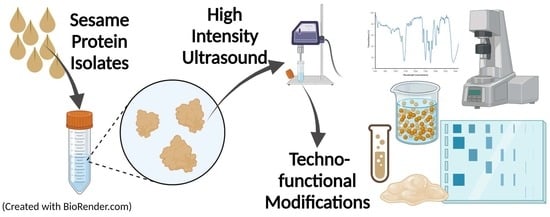

Structural Characterization, Technofunctional and Rheological Properties of Sesame Proteins Treated by High-Intensity Ultrasound

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Sesame Protein Isolate

2.3. High-Intensity Ultrasound Treatment

2.4. Physicochemical Properties

2.4.1. Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE)

2.4.2. Particle Size and Zeta Potential

2.4.3. Fourier Transform Infrared Spectroscopy (FTIR)

2.4.4. Optical and Scanning Electron Microscopy (SEM)

2.4.5. Protein Solubility

2.4.6. Surface Hydrophobicity

2.4.7. Free and Total Surface Sulfhydryl (−SH) Groups

2.5. Technofunctional Properties

2.5.1. Emulsifying Properties

2.5.2. Foaming Properties

2.5.3. Water- and Oil-Holding Capacity

2.6. Rheological Properties

2.6.1. Steady Shear Tests

2.6.2. Dynamic Shear Tests

2.6.3. Temperature Sweep Tests

2.7. Statistical Analysis

3. Results and Discussion

3.1. SDS-PAGE

3.2. Particle Size and Zeta Potential

3.3. Fourier Transform Infrared Spectroscopy (FTIR)

3.4. Optical and Scanning Electron Microscopy (SEM)

3.5. Protein Solubility

3.6. Surface Hydrophobicity

3.7. Free and Total Surface Sulfhydryl (−SH) Groups

3.8. Emulsifying Properties

3.9. Foaming Properties

3.10. Water- and Oil-Holding Capacity

3.11. Rheological Properties

3.11.1. Steady Shear Properties

3.11.2. Dynamic Shear Tests

3.11.3. Temperature Sweep Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Saricaoglu, F.T.; Gul, O.; Besir, A.; Atalar, I. Effect of high pressure homogenization (HPH) on functional and rheological properties of hazelnut meal proteins obtained from hazelnut oil industry by-products. J. Food Eng. 2018, 233, 98–108. [Google Scholar] [CrossRef]

- Yang, K.; Xu, T.R.; Fu, Y.H.; Cai, M.; Xia, Q.L.; Guan, R.F.; Zou, X.G.; Sun, P.L. Effects of ultrasonic pre-treatment on physicochemical properties of proteins extracted from cold-pressed sesame cake. Food Res. Int. 2021, 139, 109907. [Google Scholar] [CrossRef]

- Wu, D.; Tu, M.; Wang, Z.; Wu, C.; Yu, C.; Battino, M.; El-Seedi, H.R.; Du, M. Biological and conventional food processing modifications on food proteins: Structure, functionality, and bioactivity. Biotechnol. Adv. 2020, 40, 107491. [Google Scholar] [CrossRef] [PubMed]

- Tomé Constantino, A.B.; Garcia-Rojas, E.E. Modifications of physicochemical and functional properties of amaranth protein isolate (Amaranthus cruentus BRS Alegria) treated with high-intensity ultrasound. J. Cereal Sci. 2020, 95, 103076. [Google Scholar] [CrossRef]

- FAOSTAT. The Food and Agriculture Organization Corporate Statistical Database (FAOSTAT), Rome, Italy. 2020. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 17 October 2022).

- Myint, D.; Gilani, S.A.; Kawase, M.; Watanabe, K.N. Sustainable Sesame (Sesamum indicum L.) Production through Improved Technology: An Overview of Production, Challenges, and Opportunities in Myanmar. Sustainability 2020, 12, 3515. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Yu, H.-Y.; Liu, Y.-Z.; Qin, Z.; Liu, H.-M.; Ma, Y.-X.; Wang, X.-D. Isolation and structural characterization of cell wall polysaccharides from sesame kernel. LWT 2022, 163, 113574. [Google Scholar] [CrossRef]

- Di, Y.; Li, X.; Chang, X.; Gu, R.; Duan, X.; Liu, F.; Liu, X.; Wang, Y. Impact of germination on structural, functional properties and in vitro protein digestibility of sesame (Sesamum indicum L.) protein. LWT 2022, 154, 112651. [Google Scholar] [CrossRef]

- Achouri, A.; Nail, V.; Boye, J.I. Sesame protein isolate: Fractionation, secondary structure and functional properties. Food Res. Int. 2012, 46, 360–369. [Google Scholar] [CrossRef]

- Akharume, F.U.; Aluko, R.E.; Adedeji, A.A. Modification of plant proteins for improved functionality: A review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 198–224. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Ding, J.; Andrade, J.; Rababah, T.M.; Almajwal, A.; Abulmeaty, M.M.; Feng, H. Modifying the physicochemical properties of pea protein by pH−SHifting and ultrasound combined treatments. Ultrason. Sonochem. 2017, 38, 835–842. [Google Scholar] [CrossRef]

- Su, J.; Cavaco-Paulo, A. Effect of ultrasound on protein functionality. Ultrason. Sonochem. 2021, 76, 105653. [Google Scholar] [CrossRef] [PubMed]

- Majid, I.; Nayik, G.A.; Nanda, V.; Yildiz, F. Ultrasonication and food technology: A review. Cogent Food Agric. 2015, 1, 1071022. [Google Scholar] [CrossRef]

- Du, H.; Zhang, J.; Wang, S.; Manyande, A.; Wang, J. Effect of high-intensity ultrasonic treatment on the physicochemical, structural, rheological, behavioral, and foaming properties of pumpkin (Cucurbita moschata Duch.)-seed protein isolates. LWT 2022, 155, 112952. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, X.; Liu, W.; Liu, Q.; Zhang, L.; Hu, H. Effect of high-intensity ultrasound on the structural, rheological, emulsifying and gelling properties of insoluble potato protein isolates. Ultrason. Sonochem. 2022, 85, 105969. [Google Scholar] [CrossRef] [PubMed]

- Görgüç, A.; Özer, P.; Yılmaz, F.M. Simultaneous effect of vacuum and ultrasound assisted enzymatic extraction on the recovery of plant protein and bioactive compounds from sesame bran. J. Food Compos. Anal. 2020, 87, 103424. [Google Scholar] [CrossRef]

- Gandhi, A.P.; Srivastava, J. Studies on the production of protein isolates from defatted sesame seed (Sesamum indicum) flour and their nutritional profile. ASEAN Food J. 2007, 14, 175–180. [Google Scholar]

- Laemmli, U.K. SDS-page Laemmli method. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef]

- Klompong, V.; Benjakul, S.; Kantachote, D.; Shahidi, F. Antioxidative activity and functional properties of protein hydrolysate of yellow stripe trevally (Selaroides leptolepis) as influenced by the degree of hydrolysis and enzyme type. Food Chem. 2007, 102, 1317–1327. [Google Scholar] [CrossRef]

- Robinson, H.W.; Hogden, C.G. The biuret reaction in the determination of serum proteins. 1. A study of the conditions necessary for the production of a stable color which bears a quantitative relationship to the protein concentration. J. Biol. Chem. 1940, 135, 707–725. [Google Scholar] [CrossRef]

- Arzeni, C.; Martínez, K.; Zema, P.; Arias, A.; Pérez, O.E.; Pilosof, A.M.R. Comparative study of high intensity ultrasound effects on food proteins functionality. J. Food Eng. 2012, 108, 463–472. [Google Scholar] [CrossRef]

- Segat, A.; Misra, N.N.; Fabbro, A.; Buchini, F.; Lippe, G.; Cullen, P.J.; Innocente, N. Effects of ozone processing on chemical, structural and functional properties of whey protein isolate. Food Res. Int. 2014, 66, 365–372. [Google Scholar] [CrossRef]

- Ellman, G.L. Reprint of: Tissue Sulfhydryl Groups. Arch. Biochem. Biophys. 2022, 726, 109245. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Wu, J.; Li-Chan, E.C.Y.; Zhu, L.; Zhang, F.; Xu, X.; Fan, G.; Wang, L.; Huang, X.; Pan, S. Effects of ultrasound on structural and physical properties of soy protein isolate (SPI) dispersions. Food Hydrocoll. 2013, 30, 647–655. [Google Scholar] [CrossRef]

- Pearce, K.N.; Kinsella, J.E. Emulsifying properties of proteins: Evaluation of a turbidimetric technique. J. Agric. Food Chem. 1978, 26, 716–723. [Google Scholar] [CrossRef]

- Ogunwolu, S.O.; Henshaw, F.O.; Mock, H.-P.; Santros, A.; Awonorin, S.O. Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chem. 2009, 115, 852–858. [Google Scholar] [CrossRef]

- Orruño, E.; Morgan, M.R.A. Purification and characterisation of the 7S globulin storage protein from sesame (Sesamum indicum L.). Food Chem. 2007, 100, 926–934. [Google Scholar] [CrossRef]

- Tai, S.S.; Lee, T.T.; Tsai, C.C.; Yiu, T.J.; Tzen, J.T. Expression pattern and deposition of three storage proteins, 11S globulin, 2S albumin and 7S globulin in maturing sesame seeds. Plant Physiol. Biochem. 2001, 39, 981–992. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhu, W.; Yi, J.; Liu, N.; Cao, Y.; Lu, J.; Decker, E.A.; McClements, D.J. Effects of sonication on the physicochemical and functional properties of walnut protein isolate. Food Res. Int. 2018, 106, 853–861. [Google Scholar] [CrossRef]

- Higuera-Barraza, O.A.; Torres-Arreola, W.; Ezquerra-Brauer, J.M.; Cinco-Moroyoqui, F.J.; Rodriguez Figueroa, J.C.; Marquez-Rios, E. Effect of pulsed ultrasound on the physicochemical characteristics and emulsifying properties of squid (Dosidicus gigas) mantle proteins. Ultrason. Sonochem. 2017, 38, 829–834. [Google Scholar] [CrossRef]

- Malik, M.A.; Sharma, H.K.; Saini, C.S. High intensity ultrasound treatment of protein isolate extracted from dephenolized sunflower meal: Effect on physicochemical and functional properties. Ultrason. Sonochem. 2017, 39, 511–519. [Google Scholar] [CrossRef]

- Jin, J.; Okagu, O.D.; Yagoub, A.E.A.; Udenigwe, C.C. Effects of sonication on the in vitro digestibility and structural properties of buckwheat protein isolates. Ultrason. Sonochem. 2021, 70, 105348. [Google Scholar] [CrossRef] [PubMed]

- Ding, Q.; Tian, G.; Wang, X.; Deng, W.; Mao, K.; Sang, Y. Effect of ultrasonic treatment on the structure and functional properties of mantle proteins from scallops (Patinopecten yessoensis). Ultrason. Sonochem. 2021, 79, 105770. [Google Scholar] [CrossRef] [PubMed]

- O’Sullivan, J.; Murray, B.; Flynn, C.; Norton, I. The effect of ultrasound treatment on the structural, physical and emulsifying properties of animal and vegetable proteins. Food Hydrocoll. 2016, 53, 141–154. [Google Scholar] [CrossRef]

- Yanjun, S.; Jianhang, C.; Shuwen, Z.; Hongjuan, L.; Jing, L.; Lu, L.; Uluko, H.; Yanling, S.; Wenming, C.; Wupeng, G.; et al. Effect of power ultrasound pre-treatment on the physical and functional properties of reconstituted milk protein concentrate. J. Food Eng. 2014, 124, 11–18. [Google Scholar] [CrossRef]

- Wang, N.; Zhou, X.; Wang, W.; Wang, L.; Jiang, L.; Liu, T.; Yu, D. Effect of high intensity ultrasound on the structure and solubility of soy protein isolate-pectin complex. Ultrason. Sonochem. 2021, 80, 105808. [Google Scholar] [CrossRef]

- Nazari, B.; Mohammadifar, M.A.; Shojaee-Aliabadi, S.; Feizollahi, E.; Mirmoghtadaie, L. Effect of ultrasound treatments on functional properties and structure of millet protein concentrate. Ultrason. Sonochem. 2018, 41, 382–388. [Google Scholar] [CrossRef]

- Zhang, Z.; Regenstein, J.M.; Zhou, P.; Yang, Y. Effects of high intensity ultrasound modification on physicochemical property and water in myofibrillar protein gel. Ultrason. Sonochem. 2017, 34, 960–967. [Google Scholar] [CrossRef]

- Wang, T.; Chen, X.; Wang, W.; Wang, L.; Jiang, L.; Yu, D.; Xie, F. Effect of ultrasound on the properties of rice bran protein and its chlorogenic acid complex. Ultrason. Sonochem. 2021, 79, 105758. [Google Scholar] [CrossRef]

- Hu, S.; Wu, J.; Zhu, B.; Du, M.; Wu, C.; Yu, C.; Song, L.; Xu, X. Low oil emulsion gel stabilized by defatted Antarctic krill (Euphausia superba) protein using high-intensity ultrasound. Ultrason. Sonochem. 2021, 70, 105294. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, L.; Wei, D.; Li, Y.; Sui, X.; Wang, Z.; Li, D. Effect of Secondary Structure determined by FTIR Spectra on Surface Hydrophobicity of Soybean Protein Isolate. Procedia Eng. 2011, 15, 4819–4827. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Zheng, B.; Guo, Z. Impact of combined ultrasound-microwave treatment on structural and functional properties of golden threadfin bream (Nemipterus virgatus) myofibrillar proteins and hydrolysates. Ultrason. Sonochem. 2020, 65, 105063. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Huang, Y.; Zhou, B.; Xu, W.; Xiang, X.; Huang, Q.; Li, S. Improvement of quality and flavor of salted egg yolks by ultrasonic assisted cooking. Ultrason. Sonochem. 2021, 75, 105579. [Google Scholar] [CrossRef]

- Yang, F.; Liu, X.; Ren, X.; Huang, Y.; Huang, C.; Zhang, K. Swirling cavitation improves the emulsifying properties of commercial soy protein isolate. Ultrason. Sonochem. 2018, 42, 471–481. [Google Scholar] [CrossRef] [PubMed]

- Gulseren, I.; Guzey, D.; Bruce, B.D.; Weiss, J. Structural and functional changes in ultrasonicated bovine serum albumin solutions. Ultrason. Sonochem. 2007, 14, 173–183. [Google Scholar] [CrossRef] [PubMed]

- Gordon, L.; Pilosof, A.M.R. Application of High-Intensity Ultrasounds to Control the Size of Whey Proteins Particles. Food Biophys. 2010, 5, 203–210. [Google Scholar] [CrossRef]

- Mir, N.A.; Riar, C.S.; Singh, S. Structural modification of quinoa seed protein isolates (QPIs) by variable time sonification for improving its physicochemical and functional characteristics. Ultrason. Sonochem. 2019, 58, 104700. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, J.; Li, Y.; Wang, Z.; Liang, J.; Wang, R.; Chen, Y.; Ma, W.; Qi, B.; Zhang, M. Effects of ultrasound on the structure and physical properties of black bean protein isolates. Food Res. Int. 2014, 62, 595–601. [Google Scholar] [CrossRef]

- Zou, Y.; Yang, H.; Li, P.P.; Zhang, M.H.; Zhang, X.X.; Xu, W.M.; Wang, D.Y. Effect of different time of ultrasound treatment on physicochemical, thermal, and antioxidant properties of chicken plasma protein. Poult. Sci. 2019, 98, 1925–1933. [Google Scholar] [CrossRef]

- Zou, Y.; Shi, H.; Chen, X.; Xu, P.; Jiang, D.; Xu, W.; Wang, D. Modifying the structure, emulsifying and rheological properties of water-soluble protein from chicken liver by low-frequency ultrasound treatment. Int. J. Biol. Macromol. 2019, 139, 810–817. [Google Scholar] [CrossRef]

- Karra, S.; Sebii, H.; Bouaziz, M.A.; Blecker, C.; Danthine, S.; Attia, H.; Besbes, S. Effect of sonication pretreatment on physicochemical, surface, thermal, and functional properties of fibro-proteic extracts from male date palm flowers. J. Food Process. Preserv. 2020, 44, e14963. [Google Scholar] [CrossRef]

- Resendiz-Vazquez, J.A.; Ulloa, J.A.; Urias-Silvas, J.E.; Bautista-Rosales, P.U.; Ramirez-Ramirez, J.C.; Rosas-Ulloa, P.; Gonzalez-Torres, L. Effect of high-intensity ultrasound on the technofunctional properties and structure of jackfruit (Artocarpus heterophyllus) seed protein isolate. Ultrason. Sonochem. 2017, 37, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Pan, Z.; Shen, K.; Cai, X.; Zheng, B.; Miao, S. Influence of ultrasound-assisted alkali treatment on the structural properties and functionalities of rice protein. J. Cereal Sci. 2018, 79, 204–209. [Google Scholar] [CrossRef]

- Zhao, Y.; Wen, C.; Feng, Y.; Zhang, J.; He, Y.; Duan, Y.; Zhang, H.; Ma, H. Effects of ultrasound-assisted extraction on the structural, functional and antioxidant properties of Dolichos lablab L. Protein. Process. Biochem. 2021, 101, 274–284. [Google Scholar] [CrossRef]

- Stathopulos, P.B.; Scholz, G.A.; Hwang, Y.M.; Rumfeldt, J.A.; Lepock, J.R.; Meiering, E.M. Sonication of proteins causes formation of aggregates that resemble amyloid. Protein Sci. 2004, 13, 3017–3027. [Google Scholar] [CrossRef]

- Ren, X.e.; Li, C.; Yang, F.; Huang, Y.; Huang, C.; Zhang, K.; Yan, L. Comparison of hydrodynamic and ultrasonic cavitation effects on soy protein isolate functionality. J. Food Eng. 2020, 265, 109697. [Google Scholar] [CrossRef]

- Hu, H.; Li-Chan, E.C.Y.; Wan, L.; Tian, M.; Pan, S. The effect of high intensity ultrasonic pre-treatment on the properties of soybean protein isolate gel induced by calcium sulfate. Food Hydrocoll. 2013, 32, 303–311. [Google Scholar] [CrossRef]

- Chandrapala, J.; Zisu, B.; Palmer, M.; Kentish, S.; Ashokkumar, M. Effects of ultrasound on the thermal and structural characteristics of proteins in reconstituted whey protein concentrate. Ultrason. Sonochem. 2011, 18, 951–957. [Google Scholar] [CrossRef]

- Amiri, A.; Sharifian, P.; Soltanizadeh, N. Application of ultrasound treatment for improving the physicochemical, functional and rheological properties of myofibrillar proteins. Int. J. Biol. Macromol. 2018, 111, 139–147. [Google Scholar] [CrossRef]

- Kahraman, O.; Petersen, G.E.; Fields, C. Physicochemical and Functional Modifications of Hemp Protein Concentrate by the Application of Ultrasonication and pH Shifting Treatments. Foods 2022, 11, 587. [Google Scholar] [CrossRef]

- Cui, Q.; Wang, L.; Wang, G.; Zhang, A.; Wang, X.; Jiang, L. Ultrasonication effects on physicochemical and emulsifying properties of Cyperus esculentus seed (tiger nut) proteins. LWT 2021, 142, 110979. [Google Scholar] [CrossRef]

- Xue, F.; Zhu, C.; Liu, F.; Wang, S.; Liu, H.; Li, C. Effects of high-intensity ultrasound treatment on functional properties of plum (Pruni domesticae semen) seed protein isolate. J. Sci. Food Agric. 2018, 98, 5690–5699. [Google Scholar] [CrossRef]

- Paglarini, C.S.; Martini, S.; Pollonio, M.A.R. Physical properties of emulsion gels formulated with sonicated soy protein isolate. Int. J. Food Sci. Technol. 2019, 54, 451–459. [Google Scholar] [CrossRef]

- Saricaoglu, F.T. Application of high-pressure homogenization (HPH) to modify functional, structural and rheological properties of lentil (Lens culinaris) proteins. Int. J. Biol. Macromol. 2020, 144, 760–769. [Google Scholar] [CrossRef] [PubMed]

- Sebii, H.; Karra, S.; Blecker, C.; Karoui, R.; Attia, H.; Besbes, S. Effect of sonication and succinylation on rheological properties and secondary structures of date palm pollen protein concentrate. Rheol. Acta 2021, 60, 543–551. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Lelas, V.; Mason, T.J.; Krešić, G.; Badanjak, M. Physical properties of ultrasound treated soy proteins. J. Food Eng. 2009, 93, 386–393. [Google Scholar] [CrossRef]

- Xiong, W.; Wang, Y.; Zhang, C.; Wan, J.; Shah, B.R.; Pei, Y.; Zhou, B.; Li, J.; Li, B. High intensity ultrasound modified ovalbumin: Structure, interface and gelation properties. Ultrason. Sonochem. 2016, 31, 302–309. [Google Scholar] [CrossRef]

| Sample | α-Helix (%) | β-Sheet (%) | β-Turn (%) | Random Coil (%) |

|---|---|---|---|---|

| C | 45.58 | 20.45 | 17.65 | 16.32 |

| US−2 | 35.53 | 26.55 | 19.11 | 18.81 |

| US−4 | 21.15 | 33.82 | 20.91 | 24.12 |

| US−6 | 16.80 | 34.53 | 21.72 | 26.95 |

| Properties | C | US−2 | US−4 | US−6 |

|---|---|---|---|---|

| Protein solubility (%) | 54.72 ± 2.31 c | 56.94 ± 1.33 c | 66.29 ± 3.88 b | 80.73 ± 3.29 a |

| Surface hydrophobicity (H0) | 66.72 ± 2.18 c | 93.88 ± 3.42 ab | 100.61 ± 3.92 a | 89.48 ± 2.41 b |

| Free −SH group (µmol/g) | 4.56 ± 0.04 c | 4.76 ± 0.03 c | 5.22 ± 0.08 b | 7.04 ± 0.34 a |

| Total −SH group (µmol/g) | 12.75 ± 0.79 c | 12.99 ± 0.28 c | 13.75 ± 0.19 b | 14.94 ± 0.39 a |

| EAI (m2/g) | 31.42 ± 0.51 c | 33.68 ± 0.61 b | 37.49 ± 0.73 a | 38.85 ± 0.8 a |

| ESI (min) | 51.09 ± 2.18 c | 60.71 ± 1.62 b | 65.94 ± 2.19 b | 77.01 ± 3.62 a |

| FC (%) | 83.95 ± 5.45 d | 113.34 ± 5.17 c | 160.19 ± 3.57 a | 151.34 ± 4.21 b |

| FS (%) | 20.7 ± 2.72 c | 30.46 ± 2.48 b | 79.17 ± 4.72 a | 86.13 ± 3.2 a |

| Water-holding capacity (g water/g) | 1.83 ± 0.09 c | 1.9 ± 0.18 bc | 2.4 ± 0.16 a | 2.02 ± 0.08 b |

| Oil-holding capacity (g oil/g) | 1.39 ± 0.13 b | 1.46 ± 0.13 ab | 1.58 ± 0.12 a | 1.61 ± 0.12 a |

| (×10−2 Pasn) | R2 | (×10−2 Pasn) | R2 | |||

|---|---|---|---|---|---|---|

| C | 9.61 | 1.17 | 0.972 | 0.44 | 1.52 | 0.994 |

| US-2 | 1.96 | 2.01 | 0.970 | 0.08 | 2.27 | 0.991 |

| US-4 | 40.65 | 0.99 | 0.990 | 0.61 | 1.89 | 0.994 |

| US-6 | 1.90 | 1.63 | 0.991 | 0.49 | 1.65 | 0.991 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gul, O.; Saricaoglu, F.T.; Atalar, I.; Gul, L.B.; Tornuk, F.; Simsek, S. Structural Characterization, Technofunctional and Rheological Properties of Sesame Proteins Treated by High-Intensity Ultrasound. Foods 2023, 12, 1791. https://doi.org/10.3390/foods12091791

Gul O, Saricaoglu FT, Atalar I, Gul LB, Tornuk F, Simsek S. Structural Characterization, Technofunctional and Rheological Properties of Sesame Proteins Treated by High-Intensity Ultrasound. Foods. 2023; 12(9):1791. https://doi.org/10.3390/foods12091791

Chicago/Turabian StyleGul, Osman, Furkan Turker Saricaoglu, Ilyas Atalar, Latife Betul Gul, Fatih Tornuk, and Senay Simsek. 2023. "Structural Characterization, Technofunctional and Rheological Properties of Sesame Proteins Treated by High-Intensity Ultrasound" Foods 12, no. 9: 1791. https://doi.org/10.3390/foods12091791