Comparative Study of a Life Cycle Assessment for Bio-Plastic Straws and Paper Straws: Malaysia’s Perspective

Abstract

:1. Introduction

2. Methodology

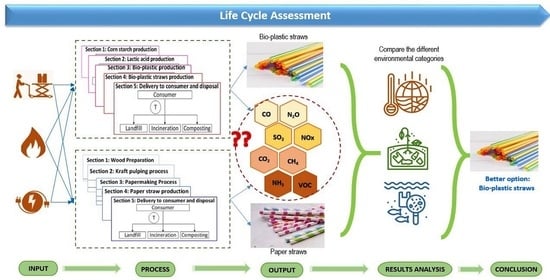

2.1. Life Cycle Assessment

2.2. Goal and Scope Definition

2.3. Inventory Analysis

- All calculations were based on 100 units of drinking straws produced, which were equal to 133 g of bio-plastic straws and 260 g of paper straws.

- Corn starch production was adapted from the corn refinery simulation [24].

- Similar physical properties in the injection molding of the PLA and the PP were assumed as the PLA straws are very flexible and perform similarly to conventional plastic straws made of PP [25].

- For the kraft pulping process, biomass combustion was used in the energy generation, which is commonly used in the pulp and paper industry [26].

- The disposal of bio-plastic and paper straws was equally divided between a composite facility, landfill and incineration. A similar amount of bio-plastic paper straws for each disposal method was ensured. The equal division was assumed for different disposal methods in order to analyze how each of the processes contributes to the GWP and AP [27].

- The landfill sites of bio-plastic and paper straws are located in Malaysia. Thus, both landfill sites have similar site characteristics, i.e., weather, humidity and temperature.

- The transportation of raw materials to the manufacturing site, the transportation of the product to the customer and the transportation of used bio-plastic and paper straws to disposal sites were based on the actual location of the supply chain in Peninsular Malaysia as a case study.

2.4. Impact Assessment

2.5. Data Interpretation

3. Results and Discussion

3.1. Overall Result of Bio-Plastic Straws

3.2. Overall Result of Paper Straws

3.3. Overall Comparison of Bio-Plastic Straws and Paper Straws

3.4. Sensitivity Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pavani, P.; Rajeswari, T.R. Impact of Heavy Metals on Environmental Pollution. J. Chem. Pharm. Sci. 2014, 94, 87–93. [Google Scholar]

- Tibbetts, J. Managing Marine Plastic Pollution. Environ. Health Perspect. 2015, 123, A90–A93. [Google Scholar] [CrossRef] [Green Version]

- Malaysian Plastics Manufacturers Association. An Advanced Plastics Recycling Industry for Malaysia; Malaysian Plastics Manufacturers Association: Petalin Jaya, Malaysia, 2019; pp. 1–31. [Google Scholar]

- Darbre, P.D. Overview of air pollution and endocrine disorders. Int. J. Gen. Med. 2018, 11, 191–207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wilcox, C.; van Sebille, E.; Hardesty, B.D.; Estes, J.A. Threat of plastic pollution to seabirds is global, pervasive, and increasing. Proc. Natl. Acad. Sci. USA 2015, 112, 11899–11904. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Butterworth, A.; Clegg, I.; Bass, C. Untangled. Marine Debris: A Global Picture of the Impact on Animal Welfare and of Animal-Focused Solutions; World Society for the Protection of Animals: London, UK, 2012; pp. 1–78. [Google Scholar]

- Prendiz, J.; Mena, M.; Vega-Baudrit, J.R. Polylactic Acid (PLA) As A Bioplastic And Its Possible Applications in the Food Industry. Food Sci. Nutr. 2019, 5, 048. [Google Scholar]

- Boonniteewanich, J.; Pitivut, S.; Tongjoy, S.; Lapnonkawow, S.; Suttiruengwong, S. Evaluation of carbon footprint of bioplastic straw compared to petroleum based straw products. Energy Procedia 2014, 56, 518–524. [Google Scholar] [CrossRef] [Green Version]

- Gironi, F.; Piemonte, V. Bioplastics and petroleum-based plastics: Strengths and weaknesses. Energy Sources A Recover. Util. Environ. Eff. 2011, 33, 1949–1959. [Google Scholar] [CrossRef]

- Guinée, J.B. Handbook on Life Cycle Assessment; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; Volume 7. [Google Scholar]

- Heijungs, R.; Sangwon, S. The Computational Structure of Life Cycle Assessment; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; Volume 11. [Google Scholar]

- Wu, W. Carbon Footprint A Case Study on the Municipality of Haninge. Master’s Thesis, School of Technology and Health (STH), Stockholm, Sweden, 2011. [Google Scholar]

- Kunhikrishnan, A.; Thangarajan, R.; Bolan, N.; Xu, Y.; Mandal, S.; Gleeson, D.; Seshadri, B.; Zaman, M.; Barton, L.; Tang, C.; et al. Functional Relationships of Soil Acidification, Liming, and Greenhouse Gas Flux. Adv. Agron. 2016, 139, 1–71. [Google Scholar]

- Hunter, K.A.; Liss, P.S.; Surapipith, L.V.; Dentener, F.; Duce, R.; Kanakidou, M.; Kubilay, N.; Mahowald, N.; Okin, G.; Sarin, M.; et al. Impacts of anthropogenic SOx, NOx and NH3 on acidification of coastal waters and shipping lanes. Geophys. Res. Lett. 2011, 38, 2–7. [Google Scholar] [CrossRef]

- Behera, D.P.; Kolandhasamy, P.; Sigamani, S.; Devi, L.P.; Ibrahim, Y.S. A preliminary investigation of marine litter pollution along Mandvi beach, Kachchh, Gujarat. Mar. Pollut. Bull. 2021, 165, 112100. [Google Scholar] [CrossRef]

- Statista. 2020. Available online: https://www-statista-com.iclibezp1.cc.ic.ac.uk/statistics/726724/weight-of-most-common-items-found-in-global-oceans/ (accessed on 25 May 2021).

- The Star. Spare that Straw, Please. Available online: https://www.thestar.com.my/news/nation/2017/08/20/spare-that-straw-please-a-seemingly-harmless-tool-that-helps-you-enjoy-your-cold-drinks-is-sapping-t/ (accessed on 17 May 2021).

- The Sun Daily. The Ban on Single-Use Plastic Straws. Available online: https://www.thesundaily.my/local/the-ban-on-single-use-plastic-straws-DL1836630 (accessed on 17 May 2021).

- Wong, H.-Y.; Goh, Y.-N.; Kiumarsi, S. Single-Use Straw Ban: Malaysians Behavioural Intentions Towards Reusable Straws; Contemporary Issues in Business and Management, Graduate School of Business, Universiti Sains Malaysia: Penang, Malaysia, 2019. [Google Scholar]

- Chitaka, T.Y.; Russo, V.; von Blottnitz, H. In pursuit of environmentally friendly straws: A comparative life cycle assessment of five straw material options in South Africa. Int. J. Life Cycle Assess. 2020, 25, 1818–1832. [Google Scholar] [CrossRef]

- Rana, K. Plasticless: A Comparative Life-Cycle, Socio-Economic, and Policy Analysis of Alternatives to Plastic Straws. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2020. [Google Scholar]

- Zanghelini, G.M.; Cherubini, E.; Dias, R.; Kabe, Y.H.O.; Delgado, J.J.S. Comparative life cycle assessment of drinking straws in Brazil. J. Clean. Prod. 2020, 276, 123070. [Google Scholar] [CrossRef]

- Chang, L.; Tan, J. An Integrated Sustainability Assessment of Drinking Straws. J. Environ. Chem. Eng. 2021, 9, 105527. [Google Scholar] [CrossRef]

- Ramírez, E.C.; Johnston, D.B.; McAloon, A.J.; Singh, V. Enzymatic corn wet milling: Engineering process and cost model. Biotechnol. Biofuels 2009, 2, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2012, 25, 927–948. [Google Scholar] [CrossRef]

- Jawjit, W.; Kroeze, C.; Soontaranun, W.; Hordijk, L. An analysis of the environmental pressure exerted by the eucalyptus-based kraft pulp industry in Thailand. Environ. Dev. Sustain. 2006, 8, 289–311. [Google Scholar] [CrossRef] [Green Version]

- Horan, E.; Norrish, M. Waste management options to control greenhouse gas emissions—Landfill, compost or incineration ? In Paper for the International Solid Waste Association (ISWA) Conference; ISWA: Vienna, Austria, 2009. [Google Scholar]

- Branchini, L.; Cagnoli, P.; de Pascale, A.; Lussu, F.; Orlandini, V.; Valentini, E. Environmental assessment of renewable fuel energy systems with cross-media effects approach. Energy Procedia 2015, 81, 655–664. [Google Scholar] [CrossRef] [Green Version]

- Morawicki, R.O.; Hager, T. Energy and Greenhouse Gases Footprint of Food Processing. Encycl. Agric. Food Syst. 2014, 3, 82–99. [Google Scholar]

- Poh, G.K.X.; Chew, I.M.L.; Tan, J. Life Cycle Optimization for Synthetic Rubber Glove Manufacturing. Chem. Eng. Technol. 2019, 42, 1771–1779. [Google Scholar] [CrossRef]

- Kuan, C.K.; Foo, D.C.Y.; Tan, R.R.; Kumaresan, S.; Aziz, R.A. Streamlined life cycle assessment of residue utilization options in Tongkat Ali (Eurycoma longifolia) water extract manufacturing process. Clean Technol. Environ. Policy 2007, 9, 225–234. [Google Scholar] [CrossRef]

- Perumal, A.; Timmons, D. Contextual Density and US Automotive Carbon Dioxide Emissions across the Rural–Urban Continuum. Int. Reg. Sci. Rev. 2017, 40, 590–615. [Google Scholar] [CrossRef]

- U.S. Department of Environment. Energy and Environmental Profile of the U.S. Pulp and Paper Industry; U.S. Department of Environment: Washington, DC, USA, 2005.

- Chaffee, C.; Yaros, B.R. Life Cycle Assessment for Three Types of Grocery Bags -Recyclable Plastic; Compostable, Biodegradable Plastic; and Recycled, Recyclable Paper. 2007. Available online: https://plastics.americanchemistry.com/Life-Cycle-Assessment-for-Three-Types-of-Grocery-Bags.pdf (accessed on 2 June 2021).

- Ciroth, A.; Fleischer, G.; Steinbach, J. Uncertainty calculation in life cycle assessments: A combined model of simulation and approximation. Int. J. Life Cycle Assess. 2004, 9, 216–226. [Google Scholar] [CrossRef]

| Index | Formula | Unit of Measure |

|---|---|---|

| Global Warming Potential | GWP = ∑ GWPi × mi | kg CO2 equivalent (kg CO2-eq) |

| Acidification Potential | AP = ∑ APi × mi | kg SO2 equivalent (kg SO2-eq) |

| Eutrophication Potential | EP = ∑ EPi × mi | kg PO4 equivalent (kg PO4-eq) |

| Item of Measurement | GWPi | APi | EPi |

|---|---|---|---|

| kg CO2-eq/kg | kg SO2-eq/kg | kg PO4-eq/kg | |

| CO | 2 | 0 | 0 |

| NOx | 0 | 0.7 | 0.13 |

| SOx | 0 | 1 | 0 |

| VOC | 3 | 0 | 0 |

| NH3 | 0 | 1.88 | 0.35 |

| CO2 | 1 | 0 | 0 |

| CH4 | 23 | 0 | 0 |

| N2O | 310 | 0 | 0 |

| Pollutants | GWPi | Corn Starch Production (Section 1) | ||||

|---|---|---|---|---|---|---|

| Corn Steeping | Germ Separation | Fiber Separation | Gluten Separation | Starch Separation | ||

| CO (g) | 2 | 2.6 × 10−1 | 1.5 | 7.7 × 10−1 | 6.0 × 10−1 | 8.0 × 10−1 |

| VOC (g) | 3 | 3.0 × 10−2 | 1.7 × 10−1 | 8.9 × 10−2 | 6.9 × 10−2 | 9.2 × 10−2 |

| CO2 (g) | 1 | 1.1 × 103 | 6.3 × 103 | 3.4 × 103 | 2.6 × 103 | 3.5 × 103 |

| Total GWP | 1.1 | 6.3 | 3.4 | 2.6 | 3.5 | |

| Overall GWP | 16.9 kg CO2-eq/100 straws | |||||

| Starting Point | Destination | Distance (km) |

|---|---|---|

| Raw Corn | Corn Starch | 187 |

| Corn Starch | Bio-Plastic Straws | 202 |

| Bio-Plastic Straws | Consumer | 50 |

| Consumer | Incineration Plant | 562 |

| Composting Facility | 315 | |

| Landfill | 27 | |

| Total distance (km) | 1343 | |

| Starting Point | Destination | Distance (km) |

|---|---|---|

| Wood Supplier | Paper Mill | 59 |

| Paper Mill | Paper Straw | 119 |

| Paper Straw | Consumer | 50 |

| Consumer | Incineration Plant | 252 |

| Composting Facility | 31 | |

| Landfill | 33 | |

| Total distance (km) | 544 | |

| Vehicle Type | Medium- and Heavy-Duty Truck |

|---|---|

| CO2 Factor (kg/km) | 0.904716 |

| CH4 Factor (g/km) | 0.011185 |

| N2O Factor (g/km) | 0.006835 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moy, C.-H.; Tan, L.-S.; Shoparwe, N.F.; Shariff, A.M.; Tan, J. Comparative Study of a Life Cycle Assessment for Bio-Plastic Straws and Paper Straws: Malaysia’s Perspective. Processes 2021, 9, 1007. https://doi.org/10.3390/pr9061007

Moy C-H, Tan L-S, Shoparwe NF, Shariff AM, Tan J. Comparative Study of a Life Cycle Assessment for Bio-Plastic Straws and Paper Straws: Malaysia’s Perspective. Processes. 2021; 9(6):1007. https://doi.org/10.3390/pr9061007

Chicago/Turabian StyleMoy, Chun-Hung, Lian-See Tan, Noor Fazliani Shoparwe, Azmi Mohd Shariff, and Jully Tan. 2021. "Comparative Study of a Life Cycle Assessment for Bio-Plastic Straws and Paper Straws: Malaysia’s Perspective" Processes 9, no. 6: 1007. https://doi.org/10.3390/pr9061007