Influence of the Drying Method on the Volatile Component Profile of Hypericum perforatum Herb: A HS-SPME-GC/MS Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material

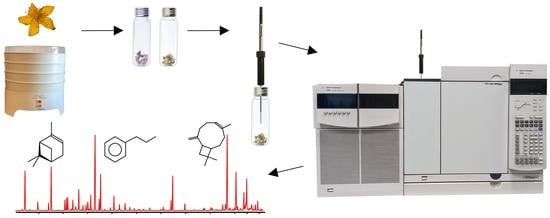

2.2. Analysis of Volatile Compounds in St. John’s Wort

2.3. Methods of Drying the St. John’s Wort Herb

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Bilia, A.R.; Gallori, S.; Vincieri, F.F. St. John’s wort and depression: Efficacy, safety and tolerability—An update. Life Sci. 2002, 70, 3077–3096. [Google Scholar] [CrossRef]

- European Union Herbal Monograph on Hypericum perforatum L., Herba (Well-Established and Traditional Use), 2nd Draft–Revision 1. Reference Number: EMA/HMPC/7695/2021 2021. Available online: https://www.ema.europa.eu/en/medicines/herbal/hyperici-herba (accessed on 23 September 2022).

- Balea, A.; Fenesan, M.; Ciotlaus, I. Traceability of Volatile Organic Compounds from Hypericum perforatum in Fresh and Dried Form and in Essential Oil. Rev. Chim. 2020, 71, 59–65. [Google Scholar] [CrossRef]

- Tokgöz, H.B.; Altan, F. Hypericum perforatum L.: A medicinal plant with potential as a curative agent against obesity-associated complications. Mol. Biol. Rep. 2020, 47, 8679–8686. [Google Scholar] [CrossRef]

- Sahebkar-Khorasani, M.; Safarian, M.; Jarahi, L.; Yousefi, M.; Salari, R.; Azizi, H. Appetite and weight control by Hypericum perforatum and acupuncture added to lifestyle modification: Study protocol for a randomized clinical trial. Adv. Integr. Med. 2020, 7, 101–107. [Google Scholar] [CrossRef]

- Zirak, N.; Shafiee, M.; Soltani, G.; Mirzaei, M.; Sahebkar, A. Hypericum perforatum in the treatment of psychiatric and neurodegenerative disorders: Current evidence and potential mechanisms of action. J. Cell. Physiol. 2018, 234, 8496–8508. [Google Scholar] [CrossRef]

- Velingkar, V.S.; Gupta, G.L.; Hegde, N.B. A current update on phytochemistry, pharmacology and herb–drug interactions of Hypericum perforatum. Phytochem. Rev. 2017, 16, 725–744. [Google Scholar] [CrossRef]

- Crockett, S.L.; Poller, B.; Tabanca, N.; Pferschy-Wenzig, E.M.; Kunert, O.; Wedge, D.E.; Bucar, F. Bioactive xanthones from the roots of Hypericum perforatum (common St John’s wort). J. Sci. Food Agric. 2010, 91, 428–434. [Google Scholar] [CrossRef] [Green Version]

- Rizzo, P.; Altschmied, L.; Ravindran, B.M.; Rutten, T.; D’Auria, J.C. The Biochemical and Genetic Basis for the Biosynthesis of Bioactive Compounds in Hypericum perforatum L., One of the Largest Medicinal Crops in Europe. Genes 2020, 11, 1210. [Google Scholar] [CrossRef]

- Burdejova, L.; Vitova, E. Assessment of volatile compounds with emphasis on volatile allergens in selected dried medicinal plants using solid phase microextraction coupled with gas chromatography–mass spectrometry. Chem. Pap. 2020, 74, 1679–1690. [Google Scholar] [CrossRef]

- Rodriguez-Landa, J.F.; Contreras, C.M. A review of clinical and experimental observations about antidepressant actions and side effects produced by Hypericum perforatum extracts. Phytomedicine 2003, 10, 688–699. [Google Scholar] [CrossRef]

- Smith, T.; Majid, F.; Eckl, V.; Reynolds, C.M. Herbal supplement sales in US increase by record-breaking 17.3% in 2020. Herbal Gram. 2021, 131, 52–65. [Google Scholar]

- Jadhav, C.A.; Vikhe, D.N.; Jadhav, R.S. Global and domestic market of herbal medicines: A review. Res. J. Sci. Tech. 2020, 12, 327–330. [Google Scholar] [CrossRef]

- Herbal Medicine Market Size and Trends Analysis by Market Research Future. Available online: https://www.marketresearchfuture.com/reports/herbal-medicine-market-3250 (accessed on 15 September 2022).

- Food Dehydrator Market Size By Technology (Vertical Airflow, Horizontal Airflow), by End-Use (Commercial Usage {Food & Beverage Industry, Nutraceutical Industry, Herbal Products Industry, Hotels, Restaurants and Catering (HoReCa) Sector}, Domestic/Residential Usage), by Energy Source (Electric, Biofuel, Solar, Other) Industry Analysis Report, Regional Outlook, Growth Potential, Price Trends, Competitive Landscape & Forecast, 2022–2030. Available online: https://www.gminsights.com/industry-analysis/food-dehydrator-market (accessed on 20 November 2022).

- Smelcerovic, A.; Spiteller, M.; Ligon, A.P.; Smelcerovic, Z.; Raabe, N. Essential oil composition of Hypericum L. species from Southeastern Serbia and their chemotaxonomy. Biochem. Syst. Ecol. 2007, 35, 99–113. [Google Scholar] [CrossRef]

- Chauhan, R.S.; Vashistha, R.K.; Nautiyal, M.C.; Tava, A.; Cecotti, R. Essential oil composition of Hypericum perforatum L. from cultivated source. J. Essent. Oil Res. 2011, 23, 20–25. [Google Scholar] [CrossRef]

- Lewicki, P.P.; Pawlak, G. Effect of Drying on Microstructure of Plant Tissue. Dry. Technol. 2003, 21, 657–683. [Google Scholar] [CrossRef]

- Funebo, T.; Ahrne, L.; Kidman, S.; Langton, M.; Skjoldebrand, C. Microwave heat treatment of apple before air dehydration—Effects on physical properties and microstructure. J. Food Eng. 2000, 46, 173–182. [Google Scholar] [CrossRef]

- Chua, L.Y.W.; Chong, C.H.; Chua, B.L. Influence of Drying Methods on the Antibacterial, Antioxidant and Essential Oil Volatile Composition of Herbs: A Review. Food Bioprocess Technol. 2019, 12, 450–476. [Google Scholar] [CrossRef]

- Yoruk, R.; Marshall, M.R. Physicochemical properties and function of plant polyphenol oxidase: A review. J. Food Biochem. 2003, 27, 361–422. [Google Scholar] [CrossRef]

- Panadare, D.; Rathod, V.K. Extraction and purification of polyphenol oxidase: A review. Biocatal. Agric. Biotechnol. 2018, 14, 431–437. [Google Scholar] [CrossRef]

- Kalsoom, U.; Bhatti, H.N.; Asgher, M. Characterization of plant peroxidases and their potential for degradation of dyes: A review. Appl. Biochem. Biotechnol. 2015, 176, 1529–1550. [Google Scholar] [CrossRef]

- Barros, M.; Fleuri, L.F.; Macedo, G.A. Seed lipases: Sources, applications and properties—A review. Braz. J. Chem. Eng. 2010, 27, 15–29. [Google Scholar] [CrossRef]

- Avramiuc, M. Comparative study on the Lipase activity from plant sources, under various conditions of pH, temperature and Substrate. J. Food Saf. 2016, 15, 21–28. [Google Scholar]

- Mitou, G.; Budak, H.; Gozuacik, D. Techniques to study autophagy in plants. Int. J. Plant Genom. 2009, 2009, 451357. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morshedloo, M.R.; Ebadi, A.; Maggi, F.; Fattahi, R.; Yazdani, D.; Jafari, M. Chemical characterization of the essential oil compositions from Iranian populations of Hypericum perforatum L. Ind. Crops Prod. 2015, 76, 565–573. [Google Scholar] [CrossRef]

- Schwob, I.; Bessière, J.-M.; Viano, J. Composition of the essential oils of Hypericum perforatum L. from southeastern France. Comptes Rendus—Biol. 2002, 325, 781–785. [Google Scholar] [CrossRef]

- Ciccarelli, D.; Andreucci, A.C.; Pagni, A.M. Translucent Glands and Secretory Canals in Hypericum perforatum L. (Hypericaceae): Morphological, Anatomical and Histochemical Studies During the Course of Ontogenesis. Ann. Bot. 2001, 88, 637–644. [Google Scholar] [CrossRef]

| Flower | Leaf | Stem | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RT [min] | Compound | Group | CAS | RI 5MS | RI NIST | Fresh | M1 | M2 | M3 | Fresh | M1 | M2 | M3 | Fresh | M1 | M2 | M3 |

| 6.10 | Propanedioic acid, dimethyl- | SCFA | 595-46-0 | 753.7 | - | - | - | - | - | - | - | - | 0.03 | - | - | - | 0.13 |

| 7.11 | Octane | Alk | 111-65-9 | 800.0 | 800.0 | 0.02 | 0.01 | 0.02 | tr | - | - | - | - | 0.05 | tr | tr | - |

| 7.11 | Hexanal | Ald | 66-25-1 | 800.0 | 800.0 | - | 0.06 | - | 0.04 | 0.28 | 0.20 | 0.08 | 0.03 | - | 0.08 | 0.22 | 0.08 |

| 8.47 | Butanoic acid, 2-methyl- | SCFA | 116-53-0 | 847.6 | 846.0 | - | - | - | 0.02 | - | - | - | 0.03 | - | - | - | 0.36 |

| 8.63 | (E)-2-Hexenal | Ald | 6728-26-3 | 853.1 | 854.0 | 0.01 | 0.03 | 0.02 | 0.04 | 1.12 | 0.42 | 0.56 | 0.06 | - | - | - | - |

| 8.70 | 3-Hexen-1-ol, (Z)- | AOH | 928-96-1 | 855.6 | 856.0 | 0.24 | 0.01 | tr | 0.02 | 1.45 | 0.08 | 0.09 | - | 0.38 | 0.01 | 0.03 | 0.06 |

| 8.95 | Octane, 2-methyl- | Alk | 3221-61-2 | 864.3 | 866.0 | 7.04 | 15.28 | 8.40 | 4.29 | 0.40 | 6.23 | 4.76 | 3.54 | 6.03 | 11.46 | 4.51 | 5.88 |

| 9.97 | Nonane | Alk | 111-84-2 | 900.0 | 900.0 | 1.54 | 3.65 | 2.09 | 1.23 | 0.41 | 1.78 | 1.10 | 1.06 | 5.37 | 3.23 | 1.66 | 1.47 |

| 10.75 | Hexanoic acid methyl ester | Est | 106-70-7 | 925.1 | 925.0 | 0.01 | 0.01 | tr | 0.25 | tr | 0.01 | tr | 0.22 | - | tr | tr | - |

| 10.84 | α-Thujene | MT | 2867-05-2 | 928.0 | 928.0 | 1.19 | 0.26 | 0.15 | 0.15 | 1.94 | 0.44 | 0.33 | 0.10 | 2.13 | 1.55 | 0.60 | 0.10 |

| 11.06 | α-Pinene | MT | 80-56-8 | 935.0 | 935.0 | 7.42 | 8.41 | 7.47 | 2.60 | 3.09 | 1.07 | 0.71 | 1.95 | 5.19 | 2.26 | 2.36 | 1.57 |

| 11.60 | Isocaproic acid | SCFA | 646-07-1 | 952.4 | 955.0 | - | - | - | 0.35 | - | - | - | 0.48 | - | - | - | 0.75 |

| 11.87 | Benzaldehyde | Ar | 100-52-7 | 961.1 | 961.0 | 0.01 | 0.04 | 0.02 | 1.32 | 0.01 | 0.22 | 0.07 | 0.92 | 0.03 | 0.04 | 0.06 | 2.56 |

| 12.19 | Nonane, 3-methyl- | Alk | 5911-04-6 | 971.4 | 976.0 | 1.43 | 5.33 | 3.05 | 2.34 | 0.12 | 2.09 | 1.47 | 2.34 | 3.76 | 4.87 | 2.28 | 2.31 |

| 12.30 | Sabinene | MT | 3387-41-5 | 974.9 | 975.0 | 1.30 | 0.09 | 0.06 | tr | 7.77 | 0.28 | 0.17 | 0.01 | 1.31 | 0.10 | 0.15 | 0.03 |

| 12.42 | β-Pinene | MT | 127-91-3 | 978.8 | 979.0 | 1.95 | 1.77 | 2.39 | 1.33 | 3.64 | 1.11 | 0.69 | 1.17 | 4.36 | 2.47 | 1.37 | 1.23 |

| 12.58 | Hexanoic acid | SCFA | 142-62-1 | 983.9 | 984.0 | - | - | - | 0.67 | - | - | - | 0.47 | - | - | - | 1.09 |

| 12.71 | 6-Methyl-5-heptene-2-one | Ket | 110-93-0 | 988.1 | 988.0 | 0.19 | 0.11 | 0.08 | 0.04 | 0.01 | 0.30 | 0.11 | 0.05 | 0.02 | 0.05 | 0.23 | 0.12 |

| 12.83 | β-myrcene | MT | 123-35-3 | 992.0 | 992.0 | 1.57 | 1.49 | 1.31 | 0.25 | 3.38 | 0.35 | 0.38 | 0.16 | 1.88 | 2.12 | 0.79 | 0.06 |

| 13.08 | Decane | Alk | 124-18-5 | 1000.0 | 1000.0 | 0.25 | 0.37 | 0.18 | 0.08 | 0.21 | 0.12 | 0.08 | 0.29 | 0.27 | 0.18 | 0.12 | 0.36 |

| 13.28 | α-Phellandrene | MT | 99-83-2 | 1006.5 | 1006.0 | 0.12 | 0.24 | 0.26 | 0.01 | 0.33 | 0.05 | 0.12 | 0.05 | 0.22 | 0.31 | 0.19 | 0.06 |

| 13.44 | 2,4-Heptadienal, (E,E)- | Ald | 4313-03-5 | 1011.6 | 1012.0 | - | 0.03 | - | - | - | 0.18 | - | - | - | 0.03 | 0.05 | - |

| 13.51 | Acetic acid, hexyl ester | Est | 142-92-7 | 1013.9 | 1014.0 | 0.16 | - | - | 0.01 | 0.01 | - | - | tr | - | - | - | - |

| 13.65 | α-Terpinene | MT | 99-86-5 | 1018.4 | 1018.0 | 0.77 | 0.51 | 0.43 | 0.10 | 1.40 | 0.19 | 0.19 | 0.04 | 1.20 | 0.87 | 0.49 | 0.05 |

| 13.91 | p-Cymene | ArMT | 99-87-6 | 1026.8 | 1027.0 | 0.72 | 1.75 | 0.96 | 0.92 | 0.33 | 1.48 | 1.39 | 0.86 | 1.22 | 4.90 | 2.87 | 0.54 |

| 14.03 | 2-Octanol, 2-methyl- | AOH | 628-44-4 | 1030.6 | - | - | - | - | 2.65 | - | - | - | 2.79 | - | - | - | 3.60 |

| 14.05 | Limonene | MT | 138-86-3 | 1031.3 | 1031.0 | 1.58 | 1.26 | 1.20 | 0.01 | 3.20 | 0.45 | 0.47 | 0.03 | 2.29 | 1.78 | 0.84 | - |

| 14.17 | Benzyl alcohol | Ar | 100-51-6 | 1035.2 | 1035.6 | 0.28 | 0.12 | 0.06 | 0.05 | 0.03 | 0.06 | 0.06 | 0.02 | 0.14 | 0.01 | 0.01 | 0.09 |

| 14.29 | β-trans-ocimene | MT | 3779-61-1 | 1039.0 | 1039.0 | 2.28 | 0.70 | 0.75 | 0.13 | 6.00 | 0.07 | 0.12 | 0.12 | 0.82 | 0.29 | 0.16 | 0.03 |

| 14.49 | Benzenacetaldehyd | Ar | 122-78-1 | 1045.5 | 1045.6 | 0.03 | 0.03 | 0.01 | 0.84 | 0.05 | 0.13 | 0.05 | 0.52 | 0.47 | 0.01 | 0.04 | 1.34 |

| 14.64 | β-cis-Ocimene | MT | 3338-55-4 | 1050.3 | 1051.0 | 14.96 | 2.17 | 2.22 | 0.33 | 25.23 | 0.19 | 0.29 | 0.31 | 3.20 | 0.82 | 0.39 | 0.15 |

| 14.98 | γ-Terpinene | MT | 99-85-4 | 1061.3 | 1061.4 | 1.59 | 0.85 | 0.77 | 0.26 | 2.56 | 0.28 | 0.22 | 0.25 | 2.62 | 2.67 | 0.97 | 0.08 |

| 15.09 | Decane, 2-methyl- | Alk | 6975-98-0 | 1064.8 | 1065.0 | 5.55 | 9.13 | 5.21 | 5.81 | 0.18 | 3.48 | 3.98 | 5.41 | 3.36 | 10.71 | 4.16 | 3.41 |

| 15.42 | Linalool oxide | MTO | 5989-33-3 | 1075.5 | 1075.0 | tr | 0.03 | 0.02 | 0.70 | tr | 0.02 | 0.01 | 0.64 | 0.01 | 0.01 | 0.02 | 1.23 |

| 15.90 | α-Terpinolen | MT | 586-62-9 | 1091.0 | 1091.0 | 0.41 | 0.26 | 0.29 | 0.35 | 0.92 | 0.05 | 0.07 | 0.24 | 0.70 | 0.50 | 0.20 | 0.35 |

| 16.18 | Undecane | Alk | 1120-21-4 | 1100.0 | 1100.0 | 2.09 | 4.17 | 3.38 | 3.99 | 0.48 | 3.28 | 2.27 | 4.13 | 7.57 | 6.81 | 3.97 | 2.69 |

| 16.63 | Benzeneethanol | Ar | 60-12-8 | 1115.2 | 1115.1 | 0.76 | 0.19 | 0.07 | 1.12 | 0.09 | 0.19 | 0.11 | 0.91 | 1.08 | 0.01 | 0.04 | 1.76 |

| 17.09 | Neo-allo-ocimene | MT | 7216-56-0 | 1130.6 | 1131.0 | 0.83 | 0.41 | 0.51 | 0.05 | 1.99 | 0.03 | 0.05 | 0.05 | 0.22 | 0.21 | 0.15 | 0.02 |

| 17.14 | 1,3,8-p-Menthatriene | MT | 460-01-5 | 1132.3 | 1132.0 | 0.22 | 0.34 | 0.40 | 0.03 | 0.19 | 0.03 | 0.05 | 0.15 | 0.10 | 0.22 | 0.18 | 0.15 |

| 17.47 | Alloocimene | MT | 673-84-7 | 1143.4 | 1142.0 | 0.44 | 0.44 | 0.55 | 0.23 | 0.16 | 0.04 | 0.06 | 0.11 | 0.03 | 0.22 | 0.15 | 0.29 |

| 17.63 | Verbenol | MTO | 473-67-6 | 1148.8 | 1148.0 | - | tr | tr | 0.18 | - | tr | tr | 0.24 | tr | tr | tr | 0.34 |

| 18.16 | Acetic acid, phenylmethyl ester | Ar | 140-11-4 | 1166.7 | 1165.0 | 0.19 | - | - | - | tr | - | - | - | - | - | - | - |

| 18.29 | Undecane, 3-methyl- | Alk | 1002-43-3 | 1171.0 | 1171.0 | 0.16 | 0.22 | 0.21 | 0.33 | 0.01 | 0.13 | 0.11 | 0.23 | 0.18 | 0.29 | 0.19 | 0.23 |

| 18.38 | Benzoic acid, ethyl ester | Ar | 93-89-0 | 1174.1 | 1172.9 | 0.01 | 0.11 | 0.01 | 0.02 | 0.03 | tr | 0.01 | 0.03 | tr | - | - | 0.04 |

| 18.46 | trans-Linalool 3,7-oxide | MTO | 39028-58-5 | 1176.8 | 1178.0 | - | tr | tr | 0.15 | - | tr | tr | 0.20 | - | - | tr | 0.33 |

| 18.61 | Terpinen-4-ol | MTO | 562-74-3 | 1181.8 | 1181.5 | 0.18 | 0.16 | 0.25 | 0.99 | 0.87 | 0.13 | 0.13 | 1.00 | 0.13 | 0.39 | 0.30 | 1.27 |

| 18.80 | p-Cymen-8-ol | ArMTO | 1197-01-9 | 1188.2 | 1188.0 | tr | 0.01 | 0.01 | 0.19 | tr | tr | 0.01 | 0.23 | 0.03 | 0.02 | 0.10 | 0.28 |

| 18.99 | α-Terpineol | MTO | 98-55-5 | 1194.6 | 1195.0 | tr | 0.04 | 0.10 | 0.50 | 0.02 | 0.02 | 0.01 | 0.47 | tr | 0.01 | 0.01 | 0.53 |

| 19.10 | Methyl salicylate | Ar | 119-36-8 | 1198.3 | 1198.0 | 0.32 | 0.12 | 0.01 | - | 0.11 | 0.01 | 0.02 | - | tr | tr | 0.01 | - |

| 19.15 | Dodecane | Alk | 112-40-3 | 1200.0 | 1200.0 | 0.02 | 0.05 | 0.07 | 0.04 | tr | 0.02 | 0.04 | 0.01 | 0.02 | 0.06 | 0.06 | 0.02 |

| 19.33 | Decanal | Ald | 112-31-2 | 1206.4 | 1206.0 | 0.02 | 0.04 | 0.04 | 0.06 | 0.01 | 0.04 | 0.07 | 0.01 | 0.03 | 0.01 | 0.08 | 0.03 |

| 19.60 | Verbenone | MTO | 80-57-9 | 1216.0 | 1217.0 | 0.02 | 0.02 | tr | 1.56 | tr | 0.01 | 0.01 | 1.39 | 0.02 | tr | - | 1.91 |

| 20.07 | Methyl thymyl ether | ArMTO | 1076-56-8 | 1232.6 | 1233.0 | 0.11 | 0.18 | 0.17 | 0.06 | tr | 0.02 | 0.07 | 0.07 | 0.01 | 0.34 | 0.12 | 0.05 |

| 20.21 | Carvacrol methyl ether | ArMTO | 6379-73-3 | 1237.6 | 1238.0 | 0.38 | 0.13 | 0.11 | 0.03 | 0.56 | 0.01 | 0.01 | 0.05 | 0.10 | 0.16 | 0.09 | 0.03 |

| 20.84 | β-Phenethyl acetate | ArMTO | 103-45-7 | 1259.9 | 1260.0 | 1.45 | - | - | 0.12 | 0.02 | tr | - | 0.07 | tr | - | - | 0.07 |

| 20.84 | 3-Carvomenthenone | MTO | 89-81-6 | 1259.9 | 1259.0 | - | 0.03 | 0.03 | - | 0.03 | tr | tr | - | - | 0.01 | tr | - |

| 20.97 | Dodecane, 2-methyl- | Alk | 1560-97-0 | 1264.5 | 1265.0 | 5.33 | 5.62 | 5.44 | 7.00 | 0.01 | 1.68 | 3.81 | 3.12 | 0.90 | 4.15 | 3.75 | 2.35 |

| 21.97 | Tridecane | Alk | 629-50-5 | 1300.0 | 1300.0 | 0.91 | 1.34 | 1.44 | 1.65 | 0.01 | 0.88 | 1.01 | 0.82 | 1.21 | 1.48 | 1.50 | 1.38 |

| 22.64 | Decanoic acid, methyl ester | Est | 110-42-9 | 1325.2 | 1325.0 | - | tr | tr | 0.22 | - | - | - | 0.17 | - | tr | tr | 0.25 |

| 22.84 | Benzoic acid, 2-methylpropyl ester | Ar | 120-50-3 | 1332.7 | 1331.2 | 0.01 | 0.48 | 0.06 | 0.01 | tr | 0.02 | 0.02 | 0.03 | tr | 0.04 | 0.02 | tr |

| 23.09 | Benzoic acid, 2-methoxy-, methyl ester | Ar | 606-45-1 | 1342.1 | 1335.0 | tr | 0.04 | tr | tr | 0.01 | tr | 0.01 | tr | 0.01 | tr | tr | tr |

| 23.14 | Elemene isomer | ST | - | 1344.0 | 1343.7 | 0.04 | 0.01 | 0.10 | 0.09 | 0.35 | 0.05 | 0.11 | 0.16 | 0.11 | tr | 0.03 | 0.10 |

| 23.47 | α-Cubebene | ST | 17699-14-8 | 1356.4 | 1356.0 | 0.22 | 0.25 | 1.10 | 0.58 | 0.34 | 1.40 | 1.42 | 0.95 | 0.15 | 0.20 | 1.06 | 0.62 |

| 23.57 | α-Longipinene | ST | 5989-08-2 | 1360.2 | 1356.4 | 0.36 | 0.49 | 0.54 | 0.71 | 0.11 | 0.33 | 0.26 | 0.58 | 0.50 | 0.59 | 0.89 | 0.58 |

| 24.09 | Ylangene | ST | 14912-44-8 | 1379.7 | 1377.0 | 0.39 | 0.60 | 0.91 | 0.87 | 0.20 | 1.07 | 0.90 | 0.97 | 0.43 | 0.69 | 1.16 | 0.71 |

| 24.21 | α-Copaene | ST | 3856-25-5 | 1384.2 | 1384.0 | 0.34 | 0.62 | 1.41 | 1.34 | 0.48 | 1.80 | 2.06 | 1.90 | 0.19 | 0.40 | 1.54 | 1.22 |

| 24.36 | α-Cedrene | ST | 469-61-4 | 1389.8 | 1386.0 | tr | 0.02 | 0.31 | 0.04 | 0.01 | 0.51 | 0.17 | 0.08 | tr | 0.30 | 0.17 | 0.04 |

| 24.48 | β-Bourbonene | ST | 5208-59-3 | 1394.4 | 1394.5 | 0.08 | 0.15 | 0.50 | 0.42 | 0.31 | 1.53 | 1.01 | 0.89 | 0.18 | 0.62 | 1.40 | 0.75 |

| 25.05 | β-cis-Caryophyllene | ST | 118-65-0 | 1416.7 | 1413.4 | 0.65 | 0.16 | 0.10 | 0.06 | tr | 0.02 | 0.06 | 0.04 | 0.03 | 0.08 | 0.08 | 0.08 |

| 25.12 | α-Gerjunene | ST | 489-40-7 | 1419.4 | 1419.0 | 0.10 | 0.10 | 0.16 | 0.19 | 0.21 | 0.10 | 0.42 | 0.37 | 0.06 | tr | 0.20 | 0.20 |

| 25.28 | Cedrene | ST | 11028-42-5 | 1425.8 | 1422.0 | 1.13 | 1.00 | 0.48 | 0.61 | 0.69 | 5.51 | 2.75 | 2.18 | 2.00 | 2.88 | 2.35 | 2.03 |

| 25.41 | β-Caryophyllen | ST | 87-44-5 | 1431.0 | 1431.0 | 12.73 | 11.52 | 11.62 | 10.87 | 6.81 | 5.26 | 12.46 | 13.42 | 6.37 | 7.86 | 10.44 | 12.49 |

| 25.61 | β-Copaene | ST | 18252-44-3 | 1438.9 | 1436.9 | 0.27 | 0.39 | 1.08 | 1.01 | 0.55 | 1.62 | 2.20 | 1.69 | 0.23 | 0.34 | 1.22 | 1.23 |

| 25.89 | Aromandendrene | ST | 489-39-4 | 1450.0 | 1440.0 | 0.18 | 0.30 | 0.75 | 0.77 | 0.30 | 1.66 | 0.93 | 0.71 | 0.17 | 0.45 | 0.69 | 0.57 |

| 26.14 | (E)-β-Famesene | ST | 18794-84-8 | 1459.9 | 1460.0 | 4.63 | 3.86 | 4.73 | 3.99 | 0.58 | 7.87 | 4.40 | 3.34 | 11.73 | 1.30 | 9.73 | 2.82 |

| 26.17 | α-Himachalene | ST | 3853-83-6 | 1461.1 | 1460.6 | 0.85 | 1.52 | 1.26 | 1.66 | 0.13 | 0.87 | 0.71 | 1.53 | 0.84 | 3.08 | 1.88 | 1.45 |

| 26.26 | α-Humulene | ST | 6753-98-6 | 1464.7 | 1464.5 | 0.53 | 0.52 | 1.02 | 0.92 | 0.63 | 1.32 | 1.85 | 1.23 | 0.40 | 0.57 | 1.16 | 0.99 |

| 26.56 | β-Acoradiene | ST | 43219-80-3 | 1476.6 | 1471.0 | 0.05 | 0.13 | 0.63 | 0.26 | 0.12 | 1.94 | 1.15 | 0.63 | 0.07 | 1.51 | 0.85 | 0.42 |

| 26.78 | γ-Muurolene | ST | 30021-74-0 | 1485.3 | 1485.2 | 2.18 | 1.85 | 3.91 | 3.97 | 1.71 | 8.08 | 5.70 | 4.46 | 3.71 | 2.29 | 4.56 | 3.65 |

| 26.87 | α-Curcumene | ArST | 644-30-4 | 1488.9 | 1488.0 | 0.30 | 0.84 | 0.92 | 1.01 | 0.10 | 1.41 | 0.80 | 0.85 | 0.83 | 3.82 | 3.30 | 1.04 |

| 26.91 | Germacrene D | ST | 23986-74-5 | 1490.5 | 1491.0 | 0.69 | 0.29 | 1.77 | 1.35 | 7.53 | 2.21 | 5.38 | 3.11 | 1.80 | 0.03 | 1.39 | 1.26 |

| 27.01 | Alloaromadendrene | ST | 25246-27-9 | 1494.4 | 1487.0 | 4.01 | 1.08 | 2.84 | 1.88 | 1.47 | 2.40 | 3.24 | 2.94 | 5.86 | 1.01 | 1.91 | 2.33 |

| 27.23 | γ-Amorphene | ST | 6980-46-7 | 1503.4 | 1495.0 | 0.31 | 0.29 | 1.12 | 1.03 | 0.84 | 1.72 | 1.85 | 1.33 | 0.38 | 0.25 | 0.90 | 0.94 |

| 27.34 | α-Muurolene | ST | 10208-80-7 | 1508.0 | 1507.3 | 0.21 | 0.28 | 0.86 | 1.11 | 0.88 | 1.61 | 1.58 | 1.48 | 0.25 | 0.25 | 0.83 | 1.28 |

| 27.43 | β-Himachalene | ST | 1461-03-6 | 1511.8 | 1511.8 | 1.02 | 0.94 | 1.12 | 1.12 | 0.48 | 0.41 | 0.37 | 0.62 | 1.88 | 0.79 | 1.26 | 0.44 |

| 27.71 | γ-Cadinene | ST | 39029-41-9 | 1523.5 | 1524.0 | 0.80 | 0.96 | 2.44 | 3.41 | 1.69 | 4.97 | 4.39 | 3.70 | 1.06 | 1.12 | 2.89 | 3.09 |

| 27.91 | δ-Cadinene | ST | 483-76-1 | 1531.9 | 1530.8 | 1.37 | 1.86 | 4.37 | 5.31 | 3.43 | 8.74 | 6.95 | 5.92 | 1.63 | 1.48 | 3.97 | 4.07 |

| 28.27 | α-Cadinene | ST | 24406-05-1 | 1547.1 | 1544.0 | 0.18 | 0.22 | 0.71 | 0.83 | 0.57 | 1.26 | 1.25 | 0.97 | 0.27 | 0.25 | 0.64 | 0.67 |

| 28.42 | α-Calacorene | ArST | 21391-99-1 | 1553.4 | 1550.0 | 0.03 | 0.15 | 0.34 | 0.56 | 0.02 | 0.69 | 0.74 | 0.64 | 0.01 | 0.14 | 0.44 | 0.42 |

| 28.74 | Nerolidol | STO | 7212-44-4 | 1566.8 | 1566.0 | 0.05 | 0.10 | 0.22 | 0.16 | 0.03 | 0.43 | 0.45 | 0.10 | 0.01 | 0.01 | 0.14 | 0.08 |

| 28.97 | 3-Hexen-1-ol, benzoate, (Z)- | Ar | 25152-85-6 | 1576.5 | 1571.0 | 0.08 | 0.05 | 0.04 | - | 0.28 | 0.02 | 0.11 | - | tr | tr | 0.03 | - |

| 29.27 | Spathulenol | STO | 6750-60-3 | 1589.1 | 1590.0 | - | 0.17 | 0.65 | 1.00 | 0.03 | 2.19 | 2.95 | 0.91 | 0.01 | 0.31 | 1.79 | 1.04 |

| 29.44 | Caryophyllene oxide | STO | 1139-30-6 | 1596.2 | 1596.0 | 0.07 | 0.31 | 0.56 | 1.83 | 0.09 | 1.29 | 2.04 | 1.49 | 0.04 | 1.12 | 3.83 | 1.77 |

| 29.68 | Mintketone | STO | 73809-82-2 | 1606.7 | 1603.0 | - | 0.05 | 0.18 | 0.01 | tr | 1.12 | 1.40 | 0.05 | tr | 0.15 | 0.86 | 0.04 |

| 29.90 | Ledol | STO | 577-27-5 | 1616.4 | 1616.0 | 0.03 | 0.04 | 0.07 | 0.34 | 0.17 | 0.07 | 0.54 | 0.35 | 0.04 | tr | 0.29 | 0.41 |

| 31.00 | α-Cardinol | STO | 481-34-5 | 1665.3 | 1665.4 | 0.01 | 0.01 | tr | 0.44 | 0.18 | tr | tr | 0.34 | 0.07 | tr | tr | 0.45 |

| 31.47 | Cadalene | ArST | 483-78-3 | 1686.2 | 1688.1 | tr | 0.25 | 0.28 | 0.36 | tr | 0.40 | 0.42 | 0.36 | tr | 0.30 | 0.37 | 0.40 |

| 31.78 | Heptadecane | Alk | 629-78-7 | 1700.0 | 1700.0 | 0.01 | 0.23 | 0.37 | 0.76 | 0.02 | 0.15 | 1.42 | 0.41 | 0.01 | 0.06 | 0.21 | 0.33 |

| 32.32 | Methyl tetradecanoate | Est | 124-10-7 | 1725.4 | 1726.0 | - | tr | tr | 0.31 | - | - | - | 0.25 | - | tr | tr | 0.54 |

| 33.37 | Benzyl benzoate | Ar | 120-51-4 | 1774.6 | 1774.0 | tr | 0.03 | 0.02 | tr | tr | 0.01 | 0.02 | tr | tr | tr | 0.02 | 0.03 |

| 33.91 | Octadecane | Alk | 593-45-3 | 1800.0 | 1800.0 | tr | 0.06 | 0.02 | 0.09 | tr | 0.04 | 0.02 | 0.03 | tr | 0.01 | 0.01 | 0.03 |

| 35.95 | Nonadecane | Alk | 629-92-5 | 1900.0 | 1900.0 | tr | 0.18 | 0.18 | 0.49 | tr | 0.02 | 0.04 | 0.17 | tr | 0.01 | 0.02 | 0.07 |

| 36.48 | Hexadecanoic acid, methyl ester | Est | 112-39-0 | 1927.2 | 1927.3 | - | tr | tr | 1.03 | - | tr | tr | 0.81 | - | tr | tr | 2.76 |

| 37.80 | Hexadecanoic acid, ethyl ester | Est | 628-97-7 | 1994.9 | 1995.7 | - | - | - | 0.28 | - | - | - | 0.12 | - | - | - | 0.76 |

| 39.73 | Linoleic acid, methyl ester | Est | 112-63-0 | 2098.4 | 2099.0 | - | - | - | 0.43 | - | - | - | 0.07 | - | - | - | 1.18 |

| 39.82 | Oleic acid, methyl ester | Est | 112-62-9 | 2103.4 | 2103.0 | - | - | - | 0.58 | - | - | - | 0.15 | - | - | - | 1.19 |

| 40.26 | Octadecanoic acid, methyl ester | Est | 112-61-8 | 2127.9 | 2128.0 | - | - | - | 0.06 | - | - | - | - | - | - | - | 0.07 |

| 40.92 | Linoleic acid ethyl ester | Est | 544-35-4 | 2164.8 | 2162.9 | - | - | - | 0.06 | - | - | - | - | - | - | - | 0.13 |

| 41.04 | Oleic acid, ethyl ester | Est | 111-62-6 | 2171.5 | 2171.0 | - | - | - | 0.06 | - | - | - | - | - | - | - | 0.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dudek, K.; Pietryja, M.J.; Kurkiewicz, S.; Kurkiewicz, M.; Błońska-Fajfrowska, B.; Wilczyński, S.; Dzierżęga-Lęcznar, A. Influence of the Drying Method on the Volatile Component Profile of Hypericum perforatum Herb: A HS-SPME-GC/MS Study. Processes 2022, 10, 2593. https://doi.org/10.3390/pr10122593

Dudek K, Pietryja MJ, Kurkiewicz S, Kurkiewicz M, Błońska-Fajfrowska B, Wilczyński S, Dzierżęga-Lęcznar A. Influence of the Drying Method on the Volatile Component Profile of Hypericum perforatum Herb: A HS-SPME-GC/MS Study. Processes. 2022; 10(12):2593. https://doi.org/10.3390/pr10122593

Chicago/Turabian StyleDudek, Karolina, Marcelin Jan Pietryja, Slawomir Kurkiewicz, Małgorzata Kurkiewicz, Barbara Błońska-Fajfrowska, Sławomir Wilczyński, and Anna Dzierżęga-Lęcznar. 2022. "Influence of the Drying Method on the Volatile Component Profile of Hypericum perforatum Herb: A HS-SPME-GC/MS Study" Processes 10, no. 12: 2593. https://doi.org/10.3390/pr10122593