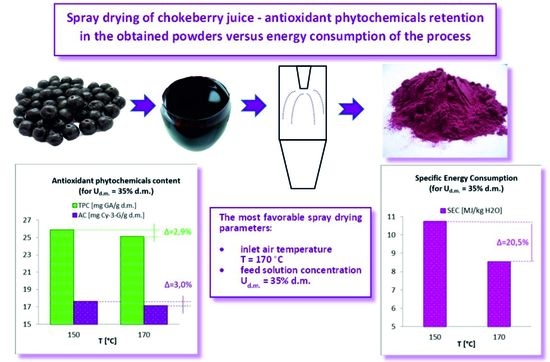

Spray Drying of Chokeberry Juice—Antioxidant Phytochemicals Retention in the Obtained Powders versus Energy Consumption of the Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Spray Drying

2.3. Moisture Content (MC)

2.4. Powder Yield (PY)

- Mp, Mf—mass of powder and feed solution, respectively,

- DMp, DMf—percentage of dry matter in the powder and feed solution, respectively.

2.5. Total (TWEC) and Effective Water Evaporation Capacity (EWEC)

- —mass flow rate of the feed solution and powder, respectively,

- WCf, WCp—water content in feed solution and powder, respectively.

2.6. Specific Energy Consumption (SEC)

2.7. Total Polyphenol Content (TPC)

2.8. Anthocyanin Content (AC)

2.9. Statistical Analysis

3. Results and Discussion

3.1. Moisture Content (MC)

3.2. Powder Yield (PY)

3.3. Total (TWEC) and Effective Water Evaporation Capacity (EWEC)

3.4. Specific Energy Consumption (SEC)

3.5. Total Polyphenol Content (TPC) and TPC–SEC Relationship

3.6. Anthocyanin Content (AC) and AC–SEC Relation

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jurendić, T.; Ščetar, M. Aronia melanocarpa Products and By-Products for Health and Nutrition: A Review. Antioxidants 2021, 10, 1052. [Google Scholar] [CrossRef] [PubMed]

- Jurikova, T.; Mlcek, J.; Skrovankova, S.; Sumczynski, D.; Sochor, J.; Hlavacova, I.; Snopek, L.; Orsavova, J. Fruits of Black Chokeberry Aronia melanocarpa in the Prevention of Chronic Diseases. Molecules 2017, 22, 944. [Google Scholar] [CrossRef] [PubMed]

- Banjari, I.; Misir, A.; Šavikin, K.; Jokić, S.; Molnar, M.; De Zoysa, H.K.S.; Waisundara, V.Y. Antidiabetic Effects of Aronia melanocarpa and Its Other Therapeutic Properties. Front. Nutr. 2017, 4, 53. [Google Scholar] [CrossRef]

- Cebova, M.; Klimentova, J.; Janega, P.; Pechanova, O. Effect of bioactive compound of Aronia melanocarpa on cardiovascular system in experimental hypertension. Oxidative Med. Cell Longev. 2017, 2017, 8156594. [Google Scholar] [CrossRef] [PubMed]

- Sidor, A.; Gramza-Michałowska, A. Black Chokeberry Aronia Melanocarpa L.—A Qualitative Composition, Phenolic Profile and Antioxidant Potential. Molecules 2019, 24, 3710. [Google Scholar] [CrossRef]

- Bataraga, A.; Valkovska, V. Phytochemical Profile of Chokeberry (Aronia melanocarpa). Key Eng. Mater. 2020, 850, 184–189. [Google Scholar] [CrossRef]

- Gawałek, J. Effect of Spray Dryer Scale Size on the Properties of Dried Beetroot Juice. Molecules 2021, 26, 6700. [Google Scholar] [CrossRef] [PubMed]

- Gawałek, J.; Domian, E. Tapioca dextrin as an alternative carrier in the spray drying of fruit juices—A case study of chokeberry powder. Foods 2020, 9, 1125. [Google Scholar] [CrossRef]

- Gawałek, J.; Domian, E.; Ryniecki, A.; Bakier, S. Effects of the spray drying conditions of chokeberry (Aronia melanocarpa L.) juice concentrate on the physicochemical properties of powders. Int. J. Food Sci. Technol. 2017, 52, 1933–1941. [Google Scholar] [CrossRef]

- Muzaffar, K.; Nayik, G.A.; Kumar, P. Production of fruit juice powders by spray drying technology. Int. J. Adv. Res. Sci. Eng. Technol. 2018, 7, 59–67. [Google Scholar]

- Gharsalloui, A.; Roudaut, G.; Chambin, O.; Voilley, A.; Saurel, R. Applications of spray drying in microencapsulation of food ingredients: An overview. Int. Food Res. J. 2007, 40, 1107–1121. [Google Scholar] [CrossRef]

- Bednarska, M.A.; Janiszewska-Turak, E. The influence of spray drying parameters and carrier material on the physico-chemical properties and quality of chokeberry juice powder. J. Food Sci. Technol. 2020, 57, 564–577. [Google Scholar] [CrossRef] [PubMed]

- Janiszewska-Turak, E.; Sak, A.; Witrowa-Rajchert, D. The influence of carrier material on the stability of chokeberry juice microcapsules. Int. Agrophysics 2019, 33, 517–525. [Google Scholar] [CrossRef]

- Ćujić, N.; Stanisavljević, N.; Šavikin, K.; Kalušević, A.; Nedovic, V.; Samardzic, J.; Janković, T. Application of gum Arabic in the production of spray-dried chokeberry polyphenols, microparticles characterisation and in vitro digestion method. Lek. Sirovine 2018, 38, 9–16. [Google Scholar] [CrossRef]

- Ćujić-Nikolić, N.; Stanisavljević, N.; Šavikin, K.; Kalušević, A.; Nedović, V.; Samardžić, J.; Janković, T. Chokeberry polyphenols preservation using spray drying: Effect of encapsulation using maltodextrin and skimmed milk on their recovery following in vitro digestion. J. Microencapsul. 2019, 36, 693–703. [Google Scholar] [CrossRef]

- Tzatsi, P.; Goula, A.M. Encapsulation of Extract from Unused Chokeberries by Spray Drying, Co-crystallization, and Ionic Gelation. Waste Biomass Valor 2021, 12, 4567–4585. [Google Scholar] [CrossRef]

- Vidović, S.; Ramić, M.; Ambrus, R.; Vladić, J.; Szabó-Révész, P.; Gavarić, A. Aronia Berry Processing by Spray Drying. Food Technol. Biotechnol. 2019, 57, 513–524. [Google Scholar] [CrossRef]

- Pieczykolan, E.; Kurek, M.A. Use of guar gum, gum arabic, pectin, beta-glucan and inulin for microencapsulation of anthocyanins from chokeberry. Int. J. Biol. Macromol. 2019, 129, 665–671. [Google Scholar] [CrossRef]

- Azmi, M.Z.; Rukunudin, I.H.; Ismail, H.A.; Aznan, A.A. Specific Energy Consumption and Drying Efficiency Analysis of Commercial Mixed-Flow Batch Type Seed Drying System. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 55, 39–50. [Google Scholar]

- Shreve, B.; Thiex, N.; Wolf, M. National Forage Testing Association Reference Method: Dry Matter by Oven Drying for 3 Hours at 105 °C. In NFTA Reference Methods; National Forage Testing Association: Omaha, Nebraska, 2006. [Google Scholar]

- Giusti, M.M.; Wrolstad, R.E. Characterization and measurement of anthocyanins by UV-visible spectroscopy. Curr. Protoc. Food Anal. Chem. Red. 2001, F1.2.1–F1.2.13. [Google Scholar] [CrossRef]

- Pui, L.P.; Saleena, L.A.K. Effects of spray-drying parameters on physicochemical properties of powdered fruits. Foods Raw Mater. 2022, 10, 235–251. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Influence of process conditions on the physicochemical properties of acai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Fazeli, M.; Emam-Djomeh, Z.; Kalbasi Ashtari, A.; Omid, M. Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food Bioprod. Process. 2012, 90, 667–675. [Google Scholar] [CrossRef]

- Mishra, P.; Mishra, S.; Mahanta, C.L. Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod. Process. 2014, 92, 252–258. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, F.; Guo, H. Optimization of bayberry juice spray drying process using response surface methodology. Food Sci. Biotechnol. 2017, 26, 1235–1244. [Google Scholar] [CrossRef]

- Bastías-Montes, J.M.; Choque-Chávez, M.C.; Alarcón-Enos, J.; Quevedo-León, R.; Muñoz-Fariña, O.; Vidal-San-Martín, C. Effect of spray drying at 150, 160, and 170 °C on the physical and chemical properties of maqui extract (Aristotelia chilensis (Molina) Stuntz). Chil. J. Agric. Res. 2019, 79, 144–152. [Google Scholar] [CrossRef]

- Santos, D.; Maurício, A.C.; Sencadas, V.; Santos, J.; Fernandes, M.H.; Gomes, P.S. Spray Drying: An Overview. In Biomaterials-Physics and Chemistry-New Edition; Pignatello, R., Musumeci, T., Eds.; IntechOpen: London, UK, 2017; pp. 9–35. [Google Scholar]

- Patel, R.; Patel, M.; Suthar, A. Spray drying technology: An overview. Indian J. Sci. Technol. 2009, 2, 44–47. [Google Scholar] [CrossRef]

- Sharifi, A.; Niakousari, M.; Maskooki, A.; Mortazavi, S.A. Effect of spray drying conditions on the physicochemical properties of barberry (Berberis vulgaris) extract powder. Int. Food Res. J. 2015, 22, 2364–2370. [Google Scholar]

- Baker, C.; McKenzie, K. Energy Consumption of Industrial Spray Dryers. Dry. Technol. 2005, 23, 365–386. [Google Scholar] [CrossRef]

- Barańska, A.; Jedlińska, A.; Samborska, K. Dehumidified-Air Assisted Spray Drying of Buckwheat Honey with Maltodextrin and Skim Milk Powder as Carriers. Appl. Sci. 2021, 11, 3150. [Google Scholar] [CrossRef]

- Al-Mansour, H.E.; Al-Busairi, B.H.; Baker, C.G.J. Energy Consumption of a Pilot-Scale Spray Dryer. Dry. Technol. 2011, 29, 1901–1910. [Google Scholar] [CrossRef]

- Bakowska-Barczak, A.M.; Kolodziejczyk, P.P. Black currant polyphenols: Their storage stability and microencapsulation. Ind. Crops Prod. 2011, 34, 1301–1309. [Google Scholar] [CrossRef]

- Lingua, S.M.; Salomón, V.; Baroni, M.V.; Blajman, J.E.; Maldonado, L.M.; Paez, R. Effect of Spray Drying on the Microencapsulation of Blueberry Natural Antioxidants. Proceedings 2021, 70, 26. [Google Scholar]

- Romero-Román, M.E.; Schoebitz, M.; Fuentealba, J.; García-Viguera, C.; Belchí, M.D.L. Phenolic Compounds in Calafate Berries Encapsulated by Spray Drying: Neuroprotection Potential into the Ingredient. Antioxidants 2021, 10, 1830. [Google Scholar] [CrossRef] [PubMed]

- Shishir, M.R.I.; Chen, W. Trends of spray drying: A critical review on drying of fruit and vegetable juices. Trends Food Sci. Technol. 2017, 65, 49–67. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Spray Drying of Tomato Pulp: Effect of Feed Concentration. Dry. Technol. 2004, 22, 2309–2330. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gawałek, J. Spray Drying of Chokeberry Juice—Antioxidant Phytochemicals Retention in the Obtained Powders versus Energy Consumption of the Process. Foods 2022, 11, 2898. https://doi.org/10.3390/foods11182898

Gawałek J. Spray Drying of Chokeberry Juice—Antioxidant Phytochemicals Retention in the Obtained Powders versus Energy Consumption of the Process. Foods. 2022; 11(18):2898. https://doi.org/10.3390/foods11182898

Chicago/Turabian StyleGawałek, Jolanta. 2022. "Spray Drying of Chokeberry Juice—Antioxidant Phytochemicals Retention in the Obtained Powders versus Energy Consumption of the Process" Foods 11, no. 18: 2898. https://doi.org/10.3390/foods11182898