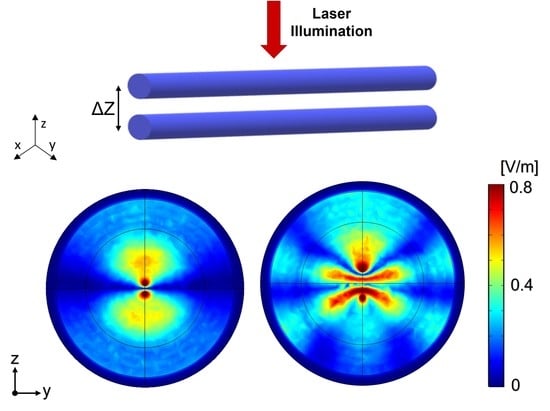

All-Optical Nanosensor for Displacement Detection in Mechanical Applications

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Case Study for Operation Wavelength at 1064 nm

- (1)

- It is not recommended to work with variations of the distance between the nanowires greater than 400 nm because the deformation of the nanocylinders can cause second harmonics.

- (2)

- The identification of intervals with linear behavior is highly desirable, and according to the first recommendation, it is not necessary to consider the whole range. In our case, selecting small displacement intervals with the best possible linear behavior is sufficient.

3.2. Case Study for Operation Wavelength at 1310 nm

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahoulou, S.; Perret, E.; Nedelec, J.-M. Functionalization and Characterization of Silicon Nanowires for Sensing Applications: A Review. Nanomaterials 2021, 11, 999. [Google Scholar] [CrossRef]

- Ramos, D.; Gil-Santos, E.; Malvar, O.; Llorens, J.M.; Pini, V.; Paulo, A.S.; Calleja, M.; Tamayo, J. Silicon nanowires: Where mechanics and optics meet at the nanoscale. Sci. Rep. 2013, 3, 3445. [Google Scholar] [CrossRef] [Green Version]

- Sanii, B.; Ashby, P.D. High sensitivity deflection detection of nanowires. Phys. Rev. Lett. 2010, 104, 147203. [Google Scholar] [CrossRef]

- Midolo, L.; Schliesser, A.; Fiore, A. Nano-opto-electro-mechanical systems. Nat. Nanotechnol. 2018, 13, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Singh, P.; Yadava, R.D.S. Nanosensor for Health Care. In Nanosensors for Smart Cities; Han, B., Tomer, V.K., Nguyen, T.A., Farmani, A., Singh, P.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 433–450. [Google Scholar]

- Kanygin, M.A.; Bahreyni, B. Self-powered integrated opto-electro-mechanical nano-actuators. Nano Energy 2021, 88, 106280. [Google Scholar] [CrossRef]

- Neethirajan, S.; Weng, X.; Tah, A.; Cordero, J.O.; Ragavan, K.V. Nano-biosensor platforms for detecting food allergens—New trends. Sens. Bio-Sens. Res. 2018, 18, 13–30. [Google Scholar] [CrossRef]

- Guardiola, C.; Márquez, A.; Jiménez-Ramos, M.D.C.; López, J.G.; Baratto-Roldán, A.; Muñoz-Berbel, X. Dosimetry with gafchromic films based on a new micro-opto-electro-mechanical system. Sci. Rep. 2021, 11, 10414. [Google Scholar] [CrossRef]

- Wu, S.; Gong, C.; Zuo, C.; Li, S.; Zhang, J.; Dai, Z.; Yang, K.; Zhao, M.; Rui, N.; Xu, Z.; et al. Weak Radio-Frequency Signal Detection Based on Piezo-Opto-Electro-Mechanical System: Architecture Design and Sensitivity Prediction. IEEE Internet Things J. 2021, 8, 10085–10102. [Google Scholar] [CrossRef]

- Yang, Y.T.; Callegari, C.; Feng, X.L.; Ekinci, K.L.; Roukes, M.L. Zeptogram-scale nanomechanical mass sensing. Nano Lett. 2006, 6, 583–586. [Google Scholar] [CrossRef]

- Rugar, D.; Budakian, R.; Mamin, H.J.; Chui, B.W. Single spin detection by magnetic resonance force microscopy. Nature 2004, 430, 329–332. [Google Scholar] [CrossRef]

- Galeotti, F.; Lindgren, G.; Petruzzella, M.; van Otten, F.W.M.; Marnani, H.S.; Mohtashami, A.; van der Heijden, R.; Fiore, A. Demonstration of atomic force microscopy imaging using an integrated opto-electro-mechanical transducer. Ultramicroscopy 2021, 230, 113368. [Google Scholar] [CrossRef]

- Sani, M.H.; Saghaei, H.; Mehranpour, M.A.; Tabrizi, A.A. A novel all-optical sensor design based on a tunable resonant nanocavity in photonic crystal microstructure applicable in MEMS accelerometers. Photonic Sens. 2021, 11, 457–471. [Google Scholar] [CrossRef]

- Gil-Santos, E.; Ruz, J.J.; Malvar, O.; Favero, I.; Lemaitre, A.; Kosaka, M.P.; García-López, S.; Calleja, M.; Tamayo, J. Optomechanical detection of vibration modes of a single bacterium. Nat. Nanotechnol. 2020, 15, 469–474. [Google Scholar] [CrossRef]

- Li, M.; Tang, H.X.; Roukes, M.L. Ultra-sensitive NEMS-based cantilevers for sensing, scanned probe and very high-frequency applications. Nat. Nanotechnol. 2007, 2, 114–120. [Google Scholar] [CrossRef]

- Fogliano, F.; Besga, B.; Reigue, A.; de Lépinay, L.M.; Heringlake, P.; Gouriou, C.; Eyraud, E.; Wernsdorfer, W.; Pigeau, B.; Arcizet, O. Ultrasensitive nano-optomechanical force sensor operated at dilution temperatures. Nat. Commun. 2021, 12, 4124. [Google Scholar] [CrossRef]

- Gavartin, E.; Verlot, P.; Kippenberg, T.J. A hybrid on-chip optomechanical transducer for ultrasensitive force measurements. Nat. Nanotechnol. 2012, 7, 509–514. [Google Scholar] [CrossRef] [Green Version]

- Xia, J.; Qiao, Q.; Zhou, G.; Chau, F.S.; Zhou, G. Opto-Mechanical Photonic Crystal Cavities for Sensing Application. Appl. Sci. 2020, 10, 7080. [Google Scholar] [CrossRef]

- Aggarwal, A.; Raman, A.; Kumar, N.; Singh, S. Nanocantilever tri-gate junctionless cuboidal nanowire-FET-based directional pressure sensor. Appl. Phys. A 2019, 125, 813. [Google Scholar] [CrossRef]

- Liu, T.; Pagliano, F.; van Veldhoven, R.; Pogoretskiy, V.; Jiao, Y.; Fiore, A. Integrated nano-optomechanical displacement sensor with ultrawide optical bandwidth. Nat. Commun. 2020, 11, 2407. [Google Scholar] [CrossRef]

- Yavas, O.; Svedendahl, M.; Dobosz, P.; Sanz, V.; Quidant, R. On-a-chip Biosensing Based on All-Dielectric Nanoresonators. Nano Lett. 2017, 17, 4421–4426. [Google Scholar] [CrossRef]

- Asghari, A.; Wang, C.; Yoo, K.M.; Rostamian, A.; Xu, X.; Shin, J.-D.; Dalir, H.; Chen, R.T. Fast, accurate, point-of-care COVID-19 pandemic diagnosis enabled through advanced lab-on-chip optical biosensors: Opportunities and challenges. Appl. Phys. Rev. 2021, 8, 031313. [Google Scholar] [CrossRef]

- Kwon, H.; Zheng, T.; Faraon, A. Nano-electromechanical Tuning of Dual-Mode Resonant Dielectric Metasurfaces for Dynamic Amplitude and Phase Modulation. Nano Lett. 2021, 21, 2817–2823. [Google Scholar] [CrossRef]

- Barreda, A.; Saiz, J.M.; González, F.; Moreno, F.; Albella, P. Recent advances in high refractive index dielectric nanoantennas: Basics and applications. AIP Adv. 2019, 9, 040701. [Google Scholar] [CrossRef] [Green Version]

- Khansili, N.; Rattu, G.; Krishna, P.M. Label-free optical biosensors for food and biological sensor applications. Sens. Actuators B Chem. 2018, 265, 35–49. [Google Scholar] [CrossRef]

- Algorri, J.F.; García-Cámara, B.; Urruchi, V.; Sánchez-Pena, J.M. High-Sensitivity Fabry-Pérot Temperature Sensor Based on Liquid Crystal Doped with Nanoparticles. IEEE Photonic Technol. Lett. 2015, 27, 292–295. [Google Scholar] [CrossRef]

- Algorri, J.F.; Zografopoulos, D.C.; Ferraro, A.; García-Cámara, B.; Beccherelli, R.; Sánchez-Pena, J.M. Ultrahigh-quality factor resonant dielectric metasurfaces based on hollow nanocuboids. Opt. Express 2019, 27, 6320–6330. [Google Scholar] [CrossRef]

- Elshorgaby, M.H.; Cuadrado, A.; García-Cámara, B.; Vergaz, R.; Gómez-Pedrero, J.A.; Alda, J. Ultra-Narrow Spectral Response of a Hybrid Plasmonic-Grating Sensor. IEEE Sens. J. 2020, 20, 3520–3528. [Google Scholar]

- Wang, Y.C.; Zhao, C.; Wang, J.; Luo, X.; Xie, L.; Zhan, S.; Kim, J.; Wang, X.; Liu, X.; Ying, Y. Wearable plasmonic-metasurface sensor for noninvasive and universal molecular fingerprint detection on biointerfaces. Sci. Adv. 2021, 7, eabe4553. [Google Scholar] [CrossRef]

- Koya, A.N.; Cunha, J.; Guerrero-Becerra, K.A.; Garoli, D.; Wang, T.; Juodkazis, S.; Zaccaria, R.P. Plasmomechanical Systems: Principles and Applications. Adv. Funct. Mater. 2021, 31, 2103706. [Google Scholar] [CrossRef]

- Thijssen, R.; Kippenberg, T.J.; Polman, A.; Verhagen, E. Plasmomechanical Resonators Based on Dimer Nanoantennas. Nano Lett. 2015, 15, 3971–3976. [Google Scholar] [CrossRef]

- Lamothe, E.; Lévêque, G.; Martin, O.J.F. Optical forces in coupled plasmonic nanosystems: Near field and far field interaction regimes. Opt. Express 2007, 15, 9631–9644. [Google Scholar] [CrossRef]

- García-Cámara, B.; Gómez-Medina, R.; Sáenz, J.J.; Sepúlveda, B. Sensing with magnetic dipolar resonances in semiconductor nanospheres. Opt. Express 2013, 21, 23007–23020. [Google Scholar] [CrossRef] [Green Version]

- Llobet, J.; Rius, G.; Chuquitarqui, A.; Borrise, X.; Koops, R.; van Veghel, M.G.; Perez-Murano, F. Arrays of suspended silicon nanowires defined by ion beam implantation: Mechanical coupling and combination with CMOS technology. Nanotechnology 2018, 29, 155303. [Google Scholar] [CrossRef] [Green Version]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: Cambridge, MA, USA, 1998. [Google Scholar]

- Zhu, G.; Liao, Q. Highly efficient collection for photon emission enhanced by the hybrid photonic-plasmonic cavity. Opt. Express 2018, 26, 31391–31401. [Google Scholar] [CrossRef]

- Barreda, Á.I.; Sanz, J.M.; González, F. Using linear polarization for sensing and sizing dielectric nanoparticles. Opt. Express 2015, 23, 9157–9166. [Google Scholar] [CrossRef]

- Bouaziz, D.; Chabrol, G.; Guessoum, A.; Demagh, N.-E.; Lecler, S. Photonic Jet-Shaped Optical Fiber Tips versus Lensed Fibers. Photonics 2021, 8, 373. [Google Scholar] [CrossRef]

- Evlyukhin, A.B.; Reinhardt, C.; Chichkov, B.N. Multipole light scattering by nonspherical nanoparticles in the discrete dipole approximation. Phys. Rev. B Condens. Matter Mater. Phys. 2011, 84, 235429. [Google Scholar] [CrossRef]

- Farahani, J.N.; Pohl, D.W.; Eisler, H.-J.; Hecht, B. Single quantum dot coupled to a scanning optical antenna: A tunable superemitter. Phys. Rev. Lett. 2005, 95, 017402. [Google Scholar] [CrossRef]

- Anger, P.; Bharadwaj, P.; Novotny, L. Enhancement and quenching of singlemolecule fluorescence. Phys. Rev. Lett. 2006, 96, 113002. [Google Scholar] [CrossRef]

| Distance between Nanowires (nm) | Electric Field (V/m) | ||

|---|---|---|---|

| 1064 nm | Interval I | 500–750 | 0.019–0.295 |

| Interval II | 825–1575 | 0.297–0.011 | |

| Interval III | 1575–1925 | 0.011–0.298 | |

| 1064 nm | Interval I | |

| Interval II | ||

| Interval III | ||

| Distance between Nanowires (nm) | Electric Field (V/m) | ||

|---|---|---|---|

| 1310 nm | Interval I | 650–950 | 0.005–0.346 |

| Interval II | 975–1950 | 0.336–0.009 | |

| Interval III | 1950–2200 | 0.009–0.273 | |

| 1310 nm | Interval I | |

| Interval II | ||

| Interval III | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Escandell, L.; Álvarez-Rodríguez, C.; Barreda, Á.; Zaera, R.; García-Cámara, B. All-Optical Nanosensor for Displacement Detection in Mechanical Applications. Nanomaterials 2022, 12, 4107. https://doi.org/10.3390/nano12224107

Escandell L, Álvarez-Rodríguez C, Barreda Á, Zaera R, García-Cámara B. All-Optical Nanosensor for Displacement Detection in Mechanical Applications. Nanomaterials. 2022; 12(22):4107. https://doi.org/10.3390/nano12224107

Chicago/Turabian StyleEscandell, Lorena, Carlos Álvarez-Rodríguez, Ángela Barreda, Ramón Zaera, and Braulio García-Cámara. 2022. "All-Optical Nanosensor for Displacement Detection in Mechanical Applications" Nanomaterials 12, no. 22: 4107. https://doi.org/10.3390/nano12224107