A Four-Band Terahertz Metamaterial Sensor Based on Symmetric E-Shaped Structure

Abstract

:1. Introduction

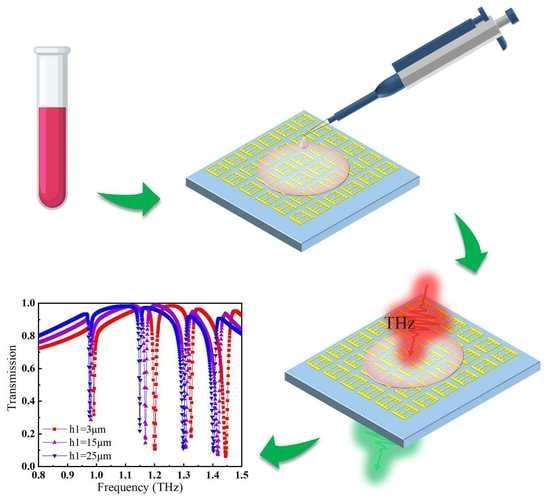

2. Design and Simulation

3. Results and Discussion

3.1. Analysis of the Resonance Mechanism

3.2. Analysis of Stability

3.3. Analysis of Sensing Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, W.; Luo, H.; He, L.; Duan, W.; Tao, Y.; Wang, X.; Li, S. Detection of heavy metals in vegetable soil based on THz spectroscopy. Comput. Electron. Agric. 2022, 197, 106923. [Google Scholar] [CrossRef]

- Cai, J.; Guang, M.; Zhou, J.; Qu, Y.; Xu, H.; Sun, Y.; Xiong, H.; Liu, S.; Chen, X.; Jin, J. Dental caries diagnosis using terahertz spectroscopy and birefringence. Opt. Express 2022, 30, 13134–13147. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Zhu, D.; Wang, Y.; Zhu, Z.; Tang, W.; Tian, Z.; Peng, Y.; Zhu, Y. Moxa Wool in Different Purities and Different Growing Years Measured by Terahertz Spectroscopy. Plant Phenomics 2022, 2022, 9815143. [Google Scholar] [CrossRef] [PubMed]

- Ueno, Y.; Ajito, K. Analytical Terahertz Spectroscopy. Anal. Sci. Int. J. Jpn. Soc. Anal. Chem. 2008, 24, 185–192. [Google Scholar] [CrossRef] [Green Version]

- Menikh, A. Terahertz-Biosensing Technology: Progress, Limitations, and Future Outlook; Springer: Berlin/Heidelberg, Germany, 2010; Volume 8, pp. 283–295. [Google Scholar]

- Shao, Y.; Gu, W.; Qiu, Y.A.; Wang, S.; Peng, Y.; Zhu, Y.; Zhuang, S. Lipids monitoring in Scenedesmus obliquus based on terahertz technology. Biotechnol. Biofuels 2020, 13, 161. [Google Scholar] [CrossRef]

- Im, J.; Goo, T.; Kim, J.; Choi, S.; Hong, S.J.; Bahk, Y.M. Detection of Microplastic in Salts Using Terahertz Time-Domain Spectroscopy. Sensors 2021, 21, 3161. [Google Scholar] [CrossRef]

- Zhu, Z.; Bian, Y.; Zhang, X.; Zeng, R.; Yang, B. Examination of proline, hydroxyproline and pyroglutamic acid with different polar groups by terahertz spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 267, 120539. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S. Quantitative Analysis of Monosaccharide Concentration Using Terahertz Time-Domain Spectroscopy in Ambient Atmosphere. IEEE Trans. Instrum. Meas. 2021, 70, 1–8. [Google Scholar] [CrossRef]

- Jiang, Y.; Ge, H.; Zhang, Y. Quantitative analysis of wheat maltose by combined terahertz spectroscopy and imaging based on Boosting ensemble learning. Food Chem. 2020, 307, 125533. [Google Scholar] [CrossRef]

- Shi, J.; Li, Z.; Sang, D.K.; Xiang, Y.; Li, J.; Zhang, S.; Zhang, H. THz photonics in two dimensional materials and metamaterials: Properties, devices and prospects. J. Mater. Chem. C 2018, 6, 1291–1306. [Google Scholar] [CrossRef]

- Lee, S.; Baek, S.; Kim, T.T.; Cho, H.; Lee, S.; Kang, J.H.; Min, B. Metamaterials for Enhanced Optical Responses and their Application to Active Control of Terahertz Waves. Adv. Mater. 2020, 32, e2000250. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhao, Y.; Liang, S.; Zhang, B.; Wang, L.; Zhou, T.; Kou, W.; Lan, F.; Zeng, H.; Han, J.; et al. Large phase modulation of THz wave via an enhanced resonant active HEMT metasurface. Nanophotonics 2018, 8, 153–170. [Google Scholar] [CrossRef]

- Sensale-Rodriguez, B.; Yan, R.; Kelly, M.M.; Fang, T.; Tahy, K.; Hwang, W.S.; Jena, D.; Liu, L.; Xing, H.G. Broadband graphene terahertz modulators enabled by intraband transitions. Nat. Commun. 2012, 3, 780. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, H.; Chen, X.; Ouyang, C.; Wang, H.; Kong, D.; Yang, P.; Zhang, B.; Wang, C.; Wei, G.; Nie, T.; et al. Generation and manipulation of chiral terahertz waves in the three-dimensional topological insulator Bi2Te3. Adv. Photonics 2020, 2, 62–70. [Google Scholar] [CrossRef]

- Yang, J.; Qi, L.; Li, B.; Wu, L.; Shi, D.; Ahmed Uqaili, J.; Tao, X. A terahertz metamaterial sensor used for distinguishing glucose concentration. Results Phys. 2021, 26, 104332. [Google Scholar] [CrossRef]

- Yan, X.; Yang, M.; Zhang, Z.; Liang, L.; Wei, D.; Wang, M.; Zhang, M.; Wang, T.; Liu, L.; Xie, J.; et al. The terahertz electromagnetically induced transparency-like metamaterials for sensitive biosensors in the detection of cancer cells. Biosens. Bioelectron. 2018, 126, 485–492. [Google Scholar] [CrossRef]

- Zhang, C.; Xue, T.; Zhang, J.; Liu, L.; Xie, J.; Wang, G.; Yao, J.; Zhu, W.; Ye, X. Terahertz toroidal metasurface biosensor for sensitive distinction of lung cancer cells. Nanophotonics 2022, 11, 101–109. [Google Scholar] [CrossRef]

- Cheng, R.; Xu, L.; Yu, X.; Zou, L.; Shen, Y.; Deng, X. High-sensitivity biosensor for identification of protein based on terahertz Fano resonance metasurfaces. Opt. Commun. 2020, 473, 125850. [Google Scholar] [CrossRef]

- Wang, G.; Zhu, F.; Lang, T.; Liu, J.; Hong, Z.; Qin, J. All-metal terahertz metamaterial biosensor for protein detection. Nanoscale Res. Lett. 2021, 16, 109. [Google Scholar] [CrossRef]

- Jin, Z.A.; Ning, M.; Lld, E.; Jx, E.; Hua, F.; Jy, D.; Tcb, C.; Wz, A. Highly Sensitive Detection of Malignant Glioma Cells Using Metamaterial-inspired THz Biosensor based on Electromagnetically Induced Transparency. Biosens. Bioelectron. 2021, 185, 113241. [Google Scholar]

- Xiaoxue, D.; Xiaodong, Z.; Yafei, W.; Guoxin, M.; Yong, L.; Bin, W.; Hanping, M. Highly sensitive detection of plant growth regulators by using terahertz time-domain spectroscopy combined with metamaterials. Opt. Express 2021, 29, 36535–36545. [Google Scholar]

- Zhang, H.; Li, Z.; Hu, F.; Qin, B.; Zhao, Y.; Chen, T.; Hu, C. Sensitive distinction between herbs by terahertz spectroscopy and a metamaterial resonator. Spectrosc. Lett. 2018, 51, 174–178. [Google Scholar] [CrossRef]

- Khwanchai, T.; Habibe, D. Herbicide/pesticide sensing with metamaterial absorber in THz regime. Sens. Actuators A Phys. 2021, 331, 112960. [Google Scholar]

- Zhang, Y.; Yixing, Z.; Yunxia, Y.; Xiaoxian, S.; Maosheng, Y.; Yunpeng, R.; Xudong, R.; Lanju, L.; Jianquan, Y. High-sensitivity detection of chlorothalonil via terahertz metasensor. Mater. Res. Express 2020, 7, 095801. [Google Scholar] [CrossRef]

- Chen, Z.; Qu, F.; Wang, Y.; Nie, P. Terahertz dual-band metamaterial absorber for trace indole-3-acetic acid and tricyclazole molecular detection based on spectral response analysis. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2021, 263, 120222. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Liao, D.; Gupta, M.; Zhu, Y.; Zhuang, S.; Singh, R.; Chen, L. Terahertz Microfluidic Sensing with Dual-Torus Toroidal Metasurfaces. Adv. Opt. Mater. 2021, 9, 2100024. [Google Scholar] [CrossRef]

- Li, F.; He, K.; Tang, T.; Mao, Y.; Wang, R.; Li, C.; Shen, J. The terahertz metamaterials for sensitive biosensors in the detection of ethanol solutions. Opt. Commun. 2020, 475, 126287. [Google Scholar] [CrossRef]

- Yao, H.; Mei, H.; Zhang, W.; Zhong, S.; Wang, X. Theoretical and Experimental Research on Terahertz Metamaterial Sensor With Flexible Substrate. IEEE Photonics J. 2022, 14, 1–9. [Google Scholar] [CrossRef]

- Chen, T.; Jiang, W.; Yin, X. Dual-Band Ultrasensitive Terahertz Sensor Based on Tunable Graphene Metamaterial Absorber. Superlattices Microstruct. 2021, 154, 106898. [Google Scholar] [CrossRef]

- Ma, A.; Zhong, R.; Wu, Z.; Wang, Y.; Yang, L.; Liang, Z.; Fang, Z.; Liu, S. Ultrasensitive THz Sensor Based on Centrosymmetric F-Shaped Metamaterial Resonators. Front. Phys. 2020, 8, 584630. [Google Scholar] [CrossRef]

- Veeraselvam, A.; Mohammed, G.N.A.; Savarimuthu, K.; Vijayaraman, P.D. An Ultra-Thin Multiband Refractive Index-Based Carcinoma Sensor Using THz Radiation. IEEE Sens. J. 2022, 22, 2045–2052. [Google Scholar] [CrossRef]

- Fang, X.; Xiong, L.; Shi, J.; Ding, H.; Li, G. Narrow quadrupolar surface lattice resonances and band reversal in vertical metal-insulator-metal gratings. J. Phys. D Appl. Phys. 2021, 55, 025111. [Google Scholar] [CrossRef]

- Chen, X.; Fan, W. Ultrasensitive terahertz metamaterial sensor based on spoof surface plasmon. Sci. Rep. 2017, 7, 2092. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Yan, J.; Huang, Y.; Yang, G. Directional Fano resonance in an individual GaAs nanospheroid. Small 2019, 15, 1900546. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Wei, Y.; Zang, X.; Zhu, Y.; Zhuang, S. Excitation of dark multipolar plasmonic resonances at terahertz frequencies. Sci. Rep. 2016, 6, 22027. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Born, N.; Al-Naib, I.; Jansen, C.; Ozaki, T.; Morandotti, R.; Koch, M. Excitation of multiple trapped-eigenmodes in terahertz metamolecule lattices. Appl. Phys. Lett. 2014, 104, 101107. [Google Scholar] [CrossRef]

- Srivastava, Y.K.; Ako, R.T.; Gupta, M.; Bhaskaran, M.; Sriram, S.; Singh, R. Terahertz sensing of 7 nm dielectric film with bound states in the continuum metasurfaces. Appl. Phys. Lett. 2019, 115, 151105. [Google Scholar] [CrossRef] [Green Version]

- Karmakar, S.; Kumar, D.; Varshney, R.K.; Chowdhury, D.R. Strong terahertz matter interaction induced ultrasensitive sensing in Fano cavity based stacked metamaterials. J. Phys. D Appl. Phys. 2020, 53, 415101. [Google Scholar] [CrossRef]

- Veeraselvam, A.; Mohammed, G.N.A.; Savarimuthu, K. A Novel Ultra-Miniaturized Highly Sensitive Refractive Index-Based Terahertz Biosensor. J. Light. Technol. 2021, 39, 7281–7287. [Google Scholar] [CrossRef]

- Sharma, P.; Sharan, P. Design of photonic crystal based ring resonator for detection of different blood constituents. Opt. Commun. 2015, 348, 19–23. [Google Scholar] [CrossRef]

- Veeraselvam, A.; Mohammed, G.N.A.; Savarimuthu, K.; Sankararajan, R. A novel multi-band biomedical sensor for THz regime. Opt. Quantum Electron. 2021, 53, 354. [Google Scholar] [CrossRef]

- Sun, R.; Li, W.; Meng, T.; Zhao, G. Design and optimization of terahertz metamaterial sensor with high sensing performance. Opt. Commun. 2021, 494, 127051. [Google Scholar] [CrossRef]

- Xiong, Z.; Shang, L.; Yang, J.; Chen, L.; Guo, J.; Liu, Q.; Danso, S.A.; Li, G. Terahertz sensor with resonance enhancement based on square split-ring resonators. IEEE Access 2021, 9, 59211–59221. [Google Scholar] [CrossRef]

- Nickpay, M.-R.; Danaie, M.; Shahzadi, A. Highly sensitive THz refractive index sensor based on folded split-ring metamaterial graphene resonators. Plasmonics 2022, 17, 237–248. [Google Scholar] [CrossRef]

- Abdulkarim, Y.I.; Xiao, M.; Awl, H.N.; Muhammadsharif, F.F.; Lang, T.; Saeed, S.R.; Alkurt, F.Ö.; Bakır, M.; Karaaslan, M.; Dong, J. Simulation and lithographic fabrication of a triple band terahertz metamaterial absorber coated on flexible polyethylene terephthalate substrate. Opt. Mater. Express 2022, 12, 338–359. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, G.; Ge, H.; Wang, F.; Li, L.; Chen, X.; Lv, M.; Zhang, Y. Adaptive compressed sensing algorithm for terahertz spectral image reconstruction based on residual learning. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 281, 121586. [Google Scholar] [CrossRef]

- Baba, T. Slow light in photonic crystals. Nat. Photonics 2008, 2, 465–473. [Google Scholar] [CrossRef]

- Bandurin, D.; Mönch, E.; Kapralov, K.; Phinney, I.; Lindner, K.; Liu, S.; Edgar, J.; Dmitriev, I.; Jarillo-Herrero, P.; Svintsov, D. Cyclotron resonance overtones and near-field magnetoabsorption via terahertz Bernstein modes in graphene. Nat. Phys. 2022, 18, 462–467. [Google Scholar] [CrossRef]

| Parameters | P | h | l | d | g | w | g1 | t |

|---|---|---|---|---|---|---|---|---|

| Value/μm | 200 | 60 | 40 | 10 | 5 | 5 | 20 | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Ge, H.; Jiang, Y.; Li, G.; Wang, F.; Lv, M.; Ji, X.; Jia, Z.; Li, Z.; Zhang, Y. A Four-Band Terahertz Metamaterial Sensor Based on Symmetric E-Shaped Structure. Coatings 2022, 12, 1694. https://doi.org/10.3390/coatings12111694

Li L, Ge H, Jiang Y, Li G, Wang F, Lv M, Ji X, Jia Z, Li Z, Zhang Y. A Four-Band Terahertz Metamaterial Sensor Based on Symmetric E-Shaped Structure. Coatings. 2022; 12(11):1694. https://doi.org/10.3390/coatings12111694

Chicago/Turabian StyleLi, Li, Hongyi Ge, Yuying Jiang, Guangming Li, Fei Wang, Ming Lv, Xiaodi Ji, Zhiyuan Jia, Zhi Li, and Yuan Zhang. 2022. "A Four-Band Terahertz Metamaterial Sensor Based on Symmetric E-Shaped Structure" Coatings 12, no. 11: 1694. https://doi.org/10.3390/coatings12111694