Effects of Tea Polyphenol and Its Combination with Other Antioxidants Added during the Extraction Process on Oxidative Stability of Antarctic Krill (Euphausia superba) Oil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

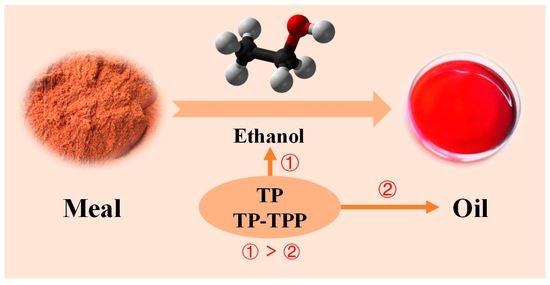

2.2. The Preparation of Krill Oil Samples Added with Antioxidants during the Extraction Process

2.3. The Preparation of Krill Oil Samples Added with Antioxidants after the Extraction Process

2.4. Accelerated Storage Experiment

2.5. Peroxide Value

2.6. Thiobarbituric Acid Reactive Substances

2.7. Fatty Acid Composition

2.8. Lipid Class Composition

2.9. Statistical Analysis

3. Results

3.1. Selection of the Most Effective Single Antioxidant Added during the Extraction Process

3.2. Selection of the Most Effective Composite Antioxidant Added during the Extraction Process

3.3. Comparison of the Accelerated Oxidative Stability of Krill Oils Added with Antioxidants at Different Time Points

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tou, J.C.; Jaczynski, J.; Chen, Y.C. Krill for human consumption: Nutritional value and potential health benefits. Nutr. Rev. 2007, 65, 63–77. [Google Scholar] [CrossRef] [PubMed]

- Ulven, S.M.; Kirkhus, B.; Lamglait, A.; Basu, S.; Elind, E.; Haider, T.; Berge, K.; Vik, H.; Pedersen, J.I.J. Metabolic effects of krill oil are essentially similar to those of fish oil but at lower dose of EPA and DHA, in healthy volunteers. Lipids 2011, 46, 37–46. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramprasath, V.R.; Eyal, I.; Zchut, S.; Jones, P. Enhanced increase of omega-3 index in healthy individuals with response to 4-week n-3 fatty acid supplementation from krill oil versus fish oil. Lipids Health Dis. 2013, 12, 178. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, D.Y.; Liu, Y.X.; Xu, Z.L.; Yin, F.W.; Song, L.; Wan, X.L.; Song, Y.K.; Zhu, B.W. Effects of long-term intake of Antarctic krill oils on artery blood pressure in spontaneously hypertensive rats. J. Sci. Food Agric. 2016, 97, 1143–1148. [Google Scholar] [CrossRef] [PubMed]

- Tandy, S.; Chung, R.W.S.; Wat, E.; Kamili, A.; Berge, K.; Griinari, M.; Cohn, J.S. Dietary krill oil supplementation reduces hepatic steatosis, glycemia, and hypercholesterolemia in high-fat-fed mice. J. Agric. Food Chem. 2009, 57, 9339–9345. [Google Scholar] [CrossRef]

- Konagai, C.; Yanagimoto, H.; Li, T.; Aging, K. Effects of krill oil containing n-3 polyunsaturated fatty acids in phospholipid form on human brain function: A randomized controlled trial in healthy elderly volunteers. Clin. Interv. Aging 2013, 8, 1247–1257. [Google Scholar] [CrossRef] [Green Version]

- Grimstad, T.; Bjørndal, B.; Cacabelos, D.; Aasprong, O.G.; Janssen, E.A.M.; Omdal, R.; Svardal, A.; Hausken, T.; Bohov, P.; Porterootin, M.; et al. Dietary supplementation of krill oil attenuates inflammation and oxidative stress in experimental ulcerative colitis in rats. Scand. J. Gastroenterol. 2012, 47, 49–58. [Google Scholar] [CrossRef]

- Fosshaug, L.E.; Berge, R.K.; Beitnes, J.O.; Berge, K.; Vik, H.; Aukrust, P.; Gullestad, L.; Vinge, L.E.; Øie, E. Krill oil attenuates left ventricular dilatation after myocardial infarction in rats. Lipids Health Dis. 2011, 10, 245. [Google Scholar] [CrossRef] [Green Version]

- Zhao, G.H.; Hu, Y.Y.; Liu, Z.Y.; Xie, H.K.; Zhang, M.; Zheng, R.; Qin, L.; Yin, F.W.; Zhou, D.Y. Simultaneous quantification of 24 aldehydes and ketones in oysters (Crassostrea gigas) with different thermal processing procedures by HPLC-electrospray tandem mass spectrometry. Food Res. Int. 2021, 147, 110559. [Google Scholar] [CrossRef] [PubMed]

- Lise Halvorsen, B.; Blomhoff, R.J. Determination of lipid oxidation products in vegetable oils and marine omega-3 supplements. Food Nutr. Res. 2011, 55, 5792. [Google Scholar] [CrossRef]

- Kazuo, M. Prevention of fish oil oxidation. J. Oleo Sci. 2019, 68, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yin, F.W.; Zhou, D.Y.; Xi, M.; Zhao, Q.; Liu, Z.; Li, D.Y.; Dong, X.; Zhu, B.W. Influence of storage conditions on the stability of phospholipids-rich krill (Euphausia superba) oil. J. Food Process. Preserv. 2016, 40, 1247–1255. [Google Scholar] [CrossRef]

- Thomsen, B.R.; Haugsgjerd, B.O.; Griinari, M.; Lu, H.F.S.; Bruheim, I.; Vogt, G.; Oterhals, Å.; Jacobsen, C. Investigation of oxidative degradation and non-enzymatic browning reactions in krill and fish oils. Eur. J. Lipid Sci. Technol. 2013, 115, 1357–1366. [Google Scholar] [CrossRef]

- Choe, E.; Min, D.B. Mechanisms and factors for edible oil oxidation. Compr. Rev. Food Sci. Food Saf. 2006, 5, 169–186. [Google Scholar] [CrossRef]

- Hraš, A.R.; Hadolin, M.; Knez, Ž.; Bauman, D. Comparison of antioxidative and synergistic effects of rosemary extract with α-tocopherol, ascorbyl palmitate and citric acid in sunflower oil. Food Chem. 2000, 71, 229–233. [Google Scholar] [CrossRef]

- Im, S.; Nam, T.G.; Lee, S.G.; Kim, Y.J.; Chun, O.K.; Kim, D.O. Additive antioxidant capacity of vitamin C and tocopherols in combination. Food Sci. Biotechnol. 2014, 23, 693–699. [Google Scholar] [CrossRef]

- Omar, K.A.; Shan, L.; Wang, Y.L.; Wang, X. Stabilizing flaxseed oil with individual antioxidants and their mixtures. Eur. J. Lipid Sci. Technol. 2010, 112, 1003–1011. [Google Scholar] [CrossRef]

- Rudnik, E.; Szczucinska, A.; Gwardiak, H.; Szulc, A.; Winiarska, A. Comparative studies of oxidative stability of linseed oil. Thermochim. Acta 2001, 370, 135–140. [Google Scholar] [CrossRef]

- Xie, D.; Gong, M.; Wei, W.; Jin, J.; Wang, X.; Wang, X.; Jin, Q. Antarctic krill (Euphausia superba) oil: A comprehensive review of chemical composition, extraction technologies, health benefits, and current applications. Compr. Rev. Food Sci. Food Saf. 2019, 18, 514–534. [Google Scholar] [CrossRef] [Green Version]

- Gigliotti, J.C.; Davenport, M.P.; Beamer, S.K.; Tou, J.C.; Jaczynski, J. Extraction and characterisation of lipids from Antarctic krill (Euphausia superba). Food Chem. 2011, 125, 1028–1036. [Google Scholar] [CrossRef]

- Chinese Standard GB 2760-2014; Food Safety National Standards-Standards for Uses of Food Additive. China Standards Press of China: Beijing, China, 2014.

- Abuzaytoun, R.; Budge, S.; Hansen, L.T.; MacKinnon, S. Modification of the ferrous oxidation-xylenol orange method for determination of peroxide value in highly pigmented sea cucumber viscera lipid. J. Am. Oil Chem. Soc. 2020, 97, 509–516. [Google Scholar] [CrossRef]

- John, L.; Cornforth, D.; Carpenter, C.E.; Sorheim, O.; Pettee, B.C.; Whittier, D.R. Color and thiobarbituric acid values of cooked top sirloin steaks packaged in modified atmospheres of 80% oxygen, or 0.4% carbon monoxide, or vacuum. Meat Sci. 2005, 69, 441–449. [Google Scholar] [CrossRef]

- Xie, H.K.; Yin, F.W.; Liu, Z.; Hu, Y.Y.; Yu, M.M.; Zhou, D.Y.; Zhu, B.W. Oxidation kinetics of polyunsaturated fatty acids esterified into triacylglycerols and phospholipids in dried scallop (Argopecten irradians) adductor muscles during storage. Food Funct. 2020, 11, 2349–2357. [Google Scholar] [CrossRef]

- Czerniak, A.; Kubiak, P.; Białas, W.; Jankowski, T. Improvement of oxidative stability of menhaden fish oil by microencapsulation within biocapsules formed of yeast cells. J. Food Eng. 2015, 167, 2–11. [Google Scholar] [CrossRef]

- Yin, F.W.; Liu, X.Y.; Fan, X.R.; Zhou, D.Y.; Xu, W.S.; Zhu, B.W.; Murata, Y.Y. Extrusion of Antarctic krill (Euphausia superba) meal and its effect on oil extraction. Int. J. Food Sci. Technol. 2015, 50, 633–639. [Google Scholar] [CrossRef]

- Lu, T.; Shen, Y.; Wang, J.H.; Xie, H.K.; Wang, Y.F.; Zhao, Q.; Zhou, D.Y.; Shahidi, F. Improving oxidative stability of flaxseed oil with a mixture of antioxidants. J. Food Process. Preserv. 2019, 44, 14355. [Google Scholar] [CrossRef]

- Ohkawa, H.; Ohishi, N.; Yagi, K. Assay for lipid peroxides in animal tissues by thiobarbituric acid reaction. Anal. Biochem. 1979, 95, 351–358. [Google Scholar] [CrossRef] [PubMed]

- Shahidi, F.; Zhong, Y. Lipid oxidation and improving the oxidative stability. Chem. Soc. Rev. 2010, 39, 4067–4079. [Google Scholar] [CrossRef]

- Bai, Z.; Yu, R.; Li, J.; Wang, N.; Wang, Y.; Niu, L.; Zhang, Y. Application of several novel natural antioxidants to inhibit oxidation of tree peony seed oil. Cyta J. Food 2018, 16, 1071–1078. [Google Scholar] [CrossRef]

- Pei, X.C.; Yin, F.W.; Zhong, X.; Liu, H.L.; Song, L.; Zhao, G.H.; Wang, Y.F.; Zhou, D.Y. Effects of different antioxidants and their combinations on the oxidative stability of DHA algae oil and walnut oil. Food Sci. Nutr. 2022, 10, 2804–2812. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; McClements, D.J.; Decker, E.A. Minor components in food oils: A critical review of their roles on lipid oxidation chemistry in bulk oils and emulsions. Crit. Rev. Food Sci. Nutr. 2011, 51, 901–916. [Google Scholar] [CrossRef]

- Laguerre, M.; Bayrasy, C.; Panya, A.; Weiss, J.; McClements, D.J.; Lecomte, J.; Decker, E.A.; Villeneuve, P. What makes good antioxidants in lipid-based systems? the next theories beyond the polar paradox. Crit. Rev. Food Sci. Nutr. 2015, 55, 183–201. [Google Scholar] [CrossRef]

- Villeneuve, P.; BourlieuLacanal, C.; Durand, E.; Lecomte, J.; McClements, D.J.; Decker, E.A. Lipid oxidation in emulsions and bulk oils: A review of the importance of micelles. Crit. Rev. Food Sci. Nutr. 2021, 99, 1–41. [Google Scholar] [CrossRef]

- Shen, Y.; Zheng, L.; Peng, Y.; Zhu, X.; Liu, F.; Yang, X.; Li, H. Physicochemical, antioxidant and anticancer characteristics of seed oil from three Chenopodium quinoa Genotypes. Molecules 2022, 27, 2453. [Google Scholar] [CrossRef]

- Nehdi, I.A.; Sbihi, H.M.; Tan, C.P.; Al-Resayes, S.I.; Rashid, U.; Al-Misned, F.A.; El-Serehy, H.A. Chemical composition, oxidative stability, and antioxidant activity of allium Ampeloprasum L. (wild leek) seed oil. J. Oleo Sci. 2020, 69, 413–421. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Wang, J.; Shahidi, F. Chemical characteristics of cold-pressed blackberry, black raspberry, and blueberry seed oils and the role of the minor components in their oxidative stability. J. Agric. Food Chem. 2016, 64, 5410–5416. [Google Scholar] [CrossRef]

| FA | Con | VC | TP | AP | VE | AOB | TPP | RE |

|---|---|---|---|---|---|---|---|---|

| C14:0 | 13.61 ± 0.03a | 13.68 ± 0.12a | 13.42 ± 0.29a | 13.62 ± 0.28a | 13.41 ± 0.11a | 13.65 ± 0.28a | 13.68 ± 0.18a | 13.38 ± 0.14a |

| C16:0 | 28.75 ± 0.06a | 27.96 ± 0.31a | 26.31 ± 0.10a | 28.37 ± 0.31a | 27.34 ± 0.09a | 27.25 ± 0.23a | 27.14 ± 0.23a | 27.13 ± 0.16a |

| C16:1 | 5.10 ± 0.10a | 5.11 ± 0.12c | 5.12 ± 0.09e | 5.01 ± 0.04b | 5.22 ± 0.20d | 5.11 ± 0.09d | 5.08 ± 0.09d | 5.20 ± 0.09d |

| C17:0 | 3.43 ± 0.10ab | 3.52 ± 0.08a | 3.19 ± 0.10c | 3.34 ± 0.09abc | 3.42 ± 0.02a | 3.30 ± 0.04bc | 3.22 ± 0.12c | 3.31 ± 0.11bc |

| C18:0 | 2.43 ± 0.13a | 2.29 ± 0.04a | 2.35 ± 0.11a | 2.58 ± 0.24a | 2.39 ± 0.15a | 2.43 ± 0.11a | 2.47 ± 0.18a | 2.36 ± 0.02a |

| C18:2 n-6c | 5.27 ± 0.17a | 5.31 ± 0.17a | 5.72 ± 0.19b | 5.50 ± 0.01ab | 5.51 ± 0.09ab | 5.63 ± 0.24b | 5.56 ± 0.16ab | 5.64 ± 0.18b |

| C18:1 n-9c | 20.85 ± 0.12a | 20.47 ± 0.18abc | 20.15 ± 0.12c | 20.43 ± 0.35bc | 20.62 ± 0.13ab | 20.51 ± 0.21abc | 18.22 ± 0.20d | 20.26 ± 0.19bc |

| C20:0 | 1.52 ± 0.07ab | 1.51 ± 0.04ab | 1.60 ± 0.01ab | 1.47 ± 0.12a | 1.49 ± 0.04ab | 1.56 ± 0.16ab | 1.78 ± 0.06c | 1.66 ± 0.06bc |

| C20:1 | 1.27 ± 0.08a | 1.31 ± 0.10a | 1.30 ± 0.05a | 1.21 ± 0.12a | 1.39 ± 0.09a | 1.36 ± 0.04a | 1.31 ± 0.01a | 1.25 ± 0.05a |

| C18:3 n-3 | 1.32 ± 0.04a | 1.42 ± 0.06ab | 1.53 ± 0.09c | 1.40 ± 0.02ab | 1.49 ± 0.06bc | 1.53 ± 0.06c | 1.46 ± 0.04bc | 1.40 ± 0.05ab |

| C20:2 | 1.25 ± 0.04a | 1.46 ± 0.09b | 1.56 ± 0.11b | 1.41 ± 0.11ab | 1.41 ± 0.06ab | 1.40 ± 0.06ab | 1.48 ± 0.15b | 1.40 ± 0.14ab |

| C20:5 n-3 | 10.60 ± 0.25a | 11.05 ± 0.16abc | 11.78 ± 0.46c | 10.84 ± 0.02ab | 10.99 ± 0.21abc | 11.29 ± 0.16bc | 13.24 ± 0.38d | 11.37 ± 0.26c |

| C22:6 n-3 | 4.60 ± 0.08a | 4.92 ± 0.15ab | 5.97 ± 0.23d | 4.79 ± 0.10a | 5.33 ± 0.18bc | 5.38 ± 0.39c | 5.36 ± 0.15c | 5.64 ± 0.31cd |

| SFA | 49.73 ± 0.20a | 48.95 ± 0.41abc | 47.04 ± 0.17b | 49.38 ± 0.19b | 48.05 ± 0.21ab | 48.19 ± 0.70abc | 48.29 ± 0.29d | 47.84 ± 0.46bc |

| MUFA | 27.22 ± 0.15a | 26.90 ± 0.06abc | 26.60 ± 0.11c | 26.66 ± 0.27c | 27.23 ± 0.16ab | 26.98 ± 0.26abc | 24.61 ± 0.17d | 26.71 ± 0.16bc |

| PUFA | 23.04 ± 0.30a | 24.15 ± 0.38bc | 26.36 ± 0.28g | 23.96 ± 0.11b | 24.73 ± 0.35cd | 25.23 ± 0.32de | 27.11 ± 0.41h | 25.45 ± 0.38f |

| FA | Con | TP | TP-VC | TP-AP | TP-VE | TP-AOB | TP-TPP | TP-RE |

|---|---|---|---|---|---|---|---|---|

| C14:0 | 13.65 ± 0.08a | 13.25 ± 0.14b | 13.65 ± 0.11a | 13.39 ± 0.06ab | 13.54 ± 0.13ab | 13.51 ± 0.25ab | 13.46 ± 0.22ab | 13.45 ± 0.15ab |

| C16:0 | 28.64 ± 0.17a | 26.87 ± 0.17de | 27.78 ± 0.11b | 27.25 ± 0.25cd | 27.53 ± 0.21bc | 27.23 ± 0.24cd | 26.74 ± 0.23e | 27.23 ± 0.23cd |

| C16:1 | 5.22 ± 0.21ab | 4.98 ± 0.05c | 5.27 ± 0.06a | 5.26 ± 0.08a | 5.27 ± 0.14a | 5.17 ± 0.11abc | 5.04 ± 0.03bc | 5.11 ± 0.07abc |

| C17:0 | 3.36 ± 0.13ab | 3.19 ± 0.08cd | 3.38 ± 0.07ab | 3.39 ± 0.07ab | 3.47 ± 0.13a | 3.30 ± 0.07abc | 3.06 ± 0.07d | 3.22 ± 0.05bc |

| C18:0 | 2.37 ± 0.20a | 2.34 ± 0.07ab | 2.38 ± 0.07a | 2.37 ± 0.03a | 2.34 ± 0.10ab | 2.35 ± 0.04a | 2.15 ± 0.12b | 2.38 ± 0.10a |

| C18:2 n-6c | 5.30 ± 0.20a | 5.91 ± 0.17e | 5.41 ± 0.08ab | 5.64 ± 0.09bcd | 5.49 ± 0.03abc | 5.73 ± 0.15cde | 5.56 ± 0.12abc | 5.82 ± 0.16de |

| C18:1 n-9c | 20.80 ± 0.21a | 19.95 ± 0.11c | 20.67 ± 0.24a | 20.78 ± 0.10a | 20.67 ± 0.20a | 20.32 ± 0.22b | 18.39 ± 0.20d | 20.05 ± 0.08bc |

| C20:0 | 1.54 ± 0.05a | 1.54 ± 0.04a | 1.51 ± 0.10a | 1.50 ± 0.05a | 1.47 ± 0.06a | 1.50 ± 0.09a | 1.81 ± 0.14b | 1.50 ± 0.10a |

| C20:1 | 1.32 ± 0.03b | 1.37 ± 0.09ab | 1.41 ± 0.06ab | 1.33 ± 0.04b | 1.46 ± 0.09a | 1.33 ± 0.03b | 1.16 ± 0.06c | 1.32 ± 0.06b |

| C18:3 n-3 | 1.37 ± 0.05b | 1.44 ± 0.01ab | 1.40 ± 0.04ab | 1.51 ± 0.06a | 1.40 ± 0.04ab | 1.45 ± 0.01ab | 1.08 ± 0.03c | 1.47 ± 0.14ab |

| C20:2 | 1.28 ± 0.05a | 1.55 ± 0.10d | 1.43 ± 0.09bcd | 1.36 ± 0.03abc | 1.39 ± 0.01bc | 1.50 ± 0.11cd | 1.33 ± 0.05a | 1.41 ± 0.11bcd |

| C20:5 n-3 | 10.55 ± 0.30a | 11.74 ± 0.31c | 10.94 ± 0.17ab | 11.08 ± 0.18b | 11.06 ± 0.10b | 11.28 ± 0.24bc | 14.26 ± 0.49d | 11.29 ± 0.24bc |

| C22:6 n-3 | 4.60 ± 0.14a | 5.87 ± 0.24d | 4.77 ± 0.09ab | 5.13 ± 0.16bc | 4.91 ± 0.16ab | 5.33 ± 0.33c | 6.06 ± 0.16d | 5.74 ± 0.28d |

| SFA | 49.56 ± 0.31a | 47.18 ± 0.38d | 48.70 ± 0.14b | 47.90 ± 0.19c | 48.35 ± 0.22bc | 47.89 ± 0.37c | 47.22 ± 0.57d | 47.79 ± 0.50cd |

| MUFA | 27.34 ± 0.15a | 26.30 ± 0.25c | 27.35 ± 0.22a | 27.37 ± 0.08a | 27.40 ± 0.18a | 26.82 ± 0.14b | 24.59 ± 0.27d | 26.48 ± 0.16c |

| PUFA | 23.10 ± 0.32a | 26.51 ± 0.51e | 23.95 ± 0.31b | 24.73 ± 0.26bc | 24.26 ± 0.21b | 25.29 ± 0.48cd | 28.19 ± 0.70f | 25.73 ± 0.50d |

| FA | 0-Day | 8-Day | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Con | TP-D | TP-TPP-D | TP-A | TP-TPP-A | Con | TP-D | TP-TPP-D | TP-A | TP-TPP-A | |

| C14:0 | 13.78 ± 0.28A | 14.29 ± 1.09A | 13.46 ± 0.55A | 14.21 ± 0.59A | 13.20 ± 0.49A | 14.53 ± 0.05a | 14.46 ± 0.47a | 14.56 ± 0.30a | 14.33 ± 0.28a | 14.73 ± 0.38a |

| C16:0 | 28.89 ± 0.26A | 25.64 ± 0.91C | 26.61 ± 0.32BC | 27.06 ± 0.93B | 27.28 ± 0.26B | 29.40 ± 0.33a | 28.11 ± 0.41b | 26.05 ± 0.10d | 29.06 ± 0.55a | 27.13 ± 0.22c |

| C16:1 | 5.18 ± 0.09A | 5.85 ± 0.24B | 5.09 ± 0.52A | 5.40 ± 0.29AB | 5.42 ± 0.12AB | 5.67 ± 0.08a | 5.40 ± 0.46a | 5.63 ± 0.10a | 5.41 ± 0.32a | 5.18 ± 0.22a |

| C17:0 | 3.26 ± 0.11AB | 3.05 ± 0.41A | 3.01 ± 0.18A | 3.61 ± 0.23B | 3.11 ± 0.04A | 3.75 ± 0.18a | 3.48 ± 0.06b | 3.87 ± 0.04a | 3.66 ± 0.11ab | 3.48 ± 0.15b |

| C18:0 | 2.46 ± 0.15A | 2.21 ± 0.12BC | 2.17 ± 0.06C | 2.37 ± 0.08AB | 2.28 ± 0.07ABC | 2.89 ± 0.06a | 2.40 ± 0.16b | 2.47 ± 0.05b | 2.36 ± 0.25b | 2.63 ± 0.12ab |

| C18:2 n-6c | 5.43 ± 0.01A | 5.72 ± 0.20AB | 5.66 ± 0.10AB | 5.85 ± 0.25B | 5.75 ± 0.30AB | 4.97 ± 0.08a | 5.56 ± 0.12bc | 6.08 ± 0.29d | 5.36 ± 0.31ab | 5.96 ± 0.25cd |

| C18:1 n-9c | 20.47 ± 0.44A | 19.04 ± 0.46BC | 18.39 ± 0.46C | 19.14 ± 0.63BC | 19.56 ± 0.34B | 20.73 ± 0.22a | 19.58 ± 1.29b | 18.45 ± 0.09b | 19.32 ± 0.39b | 19.48 ± 0.32b |

| C20:0 | 1.51 ± 0.11A | 1.92 ± 0.31B | 1.73 ± 0.07AB | 1.56 ± 0.12A | 1.77 ± 0.02AB | 1.97 ± 0.05a | 1.84 ± 0.37a | 1.96 ± 0.10a | 1.79 ± 0.09a | 1.83 ± 0.11a |

| C20:1 | 1.32 ± 0.01A | 1.25 ± 0.13A | 1.11 ± 0.08B | 1.33 ± 0.05A | 1.34 ± 0.05A | 2.17 ± 0.10a | 1.25 ± 0.09b | 1.35 ± 0.02b | 1.34 ± 0.20b | 1.44 ± 0.01b |

| C18:3 n-3 | 1.25 ± 0.12A | 1.07 ± 0.11A | 1.09 ± 0.16A | 1.05 ± 0.05A | 1.16 ± 0.16A | 0.91 ± 0.08a | 1.19 ± 0.12b | 1.00 ± 0.05a | 0.99 ± 0.06a | 1.01 ± 0.06a |

| C20:2 | 1.25 ± 0.04AB | 1.32 ± 0.19AB | 1.17 ± 0.10A | 1.16 ± 0.17A | 1.47 ± 0.18B | 1.00 ± 0.06a | 1.20 ± 0.03b | 1.05 ± 0.09a | 1.38 ± 0.09c | 1.29 ± 0.09bc |

| C20:5 n-3 | 10.63 ± 0.26A | 12.36 ± 0.19B | 14.08 ± 0.13C | 12.40 ± 0.46B | 12.14 ± 0.50B | 8.23 ± 0.25a | 11.02 ± 0.04b | 12.63 ± 0.91c | 10.04 ± 0.78b | 10.98 ± 0.52b |

| C22:6 n-3 | 4.57 ± 0.01A | 6.28 ± 0.66B | 6.46 ± 0.77B | 4.87 ± 0.28A | 5.53 ± 0.44AB | 3.78 ± 0.24a | 4.52 ± 0.47b | 4.91 ± 0.25b | 4.96 ± 0.58b | 4.88 ± 0.29b |

| SFA | 49.90 ± 0.70A | 47.11 ± 0.84B | 46.96 ± 0.12B | 48.94 ± 0.06A | 47.64 ± 0.67B | 52.54 ± 0.36a | 50.29 ± 0.83bc | 48.91 ± 0.41d | 51.20 ± 0.59b | 49.79 ± 0.71cd |

| MUFA | 26.97 ± 0.35A | 26.14 ± 0.38AB | 24.59 ± 0.99C | 25.86 ± 0.36B | 26.31 ± 0.29AB | 28.57 ± 0.17a | 26.23 ± 0.96b | 25.43 ± 0.20b | 26.07 ± 0.25b | 26.10 ± 0.19b |

| PUFA | 23.13 ± 0.35A | 26.75 ± 0.71C | 28.45 ± 1.01D | 25.20 ± 0.42B | 26.05 ± 0.79BC | 18.89 ± 0.38a | 23.49 ± 0.44bc | 25.66 ± 0.53d | 22.73 ± 0.76b | 24.11 ± 0.89c |

| Time | Sample Names | TG | FFA | DG | Cho | MG | PL |

|---|---|---|---|---|---|---|---|

| 0-day | Con | 44.21 ± 0.24A | 0.66 ± 0.01D | 2.24 ± 0.18A | 1.68 ± 0.07A | 0.31 ± 0.02A | 50.90 ± 0.36B |

| TP-D | 44.59 ± 0.18AB | 0.60 ± 0.01B | 2.48 ± 0.20A | 1.78 ± 0.06A | 0.32 ± 0.04A | 50.23 ± 0.08A | |

| TP-TPP-D | 44.47 ± 0.24AB | 0.53 ± 0.01A | 2.48 ± 0.06A | 1.84 ± 0.14A | 0.35 ± 0.02A | 50.32 ± 0.38A | |

| TP-A | 44.66 ± 0.13B | 0.62 ± 0.01C | 2.22 ± 0.27A | 1.83 ± 0.12A | 0.35 ± 0.01A | 50.32 ± 0.31A | |

| TP-TPP-A | 44.44 ± 0.18AB | 0.61 ± 0.02BC | 2.23 ± 0.26A | 1.85 ± 0.14A | 0.32 ± 0.02A | 50.54 ± 0.18AB | |

| 8-day | Con | 44.47 ± 0.42a | 0.85 ± 0.01d | 2.73 ± 0.24b | 1.82 ± 0.16a | 0.34 ± 0.01a | 49.80 ± 0.40a |

| TP-D | 44.72 ± 0.15a | 0.73 ± 0.01b | 2.58 ± 0.21ab | 1.95 ± 0.06a | 0.34 ± 0.01a | 49.68 ± 0.03a | |

| TP-TPP-D | 44.53 ± 0.08a | 0.68 ± 0.02a | 2.71 ± 0.08b | 1.80 ± 0.23a | 0.34 ± 0.01a | 49.94 ± 0.23a | |

| TP-A | 44.54 ± 0.36a | 0.77 ± 0.02c | 2.35 ± 0.05a | 1.80 ± 0.13a | 0.36 ± 0.03a | 50.18 ± 0.29a | |

| TP-TPP-A | 44.52 ± 0.10a | 0.76 ± 0.01bc | 2.39 ± 0.11a | 1.94 ± 0.09a | 0.35 ± 0.01a | 50.04 ± 0.26a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Liu, F.; Luo, Y.; Zeng, X.; Pei, X.; Zhao, G.; Zhang, M.; Zhou, D.; Yin, F. Effects of Tea Polyphenol and Its Combination with Other Antioxidants Added during the Extraction Process on Oxidative Stability of Antarctic Krill (Euphausia superba) Oil. Foods 2022, 11, 3768. https://doi.org/10.3390/foods11233768

Wang Z, Liu F, Luo Y, Zeng X, Pei X, Zhao G, Zhang M, Zhou D, Yin F. Effects of Tea Polyphenol and Its Combination with Other Antioxidants Added during the Extraction Process on Oxidative Stability of Antarctic Krill (Euphausia superba) Oil. Foods. 2022; 11(23):3768. https://doi.org/10.3390/foods11233768

Chicago/Turabian StyleWang, Ziwei, Fujun Liu, Ying Luo, Xiangbo Zeng, Xuechen Pei, Guanhua Zhao, Min Zhang, Dayong Zhou, and Fawen Yin. 2022. "Effects of Tea Polyphenol and Its Combination with Other Antioxidants Added during the Extraction Process on Oxidative Stability of Antarctic Krill (Euphausia superba) Oil" Foods 11, no. 23: 3768. https://doi.org/10.3390/foods11233768