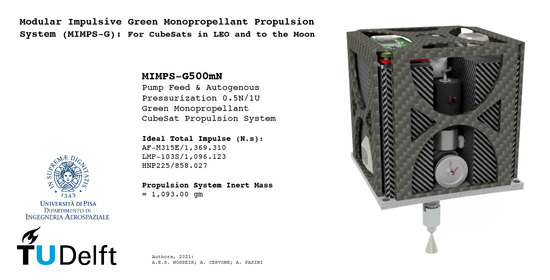

Modular Impulsive Green Monopropellant Propulsion System (MIMPS-G): For CubeSats in LEO and to the Moon

Abstract

:1. Introduction

1.1. Space Mission Requirments

1.2. Green Monopropellants Trade-Off Study

1.3. Unconventional Feed and Pressurization Systems

2. System Analysis and Design Methodology

2.1. Requirements and Design Considerations

2.2. Design Process and Methodology

2.3. MIMPS-G ConOps

3. Preliminary Design Study

3.1. Equations and Formulae

- : is the wet mass of the propulsion system.

- : is the propellant mass.

- : is the inert or dry mass of the propulsion system.

- : is the initial mass of the propulsion system.

- : the payload here is considered any and every part outside the propulsion system envelope (not only the payload of the spacecraft).

- : is the final mass of the propulsion system.

4. Results and Discussion

5. Market Survey on Small Satellites Monopropellant Propulsion

5.1. State-of-the-Art CubeSat Monopropellant Propulsion

5.2. Commercial Off-the-Shelf Monopropellant Thrusters

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Dinardi, A.; Anflo, K.; Friedhoff, P. On-Orbit Commissioning of High Performance Green Propulsion (HPGP) in the SkySat Constellation. In Proceedings of the 31st Annual AIAA/USU Conference on Small Satellites, Logan, UT, USA, 5–10 August 2017. [Google Scholar]

- Klesh, A.; Clement, B.; Colley, C.; Essmiller, J.; Forgette, D.; Krajewski, J.; Marinan, A. MarCO: Early Operations of the First CubeSats to Mars. In Proceedings of the 32nd Annual AIAA/USU Conference on Small Satellites, Logan, UT, USA, 4–9 August 2018. [Google Scholar]

- NASA. Pathfinder Technology Demonstrator. 23 April 2021. Available online: https://www.nasa.gov/directorates/spacetech/small_spacecraft/Pathfinder_Technology_Demonstrator/ (accessed on 9 June 2021).

- Kristinsson, Ö.; Freeman, D.; Petro, E.; Lozano, P.C.; Hsu, A.; Young, J.A.; Martel, F. Operation and Performance of a Fully-Integrated ionic-Electrospray Propulsion System. In Proceedings of the 36th International Electric Propulsion Conference, Vienna, Austria, 15–20 September 2019. [Google Scholar]

- Levchenko, I.; Bazaka, K.; Ding, Y.; Raitses, Y.; Mazouffre, S.; Henning, T.; Klar, P.J.; Shinohara, S.; Schein, J.; Garrigues, L.; et al. Space micropropulsion systems for Cubesats and small satellites: From proximate targets to furthermost frontiers. Appl. Phys. Rev. 2018, 5, 011104. [Google Scholar] [CrossRef]

- Rovey, J.L.; Lyne, C.T.; Mundahl, A.J.; Rasmont, N.; Glascock, M.S.; Wainwright, M.J.; Berg, S.P. Review of multimode space propulsion. Prog. Aerosp. Sci. 2020, 118, 100627. [Google Scholar] [CrossRef]

- Nosseir, A.E.S.; Pasini, A.; Cervone, A. Modular Impulsive Green-Monopropellant Propulsion System For Micro/Nano Satellites High-Thrust Orbital Maneuvers (MIMPS-G). In Proceedings of the 71st International Astronautical Congress, CyberSpace Edition, 12–14 October 2020. [Google Scholar]

- Nosseir, A.E.S.; Cervone, A.; Pasini, A. Modular Impulsive Green Monopropellant Propulsion System (MIMPS-G): System Analysis and Preliminary Design. In Proceedings of the Space Propulsion Conference 2020+1, Virtual Event, 17–19 March 2021. [Google Scholar]

- Nosseir, A.E.S.; Pasini, A.; Cervone, A. A Survey of Energetic Ionic Liquid Green Monopropellants and Investigation of Feed and Pressurization Systems For Small Satellites High-Thrust Impulsive Propulsion. In Proceedings of the Space Propulsion Conference 2020+1, Virtual Event, 17–19 March 2021. [Google Scholar]

- Nardini, F.T.; Coletti, M.; Reissner, A.; Krejci, D. Propulsion Systems. In Nanosatellites: Space and Ground Technologies, Operations and Economics; Wiley: Hoboken, NJ, USA, 2020; pp. 85–114. [Google Scholar]

- Zandbergen, B. Aerospace Design and Systems Engineering Elements I—Spacecraft Design and Sizing—Course Notes; TU Delft: Delft, The Netherlands, 2020. [Google Scholar]

- Lemmer, K. Propulsion for CubeSats. Acta Astronaut. 2017, 134, 231–243. [Google Scholar] [CrossRef]

- Tsay, M.; Lafko, D.; Zwahlen, J.; William, C. Development of Busek 0.5N Monopropellant Thruster. In Proceedings of the 27th Annual AIAA/USU Conference on Small Satellites, Logan, UT, USA, 10–15 August 2013. [Google Scholar]

- Masse, R.K.; Allen, M.; Driscoll, E.; Spores, R.A. AF-M315E Propulsion System Advances & Improvements. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar]

- NASA. Green Propellant Infusion Mission (GPIM) Overview. NASA, 5 December 2019. Available online: https://www.nasa.gov/mission_pages/tdm/green/overview.html (accessed on 24 April 2020).

- Wilhelm, M.; Negri, M.; Ciezki, H.; Schlechtriem, S. Preliminary tests on thermal ignition of ADN-based liquid monopropellants. Acta Astronaut. 2019, 158, 388–396. [Google Scholar] [CrossRef]

- Anflo, K.; Crowe, B. In-Space Demonstration of an ADN-based Propulsion System. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011. [Google Scholar]

- Wingborg, N. Heat of Formation of ADN-Based Liquid Monopropellants. Propellants Explos. Pyrotech. 2019, 44, 1090–1095. [Google Scholar] [CrossRef]

- Anflo, K.; Grönland, T.; Wingborg, N. Development and Testing of ADN-Based Monopropellants in Small Rocket Engines. In Proceedings of the 36th AIAA/ASME/SAE/ASEE, Cleveland, OH, USA, 24–28 July 2000. [Google Scholar]

- Anflo, K.; Wingborg, N. Dinitramide Based Liquid Mono-Propellants. Sweden Patent WO0050363, 31 August 2000. [Google Scholar]

- Larsson, A.; Wingborg, N.; Elfsberg, M.; Appelgren, P. Characterization and Electrical Ignition of ADN-Based Liquid Monopropellants—FOI-R—1639–SE; Weapns and Protection—FOI: Tumba, Sweden, 2005. [Google Scholar]

- Wingborg, N.; Eldsäter, C.; Skifs, H. Formulation and Characterization of ADN-based Liquid Monopropellants. In Proceedings of the 2nd International Conference on Green Propellants for Space Propulsion, Cagliari, Sardinia, Italy, 7—8 June 2004. [Google Scholar]

- Wingborg, N.; Johansson, M.; Bodin, L. Initial Development of a Laboratory Rocket Thruster for ADN-Based Liquid Monopropellants—FOI-R—2123–SE; Weapons and Protection—FOI: Tumba, Sweden, 2006. [Google Scholar]

- Igarashi, S.; Matsuura, Y.; Hatai, K.; Ikeda, H. Safe 0.5N Green Monopropellant Thruster for Small Satellite Propulsion Systems. In Proceedings of the AIAA Propulsion and Energy Forum, Indianapolis, IN, USA, 19—22 August 2019. [Google Scholar]

- Igarashi, S.; Matsuura, Y. Development Status of a Hyrazine Alternative and Low-cost Thruster Using HAN/HN-Based Green Propellant. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10—12 July 2017. [Google Scholar]

- Igarashi, S.; Matsuura, Y.; Ikeda, H.; Nagata, T.; Hatai, K. 0.5 N Thruster for Small Satellite Propulsion System Using HAN/HN-Based Safe Green Monopropellant HNP225. In Proceedings of the Space Propulsion Conference 2020+1, Virtual, 17–19 March 2021. [Google Scholar]

- Nosseir, A.E.S.; Cervone, A.; Pasini, A. Review of State-of-the-Art Green Monopropellants: For Propulsion Systems Analysts and Designers. Aerospace 2021, 8, 20. [Google Scholar] [CrossRef]

- Gohardani, S.; Stanojev, J.; Demaire, A.; Anflo, K.; Persson, M.; Wingborg, N.; Nilsson, C. Green space propulsion: Opportunities and Prospects. Prog. Aerosp. Sci. 2014, 71, 128–149. [Google Scholar] [CrossRef]

- Masse, R.; Spores, R.A.; Kimbrel, S.; Allen, M.; Lorimor, E.; Myers, P. GPIM AF-M315E Propulsion System. In Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference, Orlando, FL, USA, 27–29 July 2015. [Google Scholar]

- Ruby, L.; Christian, C.; Lehmann, E.A. Autogenous Pressurization for Space Vehicle Propulsion Systems. In Proceedings of the AIAA 4th Propulsion Joint Specialist Conference, Cleveland, OH, USA, 10–14 June 1968. [Google Scholar]

- ROCKET LAB. Electron Revolutionary Design. ROCKET LAB, 2021. Available online: https://www.rocketlabusa.com/electron/ (accessed on 20 January 2021).

- Sutton, G.P. Rocket Propulsion Elements, 9th ed.; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Humble, R.W.; Henry, G.N.; Larson, W.J. Space Propulsion Analysis and Design; McGraw-Hill Companies, Incorporated: New York, NY, USA, 1995. [Google Scholar]

- NASA, Space Vehicle Design Criteria Office (Chemical Propulsion). Pressurization Systems for Liquid Rockets—SP-8112; NASA: Cleveland, OH, USA, 1975.

- Flight Works, Inc. Magnetic Drive Gear Pumps. Flight Works, Inc., 2014. Available online: https://products.flightworksinc.com/item/micro-gear-pumps/m-series-magnetic-drive-gear-pumps/2205-m03c40 (accessed on 21 September 2020).

- Mengali, G.; Quarta, A. Fondamenti di Meccanica del Volo Spaziale; University of Pisa Press: Pisa, Italy, 2013. [Google Scholar]

- Tyvak. Deployment Hardware. A Terran Orbital Corporation. 2020. Available online: https://www.tyvak.com/launch-services/ (accessed on 1 August 2020).

- ISISPACE. Deployers Datasheet. 2016. Available online: https://www.isispace.nl/wp-content/uploads/2016/02/CubeSat-deployers-Brochure-web-compressed.pdf (accessed on 1 August 2020).

- EXOLAUNCH. EXOpod Technical Documentation. 2020. Available online: https://www.exolaunch.com/exopod.html (accessed on 1 August 2020).

- Berg, S.P.; Rovey, J.L. Assessment of Multi-Mode Spacecraft Micropropulsion Systems. In Proceedings of the AIAA Propulsion and Energy Forum, Cleveland, OH, USA, 28–30 July 2014. [Google Scholar]

- Rovey, J.L.; Lyne, C.T.; Mundahl, A.J.; Rasmont, N. Review of Chemical-Electric Multimode Space Propulsion. In Proceedings of the AIAA Propulsion and Energy Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Rhodes, L.; Ronney, P.D. Dynamics of a Small-Scale Hydrogen Peroxide Vapor Propulsion System. J. Propuls. Power 2019, 35, 595–600. [Google Scholar] [CrossRef]

- Busek Company, Inc. Datasheet—BGT-X5 Green Monopropellant Thruster; Busek Company, Inc., 2016; Available online: http://busek.com/index_htm_files/70008517E.pdf (accessed on 29 June 2020).

- Tsay, M.; Frongillo, J.; Lafko, D.; Zwahlen, J. Development Status and 1U CubeSat Application of Busek’s 0.5N Green Monopropellant Thruster. In Proceedings of the 28th Anual AIAA/USU Conference on Small Satellites, Logan, UT, USA, 2–7 August 2014. [Google Scholar]

- Tsay, M.; Feng, C.; Paritsky, L.; Zwahlen, J.; Lafko, D.; Robin, M. Complete EM System Development for Busek’s 1U CubeSat Green Propulsion Module. In Proceedings of the 52nd AIAA/ SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar]

- Freudenmann, D.; Ciezki, H.K. ADN and HAN-Based Monopropellants—A Minireview on Compatibility and Chemical Stability in Aqueous Media. Propellants Explos. Polytech. 2019, 44, 1084–1089. [Google Scholar] [CrossRef]

- CP Lab Safety. Acetal and Delrin® (Polyoxymethylene) Chemical Compatibility Chart. CP Lab Safety, 2018. Available online: https://www.calpaclab.com/acetal-polyoxymethylene-chemical-compatibility-chart/ (accessed on 25 August 2020).

- Gorbunov, N.; Nenasheva, M.V.; Sinikova, N.A.; Kardasheva, Y.S.; Maksimov, A.L.; Karakhanov, E.A. Tandem Hydroformylation–Acetalization Using a Water-Soluble Catalytic System: A Promising Procedure for Preparing Valuable Oxygen-Containing Compounds from Olefi ns and Polyols. Russ. J. Appl. Chem. 2018, 91, 990–995. [Google Scholar] [CrossRef]

- PMD Tech. PMD Technology Low Gravity Fluid Dynamics. 2011. Available online: http://www.pmdtechnology.com/PMD%20Types/PMD%20Types%20-%20Sponges.html (accessed on 25 August 2020).

- Hartwig, J.W. Propellant Management Devices for Low-Gravity Fluid Management: Past, Present, and Future Applications. J. Spacecr. Rocket. 2017, 54, 808–824. [Google Scholar] [CrossRef]

- Igarashi, S.; Yamamoto, K.; Fukuchi, A.B. Development Status of a 0.5N-Class Low-Cost Thruster for Small Satellites. In Proceedings of the AIAA Propulsion and Energy Forum Joint Propulsion Conference, Cincinnati, OH, USA, 9 July 2018. [Google Scholar]

- Huggins, G.M.; Talaksi, A.; Andrews, D.; Lightsey, E.G.; Cavender, D.; McQueen, D.; Williams, H.; Diaz, C.; Baker, J.; Kowalkowski, M. Development of a CubeSat-Scale Green Monopropellant Propulsion System for NASA’s Lunar Flashlight Mission. In Proceedings of the AIAA SciTech Forum, Virtual Event, 11–21 January 2021. [Google Scholar]

- NanoAvionics. CubeSat Propulsion System EPSS. NanoAvionics, 2019. Available online: https://nanoavionics.com/cubesat-components/cubesat-propulsion-system-epss/ (accessed on 29 June 2020).

- Aerojet Rocketdyne. Modular Propulsion Systems Datasheet. Available online: https://www.rocket.com/sites/default/files/documents/CubeSat%20Mod%20Prop-2sided.pdf (accessed on 1 May 2020).

- IHI Aerospace Co., Ltd. Gallery Movie and Photo—Pinot-View2.JP. IHI Aerospace Co., Ltd., 2020. Available online: https://www.ihi.co.jp/ia/en/products/space/pinot/pinot-g/en/gallery/Pinot-View2.JPG (accessed on 20 January 2021).

- Morris, D.; Noble, R. CubeSat Advanced Technology Propulsion System Concept. In Proceedings of the 28th Annual AIAA/USU Conference on Small Satellites, Logan, UT, USA, 2–7 August 2014. [Google Scholar]

- IHI Aerospace Co., Ltd. Pinot Propulsion Module Series. IHI Aerospace Co., Ltd., 2020. Available online: https://www.ihi.co.jp/ia/en/products/space/pinot/pinot-g/en/index.html (accessed on 20 January 2021).

- Andrews, D.; Huggins, G.; Lightsey, E.G.; Cavender, D.; Baker, J. Design of a Green Monopropellant Propulsion System for the Lunar Fllight CubeSat Mission. In Proceedings of the 34th Annual Small Satellite Conference, Technical Session IX: Propulsion, SSC20-IX-07, Logan, UT, USA, 1–6 August 2020. [Google Scholar]

- Bradford-ECAPS. HPGP Thrusters. 2020. Available online: https://www.ecaps.space/products-overview-ecaps.php (accessed on 25 January 2021).

- Busek Co. Green Monopropellant Thrusters. 2020. Available online: http://www.busek.com/technologies__greenmonoprop.htm (accessed on 25 January 2021).

| Orbit Altitude (km) | Spacecraft Mass (kg) | Lifetime (y m d) | ΔV for 50% Increase Life-Time (m s−1) |

|---|---|---|---|

| 200 | 1 | 1.3 d | 9.28 |

| 4 | 4.4 d | 7.92 | |

| 8 | 2.8 d | 8.80 | |

| 10 | 3 d | 8.57 | |

| 300 | 1 | 21.8 d | 11.96 |

| 4 | 2 m 26 d | 11.67 | |

| 8 | 1 m 22 d | 11.77 | |

| 10 | 1 m 26 d | 15.76 | |

| 400 | 1 | 6 m 13 d | 14.20 |

| 4 | 2 y 1 m 11 d | 13.77 | |

| 8 | 1 y 3 m 12 d | 14.01 | |

| 10 | 1 y 4 m 18 d | 14.01 |

| Maneuvers | ΔV (km s−1) |

|---|---|

| LEO to GEO a | 3.95 (no plane change) |

| GTO to GEO | 1.5 (no plane change) |

| LEO to Earth Escape | 3.2 * |

| LEO to Lunar Orbit | 3.9 |

| GTO to Lunar Orbit | 1.7 |

| Propellant | Formulation | Isp (s) | ρ (g cm−3) | ρIsp (g s cm−3) | Tc (K) |

|---|---|---|---|---|---|

| LMP-103S | (1) 63.0% (2) 18.4% (6) 18.6% | 252 | 1.24 | 312.48 | 1903 |

| FLP-103 | (1) 63.4% (2) 11.2% (5) 25.4% | 254 | 1.31 | 332.74 | 2033 |

| FLP-106 | (1) 64.6% (3) 11.5% (5) 23.9% | 255 | 1.357 | 344.6 | 2087 |

| FLP-107 | (1) 65.4% (4) 9.3% (5) 25.3% | 258 | 1.351 | 348.5 | 2142 |

| Propellant | Theoretical Vacuum Isp (s) | Density ρ (g cm−3) | VolumetricρIsp (g s cm−3) | Chamber Temp. Tc (K) |

| HNP209 | 260 | 1.32 | 343 | ~1900 |

| HNP221 | 241 | 1.22 | 294 | 1394 |

| HNP225 | 213 | 1.16 | 245 | 990 |

| Propellant | Theoretical Vacuum Isp (s) | Density ρ (g cm−3) | Volumetric ρIsp (g s cm−3) | Chamber Temp. Tc (K) | Freezing Temp. TF (°C) | Vapor Pressure (kPa) | Maturity |

|---|---|---|---|---|---|---|---|

| AF-M315E | 266 | 1.47 | 391 | 2166 | <−80 | 1.4 | High |

| LMP-103S | 252 | 1.24 | 312.48 | 1903 | −7 | 13.6 | High |

| FLP-106 | 255 | 1.357 | 344.6 | 2087 | 0 | 2.1 | Medium |

| HNP225 * | 213 | 1.16 | 245 | 990 | ≤−10 | uncertain | Low |

| Requirement | Description |

|---|---|

| 1 | Use of Green propellant complying with ECHA–REACH directive articles. |

| 2 | Use of monopropellants classified as EIL. |

| 3 | EIL Green Monopropellants should have specific impulse performance of Isp ≥ 200 s. |

| 4 | Freezing temperature of the propellant shall be ≤−10 °C. |

| 5 | Propellant must be liquid within pressure range [0.1, 3] MPa and temperature range [−30, +80] °C. |

| 6 | Propellant shall possess Low Vapor Pressure, typically below 20 kPa at room temperature (LMP-103S is ~14 kPa @ 25 °C [16]). |

| Trade-off Criteria | Symbol | Method of Calculation | Value Function |

|---|---|---|---|

| Specific Impulse | Isp (s) | RPA simulations and literature. | Knockout condition per Requirement #3 |

| Volumetric Specific Impulse | ρIsp (g s cm−3) | RPA simulation and Propellant Thermodynamic properties Literature. | The higher the better |

| Combustion Temperature | Tc (K) | RPA simulation and Propellant Thermochemical Literature. | The lower the better |

| Freezing Temperature | TF (°C) | Literature | The lower the better |

| Vapor Pressure | Pvap (kPa) | Literature | The lower the better |

| Propellant | Score per Criterion | Overall Score (Ranked) | ||||

|---|---|---|---|---|---|---|

| Isp | ρIsp | Tc | TF | Vapor Pressure | ||

| AF-M315E | 10 | 10 | 2 | 10 | 10 | 42 |

| HNP225 | 10 | 0 | 20 | 2 | 0/Uncertain | 32 |

| LMP-103S | 10 | 5 | 6 | 3 | 3.5 | 27.5 |

| FLP-106 | 10 | 7 | 0 | 0 | 9 | 26 |

| Total Tank Empty Volume = 420 cm3 | |||

|---|---|---|---|

| PMD and Ullage = 15% | |||

| Allowable Propellant Volume = 357 cm3 | |||

| Propellants | |||

| AF-M315E | HNP225 | LMP-103S | |

| ρ (g cm−3) | 1.4699 | 1.15023 | 1.2420 |

| (g) | 524.75 | 410.632 | 443.394 |

| (N s) | 1369.310 | 858.027 | 1096.123 |

| Extension Tank Allowable Prop. Volume = 474.1 cm3 | |||

| (N s) | 1818.721 | 1139.627 | 1455.859 |

| Part | Materials/Comments | Mass (g) |

|---|---|---|

| Cover | Carbon Fiber Reinforce Composites ρ = 1.430 g cm−3 | 65 |

| Base | Aluminum 6061-AHC ρ = 2.79 g cm−3 | 101 |

| Carbon–Carbon Laminate ρ = 1.7 g cm−3 | ||

| Micro e-Pump | COTS micro gear pump (7 W–12 VDC) | 75 |

| 3-way solenoid micro FCV | COTS Acetal polymer (Delrin®) ª Material Compatibility A-Excellent with Alcohols and aqueous Ammonium nitrate [46,47,48] (2 W) | 45 |

| Piezo Microvalve–Thruster FCV | Piezo tech/Titanium-wet (200 mW) | 67 |

| Thruster 0.5 N | Niobium/Titanium (Heaters 7–12 W; 12 VDC) without FCV | 80 |

| Storage Tank | CFRP 2 mm thick. ρ = 1.430 g cm−3 | 148 |

| Ti64 1 mm thick. ρ = 4.43 g cm−3 | 228 | |

| Tank I/O ports | 5 ports × 20 g “Rough estimate” | ~100 |

| Tank Heater | Polyimide ThermofoilTM Heaters (4 W; 6–12 VDC) | 4 |

| PMD § | Titanium alloys and Acetal (Delrin®) Sponge and Vanes [49,50] (no steel, no CFRP) “Rough estimate” | ~50 |

| Microtube/Piping | Titanium alloy Grade 1 ɸin = 3 mm; t = 0.5 mm; total length = 363.6 mm | ≤10 |

| Computer, Sensors, and Interfaces | SBC *; Driver; 1 Pressure, 1 Temp. Sensors; Wiring | ≤120 |

| Total Inert Mass | 1093 | |

| Propellant | AF-M315E | LMP-103S | HNP225 |

|---|---|---|---|

| Propulsion System Size | 1U + “Tuna Can” protrusion volume | ||

| (g) | 1093 | ||

| (g) | 524.75 | 443.394 | 410.632 |

| (g) | 1617.75 | 1536.394 | 1503.632 |

| Spacecraft Size | 3 U–3 kg | ||

| (kg) | 2.47525 | 2.556606 | 2.589368 |

| (kg) | 1.38225 | 1.463606 | 1.496368 |

| Thrust | 0.5 N | ||

| (s) | 266 * | 252 * | 213 ** |

| (N s) | 1369.310 | 1096.123 | 858.027 |

| (m s−1) | 501.723 | 395.370 | 307.575 |

| Propulsion System | MPS-135 | BGT-X5 | EPSS C1 | Pinot-G | LFPS |

|---|---|---|---|---|---|

| Propellant | AF-M315E | AF-M315E | ADN-based blend | HNP225 | AF-M315E |

| Size | 4U | 1U | 1U | ∅350–135 mm | 2.5U |

| Thrust (N) | 1 N × 4 thrusters | 0.5 N | 0.1 N | 0.5 N × 4 thrusters | 0.1 N × 4 thrusters |

| Propellant Mass (kg) | ~3.7 | ~0.26 [12] | 0.33 | 0.4 | ~2 (a) [58] |

| Wet Mass (kg) | 7.2 | 1.5 | 1.2 | 10 | 5.55 |

| Total Impulse (N s) | >7290 | 565 | 650 | ~667.08 (a) [57] | >2500 |

| Feed and Pressurization | Pump | PLPS (b)–gas generator | Barrier separated const. pressure gas | Pressurization in orbit–gas generators | Pump |

| Thruster (HPGP) | 0.1 N | 0.5 N | 1 N |

|---|---|---|---|

| Thrust Range | 30–100 mN | 0.12–0.5 N | 0.25–1 N |

| Inlet Pressure Range (MPa) | 0.23–0.45 | 0.2–0.9 | 0.45–2.2 |

| Nozzle Ae/At | 100:1 | 100:1 | 100:1 |

| Steady state vacuum Isp (s) | 196–209 | 178–219 | 204–231 |

| MIB * (mNs) | ≤5 | ≤35 | ≤70 |

| OAL ** (mm) | 55 ex. FCV | 155 | 178 |

| Mass (g) | 40 ex. FCV | 180 | 380 |

| Pull-in Voltage (VDC) | 10 ± 2.5 | 28 ± 4 | 28 ± 4 |

| Holding Voltage (VDC) | 3.3 | 10 ± 1 | 10 ± 1 |

| Reactor Pre-heating Volt (nominal) (VDC) | 9 | 28 | 28 |

| Reactor Pre-heating Power (regulated) (W) | 6.3–8 | 8–10 | 8–10 |

| Thruster | BGT-X1 | BGT-X5 |

|---|---|---|

| Thrust (nominal) | 0.1 N | 0.5 N |

| Throttleable Range (mN) | 20–180 | 50–500 |

| Vacuum specific impulse Isp (s) | 214 | 220–225 |

| MIB * (mNs) | <14 | <50 |

| Catalyst Preheat Power (W) | 4.5 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nosseir, A.E.S.; Cervone, A.; Pasini, A. Modular Impulsive Green Monopropellant Propulsion System (MIMPS-G): For CubeSats in LEO and to the Moon. Aerospace 2021, 8, 169. https://doi.org/10.3390/aerospace8060169

Nosseir AES, Cervone A, Pasini A. Modular Impulsive Green Monopropellant Propulsion System (MIMPS-G): For CubeSats in LEO and to the Moon. Aerospace. 2021; 8(6):169. https://doi.org/10.3390/aerospace8060169

Chicago/Turabian StyleNosseir, Ahmed E. S., Angelo Cervone, and Angelo Pasini. 2021. "Modular Impulsive Green Monopropellant Propulsion System (MIMPS-G): For CubeSats in LEO and to the Moon" Aerospace 8, no. 6: 169. https://doi.org/10.3390/aerospace8060169