Impact of Some Enzymatic Treatments on Acrylamide Content in Biscuits

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biscuit Dough Ingredients

2.2. Sources of Enzymatic Powders, Baker’s Yeast, and Green Tea

2.3. Application of Component Powders for Treated Biscuit Samples

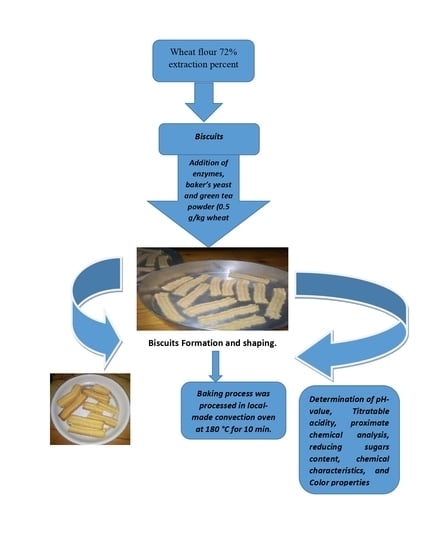

2.4. Technological Process and Preparation of Biscuit Samples

2.5. The Biscuit Formation, Shaping, and Baking Process

2.6. Proximate Chemical Analysis of Biscuits

2.7. Determination of Some Essential Minerals for Treated Biscuit Samples

2.8. Determination of Chemical Characteristics of Treated Biscuits

2.9. Determination of Color Properties for Treated Biscuit Samples

2.10. Sensory Evaluation of Treated Biscuit Samples

2.11. Determination of Some Physical Properties and Baking Quality of Processed Biscuit Samples

- L = average length of biscuits (cm);

- W = average width of biscuits (cm);

- T = average thickness of biscuits (cm).

- W—Width of biscuits (cm);

- T—Thickness of biscuits (cm).

2.12. Statistical Analysis of Treated Biscuit Samples

3. Results

3.1. Chemical Composition of Biscuit Samples

3.2. Color Characteristics for Processed Biscuits

3.3. Chemical Indicators for Biscuit Samples

3.4. Sensory Evaluation of Processed Biscuits

3.5. Essential Mineral Contents for Biscuit Samples

3.6. Physical Characteristics of Processed Biscuits

4. Conclusions

5. Future Research Needs

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Keramat, J.; LeBail, A.; Prost, C.; Jafari, M. Acrylamide in Baking Products: A Review Article. Food Bioprocess Technol. 2011, 4, 530–543. [Google Scholar] [CrossRef]

- Petisca, C.; Henriques, A.; Pérez-Palacios, T.; Pinho, O.; Ferreira, I.M.P.L.V.O. Assessment of hydroxymethylfurfural and furfural in commercial bakery products. J. Food Compos. Anal. 2014, 33, 20–25. [Google Scholar] [CrossRef]

- Vass, A.A.; Smith, R.R.; Thompson, C.V.; Burnett, M.N.; Wolf, D.A.; Synstelien, J.A.; Dulgerian, N.; Eckenrode, B.A. Decompositional Odor Analysis Database. J. Forensic Sci. 2004, 49, 1–10. [Google Scholar] [CrossRef]

- Manley, D. Chocolate and Cocoa as Biscuit Ingredients. In Manley’s Technology of Biscuits, Crackers and Cookies, 4th ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 235–246. [Google Scholar] [CrossRef]

- Manley, D. Biscuit, Cookie and Cracker Manufacturing Manuals. In Biscuit Cookie Cracker Manufacturing Manual Vol. 6 Biscuit Packaging and Storage; Woodhead Publishing Limited: Sawston, UK, 1998. [Google Scholar] [CrossRef]

- Tareke, E.; Rydberg, P.; Karlsson, P.; Eriksson, S.; Törnqvist, M. Analysis of acrylamide, a carcinogen formed in heated foodstuffs. J. Agric. Food Chem. 2002, 50, 4998–5006. [Google Scholar] [CrossRef]

- Mesias, M.; Morales, F.J. Acrylamide in bakery products. Acrylamide Food Anal. Content Potential Health Eff. 2015, 131–157. [Google Scholar]

- European Food Safety Authority. Results On Acrylamide Levels in Food from Monitoring Year 2008. EFSA J. 2010, 8, 1599. [Google Scholar] [CrossRef] [Green Version]

- Miśkiewicz, K.; Nebesny, E.; Oracz, J. Formation of acrylamide during baking of shortcrust cookies derived from various flours. Czech J. Food Sci. 2012, 30, 53–56. [Google Scholar] [CrossRef] [Green Version]

- Sazesh, B.; Goli, M. Quinoa as a wheat substitute to improve the textural properties and minimize the carcinogenic acrylamide content of the biscuit. J. Food Process. Preserv. 2020, 44, e14563. [Google Scholar] [CrossRef]

- Žilić, S.; Aktağ, I.G.; Dodig, D.; Filipović, M.; Gökmen, V. Acrylamide formation in biscuits made of different wholegrain flours depending on their free asparagine content and baking conditions. Food Res. Int. 2020, 132, 109109. [Google Scholar] [CrossRef]

- Capuano, E.; Ferrigno, A.; Acampa, I.; Serpen, A.; Açar, Ö.Ç.; Gökmen, V.; Fogliano, V. Effect of flour type on Maillard reaction and acrylamide formation during toasting of bread crisp model systems and mitigation strategies. Food Res. Int. 2009, 42, 1295–1302. [Google Scholar] [CrossRef]

- Condon, E.M.; Crepinsek, M.K.; Fox, M.K. School Meals: Types of Foods Offered to and Consumed by Children at Lunch and Breakfast. J. Am. Diet. Assoc. 2009, 109, S67–S78. [Google Scholar] [CrossRef]

- Augusto, F.R.; Hilário, A.P. The Rise of Food Charity in Europe; Lambie-Mumford, H., Silvasti, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Baskar, G.; Aiswarya, R. Overview on mitigation of acrylamide in starchy fried and baked foods. J. Sci. Food Agric. 2018, 98, 4385–4394. [Google Scholar] [CrossRef]

- Arisseto, A.P.; Toledo, M.C.; Govaert, Y.; Van Loco, J.; Fraselle, S.; Weverbergh, E.; Degroodt, J.M. Determination of acrylamide levels in selected foods in Brazil. Food Addit. Contam. 2007, 24, 236–241. [Google Scholar] [CrossRef]

- Lindsay, R.C.; Jang, S. Chemical Intervention Strategies for Substantial Suppression of Acrylamide Formation in Fried Potato Products. Adv. Exp. Med. Biol. 2005, 561, 393–404. [Google Scholar] [CrossRef]

- Jung, M.; Choi, D.; Ju, J. A Novel Technique for Limitation of Acrylamide Formation in Fried and Baked Corn Chips and in French Fries. J. Food Sci. 2003, 68, 1287–1290. [Google Scholar] [CrossRef]

- Vinci, R.M.; Mestdagh, F.; De Meulenaer, B. Acrylamide formation in fried potato products—Present and future, a critical review on mitigation strategies. Food Chem. 2012, 133, 1138–1154. [Google Scholar] [CrossRef]

- Baardseth, P.; Blom, H.; Sundt, T.W.; Slinde, E. Reduction of Acrylamide Formation. U.S. Patent 20060147606, 6 July 2006. [Google Scholar]

- Batool, T.; Makky, E.A.; Jalal, M.; Yusoff, M.M. A Comprehensive Review on l-Asparaginase and Its Applications. Appl. Biochem. Biotechnol. 2016, 178, 900–923. [Google Scholar] [CrossRef] [Green Version]

- Capuano, E.; Fogliano, V. Acrylamide and 5-hydroxymethylfurfural (HMF): A review on metabolism, toxicity, occurrence in food and mitigation strategies. LWT-Food Sci. Technol. 2011, 44, 793–810. [Google Scholar] [CrossRef]

- Lingnert, H.; Grivas, S.; Jägerstad, M.; Skog, K.; Törnqvist, M.; Åman, P. Acrylamide in food: Mechanisms of formation and influencing factors during heating of foods. Scand. J. Nutr. 2002, 46, 159–172. [Google Scholar] [CrossRef]

- Svensson, K.; Abramsson, L.; Becker, W.; Glynn, A.; Hellenäs, K.-E.; Lind, Y.; Rosén, J. Dietary intake of acrylamide in Sweden. Food Chem. Toxicol. 2003, 41, 1581–1586. [Google Scholar] [CrossRef]

- Zyzak, D.V.; Sanders, R.A.; Stojanovic, M.; Tallmadge, D.H.; Eberhart, B.L.; Ewald, D.K.; Gruber, D.C.; Morsch, T.R.; Strothers, M.A.; Rizzi, G.P.; et al. Acrylamide Formation Mechanism in Heated Foods. J. Agric. Food Chem. 2003, 51, 4782–4787. [Google Scholar] [CrossRef] [PubMed]

- Pedreschi, F.; Mariotti, S.; Granby, K.; Risum, J. Acrylamide reduction in potato chips by using commercial asparaginase in combination with conventional blanching. LWT Food Sci. Technol. 2011, 44, 1473–1476. [Google Scholar] [CrossRef]

- Aiswarya, R.; Baskar, G. Enzymatic mitigation of acrylamide in fried potato chips using asparaginase from Aspergillus terreus. Int. J. Food Sci. Technol. 2018, 53, 491–498. [Google Scholar] [CrossRef]

- Pedreschi, F.; Mariotti, M.S.; Granby, K. Current issues in dietary acrylamide: Formation, mitigation and risk assessment. J. Sci. Food Agric. 2014, 94, 9–20. [Google Scholar] [CrossRef]

- Wang, S.; Yu, J.; Xin, Q.; Wang, S.; Copeland, L. Effects of starch damage and yeast fermentation on acrylamide formation in bread. Food Control 2017, 73, 230–236. [Google Scholar] [CrossRef]

- Choi, I.; Zhong, Q. Gluconic acid as a chelator to improve clarity of skim milk powder dispersions at pH 3.0. Food Chem. 2021, 344, 128639. [Google Scholar] [CrossRef]

- Kornecki, J.F.; Carballares, D.; Tardioli, P.W.; Rodrigues, R.C.; Berenguer-Murcia, Á.; Alcántara, A.R.; Fernandez-Lafuente, R. Enzyme production of D-gluconic acid and glucose oxidase: Successful tales of cascade reactions. Catal. Sci. Technol. 2020, 10, 5740–5771. [Google Scholar] [CrossRef]

- Jiang, D.F.; Chen, J.; Li, F.; Li, W.; Yu, L.; Zheng, F.; Wang, X. Deoxynivalenol and its acetyl derivatives in bread and biscuits in Shandong province of China. Food Addit. Contam. Part B Surveill. 2018, 11, 43–48. [Google Scholar] [CrossRef]

- Szweda, R.T.; Schmidt, K.; Zorn, H. Bleaching of colored whey and milk by a multiple-enzyme system. Eur. Food Res. Technol. 2013, 237, 377–384. [Google Scholar] [CrossRef]

- Valencia, P.; Espinoza, K.; Ramirez, C.; Franco, W.; Urtubia, A. Technical Feasibility of Glucose Oxidase as a Prefermentation Treatment for Lowering the Alcoholic Degree of Red Wine. Am. J. Enol. Vitic. 2017, 68, 386–389. [Google Scholar] [CrossRef]

- Gong, Q.; Sun, L.-P.; Wu, Z.; Huo, L.-H.; Zhao, H. Enhanced non-enzymatic glucose sensing of Cu–BTC-derived porous copper@carbon agglomerate. J. Mater. Sci. 2018, 53, 7305–7315. [Google Scholar] [CrossRef]

- Visvanathan, R.; Jayathilake, C.; Liyanage, R.; Sivakanesan, R. Applicability and reliability of the glucose oxidase method in assessing α-amylase activity. Food Chem. 2019, 275, 265–272. [Google Scholar] [CrossRef]

- Walker, G.M. Yeasts. In Desk Encyclopedia of Microbiology; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2009; pp. 1174–1187. [Google Scholar]

- Goffeau, A.; Barrell, B.G.; Bussey, H.; Davis, R.W.; Dujon, B.; Feldmann, H.; Galibert, F.; Hoheisel, J.D.; Jacq, C.; Johnston, M.; et al. Life with 6000 genes. Science 1996, 274, 546–567. [Google Scholar] [CrossRef] [Green Version]

- Gallone, B.; Steensels, J.; Prahl, T.; Soriaga, L.; Saels, V.; Herrera-Malaver, B.; Merlevede, A.; Roncoroni, M.; Voordeckers, K.; Miraglia, L.; et al. Domestication and Divergence of Saccharomyces cerevisiae Beer Yeasts. Cell 2016, 166, 1397–1410.e16. [Google Scholar] [CrossRef] [Green Version]

- Warringer, J.; Zörgö, E.; Cubillos, F.A.; Zia, A.; Gjuvsland, A.; Simpson, J.T.; Forsmark, A.; Durbin, R.; Omholt, S.W.; Louis, E.J.; et al. Trait Variation in Yeast Is Defined by Population History. PLoS Genet. 2011, 7, e1002111. [Google Scholar] [CrossRef] [Green Version]

- Fredriksson, H.; Tallving, J.; Rosén, J.; Åman, P. Fermentation Reduces Free Asparagine in Dough and Acrylamide Content in Bread. Cereal Chem. 2004, 81, 650–653. [Google Scholar] [CrossRef]

- Huang, Y.; Lu, J.; Li, M.; Li, C.; Wang, Y.; Shen, M.; Chen, Y.; Nie, S.; Zeng, M.; Chen, J.; et al. Effect of acidity regulators on acrylamide and 5-hydroxymethylfurfural formation in French fries: The dual role of pH and acid radical ion. Food Chem. 2022, 371, 131154. [Google Scholar] [CrossRef]

- Fink, M.; Andersson, R.; Rosén, J.; Åman, P. Effect of added asparagine and glycine on acrylamide content in yeast-leavened bread. Cereal Chem. 2006, 83, 218–222. [Google Scholar] [CrossRef]

- Huang, W.; Yu, S.; Zou, Q.; Tilley, M. Effects of frying conditions and yeast fermentation on the acrylamide content in you-tiao, a traditional Chinese, fried, twisted dough-roll. Food Res. Int. 2008, 41, 918–923. [Google Scholar] [CrossRef]

- Matthäus, B.; Haase, N.U. Acrylamide—Still a matter of concern for fried potato food? Eur. J. Lipid Sci. Technol. 2014, 116, 675–687. [Google Scholar] [CrossRef]

- Isanbulatova, E.S. Russiaâ€TM S Export Potential in The Global Tea Market. Bus. Strateg. 2022, 10, 57–59. [Google Scholar] [CrossRef]

- Yang, Y.; Guan, J.; Yin, J.; Shao, B.; Li, H. Urinary levels of bisphenol analogues in residents living near a manufacturing plant in south China. Chemosphere 2014, 112, 481–486. [Google Scholar] [CrossRef] [PubMed]

- Burillo, J.; Marqués, P.; Jiménez, B.; González-Blanco, C.; Benito, M.; Guillén, C. Insulin resistance and diabetes mellitus in Alzheimer’s disease. Cells 2021, 10, 1236. [Google Scholar] [CrossRef] [PubMed]

- Shang, Y.; Xu, X.; Gao, B.; Wang, S.; Duan, X. Single-atom catalysis in advanced oxidation processes for environmental remediation. Chem. Soc. Rev. 2021, 50, 5281–5322. [Google Scholar] [CrossRef]

- Sebastian, R.S.; Kuczmarski, M.F.; Enns, C.W.; Goldman, J.D.; Murayi, T.; Moshfegh, A.J.; Zonderman, A.B.; Evans, M.K. Application of the Database of Flavonoid Values for USDA Food Codes 2007–2010 in assessing intake differences between the Healthy Aging in Neighborhoods of Diversity across the Life Span (HANDLS) study and What We Eat in America (WWEIA), NHANES. J. Food Compos. Anal. 2021, 104, 104124. [Google Scholar] [CrossRef]

- Song, W.O.; Chun, O.K. Tea Is the Major Source of Flavan-3-ol and Flavonol in the U.S. Diet. J. Nutr. 2008, 138, 1543S–1547S. [Google Scholar] [CrossRef] [Green Version]

- Mildner-Szkudlarz, S.; Różańska, M.; Piechowska, P.; Waśkiewicz, A.; Zawirska-Wojtasiak, R. Effects of polyphenols on volatile profile and acrylamide formation in a model wheat bread system. Food Chem. 2019, 297, 125008. [Google Scholar] [CrossRef]

- Torres, A.M.; Palacios, S.A.; Yerkovich, N.; Palazzini, J.M.; Battilani, P.; Leslie, J.F.; Logrieco, A.F.; Chulze, S.N. Fusarium head blight and mycotoxins in wheat: Prevention and control strategies across the food chain. World Mycotoxin J. 2019, 12, 333–355. [Google Scholar] [CrossRef]

- Fu, Z.; Yoo, M.J.; Zhou, W.; Zhang, L.; Chen, Y.; Lu, J. Effect of (−)-epigallocatechin gallate (EGCG) extracted from green tea in reducing the formation of acrylamide during the bread baking process. Food Chem. 2018, 242, 162–168. [Google Scholar] [CrossRef]

- Zbikowska, A.; Kowalska, M.; Pieniowska, J. Assessment of shortcrust biscuits with reduced fat content of microcrystalline cellulose and psyllium as fat replacements. J. Food Process. Preserv. 2018, 42, e13675. [Google Scholar] [CrossRef]

- AACC International. International. Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2000. [Google Scholar]

- Sheng, Y.Y.; Irons, G.A. Measurement and modeling of turbulence in the gas/liquid two-phase zone during gas injection. Metall. Trans. B 1993, 24, 695–705. [Google Scholar] [CrossRef]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Khoshnam, F.; Zargar, B.; Pourreza, N.; Parham, H. Acetone extraction and HPLC determination of acrylamide in potato chips. J. Iran. Chem. Soc. 2010, 7, 853–858. [Google Scholar] [CrossRef]

- Wang, H.; Lee, A.W.; Shuang, S.; Choi, M.M. SPE/HPLC/UV studies on acrylamide in deep-fried flour-based indigenous Chinese foods. Microchem. J. 2008, 89, 90–97. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.J.; Vakharia, D.P. Teaching–learning-based optimization: A novel method for constrained mechanical design optimization problems. Comput. Aided Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Hooda, S.; Jood, S. Effect of fenugreek flour blending on physical, organoleptic and chemical characteristics of wheat bread. Nutr. Food Sci. 2005, 35, 229–242. [Google Scholar] [CrossRef]

- Gomez, D.E.; Alonso, D.F.; Yoshiji, H.; Thorgeirsson, U.P. Tissue inhibitors of metalloproteinases: Structure, regulation and biological functions. Eur. J. Cell Biol. 1997, 74, 111–122. [Google Scholar]

- Akubor, P.I.; Ukwuru, M.U. Functional properties and biscuit making potential of soybean and cassava flour blends. Plant Foods Hum. Nutr. 2003, 58, 1–12. [Google Scholar] [CrossRef]

- Das, A.B.; Srivastav, P.P. Acrylamide in snack foods. Toxicol. Mech. Methods 2012, 22, 163–169. [Google Scholar] [CrossRef]

- Agrahar-Murugkar, D.; Gulati, P.; Kotwaliwale, N.; Gupta, C. Evaluation of nutritional, textural and particle size characteristics of dough and biscuits made from composite flours containing sprouted and malted ingredients. J. Food Sci. Technol. 2015, 52, 5129–5137. [Google Scholar] [CrossRef] [Green Version]

- Cauvain, S. Principles of dough formation. In Technology of Breadmaking; Springer: Berlin/Heidelberg, Germany, 2015; pp. 303–337. [Google Scholar]

- Arimi, J.; Duggan, E.; O’Sullivan, M.; Lyng, J.; O’Riordan, E. Effect of water activity on the crispiness of a biscuit (Crackerbread): Mechanical and acoustic evaluation. Food Res. Int. 2010, 43, 1650–1655. [Google Scholar] [CrossRef]

- Ciesarová, Z.; Kukurová, K.; Bednáriková, A.; Morales, F.J. Effect of heat treatment and dough formulation on the formation of Maillard reaction products in fine bakery products—Benefits and weak points. J. Food Nutr. Res. 2009, 48, 20–30. [Google Scholar]

- Zhang, Y.; Ren, Y.; Zhang, Y. New Research Developments on Acrylamide: Analytical Chemistry, Formation Mechanism, and Mitigation Recipes. Chem. Rev. 2009, 109, 4375–4397. [Google Scholar] [CrossRef] [PubMed]

- Yadav, D.N.; Thakur, N.; Sunooj, K.V.; Singh, K.K. Effect of de-oiled peanut meal flour (DPMF) on the textural, organoleptic and physico chemical properties of bread. Int. Food Res. J. 2013, 20, 1307–1312. [Google Scholar]

- Lagrain, B.; Thewissen, B.G.; Brijs, K.; Delcour, J.A. Impact of Redox Agents on the Extractability of Gluten Proteins during Bread Making. J. Agric. Food Chem. 2007, 55, 5320–5325. [Google Scholar] [CrossRef]

- Rydberg, P.; Eriksson, S.; Tareke, E.; Karlsson, P.; Ehrenberg, L.; Törnqvist, M. Factors that influence the acrylamide content of heated foods. Adv. Exp. Med. Biol. 2005, 561, 317–328. [Google Scholar] [CrossRef]

- Mottur, G. A scientific look at potato chips: The original savory snack. Cereal Foods World 1989, 34, 620–626. Available online: https://agris.fao.org/agris-search/search.do?recordID=US9009187 (accessed on 12 January 2022).

- Mottram, D.S.; Wedzicha, B.L.; Dodson, A.T. Food chemistry: Acrylamide is formed in the Maillard reaction. Nature 2002, 419, 448–449. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Van der Fels-Klerx, H.J.; Peters, R.J.B.; Van Boekel, M.A.J.S. Acrylamide and 5-hydroxymethylfurfural formation during baking of biscuits: Part I: Effects of sugar type. Food Chem. 2016, 192, 575–585. [Google Scholar] [CrossRef]

- Schouten, M.A.; Fryganas, C.; Tappi, S.; Romani, S.; Fogliano, V. The use of kidney bean flour with intact cell walls reduces the formation of acrylamide in biscuits. Food Control 2022, 140, 109054. [Google Scholar] [CrossRef]

- Barber, S.; Torner, M.J.; Martínez-Anaya, M.A.; de Barber, C.B. Microflora of the sour dough of wheat flour bread IX Biochemical characteristics and baking performance of wheat doughs elaborated with mixtures of pure microorganisms. Z. Lebensm. Unters. Forsch. 1989, 189, 6–11. [Google Scholar]

- Curtis, T.; Halford, N.G. Food security: The challenge of increasing wheat yield and the importance of not compromising food safety. Ann. Appl. Biol. 2014, 164, 354–372. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, H.T.; van der Fels-Klerx, H.J.; van Boekel, M.A.J.S. Acrylamide and 5-hydroxymethylfurfural formation during biscuit baking. Part II: Effect of the ratio of reducing sugars and asparagine. Food Chem. 2017, 230, 14–23. [Google Scholar] [CrossRef] [PubMed]

- Weisshaar, R. Acrylamide in bakery products—Results from model experiments. Dtsch. Leb. 2004, 100, 92. [Google Scholar]

- Mustafa, A.; Fink, M.; Kamal-Eldin, A.; Rosén, J.; Andersson, R.; Åman, P. Interaction effects of fermentation time and added asparagine and glycine on acrylamide content in yeast-leavened bread. Food Chem. 2009, 112, 767–774. [Google Scholar] [CrossRef]

- Claus, A.; Carle, R.; Schieber, A. Acrylamide in cereal products: A review. J. Cereal Sci. 2008, 47, 118–133. [Google Scholar] [CrossRef]

- Zhang, Y.; Ying, T.; Zhang, Y. Reduction of Acrylamide and Its Kinetics by Addition of Antioxidant of Bamboo Leaves (AOB) and Extract of Green Tea (EGT) in Asparagine–Glucose Microwave Heating System. J. Food Sci. 2008, 73, C60–C66. [Google Scholar] [CrossRef]

- Marková, L.; Ciesarová, Z.; Kukurová, K.; Zieliński, H.; Przygodzka, M.; Bednáriková, A.; Šimko, P. Influence of various spices on acrylamide content in buckwheat ginger cakes. Chem. Pap. 2012, 66, 949–954. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y. Formation and reduction of acrylamide in Maillard reaction: A review based on the current state of knowledge. Crit. Rev. Food Sci. Nutr. 2007, 47, 521–542. [Google Scholar] [CrossRef]

- Hamlet, C.G.; Sadd, P.A.; Liang, L. Correlations between the Amounts of Free Asparagine and Saccharides Present in Commercial Cereal Flours in the United Kingdom and the Generation of Acrylamide during Cooking. ACS Publ. 2008, 56, 6145–6153. Available online: https://pubs.acs.org/doi/pdf/10.1021/jf703743g (accessed on 31 August 2022). [CrossRef]

- Springer, M.; Fischer, T.; Lehrack, A.; Freund, W. Development of acrylamide in baked products. Getreide Mehl Brot 2003, 57, 274–278. [Google Scholar]

- Kumar, N.S.M.; Shimray, C.A.; Indrani, D.; Manonmani, H.K. Reduction of Acrylamide Formation in Sweet Bread with l-Asparaginase Treatment. Food Bioprocess Technol. 2014, 7, 741–748. [Google Scholar] [CrossRef]

- European Food Safety Authority. Results on acrylamide levels in food from monitoring years 2007–2009 and Exposure assessment. EFSA J. 2011, 9, 2133. [Google Scholar] [CrossRef] [Green Version]

- Hendriksen, H.V.; Kornbrust, B.A.; Ostergaard, P.R.; Stringer, M.A. Evaluating the potential for enzymatic acrylamide mitigation in a range of food products using an asparaginase from Aspergillus oryzae. J. Agric. Food Chem. 2009, 57, 4168–4176. [Google Scholar] [CrossRef]

- Vass, M.; Amrein, T.M.; Schönbächler, B.; Escher, F.; Amadò, R. Ways to reduce the acrylamide formation in cracker products. Czech J. Food Sci. 2018, 22, S19–S21. [Google Scholar] [CrossRef]

- Zou, P.; Oh, S.S.Y.; Kiang, K.H.; Low, M.Y.; Bloodworth, B.C. Detection of sibutramine, its two metabolites and one analogue in a herbal product for weight loss by liquid chromatography triple quadrupole mass spectrometry and time-of-flight mass spectrometry. Rapid Commun. Mass Spectrom. 2007, 21, 614–618. [Google Scholar] [CrossRef]

- Anese, M.; Suman, M.; Nicoli, M.C. Acrylamide removal from heated foods. Food Chem. 2010, 119, 791–794. [Google Scholar] [CrossRef]

- Thomas, A.; Thomas, A. Acrylamide—A potent carcinogen in food. Int. J. Sci. Res. 2014, 3, 2319–7064. [Google Scholar]

- Bartkiene, E.; Jakobsone, I.; Pugajeva, I.; Bartkevics, V.; Zadeike, D.; Juodeikiene, G. Reducing of acrylamide formation in wheat biscuits supplemented with flaxseed and lupine. Lwt Food Sci. Technol. 2016, 65, 275–282. [Google Scholar] [CrossRef]

- Batool, Z.; Sadir, S.; Liaquat, L.; Tabassum, S.; Madiha, S.; Rafiq, S.; Tariq, S.; Batool, T.S.; Saleem, S.; Naqvi, F.; et al. Repeated administration of almonds increases brain acetylcholine levels and enhances memory function in healthy rats while attenuates memory deficits in animal model of amnesia. Brain Res. Bull. 2016, 120, 63–74. [Google Scholar] [CrossRef]

- Gökmen, V.; Şenyuva, H.Z. Acrylamide formation is prevented by divalent cations during the Maillard reaction. Food Chem. 2007, 103, 196–203. [Google Scholar] [CrossRef]

| Parameter | BT0 | BT1 | BT2 | BT3 | BT4 | BT5 |

|---|---|---|---|---|---|---|

| Asparaginase | -- | 0.5 gm/kg wheat flour | -- | -- | -- | -- |

| Glucose oxidase | -- | 0.5 gm/kg wheat flour | -- | -- | -- | |

| Mixed enzymes (1:1) | -- | -- | 0.5 gm/kg wheat flour | -- | -- | |

| Baker’s yeast | -- | -- | -- | 0.5 gm/kg wheat flour | -- | |

| Green tea | -- | -- | -- | -- | 0.5 gm/kg wheat flour |

| Parameter | BT0 | BT1 | BT2 | BT3 | BT4 | BT5 | F. Test |

|---|---|---|---|---|---|---|---|

| Protein (%) | 8.30 ab ± 0.44 | 8.60 a ± 0.26 | 8.56 a ± 0.12 | 8.63 a ± 0.23 | 8.36 ab ± 0.31 | 8.00 b ± 0.32 | * |

| Ash (%) | 0.846 b ± 0.035 | 0.850 b ± 0.030 | 0.826 b ± 0.021 | 0.853 b ± 0.015 | 1.566 a ± 0.306 | 1.533 a ± 0.306 | NS |

| Fat (%) | 18.30 a ± 0.44 | 17.96 a ± 0.50 | 18.20 a ± 0.70 | 18.10 a ± 0.72 | 18.16 a ± 0.32 | 18.43 a ± 0.15 | * |

| Fibers (%) | 2.63 a ± 0.15 | 2.46 a ± 0.32 | 2.40 a ± 0.10 | 2.56 a ± 0.15 | 1.34 b ± 0.24 | 1.63 b ± 0.21 | * |

| Moisture (%) | 5.27 c ± 0.60 | 12.83 a ± 0.31 | 12.93 a ± 0.49 | 11.96 b ± 0.68 | 3.38 d ± 0.51 | 3.12 d ± 0.20 | * |

| Carbohydrates (%) | 64.65 b ± 1.28 | 57.28 c ± 0.29 | 57.07 c ± 1.06 | 57.88 c ± 0.66 | 67.17 a ± 0.47 | 66.94 a ± 0.40 | * |

| Energy (k. calories/g) | 456.5 b ± 1.53 | 425.2 c ± 3.84 | 426.3 c ± 1.96 | 428.9 c ± 6.75 | 465.6 a ± 0.65 | 466.9 a ± 2.61 | * |

| pH value | 6.86 a ± 0.25 | 6.50 a ± 0.26 | 5.53 b ± 0.44 | 5.40 b ± 0.25 | 4.66 c ± 0.21 | 4.53 c ± 0.15 | * |

| Total Titratable Acidity (TTA) % | 0.376 a ± 0.015 | 0.356 a ± 0.006 | 0.276 c ± 0.015 | 0.330 b ± 0.020 | 0.276 c ± 0.012 | 0.246 d ± 0.012 | * |

| Parameter/Treatment | BT0 | BT1 | BT2 | BT3 | BT4 | BT5 | F. Test |

|---|---|---|---|---|---|---|---|

| Reducing sugar content (mg/100 g) | 5633.3 a ± 305.5 | 5500.0 a ± 264.6 | 3400.0 d ± 360.6 | 3900.0 c ± 0.0 | 2700.0 e ± 0.0 | 4800.0 b ± 0.0 | * |

| Asparagine content (mg/kg) | 478.6 a ± 1.5 | 151.3 f ± 1.5 | 470.0 b ± 2.0 | 241.3 d ± 1.5 | 222.3 e ± 3.2 | 423.3 c ± 3.5 | * |

| Asparagine/Reducing sugar ratio | 0.085 b ± 0.004 | 0.027 d ± 0.001 | 0.139 a ± 0.014 | 0.062 c ± 0.000 | 0.082 b ± 0.001 | 0.088 b ± 0.001 | * |

| Reduction in Asparagine (%) | 0.00 f ± 0.00 | 68.31 a ± 0.25 | 1.60 e ± 0.24 | 49.48 c ± 0.42 | 53.45 b ± 0.75 | 11.37 d ± 0.55 | * |

| Acrylamide (mg/kg) | 868.0 a ± 7.9 | 283.0 c ± 3.0 | 312.0 b ± 3.5 | 262.6 d ± 4.6 | 214.3 f ± 2.1 | 230.6 e ± 2.1 | * |

| Asparagine/Acrylamide ratio | 0.551 e ± 0.004 | 0.534 e ± 0.005 | 1.506 b ± 0.018 | 0.919 d ± 0.018 | 1.037 c ± 0.012 | 1.835 a ± 0.026 | * |

| Reduction in acrylamide (%) | 0.00 f ± 0.00 | 67.28 d ± 0.35 | 63.93 e ± 0.40 | 69.63 c ± 0.53 | 75.22 a ± 0.24 | 73.33 b ± 0.24 | * |

| Parameter/Treatment | BT0 | BT1 | BT2 | BT3 | BT4 | BT5 | F. Test |

|---|---|---|---|---|---|---|---|

| Length (cm) | 9.30 c ± 0.10 | 9.50 bc ± 0.10 | 9.00 d ± 0.01 | 9.56 b ± 0.25 | 10.33 a ± 0.15 | 9.50 bc ± 0.20 | * |

| Width, W (cm) | 1.70 c ± 0.10 | 1.70 c ± 0.26 | 1.83 c ± 0.12 | 1.80 c ± 0.01 | 2.60 a ± 0.10 | 2.13 b ± 0.15 | * |

| Thickness, T (cm) | 0.73 c ± 0.06 | 0.86 c ± 0.06 | 0.83 c ± 0.06 | 0.86 c ± 0.06 | 1.46 a ± 0.15 | 1.16 b ± 0.15 | * |

| Volume (cm3) | 11.58 c ± 1.00 | 13.92 c ± 1.63 | 13.71 c ± 0.05 | 14.94 c ± 1.35 | 39.42 a ± 4.66 | 23.65 b ± 3.79 | * |

| Spread ratio (SF) | 2.32 a ± 0.23 | 1.97 abc ± 0.41 | 2.21 ab ± 0.28 | 2.08 abc ± 0.14 | 1.78 c ± 0.15 | 1.84 bc ± 0.23 | * |

| Weight (g) | 8.63 ab ± 0.21 | 8.53 b ± 0.06 | 8.26 c ± 0.06 | 8.53 b ± 0.06 | 8.23 c ± 0.15 | 8.80 a ± 0.10 | * |

| Density (g/v) | 0.747 a ± 0.048 | 0.619 b ± 0.074 | 0.603 b ± 0.004 | 0.574 b ± 0.053 | 0.210 d ± 0.023 | 0.377 c ± 0.054 | * |

| Baking loss (%) | 29.13c ± 0.86 | 29.69c ± 1.56 | 26.08d ± 2.17 | 30.98b ± 0.63 | 18.99e ± 0.92 | 33.07a ± 0.76 | * |

| Parameter/Treatment | BT0 | BT1 | BT2 | BT3 | BT4 | BT5 | F. Test |

|---|---|---|---|---|---|---|---|

| Length (cm) | 9.30 c ± 0.10 | 9.50 bc ± 0.10 | 9.00 d ± 0.01 | 9.56 b ± 0.25 | 10.33 a ± 0.15 | 9.50 bc ± 0.20 | * |

| Width, W (cm) | 1.70 c ± 0.10 | 1.70 c ± 0.26 | 1.83 c ± 0.12 | 1.80 c ± 0.01 | 2.60 a ± 0.10 | 2.13 b ± 0.15 | * |

| Thickness, T (cm) | 0.73 c ± 0.06 | 0.86 c ± 0.06 | 0.83 c ± 0.06 | 0.86 c ± 0.06 | 1.46 a ± 0.15 | 1.16 b ± 0.15 | * |

| Volume (cm3) | 11.58 c ± 1.00 | 13.92 c ± 1.63 | 13.71 c ± 0.05 | 14.94 c ± 1.35 | 39.42 a ± 4.66 | 23.65 b ± 3.79 | * |

| Spread ratio (SF) | 2.32 a ± 0.23 | 1.97 abc ± 0.41 | 2.21 ab ± 0.28 | 2.08 abc ± 0.14 | 1.78 c ± 0.15 | 1.84 bc ± 0.23 | * |

| Weight (g) | 8.63 ab ± 0.21 | 8.53 b ± 0.06 | 8.26 c ± 0.06 | 8.53 b ± 0.06 | 8.23 c ± 0.15 | 8.80 a ± 0.10 | * |

| Density (g/v) | 0.747 a ± 0.048 | 0.619 b ± 0.074 | 0.603 b ± 0.004 | 0.574 b ± 0.053 | 0.210 d ± 0.023 | 0.377 c ± 0.054 | * |

| Baking loss (%) | 29.13 c ± 0.86 | 29.69 c ± 1.56 | 26.08 d ± 2.17 | 30.98 b ± 0.63 | 18.99 e ± 0.92 | 33.07 a ± 0.76 | * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Sayed, A.A.; Abdelhady, M.M.; Jaafari, S.A.; Alanazi, T.M.; Mohammed, A.S. Impact of Some Enzymatic Treatments on Acrylamide Content in Biscuits. Processes 2023, 11, 1041. https://doi.org/10.3390/pr11041041

El-Sayed AA, Abdelhady MM, Jaafari SA, Alanazi TM, Mohammed AS. Impact of Some Enzymatic Treatments on Acrylamide Content in Biscuits. Processes. 2023; 11(4):1041. https://doi.org/10.3390/pr11041041

Chicago/Turabian StyleEl-Sayed, Amr A., Magdy M. Abdelhady, Saleh A. Jaafari, Tariq M. Alanazi, and Alaa S. Mohammed. 2023. "Impact of Some Enzymatic Treatments on Acrylamide Content in Biscuits" Processes 11, no. 4: 1041. https://doi.org/10.3390/pr11041041