Open AccessArticle

Fabrication of CdS/CdTe-Based Thin Film Solar Cells Using an Electrochemical Technique

by

I. M. Dharmadasa, P. A. Bingham, O. K. Echendu, H. I. Salim, T. Druffel, R. Dharmadasa, G. U. Sumanasekera, R. R. Dharmasena, M. B. Dergacheva, K. A. Mit, K. A. Urazov, L. Bowen, M. Walls and A. Abbas

Cited by 95 | Viewed by 14620

Abstract

Thin film solar cells based on cadmium telluride (CdTe) are complex devices which have great potential for achieving high conversion efficiencies. Lack of understanding in materials issues and device physics slows down the rapid progress of these devices. This paper combines relevant results

[...] Read more.

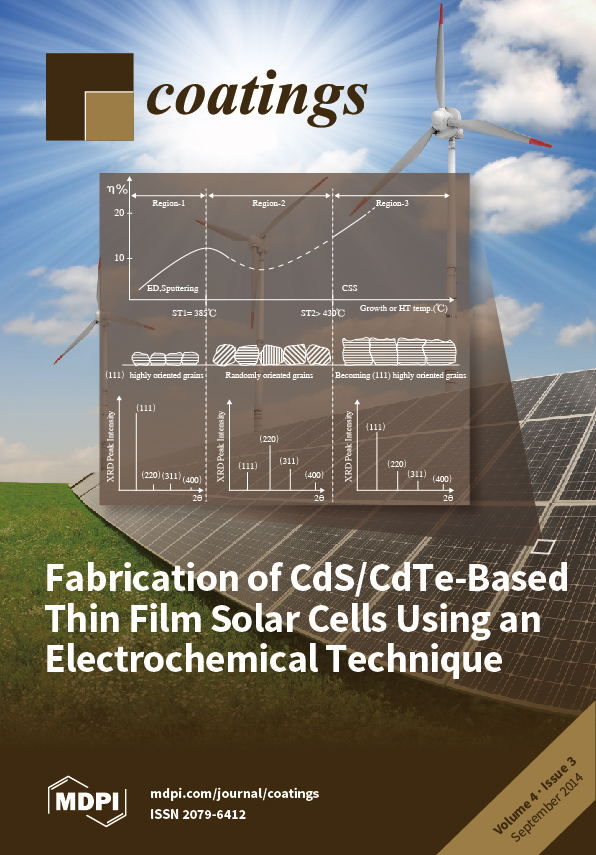

Thin film solar cells based on cadmium telluride (CdTe) are complex devices which have great potential for achieving high conversion efficiencies. Lack of understanding in materials issues and device physics slows down the rapid progress of these devices. This paper combines relevant results from the literature with new results from a research programme based on electro-plated CdS and CdTe. A wide range of analytical techniques was used to investigate the materials and device structures. It has been experimentally found that n-, i- and p-type CdTe can be grown easily by electroplating. These material layers consist of nano- and micro-rod type or columnar type grains, growing normal to the substrate. Stoichiometric materials exhibit the highest crystallinity and resistivity, and layers grown closer to these conditions show n → p or p → n conversion upon heat treatment. The general trend of CdCl

2 treatment is to gradually change the CdTe material’s n-type electrical property towards i-type or p-type conduction. This work also identifies a rapid structural transition of CdTe layer at 385 ± 5 °C and a slow structural transition at higher temperatures when annealed or grown at high temperature. The second transition occurs after 430 °C and requires more work to understand this gradual transition. This work also identifies the existence of two different solar cell configurations for CdS/CdTe which creates a complex situation. Finally, the paper presents the way forward with next generation CdTe-based solar cells utilising low-cost materials in their columnar nature in graded bandgap structures. These devices could absorb UV, visible and IR radiation from the solar spectrum and combine impact ionisation and impurity photovoltaic (PV) effect as well as making use of IR photons from the surroundings when fully optimised.

Full article

►▼

Show Figures