Blockchain-Based Traceability System That Ensures Food Safety Measures to Protect Consumer Safety and COVID-19 Free Supply Chains

Abstract

:1. Introduction

2. Background Studies

2.1. Overview Blockchain Technology

2.2. COVID-19 and Food Contamination

| Authors | Title | Reference |

|---|---|---|

| Bumblauskas et al. | A blockchain use case in food distribution: Do you know where your food has been? | [28] |

| Nir Kshetri | 5G in E-Commerce Activities | [29] |

| Cen et al. | Improving Business Process Interoperability by Shared Ledgers | [30] |

| Edwards et al. | Blockchain meets the supply chain | [31] |

| Alzahrani et al. | Block-Supply Chain: A New Anti-Counterfeiting Supply Chain Using NFC and Blockchain | [32] |

| Feng Tian | An agri-food supply chain traceability system for China based on RFID & blockchain technology | [33] |

| Feng Tian | A Supply Chain Traceability System for Food Safety Based on HACCP, Blockchain & Internet of Things | [34] |

| Ramundo et al. | State of the art of technology in the food sector value chain towards the IoT | [35] |

| Daniel et al. | Blockchain application in food supply information security | [36] |

| Baralla et al. | Ensure Traceability in European Food Supply Chain by Using a Blockchain System | [37] |

| Chen et al. | Processes, benefits, and challenges for adoption of blockchain technologies in food supply chains: a thematic analysis | [38] |

| Oslen et al. | Applications, limitations, costs, and benefits related to the use of blockchain technology in the food industry | [39] |

| Walter G. Johnson | Blockchain Meets Genomics: Governance Considerations for Promoting Food Safety and Public Health | [40] |

| Mondal et al. | Blockchain Inspired RFID-Based Information Architecture for Food Supply Chain | [41] |

| Xu et al. | Application of blockchain technology in food safety control: current trends and future prospects | [42] |

| Feng et al. | Applying blockchain technology to improve agri-food traceability: a review of development methods, benefits and challenges | [43] |

| Qian et al. | Filling the trust gap of food safety in food trade between the EU and China: An interconnected conceptual traceability framework based on blockchain | [44] |

| Hao et al. | A Novel Visual Analysis Method of Food Safety Risk Traceability Based on Blockchain | [45] |

| Adnan et al. | Application of Blockchain and Internet of Things to Ensure Tamper-Proof Data Availability for Food Safety | [17] |

| Behnke et al. | Boundary conditions for traceability in food supply chains using blockchain technology | [46] |

| Reuters | Chickens and eggs: Retailer Carrefour adopts blockchain to track fresh produce | [47] |

| Parshar et al. | Blockchain-Based Traceability and Visibility for Agricultural Products: A Decentralized Way of Ensuring Food Safety in India | [48] |

3. Blockchain-Based Solution for Importers/Exporters

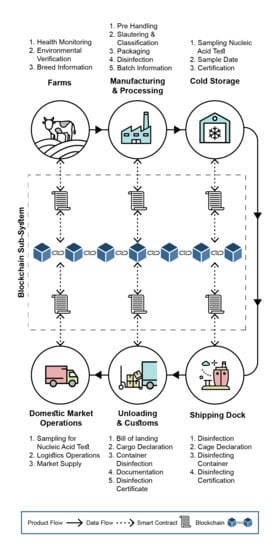

3.1. Blockchain Network Architecture

3.2. Application Layer

3.3. Blockchain Layer

3.4. Physical Layer

4. Blockchain Network Integration

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Archived: WHO Timeline—COVID-19. Available online: https://www.who.int/news/item/27-04-2020-who-timeline—covid-19 (accessed on 2 April 2021).

- Nakat, Z.; Bou-Mitri, C. COVID-19 and the food industry: Readiness assessment. Food Control 2020, 121, 107661. [Google Scholar] [CrossRef]

- Food Safety and the Coronavirus Disease 2019 (COVID-19) | FDA. Available online: https://www.fda.gov/food/food-safety-during-emergencies/food-safety-and-coronavirus-disease-2019-covid-19 (accessed on 2 April 2021).

- Hailu, G. Economic thoughts on COVID-19 for Canadian food processors. Can. J. Agric. Econ. Can. D’Agroecon. 2020, 68, 163–169. [Google Scholar] [CrossRef]

- McEwan, K.; Marchand, L.; Shang, M.Z.; Bucknell, D. Potential implications of COVID-19 on the Canadian pork industry. Can. J. Agric. Econ. Can. D’Agroecon. 2020, 68, 201–206. [Google Scholar] [CrossRef] [Green Version]

- Galanakis, C.M. The Food Systems in the Era of the Coronavirus (COVID-19) Pandemic Crisis. Foods 2020, 9, 523. [Google Scholar] [CrossRef]

- Update: COVID-19 Among Workers in Meat and Poultry Processing Facilities—United States, April–May 2020 | MMWR. Available online: https://www.cdc.gov/mmwr/volumes/69/wr/mm6927e2.htm?s_cid=mm6927e2_w (accessed on 2 April 2021).

- China Finds Coronavirus on Frozen Meat, Packaging from Latin America, New Zealand | Reuters. Available online: https://www.reuters.com/article/health-coronavirus-china-meat-int-idUSKBN27V0E4 (accessed on 2 April 2021).

- More Traces of COVID-19 Found on Packaging in China. Available online: https://www.foodsafety.com.au/news/more-traces-covid-19-found-packaging-china (accessed on 2 April 2021).

- Argentina Says China has Found Coronavirus Trace on Beef Shipment Packaging | Reuters. Available online: https://www.reuters.com/article/us-health-coronavirus-argentina-beef-idUSKBN27S342 (accessed on 2 April 2021).

- The State Council’s Joint Prevention and Control Mechanism Comprehensive Group issued the Work Plan for Preventive and Comprehensive Disinfection of Imported Cold Chain Food. Available online: http://www.gov.cn/xinwen/2020-11/09/content_5559179.htm (accessed on 2 April 2021).

- Exporting Meat Products to China During COVID-19. Available online: https://www.china-briefing.com/news/exporting-meat-products-to-china-during-covid-19-what-you-need-to-know/ (accessed on 2 April 2021).

- Yinghua, S.; Ningzhou, S.; Dan, L. Evolutionary game and intelligent simulation of food safety information disclosure oriented to traceability system. J. Intell. Fuzzy Syst. 2018, 35, 2657–2665. [Google Scholar] [CrossRef]

- Liu, Y.; Han, W.; Zhang, Y.; Li, L.; Wang, J.; Zheng, L. An Internet-of-Things solution for food safety and quality control: A pilot project in China. J. Ind. Inf. Integr. 2016, 3, 1–7. [Google Scholar] [CrossRef]

- Bouzembrak, Y.; Klüche, M.; Gavai, A.; Marvin, H.J. Internet of Things in food safety: Literature review and a bibliometric analysis. Trends Food Sci. Technol. 2019, 94, 54–64. [Google Scholar] [CrossRef]

- Tyagi, A.K.; Agarwal, K.; Goyal, D.; Sreenath, N. A review on security and privacy issues in internet of things. In Advances in Computing and Intelligent Systems; Springer: Berlin/Heidelberg, Germany, 2020; pp. 489–502. [Google Scholar]

- Iftekhar, A.; Cui, X.; Hassan, M.; Afzal, W. Application of Blockchain and Internet of Things to Ensure Tamper-Proof Data Availability for Food Safety. arXiv 2020, arXiv:2006.01307. [Google Scholar] [CrossRef]

- Cui, X. Wuhan University Food Safety and Food Quality Blockchain Alliance by Cui Xiaohui. Available online: http://www.foodblockchain.com.cn/ (accessed on 10 April 2021).

- Tao, Q.; Cui, X.; Huang, X.; Leigh, A.M.; Gu, H. Food Safety Supervision System Based on Hierarchical Multi-Domain Blockchain Network. IEEE Access 2019, 7, 51817–51826. [Google Scholar] [CrossRef]

- Tao, Q.; Chen, Q.; Ding, H.; Adnan, I.; Huang, X.; Cui, X. Cross-Department Secures Data Sharing in Food Industry via Blockchain-Cloud Fusion Scheme. Secur. Commun. Netw. 2021, 2021, 6668339. [Google Scholar] [CrossRef]

- Narayanan, A.; Bonneau, J.; Felten, E.; Miller, A.; Goldfeder, S. Bitcoin and Cryptocurrency Technologies: A Comprehensive Introduction; Princeton University Press: Princeton, NJ, USA, 2016. [Google Scholar]

- Kroll, J.A.; Davey, I.C.; Felten, E.W. The economics of Bitcoin mining, or Bitcoin in the presence of adversaries. Proc. WEIS 2013, 2013, 11. [Google Scholar]

- Singhal, B.; Dhameja, G.; Panda, P.S. How blockchain works. In Beginning Blockchain; Springer: Berlin/Heidelberg, Germany, 2018; pp. 31–148. [Google Scholar]

- Coronavirus: No Evidence that Food is a Source or Transmission Route | European Food Safety Authority. Available online: https://www.efsa.europa.eu/en/news/coronavirus-no-evidence-food-source-or-transmission-route (accessed on 11 April 2021).

- EUROPEAN COMMISSION DIRECTORATE-GENERAL FOR HEALTH AND FOOD SAFETY | Crisis Management in Food, Animals and Plants | Food Hygiene, COVID-19 and Food Safety. Available online: https://ec.europa.eu/food/sites/food/files/safety/docs/biosafety_crisis_covid19_qandas.pdf (accessed on 11 April 2021).

- COVID-19 and Food Safety: Guidance for Food Businesses. Available online: https://www.who.int/publications/i/item/covid-19-and-food-safety-guidance-for-food-businesses (accessed on 11 April 2021).

- Guidance on Preparing Workplaces for COVID-19. Available online: https://www.osha.gov/sites/default/files/publications/OSHA3990.pdf (accessed on 11 April 2021).

- Bumblauskas, D.; Mann, A.; Dugan, B.M.; Rittmer, J. A blockchain use case in food distribution: Do you know where your food has been? Int. J. Inf. Manag. 2020, 52, 102008. [Google Scholar] [CrossRef]

- Kshetri, N. 5G in E-Commerce Activities. IT Prof. 2018, 20, 73–77. [Google Scholar] [CrossRef]

- Cen, Y.; Wang, H.; Li, X. Improving Business Process Interoperability by Shared Ledgers. In Proceedings of the 6th International Conference on Informatics, Environment, Energy and Applications, Jeju Island, Korea, 29–31 March 2017; ACM: New York, NY, USA, 2017; pp. 89–93. [Google Scholar]

- Edwards, N. Blockchain meets the supply chain. MHD Supply Chain. Solut. 2017, 47, 48. [Google Scholar]

- Alzahrani, N.; Bulusu, N. Block-supply chain: A new anti-counterfeiting supply chain using NFC and blockchain. In Proceedings of the 1st Workshop on Cryptocurrencies and Blockchains for Distributed Systems, Munich, Germany, 15 June 2018; ACM: New York, NY, USA, 2018; pp. 30–35. [Google Scholar]

- Tian, F. An agri-food supply chain traceability system for China based on RFID & blockchain technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; pp. 1–6. [Google Scholar]

- Tian, F. A supply chain traceability system for food safety based on HACCP, blockchain & Internet of things. In Proceedings of the 2017 International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; pp. 1–6. [Google Scholar]

- Ramundo, L.; Taisch, M.; Terzi, S. State of the art of technology in the food sector value chain towards the IoT. In Proceedings of the 2nd IEEE International Forum on Research and Technologies for Society and Industry Leveraging a Better Tomorrow (RTSI 2016), Bologna, Italy, 7–9 September 2016; pp. 1–6. [Google Scholar]

- Tse, D.; Zhang, B.; Yang, Y.; Cheng, C.; Mu, H. Blockchain application in food supply information security. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 1357–1361. [Google Scholar]

- Baralla, G.; Pinna, A.; Corrias, G. Ensure Traceability in European Food Supply Chain by using a blockchain System. In Proceedings of the 2nd International Workshop on Emerging Trends in Software Engineering for Blockchain, Montreal, QC, Canada, 27 May 2019; ACM: New York, NY, USA, 2019; pp. 40–47. [Google Scholar]

- Chen, S.; Yan, J.; Tan, B.; Liu, X.; Li, Y. Processes and challenges for the adoption of blockchain technology in food supply chains: A thematic analysis. In Proceedings of the iConference 2019, Washington, DC, USA, 31 March–3 April 2019. [Google Scholar]

- Olsen, P.; Borit, M.; Syed, S. Applications, limitations, costs, and benefits related to the use of blockchain technology in the food industry. Nofima Rapp. 2019. Available online: http://hdl.handle.net/11250/2586121 (accessed on 10 January 2021).

- Johnson, W.G. Blockchain Meets Genomics: Governance Considerations for Promoting Food Safety and Public Health. J. Food Law Policy Forthcom. 2019, 75, 14. [Google Scholar]

- Mondal, S.; Wijewardena, K.; Karuppuswami, S.; Kriti, N.; Kumar, D.; Chahal, P. Blockchain Inspired RFID based Information Architecture for Food Supply Chain. IEEE Internet Things J. 2019, 6, 5803–5813. [Google Scholar] [CrossRef]

- Xu, Y.; Li, X.; Zeng, X.; Cao, J.; Jiang, W. Application of blockchain technology in food safety control current trends and future prospects. Crit. Rev. Food Sci. Nutr. 2020. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Wang, X.; Duan, Y.; Zhang, J.; Zhang, X. Applying blockchain technology to improve agri-food traceability: A review of development methods, benefits and challenges. J. Clean. Prod. 2020, 260, 121031. [Google Scholar] [CrossRef]

- Qian, J.; Wu, W.; Yu, Q.; Ruiz-Garcia, L.; Xiang, Y.; Jiang, L.; Shi, Y.; Duan, Y.; Yang, P. Filling the trust gap of food safety in food trade between the EU and China: An interconnected conceptual traceability framework based on blockchain. Food Energy Secur. 2020, 9, e249. [Google Scholar] [CrossRef]

- Hao, Z.; Mao, D.; Zhang, B.; Zuo, M.; Zhao, Z. A Novel Visual Analysis Method of Food Safety Risk Traceability Based on Blockchain. Int. J. Environ. Res. Public Health 2020, 17, 2300. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Behnke, K.; Janssen, M. Boundary conditions for traceability in food supply chains using blockchain technology. Int. J. Inf. Manag. 2020, 52, 101969. [Google Scholar] [CrossRef]

- Chickens and Eggs: Retailer Carrefour Adopts Blockchain to Track Fresh Produce | Reuters. Available online: https://www.reuters.com/article/us-carrefour-blockchain-ibm/chickens-and-eggs-retailer-carrefour-adopts-blockchain-to-track-fresh-produce-idUSKCN1MI162 (accessed on 2 April 2021).

- Prashar, D.; Jha, N.; Jha, S.; Lee, Y.; Joshi, G. Blockchain-Based Traceability and Visibility for Agricultural Products: A Decentralized Way of Ensuring Food Safety in India. Sustainability 2020, 12, 3497. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iftekhar, A.; Cui, X. Blockchain-Based Traceability System That Ensures Food Safety Measures to Protect Consumer Safety and COVID-19 Free Supply Chains. Foods 2021, 10, 1289. https://doi.org/10.3390/foods10061289

Iftekhar A, Cui X. Blockchain-Based Traceability System That Ensures Food Safety Measures to Protect Consumer Safety and COVID-19 Free Supply Chains. Foods. 2021; 10(6):1289. https://doi.org/10.3390/foods10061289

Chicago/Turabian StyleIftekhar, Adnan, and Xiaohui Cui. 2021. "Blockchain-Based Traceability System That Ensures Food Safety Measures to Protect Consumer Safety and COVID-19 Free Supply Chains" Foods 10, no. 6: 1289. https://doi.org/10.3390/foods10061289