CrossRef] [PubMed]

- Pietrasik, Z.; Gaudette, N.J. The impact of salt replacers and flavor enhancer on the processing characteristics and consumer acceptance of restructured cooked hams. Meat Sci. 2014, 96, 1165–1170. [Google Scholar] [CrossRef] [PubMed]

- Ruusunen, M.; Vainionpää, J.; Puolanne, E.; Lyly, M.; Lähteenmäki, L.; Niemistö, M.; Ahvenainen, R. Effect of sodium citrate, carboxymethyl cellulose and carrageenan levels on quality characteristics of low-salt and low-fat bologna type sausages. Meat Sci. 2003, 64, 371–381. [Google Scholar] [CrossRef]

- Ripollés, S.; Campagnol, P.C.B.; Armenteros, M.; Aristoy, M.C.; Toldrá, F. Influence of partial replacement of NaCl with KCl, CaCl2 and MgCl2 on lipolysis and lipid oxidation in dry-cured ham. Meat Sci. 2011, 89, 58–64. [Google Scholar] [CrossRef]

- Rama, R.; Chiu, N.; Silva, M.C.D.; Hewson, L.; Hort, J.; Fisk, I.D. Impact of salt crystal size on in-mouth delivery of sodium and saltiness perception from snack foods. J. Texture Stud. 2013, 44, 338–345. [Google Scholar] [CrossRef] [Green Version]

- Barbut, S.; Maurer, A.J.; Lindsay, R.C. Effects of reduced sodium chloride and added phosphates on physical and sensory properties of turkey frankfurters. J. Food Sci. 1988, 53, 62–66. [Google Scholar] [CrossRef]

- Ertbjerg, P.; Mielche, M.M.; Larsen, L.M.; Møller, A.J. Relationship between proteolytic changes and tenderness in prerigor lactic acid marinated beef. J. Sci. Food Agric. 1999, 79, 970–978. [Google Scholar] [CrossRef]

- Dimakopoulou-Papazoglou, D.; Katsanidis, E. Osmotic processing of meat: Mathematical modeling and quality parameters. Food Eng. Rev. 2020, 12, 32–47. [Google Scholar] [CrossRef]

- Alvarado, C.; McKee, S. Marination to improve functional properties and safety of poultry meat. J. Appl. Poult. Res. 2007, 16, 113–120. [Google Scholar] [CrossRef]

- Griffiths, N.M.; Wilkinson, C.C.L. The effects on broiler chicken of polyphosphate injection during commercial processing. Int. J. Food Sci. Technol. 1978, 13, 541–549. [Google Scholar] [CrossRef]

- Brewer, M.S.; Jensen, J.; Prestat, C.; Zhu, L.G.; Mckeith, F.K. Visual acceptability and consumer purchase intent of enhanced pork loin roasts. J. Muscle Foods 2002, 13, 53–68. [Google Scholar] [CrossRef]

- Sheard, P.R.; Tali, A. Injection of salt, tripolyphosphate and bicarbonate marinade solutions to improve the yield and tenderness of cooked pork loin. Meat Sci. 2004, 68, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, L.C.; Muller, M.; Vermaak, A. Sensory and preference testing of selected beef muscles infused with a phosphate and lactate blend. Meat Sci. 2008, 80, 1055–1060. [Google Scholar] [CrossRef] [PubMed]

- Detienne, N.A.; Reynolds, A.E.; Wicker, L. Phosphate marination of pork loins at high and low injection pressures. J. Food Qual. 2003, 26, 1–14. [Google Scholar] [CrossRef]

- McGee, M.R.; Henry, K.L.; Brooks, J.C.; Ray, F.K.; Morgan, J.B. Injection of sodium chloride, sodium tripolyphosphate, and sodium lactate improves Warner–Bratzler shear and sensory characteristics of pre-cooked inside round roasts. Meat Sci. 2003, 64, 273–277. [Google Scholar] [CrossRef]

- Vote, D.J.; Platter, W.J.; Tatum, J.D.; Schmidt, G.R.; Belk, K.E.; Smith, G.C.; Speer, N.C. Injection of beef strip loins with solutions containing sodium tripolyphosphate, sodium lactate, and sodium chloride to enhance palatability. J. Anim. Sci. 2000, 78, 952–957. [Google Scholar] [CrossRef]

- Robbins, K.; Jensen, J.; Ryan, K.J.; Homco-Ryan, C.; Mckeith, F.K.; Brewer, M.S. Enhancement effects on sensory and retail display characteristics of beef rounds. J. Muscle Foods 2002, 13, 279–288. [Google Scholar] [CrossRef]

- Sawyer, J.T.; Apple, J.K.; Johnson, Z.B. The impact of lactic acid concentration and sodium chloride on pH, water-holding capacity, and cooked color of injection-enhanced dark-cutting beef. Meat Sci. 2008, 79, 317–325. [Google Scholar] [CrossRef]

- Burke, R.M.; Monahan, F.J. The tenderisation of shin beef using a citrus juice marinade. Meat Sci. 2003, 63, 161–168. [Google Scholar] [CrossRef] [Green Version]

- Seuss, I.; Martin, M. The influence of marinating with food acids on the composition and sensory properties of beef. Fleischwirtschaft 1993, 73, 292–295. [Google Scholar]

- Corral, S.; Salvador, A.; Flores, M. Salt reduction in slow fermented sausages affects the generation of aroma active compounds. Meat Sci. 2013, 93, 776–785. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aaslyng, M.D.; Vestergaard, C.; Koch, A.G. The effect of salt reduction on sensory quality and microbial growth in hotdog sausages, bacon, ham and salami. Meat Sci. 2014, 96, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Colmenero, F.; Reig, M.; Toldrá, F. New approaches for the development of functional meat products. In Advanced Technologies for Meat Processing; Toldrá, F., Nollet, L.M., Eds.; CRC Press: Boca Raton, FL, USA, 2018; p. 275. [Google Scholar]

- Jiménez-Colmenero, F.; Carballo, J.; Cofrades, S. Healthier meat and meat products: Their role as functional foods. Meat Sci. 2001, 59, 5–13. [Google Scholar] [CrossRef]

- Olmedilla-Alonso, B.; Jiménez-Colmenero, F.; Sánchez-Muniz, F.J. Development and assessment of healthy properties of meat and meat products designed as functional foods. Meat Sci. 2013, 95, 919–930. [Google Scholar] [CrossRef] [Green Version]

- Keeton, J.T. Low-fat meat products-technological problems with processing. Meat Sci. 1994, 36, 261–276. [Google Scholar] [CrossRef]

- Paneras, E.D.; Bloukas, J.G.; Filis, D.G. Production of low-fat frankfurters with vegetable oils following the dietary guidelines for fatty acids. J. Muscle Foods 1998, 9, 111–126. [Google Scholar] [CrossRef]

- Marquez, E.J.; Ahmed, E.M.; West, R.L.; Johnson, D.D. Emulsion stability and sensory quality of beef frankfurters produced at different fat or peanut oil levels. J. Food Sci. 1989, 54, 867–870. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F. Healthier lipid formulation approaches in meat-based functional foods. Technological options for replacement of meat fats by non-meat fats. Trends Food Sci. Technol. 2007, 18, 567–578. [Google Scholar] [CrossRef] [Green Version]

- Da Silva, S.L.; Amaral, J.T.; Ribeiro, M.; Sebastião, E.E.; Vargas, C.; de Lima Franzen, F.; Schneider, G.; Lorenzo, J.M.; Fries, L.L.M.; Cichoski, A.J.; et al. Fat replacement by oleogel rich in oleic acid and its impact on the technological, nutritional, oxidative, and sensory properties of Bologna-type sausages. Meat Sci. 2019, 149, 141–148. [Google Scholar] [CrossRef]

- Gómez, I.; Sarriés, M.V.; Ibañez, F.C.; Beriain, M.J. Quality characteristics of a low-fat beef patty enriched by polyunsaturated fatty acids and vitamin D3. J. Food Sci. 2018, 83, 454–463. [Google Scholar] [CrossRef] [PubMed]

- Beriain, M.J.; Gómez, I.; Sánchez, M.; Insausti, K.; Sarriés, M.V.; Ibañez, F.C. The reformulation of a beef patty enriched with n-3 fatty acids and vitamin D3 influences consumers’ response under different information scenarios. Foods 2020, 9, 506. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiménez-Colmenero, F.; Delgado-Pando, G. Fibre-enriched meat products. In Fibre-Rich and WholegrAIn Foods; Delcour, J.A., Poutanen, K., Delcour, J.A., Poutanen, K., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing Limited: Cambridge UK, 2013; pp. 329–347. ISBN 978-0-85709-038-6. [Google Scholar]

- Kim, J.S.; Godber, J.S.; Prinaywiwatkul, W. Restructured beef roasts containing rice bran oil and fiber influences cholesterol oxidation and nutritional profile. J. Muscle Foods 2000, 11, 111–127. [Google Scholar] [CrossRef]

- Fernández-Ginés, J.M.; Fernández-López, J.; Sayas-Barberá, E.; Sendra, E.; Pérez-Álvarez, J.A. Lemon albedo as a new source of dietary fiber: Application to bologna sausages. Meat Sci. 2004, 67, 7–13. [Google Scholar] [CrossRef]

- Tobin, B.D.; O’Sullivan, M.G.; Hamill, R.M.; Kerry, J.P. Effect of varying salt and fat levels on the sensory and physiochemical quality of frankfurters. Meat Sci. 2012, 92, 659–666. [Google Scholar] [CrossRef]

- Ortega-Heras, M.; Villarroel, E.; Mateos, S.; García-Lomillo, J.; Rovira, J.; González-Sanjosé, M.L. Application of a seasoning obtained from red grape pomace as a salt replacer for the elaboration of marinated chicken breasts: Study of their physical-chemical and sensory properties and microbiological stability. CyTA J. Food 2020, 18, 122–131. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.; Tao, S.; Pan, J.; Lin, X.; Ji, C.; Liang, H.; Dong, X.; Li, S. Effects of l-Lysine on the physiochemical properties and sensory characteristics of salt-reduced reconstructed ham. Meat Sci. 2020, 166, 108133. [Google Scholar] [CrossRef]

- Carvalho, C.B.; Madrona, G.S.; da Silva Corradine, S.; Reche, P.M.; dos Santos Pozza, M.S.; de Prado, I.N. Evaluation of quality factors of bovine and chicken meat marinated with reduced sodium content. Food Sci. Technol. 2013, 33, 776–783. [Google Scholar] [CrossRef] [Green Version]

- Campagnol, P.C.B.; dos Santos, B.A.; Terra, N.N.; Pollonio, M.A.R. Lysine, disodium guanylate and disodium inosinate as flavor enhancers in low-sodium fermented sausages. Meat Sci. 2012, 91, 334–338. [Google Scholar] [CrossRef]

- McGough, M.M.; Sato, T.; Rankin, S.A.; Sindelar, J.J. Reducing sodium levels in frankfurters using naturally brewed soy sauce. Meat Sci. 2012, 91, 69–78. [Google Scholar] [CrossRef]

- Tobin, B.D.; O’Sullivan, M.G.; Hamill, R.M.; Kerry, J.P. The impact of salt and fat level variation on the physiochemical properties and sensory quality of pork breakfast sausages. Meat Sci. 2013, 93, 145–152. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Rhee, K.S.; Keeton, J.T.; Rhee, K.C. Properties of low-fat frankfurters containing monounsaturated and omega-3 polyunsaturated oils. J. Food Sci. 1989, 54, 500–504. [Google Scholar] [CrossRef]

- Troutt, E.S.; Hunt, M.C.; Johnson, D.E.; Claus, J.R.; Kastner, C.L.; Kropf, D.H. Characteristics of low-fat ground beef containing texture-modifying ingredients. J. Food Sci. 1992, 57, 19–24. [Google Scholar] [CrossRef]

- Bis-Souza, C.V.; Pateiro, M.; Domínguez, R.; Penna, A.L.B.; Lorenzo, J.M.; Silva Barretto, A.C. Impact of fructooligosaccharides and probiotic strains on the quality parameters of low-fat Spanish Salchichón. Meat Sci. 2020, 159, 107936. [Google Scholar] [CrossRef]

- Rubio, B.; Martínez, B.; García-Cachán, M.D.; Rovira, J.; Jaime, I. Effect of the packaging method and the storage time on lipid oxidation and colour stability on dry fermented sausage Salchichón manufactured with raw material with a high level of mono and polyunsaturated fatty acids. Meat Sci. 2008, 80, 1182–1187. [Google Scholar] [CrossRef]

- Descalzo, A.M.; Sancho, A.M. A review of natural antioxidants and their effects on oxidative status, odor and quality of fresh beef produced in Argentina. Meat Sci. 2008, 79, 423–436. [Google Scholar] [CrossRef]

- Scollan, N.; Hocquette, J.F.; Nuernberg, K.; Dannenberger, D.; Richardson, I.; Moloney, A. Innovations in beef production systems that enhance the nutritional and health value of beef lipids and their relationship with meat quality. Meat Sci. 2006, 74, 17–33. [Google Scholar] [CrossRef]

- Gómez, I.; Beriain, M.J.; Sarriés, M.V.; Insausti, K.; Mendizabal, J.A. Low-fat beef patties with augmented omega-3 fatty acid and CLA levels and influence of grape seed extract. J. Food Sci. 2014, 79, S2368–S2376. [Google Scholar] [CrossRef]

- Cofrades, S.; Guerra, M.A.; Carballo, J.; Fernández-Martín, F.; Colmenero, F.J. Plasma protein and soy fiber content effect on bologna sausage properties as influenced by fat level. J. Food Sci. 2000, 65, 281–287. [Google Scholar] [CrossRef]

- Arshad, M.S.; Kwon, J.H.; Imran, M.; Sohaib, M.; Aslam, A.; Nawaz, I.; Amjad, Z.; Khan, U.; Javed, M. Plant and bacterial proteases: A key towards improving meat tenderization, a mini review. Cogent Food Agric. 2016, 2, 1261780. [Google Scholar] [CrossRef]

- Schenková, N.; Šikulová, M.; Jeleníková, J.; Pipek, P.; Houška, M.; Marek, M. Influence of high isostatic pressure and papain treatment on the quality of beef meat. High Press. Res. 2007, 27, 163–168. [Google Scholar] [CrossRef]

- Kolle, B.K.; McKenna, D.R.; Savell, J.W. Methods to increase tenderness of individual muscles from beef rounds when cooked with dry or moist heat. Meat Sci. 2004, 68, 145–154. [Google Scholar] [CrossRef]

- Ramezani, R.; Aminlari, M.; Fallahi, H. Effect of chemically modified soy proteins and ficin-tenderized meat on the quality attributes of sausage. J. Food Sci. 2003, 68, 85–88. [Google Scholar] [CrossRef]

- Muguruma, M.; Tsuruoka, K.; Katayama, K.; Erwanto, Y.; Kawahara, S.; Yamauchi, K.; Sathe, S.K.; Soeda, T. Soybean and milk proteins modified by transglutaminase improves chicken sausage texture even at reduced levels of phosphate. Meat Sci. 2003, 63, 191–197. [Google Scholar] [CrossRef]

- Kuraishi, C.; Yamazaki, K.; Susa, Y. Transglutaminase: Its utilization in the food industry. Food Rev. Int. 2001, 17, 221–246. [Google Scholar] [CrossRef]

- Kuraishi, C.; Sakamoto, J.; Yamazaki, K.; Susa, Y.; Kuhara, C.; Soeda, T. Production of restructured meat using microbial transglutaminase without salt or cooking. J. Food Sci. 1997, 62, 488–490. [Google Scholar] [CrossRef]

- Tseng, T.F.; Liu, D.C.; Chen, M.T. Evaluation of transglutaminase on the quality of low-salt chicken meat-balls. Meat Sci. 2000, 55, 427–431. [Google Scholar] [CrossRef]

- Kilic, B. Effect of microbial transglutaminase and sodium caseinate on quality of chicken döner kebab. Meat Sci. 2003, 63, 417–421. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Expression of recombinant transglutaminase gene in Pichia pastoris and its uses in restructured meat products. Food Chem. 2019, 291, 245–252. [Google Scholar] [CrossRef]

- Cofrades, S.; López-López, I.; Ruiz-Capillas, C.; Triki, M.; Jiménez-Colmenero, F. Quality characteristics of low-salt restructured poultry with microbial transglutaminase and seaweed. Meat Sci. 2011, 87, 373–380. [Google Scholar] [CrossRef]

- Tsao, C.Y.; Kao, Y.C.; Hsieh, J.F.; Jiang, S.T. Use of soy protein and microbial transglutaminase as a binder in low-sodium restructured meats. J. Food Sci. 2002, 67, 3502–3506. [Google Scholar] [CrossRef]

- Raveendran, S.; Parameswaran, B.; Ummalyma, S.B.; Abraham, A.; Mathew, A.K.; Madhavan, A.; Rebello, S.; Pandey, A. Applications of microbial enzymes in food industry. Food Technol. Biotechnol. 2018, 56, 16–30. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.K.; Shrivastava, N.; Ojha, B.K. Enzymes in the meat industry. In Enzymes in Food Biotechnology; Kuddus, M., Ed.; Academic Press: London, UK, 2019; pp. 111–128. ISBN 978-0-12-813280-7. [Google Scholar]

- Ansorena, D.; Zapelena, M.J.; Astiasarán, I.; Bello, J. Simultaneous addition of palatase M and protease P to a dry fermented sausage (chorizo de Pamplona) elaboration: Effect over peptidic and lipid fractions. Meat Sci. 1998, 50, 37–44. [Google Scholar] [CrossRef]

- Herranz, B.; Fernández, M.; Hierro, E.; Bruna, J.M.; Ordóñez, J.A.; de la Hoz, L. Use of Lactococcus lactis subsp. cremoris NCDO 763 and α-ketoglutarate to improve the sensory quality of dry fermented sausages. Meat Sci. 2004, 66, 151–163. [Google Scholar] [CrossRef]

- Cunningham, F.E.; Tiede, L.M. Properties of selected poultry products treated with a tenderizing marinade. Poult. Sci. 1981, 60, 2475–2479. [Google Scholar] [CrossRef]

- Quaglia, G.B.; Lombardi, M.; Sinesio, F.; Bertone, A.; Menesatti, P. Effect of enzymatic treatment on tenderness characteristics of freeze-dried meat. Food Sci. Technol. Lebensm. Wiss. Technol. 1992, 25, 143–145. [Google Scholar]

- Pietrasik, Z.; Li-Chan, E.C.Y. Response surface methodology study on the effects of salt, microbial transglutaminase and heating temperature on pork batter gel properties. Food Res. Int. 2002, 35, 387–396. [Google Scholar] [CrossRef]

- Ahmad, M.; John, S.; Bosco, D.; Ahmad, S. Evaluation of shelf life of retort pouch packaged Rogan josh, a traditional meat curry of Kashmir, India. Food Packag. Shelf Life 2017, 12, 76–82. [Google Scholar] [CrossRef]

- Zhu, M.; Du, M.; Cordray, J.; Ahn, D.U. Control of Listeria monocytogenes contamination in ready-to-eat meat products. Compr. Rev. Food Sci. Food Saf. 2005, 4, 34–42. [Google Scholar] [CrossRef]

- Sun, X.D.; Holley, R.A. Factors influencing gel formation by myofibrillar proteins in muscle foods. Compr. Rev. Food Sci. Food Saf. 2011, 10, 33–51. [Google Scholar] [CrossRef]

- Boles, J.A. Thermal processing. In Handbook of Meat Processing; Toldrá, F., Ed.; John Wiley & Sons, Ltd.: Ames, AI, USA, 2010; pp. 169–183. ISBN 978-0-8138-2089-7. [Google Scholar]

- Falowo, A.B.; Fayemi, P.O.; Muchenje, V. Natural antioxidants against lipid–protein oxidative deterioration in meat and meat products: A review. Food Res. Int. 2014, 64, 171–181. [Google Scholar] [CrossRef] [PubMed]

- Vargas-Sánchez, R.D.; Ibarra-Arias, F.J.; del Mar Torres-Martínez, B.; Sánchez-Escalante, A.; Torrescano-Urrutia, G.R. Use of natural ingredients in Japanese quail diet and their effect on carcass and meat quality—A review. Asian Australas. J. Anim. Sci. 2019, 32, 1641–1656. [Google Scholar] [CrossRef] [PubMed]

- Czerwonka, M.; Szterk, A. The effect of meat cuts and thermal processing on selected mineral concentration in beef from Holstein-Friesian bulls. Meat Sci. 2015, 105, 75–80. [Google Scholar] [CrossRef] [PubMed]

- McNeill, S.; Van Elswyk, M.E. Red meat in global nutrition. Meat Sci. 2012, 92, 166–173. [Google Scholar] [CrossRef] [PubMed]

- Wood, J.D.; Enser, M.; Fisher, A.V.; Nute, G.R.; Sheard, P.R.; Richardson, R.I.; Hughes, S.I.; Whittington, F.M. Fat deposition, fatty acid composition and meat quality: A review. Meat Sci. 2008, 78, 343–358. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Xiao, S.; Samaraweera, H.; Lee, E.J.; Ahn, D.U. Improving functional value of meat products. Meat Sci. 2010, 86, 15–31. [Google Scholar] [CrossRef]

- Rajan, S.; Kulkarni, V.V.; Chandirasekaran, V. Preparation and storage stability of retort processed Chettinad chicken. J. Food Sci. Technol. 2014, 51, 173–177. [Google Scholar] [CrossRef] [Green Version]

- Fang, Z.; Zhao, Y.; Warner, R.D.; Johnson, S.K. Active and intelligent packaging in meat industry. Trends Food Sci. Technol. 2017, 61, 60–71. [Google Scholar] [CrossRef]

- Rousset, S.; Renerre, M. Effect of CO2 or vacuum packaging on normal and high pH meat shelf-life. Int. J. Food Sci. Technol. 1991, 26, 641–652. [Google Scholar] [CrossRef]

- Bellés, M.; Alonso, V.; Roncalés, P.; Beltrán, J.A. The combined effects of superchilling and packaging on the shelf life of lamb. Meat Sci. 2017, 133, 126–132. [Google Scholar] [CrossRef]

- Łopacka, J.; Półtorak, A.; Wierzbicka, A. Effect of MAP, vacuum skin-pack and combined packaging methods on physicochemical properties of beef steaks stored up to 12days. Meat Sci. 2016, 119, 147–153. [Google Scholar] [CrossRef] [PubMed]

- Rajaei, A.; Hadian, M.; Mohsenifar, A.; Rahmani-Cherati, T.; Tabatabaei, M. A coating based on clove essential oils encapsulated by chitosan-myristic acid nanogel efficiently enhanced the shelf-life of beef cutlets. Food Packag. Shelf Life 2017, 14, 137–145. [Google Scholar] [CrossRef]

- Duran, A.; Kahve, H.I. The effect of chitosan coating and vacuum packaging on the microbiological and chemical properties of beef. Meat Sci. 2020, 162, 107961. [Google Scholar] [CrossRef] [PubMed]

- Nowak, A.; Danuta, K.; Krala, L.; Piotrowska, M.; Czyzowska, A. The effects of thyme (Thymus vulgaris) and rosemary (Rosmarinus officinalis) essential oils on Brochothrix thermosphacta and on the shelf life of beef packaged in high-oxygen modified atmosphere. Food Microbiol. 2012, 32, 212–216. [Google Scholar] [CrossRef]

- Quesada, J.; Sendra, E.; Navarro, C.; Sayas-Barberá, E. Antimicrobial active packaging including chitosan films with Thymus vulgaris L. essential oil for ready-to-eat meat. Foods 2016, 5, 57. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kanatt, S.R.; Rao, M.S.; Chawla, S.P.; Sharma, A. Effects of chitosan coating on shelf-life of ready-to-cook meat products during chilled storage. LWT Food Sci. Technol. 2013, 53, 321–326. [Google Scholar] [CrossRef]

- Soultos, N.; Tzikas, Z.; Abrahim, A.; Georgantelis, D.; Ambrosiadis, I. Chitosan effects on quality properties of Greek style fresh pork sausages. Meat Sci. 2008, 80, 1150–1156. [Google Scholar] [CrossRef]

- Kuswandi, B.; Nurfawaidi, A. On-package dual sensors label based on pH indicators for real-time monitoring of beef freshness. Food Control 2017, 82. [Google Scholar] [CrossRef]

- Biji, K.B.; Ravishankar, C.N.; Mohan, C.O.; Srinivasa Gopal, T.K. Smart packaging systems for food applications: A review. J. Food Sci. Technol. 2015, 52, 6125–6135. [Google Scholar] [CrossRef]

- McMillin, K.W. Advancements in meat packaging. Meat Sci. 2017, 132, 153–162. [Google Scholar] [CrossRef]

- Vargas, M.; Albors, A.; Chiralt, A. Application of chitosan-sunflower oil edible films to pork meat hamburgers. Procedia Food Sci. 2011, 1, 39–43. [Google Scholar] [CrossRef] [Green Version]

- Umaraw, P.; Munekata, P.E.S.; Verma, A.K.; Barba, F.J.; Singh, V.P.; Kumar, P.; Lorenzo, J.M. Edible films/coating with tailored properties for active packaging of meat, fish and derived products. Trends Food Sci. Technol. 2020, 98, 10–24. [Google Scholar] [CrossRef]

- Fu, Q.Q.; Liu, R.; Zhou, G.H.; Zhang, W.G. Effects of packaging methods on the color of beef muscles through influencing myoglobin status, metmyoglobin reductase activity and lipid oxidation. J. Food Process. Preserv. 2017, 41, e12740. [Google Scholar] [CrossRef]

- Frank, D.C.; Geesink, G.; Alvarenga, T.I.R.C.; Polkinghorne, R.; Stark, J.; Lee, M.; Warner, R. Impact of high oxygen and vacuum retail ready packaging formats on lamb loin and topside eating quality. Meat Sci. 2017, 123, 126–133. [Google Scholar] [CrossRef]

- Kameník, J.; Saláková, A.; Pavlík, Z.; Bořilová, G.; Hulanková, R.; Steinhauserová, I. Vacuum skin packaging and its effect on selected properties of beef and pork meat. Eur. Food Res. Technol. 2014, 239, 395–402. [Google Scholar] [CrossRef]

- Narváez-Bravo, C.; Rodas-González, A.; Ding, C.; López-Campos, O.; Galbraith, J.; Larsen, I.L.; Ye, J.; Siegel, D.; Aalhus, J.L. Effects of novel nitrite packaging film on the bacterial growth of bison strip-loin steaks. J. Food Process. Preserv. 2017, 41, e13311. [Google Scholar] [CrossRef]

- Bolumar, T.; LaPeña, D.; Skibsted, L.H.; Orlien, V. Rosemary and oxygen scavenger in active packaging for prevention of high-pressure induced lipid oxidation in pork patties. Food Packag. Shelf Life 2016, 7, 26–33. [Google Scholar] [CrossRef]

- Djenane, D.; Beltrán, J.A.; Camo, J.; Roncalés, P. Influence of vacuum-ageing duration of whole beef on retail shelf life of steaks packaged with oregano (Origanum vulgare L.) active film under high O2. J. Food Sci. Technol. 2016, 53, 4244–4257. [Google Scholar] [CrossRef] [Green Version]

- Battisti, R.; Fronza, N.; Vargas Júnior, Á.; da Silveira, S.M.; Damas, M.S.P.; Quadri, M.G.N. Gelatin-coated paper with antimicrobial and antioxidant effect for beef packaging. Food Packag. Shelf Life 2017, 11, 115–124. [Google Scholar] [CrossRef]

- Zimoch-Korzycka, A.; Jarmoluk, A. Polysaccharide-based edible coatings containing cellulase for improved preservation of meat quality during storage. Molecules 2017, 22, 390. [Google Scholar] [CrossRef] [Green Version]

- Park, H.Y.; Kim, S.J.; Kim, K.M.; You, Y.S.; Kim, S.Y.; Han, J. Development of antioxidant packaging material by applying corn-zein to LLDPE film in combination with phenolic compounds. J. Food Sci. 2012, 77, E273–E279. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Weller, C.L.; Hamouz, F.; Cuppett, S.; Schnepf, M. Moisture loss and lipid oxidation for precooked ground-beef patties packaged in edible starch-alginate-based composite films. J. Food Sci. 2001, 66, 486–493. [Google Scholar] [CrossRef]

- Hempel, A.W.; Papkovsky, D.B.; Kerry, J.P. Use of optical oxygen sensors in non-destructively determining the levels of oxygen present in combined vacuum and modified atmosphere packaged pre-cooked convenience-style foods and the use of ethanol emitters to extend product shelf-life. Foods 2013, 2, 507–520. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thangavelu, K.P.; Kerry, J.P.; Tiwari, B.K.; McDonnell, C.K. Novel processing technologies and ingredient strategies for the reduction of phosphate additives in processed meat. Trends Food Sci. Technol. 2019, 94, 43–53. [Google Scholar] [CrossRef]

- Scotter, M.J.; Castle, L. Chemical interactions between additives in foodstuffs: A review. Food Addit. Contam. 2004, 21, 93–124. [Google Scholar] [CrossRef]

- Nair, M.S.; Nair, D.V.T.; Johny, A.K.; Venkitanarayanan, K. Use of food preservatives and additives in meat and their detection techniques. In Meat Quality Analysis; Biswas, A.K., Mandal, P.K., Eds.; Academic Press: London, UK, 2020; pp. 187–213. ISBN 978-0-12-819233-7. [Google Scholar]

- Honikel, K.O. The use and control of nitrate and nitrite for the processing of meat products. Meat Sci. 2008, 78, 68–76. [Google Scholar] [CrossRef]

- Karwowska, M.; Kononiuk, A. Nitrates/nitrites in food—Risk for nitrosative stress and benefits. Antioxidants 2020, 9, 241. [Google Scholar] [CrossRef] [Green Version]

- Aziz, M.; Karboune, S. Natural antimicrobial/antioxidant agents in meat and poultry products as well as fruits and vegetables: A review. Crit. Rev. Food Sci. Nutr. 2018, 58, 486–511. [Google Scholar] [CrossRef]

- Karabagias, I.; Badeka, A.; Kontominas, M.G. Shelf life extension of lamb meat using thyme or oregano essential oils and modified atmosphere packaging. Meat Sci. 2011, 88, 109–116. [Google Scholar] [CrossRef]

- Radha krishnan, K.; Babuskin, S.; Azhagu Saravana Babu, P.; Sasikala, M.; Sabina, K.; Archana, G.; Sivarajan, M.; Sukumar, M. Antimicrobial and antioxidant effects of spice extracts on the shelf life extension of raw chicken meat. Int. J. Food Microbiol. 2014, 171, 32–40. [Google Scholar] [CrossRef]

- Chan, K.W.; Khong, N.M.H.; Iqbal, S.; Ch’ng, S.E.; Younas, U.; Babji, A.S. Cinnamon bark deodorised aqueous extract as potential natural antioxidant in meat emulsion system: A comparative study with synthetic and natural food antioxidants. J. Food Sci. Technol. 2014, 51, 3269–3276. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mancini, S.; Preziuso, G.; Dal Bosco, A.; Roscini, V.; Szendrő, Z.; Fratini, F.; Paci, G. Effect of turmeric powder (Curcuma longa L.) and ascorbic acid on physical characteristics and oxidative status of fresh and stored rabbit burgers. Meat Sci. 2015, 110, 93–100. [Google Scholar] [CrossRef] [PubMed]

- Zahid, M.A.; Choi, J.Y.; Seo, J.K.; Parvin, R.; Ko, J.; Yang, H.S. Effects of clove extract on oxidative stability and sensory attributes in cooked beef patties at refrigerated storage. Meat Sci. 2020, 161, 107972. [Google Scholar] [CrossRef] [PubMed]

- Ahmad Mir, S.; Ahmad Masoodi, F.; Raja, J. Influence of natural antioxidants on microbial load, lipid oxidation and sensorial quality of rista—A traditional meat product of India. Food Biosci. 2017, 20, 79–87. [Google Scholar] [CrossRef]

- Lara, M.S.; Gutierrez, J.I.; Timón, M.; Andrés, A.I. Evaluation of two natural extracts (Rosmarinus officinalis L. and Melissa officinalis L.) as antioxidants in cooked pork patties packed in MAP. Meat Sci. 2011, 88, 481–488. [Google Scholar] [CrossRef]

- Vasilatos, G.C.; Savvaidis, I.N. Chitosan or rosemary oil treatments, singly or combined to increase turkey meat shelf-life. Int. J. Food Microbiol. 2013, 166, 54–58. [Google Scholar] [CrossRef]

- Fernandes, R.P.P.; Trindade, M.A.; Lorenzo, J.M.; Munekata, P.E.S.; de Melo, M.P. Effects of oregano extract on oxidative, microbiological and sensory stability of sheep burgers packed in modified atmosphere. Food Control. 2016, 63, 65–75. [Google Scholar] [CrossRef]

- Horita, C.N.; Farías-Campomanes, A.M.; Barbosa, T.S.; Esmerino, E.A.; da Cruz, A.G.; Bolini, H.M.A.; Meireles, M.A.A.; Pollonio, M.A.R. The antimicrobial, antioxidant and sensory properties of garlic and its derivatives in Brazilian low-sodium frankfurters along shelf-life. Food Res. Int. 2016, 84, 1–8. [Google Scholar] [CrossRef]

- Bañón, S.; Díaz, P.; Rodríguez, M.; Garrido, M.D.; Price, A. Ascorbate, green tea and grape seed extracts increase the shelf life of low sulphite beef patties. Meat Sci. 2007, 77, 626–633. [Google Scholar] [CrossRef]

- Gómez, I.; Beriain, M.J.; Mendizabal, J.A.; Realini, C.; Purroy, A. Shelf life of ground beef enriched with omega-3 and/or conjugated linoleic acid and use of grape seed extract to inhibit lipid oxidation. Food Sci. Nutr. 2016, 4, 67–79. [Google Scholar] [CrossRef]

- Price, A.; Díaz, P.; Bañón, S.; Garrido, M.D. Natural extracts versus sodium ascorbate to extend the shelf life of meat-based ready-to-eat meals. Food Sci. Technol. Int. 2013. [Google Scholar] [CrossRef] [PubMed]

- Tamkutė, L.; Gil, B.M.; Carballido, J.R.; Pukalskienė, M.; Venskutonis, P.R. Effect of cranberry pomace extracts isolated by pressurized ethanol and water on the inhibition of food pathogenic/spoilage bacteria and the quality of pork products. Food Res. Int. 2019, 120, 38–51. [Google Scholar] [CrossRef] [PubMed]

- Kryževičūtė, N.; Jaime, I.; Diez, A.M.; Rovira, J.; Venskutonis, P.R. Effect of raspberry pomace extracts isolated by high pressure extraction on the quality and shelf-life of beef burgers. Int. J. Food Sci. Technol. 2017, 52, 1852–1861. [Google Scholar] [CrossRef]

- García-Lomillo, J.; González-SanJosé, M.L.; Del Pino-García, R.; Rivero-Pérez, M.D.; Muñiz-Rodríguez, P. Antioxidant and antimicrobial properties of wine byproducts and their potential uses in the food industry. J. Agric. Food Chem. 2014, 62, 12595–12602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- García-Lomillo, J.; González-SanJosé, M.L. Applications of wine pomace in the food industry: Approaches and functions. Compr. Rev. Food Sci. Food Saf. 2017, 16, 3–22. [Google Scholar] [CrossRef]

- Garcia-Lomillo, J.; González-SanJosé, M.L.; Skibsted, L.H.; Jongberg, S. Effect of skin wine pomace and sulfite on protein oxidation in beef patties during high oxygen atmosphere storage. Food Bioprocess. Technol. 2016, 9, 532–542. [Google Scholar] [CrossRef] [Green Version]

- Yogesh, K.; Ahmad, T.; Manpreet, G.; Mangesh, K.; Das, P. Characteristics of chicken nuggets as affected by added fat and variable salt contents. J. Food Sci. Technol. 2013, 50, 191–196. [Google Scholar] [CrossRef] [Green Version]

- Viuda-Martos, M.; Fernández-López, J.; Sayas-Barbera, E.; Sendra, E.; Navarro, C.; Pérez-Alvarez, J.A. Citrus co-products as technological strategy to reduce residual nitrite content in meat products. J. Food Sci. 2009, 74, R93–R100. [Google Scholar] [CrossRef]

| Treatment | Meat Product | Effects |

|---|---|---|

| Dry aging | Beef meat [5,6,8,9] Porcine meat [7] | More flavor, tenderness and juiciness in beef. Umami taste in beef and porcine meat. Nutritional changes not investigated. |

| Dry curing | Pork, beef, mutton [13] | Increased storage temperature. slightly decreased the digestibility of dried pork protein. |

| Meat products [14] | Protein quality is not significantly reduced during dehydration. | |

| Meat products from different animals [15,16] | Hardened texture, wrinkled appearance, characteristic flavor, brown color and darkening. | |

| High pressure processing | Beef, pig, chicken meat [17] | Unchanged nutritional value. |

| Different meat products [18] | Low molecular weight vitamins and flavor compounds stay intact. | |

| Beef [19] and rabbit [20] muscle | Enhanced digestibility. | |

| Meat products [22] | Improved tenderness, changes to the color quality. depending on the content of myoglobin. | |

| Goose breast [23] | Improved tenderness. | |

| Lamb meat cuts [25] | Browned, livery and oxidized flavors. | |

| Ham [29] | Improved digestibility. | |

| Ready to eat (RTE) meat products [30] | No changes in sensory properties. | |

| Pig ham [32] | Paler color and softer texture. | |

| Low-temperature long-time (LTLT) and sous vide cooking | Meat [36] | Increased tenderness and better appearance. |

| Lamb [37] and pork [38] meats | Increased flavor. | |

| Beef [39,40] | Increased tenderness. | |

| Chicken meat [42] | Increased tenderness and color. | |

| Beef [45] | Brownish red with a slight green color. | |

| Pork [47] | Juicier and more tender meat, and improved digestibility. | |

| RTE marinated beef [51] | No effects on sensory characteristics. | |

| 3D printing | Turkey and beef meats [54,56] | Novel appearance and texture. Nutritional changes not investigated. |

| Treatment | Meat Product | Effects |

|---|---|---|

| Fermentation | Dry-cured meat products, traditional Jinhua ham, Parma ham, dry-cured Iberian ham [64,66,68] | Specific aroma compounds such as alcohols, aldehydes, ketones, esters and lactones. |

| Harbin red Chinese style sausage [64] | The use of Lactobacillus fermentum led to characteristic pink color of cured meat. | |

| Fermented meat products [68] | Production of bioactive peptides. | |

| Smoking | Lamb meat [71] Sausage [78] Sausages from poultry, pork and beef meat [79] Smoked pork bacon [83] | Enhanced flavor, color and odor. Reduction of the greyish discoloration. Enhanced sensory attributes. Improvement of digestibility of indispensable amino acids. |

| Buffalo meat [80] | Combination of smoking with curing improved color, texture and odor. | |

| Curing and salting | Bovine muscle [90] | Improved texture properties. |

| Marination | Broiler chicken [100] Fresh and precooked pork meat [101,102] | Increase of the juiciness and tenderness. |

| Beef [103] | Tripolyphosphate in brine improved sensory characteristics. | |

| Beef [107,108] | Brines of salts and phosphate improved juiciness and tenderness. Color loss. | |

| Beef [109] | Acid concentrations greater than 0.3 M were not recommended, as they caused great swelling and darkening. | |

| Beef [110] | The higher acid concentration used for the brine, the greater tenderness. Solution with an acid concentration greater than 0.15 M lead to too acidic beef and rejection by panelists. |

| Compound | Reformulation Objective | Treatment | Meat Product | Effects |

|---|---|---|---|---|

| Salt | Reduction | Lowering from 2.8% to 0.5% | Hotdog sausages, bacon, ham and salami [112] Pork sausages [126] Chicken breasts [127]: Reconstructed ham [128] | Paler, softer, and less juicy products per low of 1.3–1.7% NaCl. Difficulty reducing the dietary salt intake (<1.4%) without affecting acceptance. |

| Partial substitution | Use of spice mixes, KCl or other salts | Cooked ham [92] Bovine and chicken meat [129] Fermented sausages [111,130] Frankfurt sausages [131] | Sensory quality and general acceptability were not modified if replacement ranged 30–35%. Reduced acceptance of aroma, flavor, juiciness and overall quality if NaCl was lower than 1.3%. | |

| Fat | Reduction | Addiction of vegetable oils | Pork sausages [117] Frankfurt sausage [126] Pork sausages [132] Beef and pork sausages [133] Beef patty [134] | Darker, harder, less juicy and less flavor intensity. Better nutritional value (reduction in fat and cholesterol and increase in polyunsaturated fatty acids (PUFA) or monounsaturated fatty acids (MUFA). |

| Substitution | Replacing by vegetable or fish oils, soybean proteins, carbohydrates, and synthetic compounds | Sausages, cooked minced meat [116] Veal sausages [118] Bologne sausages [120] Beef patty [121] Spanish salami [135] Sausage [1] | Decrease of meat aroma and flavor intensity. Better nutritional value (reduction in fat and cholesterol and increase in PUFA or MUFA). | |

| Enhanced nutritional value | Raw material with a high level of mono and polyunsaturated fatty acids from pigs fed with different diets | Dry fermented sausage salchichon [136] | The color was slightly affected. Improved nutritional value. | |

| Grass-fed or flaxseed-containing concentrates | Beef [137,138] | Improved fatty acid profile by increasing content in conjugated linoleic acid (CLA), eicosapentaenoic acid (EPA) and docosahexaenoic acid DHA. | ||

| Feeding with linseed seeds and CLA | Beef patty [139] | No significant change in color and odor of hamburgers enriched in n-3 and CLA. Enhanced lipid profile. | ||

| Dietary fiber | Addition of dietary fiber | Addition of dietary fiber (inulin, rice fiber, citrus fiber, etc.) | Sausages [1] Meat products [123] Roast beef [124] Bologne sausages [125,140] | Texture properties decreased (harder and less chewy structures). The 6% inulin concentration provided the best sensory characteristics. Maintained the sensory properties and acceptability. Nutritional value in PUFA improved, the fat content decreased, and the fiber content increased. |

| Objective | Treatment | Meat Product | Effects |

|---|---|---|---|

| Tenderization | Addition of papain, bromelain, ficin, | Beef meat [142] Mortadella [144] Turkey, hen and rooster thighs [157] Beef cubes [158] | Increase of tenderness. Without changes in organoleptic properties. |

| Blade tenderization, bromelain or salt/phosphate injection | Muscles from beef rounds [143] | Injection with a salt and phosphate solution resulted in the lowest Warner-Bratzler shear force (WBSF) values. WBSF values for blade tenderization and enzymatic tenderization were comparable. | |

| Restructuring | Addition of transglutaminase (TGase) | Restructured cooked ham [147] Pork gels [159] Low-salt chicken dumplings [148] Chicken sausages [145] Doner kebab of chicken [149] Sausages and ham [146] Restructured pork [150] | No effect on color. Formation of network structures, improving the textural properties: increase of springiness, firmness, decrease in adhesiveness. Increased juiciness, tenderness and overall acceptability. Increase of firmness of meat gels. |

| Bisulfite, soybean protein and TGase | Pork sticks [152] | Improvement of tensile strength and cooking performance. | |

| Sea spaghetti seaweed (3% dry matter) combined with NaCl reduction and a (TGase/caseinate) system | Restructured poultry steaks [151] | Increase in Kramer shear force. Products were acceptable. | |

| Production of flavor and aromas | Addition of palatase M and protease P | Spanish dry fermented sausage (Pamplona chorizo) [155] | Without changes in the sensory quality except a slight softening. |

| Intracellular cell free extract (L lactis NCDO 763,) and α-ketoglutarate | Dry fermented sausages [156] | Improvement of odor and flavor when L. lactis and α-ketoglutarate were combined. |

| Treatment | Meat Product | Effects |

|---|---|---|

| Air-permeable packaging, vacuum packaging and modified atmosphere packaging | High pH and normal pH beef [172] Lamb slices [173] Beef steaks [174] Beef fillets [186] Lamb steaks [187] Beef and pork steaks [188] Bison tenderloin steaks [189] | Vacuum packaging inhibits lipid oxidation, thus preventing unpleasant odors and flavors. Packaged in a modified atmosphere with semi-permeable internal vacuum film leads to an attractive bright red color. Packaging in CO2 improves color and the stability of meat color compared to vacuum package. |

| Active packaging | Pork patties [190] Beef steaks [191] Beef [175,192] | Active packaging does not affect the tenderness of the meat. Desirable bright red color. Incorporation of essential oils in the active packaging leads to unpleasant flavors and aromas. |

| Edible films and coatings | Beef [176] Pork meat [193] Minced beef [194] Ready to eat (RTE) meat products [178] Pork meat hamburgers [184] Ground-beef patties [195] | The stability of the red color is improved. Lipid oxidation is inhibited, thus preventing unpleasant odor and flavor. |

| Combination | Pre-cooked convenience-style foods: battered sausages, bacon slices, and meat and potato pies [196] | Optical oxygen sensors in combined vacuum and modified atmosphere packaged and the use of ethanol emitters: ethanol flavor and aroma were not perceived by panelists in two of the three products assessed. |

| Natural Ingredients | Meat Product | Effects | |

|---|---|---|---|

| Essential oils: thyme, oregano, pimento, clove, citron, lemon verbena, lemon, balm, cypress leaf | Lamb meat [203] Raw chicken [204] Meatballs [205] Beef patties [207] | Extracts like clove or cinnamon increase of L*, a* and b* values during storage. Concentrations of essential oils of oregano and thyme greater than 1% led to strong odor and unpleasant taste. Clove extract increased the a* values. | |

| Plant extracts: grape seed, green tea, pomegranate peel/rind, acerola, pine bark, bearberry, cinnamon bark, rosemary, garlic, oregano, sansho, ginger, sage. | Grape seed extract (GSE) and wine pomace | Low sulfite beef patties [213] Beef enriched with n-3 and CLA [139,214] Pork meatballs [215] Chicken nuggets [221] | GSE showed less color changes during the storage. GSE can darken a meat product. No modification of the sensory attributes except for the color. |

| Green tea extract | Low sulphite beef patties [213] Pork meatballs [210] | No effects on odor, taste and texture. Degradation of red color is delayed. No modification of the sensory attributes except for the color. | |

| Rosemary extract | Turkey meat [210] Pork burgers [209] | No effects on sensory characteristics. | |

| Oregano extract | Sheep burgers [211] | No effects on sensory characteristics. | |

| Garlic | Low-salt sausages [212] | No effects on aroma, flavor and overall appearance. | |

| Other fruit extracts: blueberries, raspberry pomace, pomegranate peel and pomegranate juice | Pork burgers and cooked pork ham [216] Beef burgers [217] Chicken patties [3] | Sensory quality was not negatively altered. | |

| Citrus fiber | Bologne sausage [222] | No effect on color or texture properties. When citrus fiber is combined with rosemary essential oil, the sensory parameters improved. | |

| Spices | Rabbit burgers [206] Indian sheep meat product [208] | Turmeric powder leads to higher yellow values. Cumin and cardamom led to high overall acceptability score. | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez, I.; Janardhanan, R.; Ibañez, F.C.; Beriain, M.J. The Effects of Processing and Preservation Technologies on Meat Quality: Sensory and Nutritional Aspects. Foods 2020, 9, 1416. https://doi.org/10.3390/foods9101416

Gómez I, Janardhanan R, Ibañez FC, Beriain MJ. The Effects of Processing and Preservation Technologies on Meat Quality: Sensory and Nutritional Aspects. Foods. 2020; 9(10):1416. https://doi.org/10.3390/foods9101416

Chicago/Turabian StyleGómez, Inmaculada, Rasmi Janardhanan, Francisco C. Ibañez, and María José Beriain. 2020. "The Effects of Processing and Preservation Technologies on Meat Quality: Sensory and Nutritional Aspects" Foods 9, no. 10: 1416. https://doi.org/10.3390/foods9101416