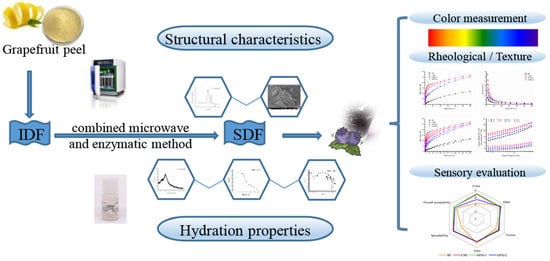

Physicochemical Characteristics of Soluble Dietary Fiber Obtained from Grapefruit Peel Insoluble Dietary Fiber and Its Effects on Blueberry Jam

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of SDF from Grapefruit Peel Insoluble Dietary Fiber (GP-IDF-SDF)

2.3. Monosaccharide Composition

2.4. Molecular Weight

2.5. Structural Characterization of GP-IDF-SDF

2.5.1. Scanning Electron Microscopy (SEM)

2.5.2. X-ray Diffraction (XRD)

2.5.3. Thermal Properties

2.5.4. Fourier Transfer-Infrared Spectroscopy (FT-IR)

2.6. Hydration Properties of GP-IDF-SDF

2.6.1. Water Holding Capacity (WHC)

2.6.2. Oil Holding Capacity (OHC)

2.6.3. Glucose Adsorption Capacity (GAC)

2.7. Formulation of Blueberry Jam

2.8. Color Measurement

2.9. Rheological Properties of Jam

2.9.1. Flow Sweep

2.9.2. Oscillatory Frequency Sweep

2.10. Texture Characteristics of Jam

2.11. Sensory Evaluation

2.12. Statistical Analysis

3. Results and Discussion

3.1. Monosaccharide Composition and Molecular Weight of GP-IDF-SDF

3.2. Structural Characterization of GP-IDF-SDF

3.2.1. Microstructure Properties

3.2.2. X-ray Diffraction and Thermal Properties

3.2.3. FT-IR Analysis

3.3. Functional Properties

3.4. Color Measurement of Jam

3.5. Rheological and Textural Properties of Jam

3.6. Sensory Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, W.; Hu, J.; Gao, H.; Chen, H.; Fang, X.; Mu, H.; Han, Y.; Liu, R. The potential cholesterol-lowering and prebiotic effects of bamboo shoot dietary fibers and their structural characteristics. Food Chem. 2020, 332, 127372. [Google Scholar] [CrossRef] [PubMed]

- Cassidy, Y.M.; Mcsorley, E.M.; Allsopp, P.J. Effect of soluble dietary fibre on postprandial blood glucose response and its potential as a functional food ingredient. J. Funct. Foods 2018, 46, 423–439. [Google Scholar] [CrossRef]

- Huang, S.; He, Y.; Zou, Y.; Liu, Z. Modification of insoluble dietary fibres in soya bean okara and their physicochemical properties. Int. J. Food Sci. Technol. 2015, 50, 2606–2613. [Google Scholar] [CrossRef]

- Lin, D.; Long, X.; Huang, Y.; Yang, Y.; Wu, Z.; Chen, H.; Zhang, Q.; Wu, D.; Qin, W.; Tu, Z. Effects of microbial fermentation and microwave treatment on the composition, structural characteristics, and functional properties of modified okara dietary fiber. LWT-Food Sci. Technol. 2020, 123, 109059. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, C.; Li, J.; Hussain, S.; Yan, S.; Wang, Q. Effects of extrusion on structural and physicochemical properties of soluble dietary fiber from nodes of lotus root. LWT-Food Sci. Technol. 2018, 93, 204–211. [Google Scholar] [CrossRef]

- Jia, M.; Chen, J.; Liu, X.; Xie, M.; Nie, S.; Chen, Y.; Xie, J.; Yu, Q. Structural characteristics and functional properties of soluble dietary fiber from defatted rice bran obtained through Trichoderma viride fermentation. Food Hydrocoll. 2019, 94, 468–474. [Google Scholar] [CrossRef]

- Huang, H.; Chen, J.; Chen, Y.; Xie, J.; Yu, Q. Modification of tea residue dietary fiber by high-temperature cooking assisted enzymatic method: Structural, physicochemical and functional properties. LWT-Food Sci. Technol. 2021, 145, 111314. [Google Scholar] [CrossRef]

- Gan, J.; Huang, Z.; Yu, Q.; Peng, G.; Xie, M. Microwave assisted extraction with three modifications on structural and functional properties of soluble dietary fibers from grapefruit peel. Food Hydrocoll. 2019, 101, 105549. [Google Scholar] [CrossRef]

- Peng, G.; Gan, J.; Dong, R.; Chen, Y.; Yu, Q. Combined microwave and enzymatic treatment improve the release of insoluble bound phenolic compounds from the grapefruit peel insoluble dietary fiber. LWT-Food Sci. Technol. 2021, 149, 111905. [Google Scholar] [CrossRef]

- Dhingra, D.; Michael, M.; Rajput, H.; Patil, R.T. Dietary Fibre in foods: A review. J. Food Sci. Technol. 2012, 49, 255–266. [Google Scholar] [CrossRef]

- Sendra, E.; Fayos, P.; Lario, Y.; Fernandez-Lopez, J.; Sayas-Barbera, E.; Perez-Alvarez, J.A. Incorporation of citrus fibers in fermented milk containing probiotic bacteria. Food Microbiol. 2008, 25, 13. [Google Scholar] [CrossRef] [PubMed]

- Figueroa, L.E.; Genovese, D.B. Fruit jellies enriched with dietary fibre: Development and characterization of a novel functional food product. LWT-Food Sci. Technol. 2019, 111, 423–428. [Google Scholar] [CrossRef]

- Shinwari, K.J.; Rao, P.S. Stability of bioactive compounds in fruit jam and jelly during processing and storage: A review. Trends Food Sci. Technol. 2018, 75, 181–193. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, Y.S.; Yoo, S.H.; Kim, K.O. Molecular structural differences between low methoxy pectins induced by pectin methyl esterase II: Effects on texture, release and perception of aroma in gels of similar modulus of elasticity. Food Chem. 2014, 145, 950–955. [Google Scholar] [CrossRef] [PubMed]

- Grigelmomiguel, N.; Martinbelloso, O. Influence of fruit dietary fibre addition on physical and sensorial properties of strawberry jams. J. Food Eng. 1999, 41, 13–21. [Google Scholar] [CrossRef]

- Du, X.; Wang, L.; Huang, X.; Jing, H.; Wang, H. Effects of different extraction methods on structure and properties of soluble dietary fiber from defatted coconut flour. LWT-Food Sci. Technol. 2021, 143, 111031. [Google Scholar] [CrossRef]

- Xue, Z.; Chen, Y.; Jia, Y.; Wang, Y.; Lu, Y.; Chen, H.; Zhang, M. Structure, thermal and rheological properties of different soluble dietary fiber fractions from mushroom Lentinula edodes (Berk.) Pegler residues. Food Hydrocoll. 2019, 95, 10–18. [Google Scholar] [CrossRef]

- Wen, Y.; Niu, M.; Zhang, B.; Zhao, S.; Xiong, S. Structural characteristics and functional properties of rice bran dietary fiber modified by enzymatic and enzyme-micronization treatments. LWT-Food Sci. Technol. 2017, 75, 344–351. [Google Scholar] [CrossRef]

- Xie, J.; Liu, S.; Dong, R.; Xie, J.; Chen, Y.; Peng, G.; Liao, W.; Xue, P.; Feng, L.; Yu, Q. Bound polyphenols from insoluble dietary fiber of defatted rice bran by solid-state fermentation with Trichoderma viride: Profile, activity, and release mechanism. J. Agric. Food Chem. 2021, 69, 5026–5039. [Google Scholar] [CrossRef]

- Yang, C.; Si, J.; Chen, Y.; Xie, J.; Tian, S.; Cheng, Y.; Hu, X.; Yu, Q. Physicochemical structure and functional properties of soluble dietary fibers obtained by different modification methods from Mesona chinensis Benth. residue. Food Res. Int. 2022, 157, 111489. [Google Scholar] [CrossRef]

- Nsor-Atindana, J.; Zhong, F.; Mothibe, K.J. In vitro hypoglycemic and cholesterol lowering effects of dietary fiber prepared from cocoa (Theobroma cacao L.) shells. Food Funct. 2012, 3, 1044–1050. [Google Scholar] [CrossRef] [PubMed]

- Abid, M.; Yaich, H.; Hidouri, H.; Attia, H.; Ayadi, M.A. Effect of substituted gelling agents from pomegranate peel on colour, textural and sensory properties of pomegranate jam. Food Chem. 2017, 239, 1047–1054. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Liao, W.; Xie, J.; Chen, Y.; Peng, G.; Xie, J.; Sun, N.; Liu, S.; Yu, C.; Yu, Q. Enrichment of yogurt with carrot soluble dietary fiber prepared by three physical modified treatments: Microstructure, rheology and storage stability. Innov. Food Sci. Emerg. Technol. 2022, 75, 102901. [Google Scholar] [CrossRef]

- Belovic, M.; Torbica, A.; Pajic-Lijakovic, I.; Mastilovic, J. Development of low calorie jams with increased content of natural dietary fibre made from tomato pomace. Food Chem. 2017, 237, 1226–1233. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, F.; Santos, B.A.D.; Nunes, G.; Soares, J.M.; Amaral, L.A.d.; Souza, G.H.O.d.; Resende, J.T.V.d.; Menegassi, B.; Rafacho, B.P.M.; Schwarz, K. Addition of orange peel in orange jam: Evaluation of sensory, physicochemical, and nutritional characteristics. Molecules 2020, 25, 1670. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Wang, Z.; Wang, Z.; Hao, Y.; Wang, J. Physicochemical and functional properties of soluble dietary fiber from different colored quinoa varieties (Chenopodium quinoa Willd). J. Cereal Sci. 2020, 95, 103045. [Google Scholar] [CrossRef]

- Huang, J.Y.; Liao, J.S.; Qi, J.R.; Jiang, W.X.; Yang, X.Q. Structural and physicochemical properties of pectin-rich dietary fiber prepared from citrus peel. Food Hydrocoll. 2020, 110, 106140. [Google Scholar] [CrossRef]

- Qi, J.; Yokoyama, W.; Masamba, K.G.; Majeed, H.; Zhong, F.; Li, Y. Structural and physico-chemical properties of insoluble rice bran fiber: Effect of acid–base induced modifications. RSC Adv. 2015, 5, 79915–79923. [Google Scholar] [CrossRef]

- Dong, W.; Wang, D.; Hu, R.; Long, Y.; Lv, L. Chemical composition, structural and functional properties of soluble dietary fiber obtained from coffee peel using different extraction methods. Food Res. Int. 2020, 136, 109497. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Y. Physicochemical and functional properties of coconut (Cocos nucifera L.) cake dietary fibres: Effects of cellulase hydrolysis, acid treatment and particle size distribution. Food Chem. 2018, 257, 135–142. [Google Scholar] [CrossRef]

- Ma, M.M.; Mu, T.H. Effects of extraction methods and particle size distribution on the structural, physicochemical, and functional properties of dietary fiber from deoiled cumin. Food Chem. 2016, 194, 237–246. [Google Scholar] [CrossRef]

- Jiang, Y.; Yin, H.; Zheng, Y.; Wang, D.; Liu, Z.; Deng, Y.; Zhao, Y. Structure, physicochemical and bioactive properties of dietary fibers from Akebia trifoliata (Thunb.) Koidz. seeds using ultrasonication/shear emulsifying/microwave-assisted enzymatic extraction. Food Res. Int. 2020, 136, 109348. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Qi, J.; Zeng, W.; Huang, Y.; Yang, X. Properties of dietary fiber from citrus obtained through alkaline hydrogen peroxide treatment and homogenization treatment. Food Chem. 2020, 311, 125873. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Ren, J.; Zhang, Y.; Li, J.; Liu, Y.; Guo, Z.; Yang, Z.; Pan, S.; Fan, G. Effects of modified starches on the processing properties of heat-resistant blueberry jam. LWT-Food Sci. Technol. 2016, 72, 447–456. [Google Scholar] [CrossRef]

- Igual, M.; Contreras, C.; Martínez-Navarrete, N. Colour and rheological properties of non-conventional grapefruit jams: Instrumental and sensory measurement. LWT-Food Sci. Technol. 2014, 56, 200–206. [Google Scholar] [CrossRef]

| Sample | L* | a* | b* | c* | ΔE |

|---|---|---|---|---|---|

| BJ | 20.72 ± 0.17 c | 1.34 ± 0.11 bc | 2.18 ± 0.06 b | 2.56 ± 0.05 b | — |

| LMJ | 22.52 ± 0.62 b | 2.02 ± 0.26 a | 2.71 ± 0.77 ab | 3.42 ± 0.59 a | 2.54 ± 0.27 c |

| GPSJ-1 | 24.22 ± 0.08 a | 1.08 ± 0.11 c | 3.11 ± 0.07 a | 3.30 ± 0.07 a | 3.85 ± 0.05 a |

| GPSJ-2 | 23.24 ± 0.55 b | 1.55 ± 0.13 b | 2.31 ± 0.45 ab | 2.79 ± 0.40 ab | 3.34 ± 0.25 b |

| Parameter | BJ | LMJ | GPSJ-1 | GPSJ-2 | |

|---|---|---|---|---|---|

| Rheological determination | Yield stress (g) | 1.52 ± 0.13 c | 10.00 ± 3.21 a | 4.43 ± 0.34 b | 8.76 ± 0.87 a |

| Consistency index, K (Pa sn) | 0.77 ± 0.059 d | 42.04 ± 3.38 a | 7.19 ± 0.32 c | 26.62 ± 0.94 b | |

| Flow behavior index, n (-) | 0.67 ± 0.014 a | 0.13 ± 0.0085 c | 0.40 ± 0.0048 b | 0.19 ± 0.0048 c | |

| R-square | 0.99585 | 0.99732 | 0.99446 | 0.99838 | |

| Hysteresis loop area, S (Pa/s) | 1357.63 ± 2.31 b | 1448.91 ± 5.71 a | 1245.70 ± 15.01 c | 1375.57 ± 25.48 b | |

| Texture determination | Gel strength (g) | 5.26 ± 0.18 d | 10.47 ± 0.30 a | 6.73 ± 0.26 c | 8.62 ± 0.66 b |

| Hardness (g) | 7.24 ± 0.31 c | 15.05 ± 0.43 a | 8.64 ± 0.45 c | 11.96 ± 0.85 b | |

| Consistency (g*sec) | 61.51 ± 1.76 c | 112.35 ± 3.40 a | 70.06 ± 2.72 c | 90.69 ± 2.94 b | |

| Adhesiveness (g) | 5.56 ± 0.22 c | 18.45 ± 0.67 a | 11.08 ± 1.85 b | 15.91 ± 1.19 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Peng, G.; Hu, X.; Xie, J.; Chen, Y.; Dong, R.; Si, J.; Yang, C.; Yu, Q. Physicochemical Characteristics of Soluble Dietary Fiber Obtained from Grapefruit Peel Insoluble Dietary Fiber and Its Effects on Blueberry Jam. Foods 2022, 11, 3735. https://doi.org/10.3390/foods11223735

Xie J, Peng G, Hu X, Xie J, Chen Y, Dong R, Si J, Yang C, Yu Q. Physicochemical Characteristics of Soluble Dietary Fiber Obtained from Grapefruit Peel Insoluble Dietary Fiber and Its Effects on Blueberry Jam. Foods. 2022; 11(22):3735. https://doi.org/10.3390/foods11223735

Chicago/Turabian StyleXie, Jiayan, Guanyi Peng, Xiaobo Hu, Jianhua Xie, Yi Chen, Ruihong Dong, Jingyu Si, Chaoran Yang, and Qiang Yu. 2022. "Physicochemical Characteristics of Soluble Dietary Fiber Obtained from Grapefruit Peel Insoluble Dietary Fiber and Its Effects on Blueberry Jam" Foods 11, no. 22: 3735. https://doi.org/10.3390/foods11223735