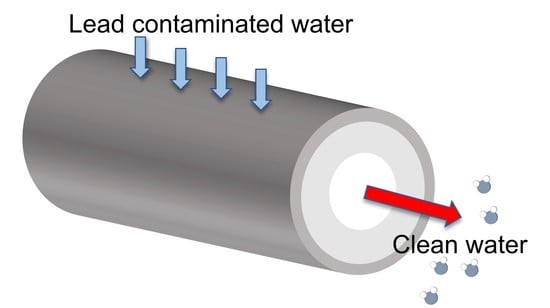

Hybrid Inorganic Organic PSF/Hap Dual-Layer Hollow Fibre Membrane for the Treatment of Lead Contaminated Water

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Synthesis of Hydroxyapatite Powder from Waste Cockle Shell

2.3. HAP Powder Characterisation

2.4. Fabrication of Dual-Layer Hollow Fibre Membrane

2.5. Membrane Characterisation

2.6. Membrane Permeability Analysis

2.7. Adsorption Analysis

2.8. Dynamic Adsorption

3. Results and Discussion

3.1. Morphology and Chemical Characteristic of the Synthesize HAP Powder

3.2. Lead Removal Studies Based on HAP Powder Adsorption Capacity

3.2.1. Effect of Initial Lead Concentration for Synthesize HAP Powder

3.2.2. Effect of Contact Time for Synthesize HAP Powder

3.2.3. Adsorption Isotherm

3.2.4. Adsorption Kinetics

3.3. Morphology Study of the Fabricated Membrane

3.4. Hydrophilicity/Hydrophobicity

3.5. Membrane Flux and Permeability

3.6. Dynamic Adsorption od PSf/HAP DLHF Membranes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mishrra, A.; Wang, Z.; Sidorkiewicz, V.; Giammar, D.E. Giammar, Effect of sodium silicate on lead release from lead service lines. Water Res. 2020, 188, 116485. [Google Scholar] [CrossRef] [PubMed]

- Karnib, M.; Kabbani, A.; Holail, H.; Olama, Z. Heavy Metals Removal Using Activated Carbon, Silica and Silica Activated Carbon Composite. Energy Procedia 2014, 50, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Briffa, J.; Sinagra, E.; Blundell, R. Blundell, Heavy metal pollution in the environment and their toxicological effects on humans. Heliyon 2020, 6, e04691. [Google Scholar] [CrossRef]

- Schwartz, G.G.; Williamson, M.R. Lead service lines and Parkinson’s disease prevalence in U.S. States. Clin. Park. Relat. Disord. 2021, 5, 100122. [Google Scholar] [CrossRef]

- Doré, E.; Deshommes, E.; Laroche, L.; Nour, S.; Prévost, M. Prévost, Study of the long-term impacts of treatments on lead release from full and partially replaced harvested lead service lines. Water Res. 2018, 149, 566–577. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Edwards, M.A. Efficacy of corrosion control and pipe replacement in reducing citywide lead exposure during the Flint, MI water system recovery. Environ. Sci. Water Res. Technol. 2020, 6, 3024–3031. [Google Scholar] [CrossRef]

- Kumar, V.; Dwivedi, S.; Oh, S. A critical review on lead removal from industrial wastewater: Recent advances and future outlook. J. Water Process. Eng. 2022, 45, 102518. [Google Scholar] [CrossRef]

- Brooks, R.; Bahadory, M.; Tovia, F.; Rostami, H. Removal of lead from contaminated water. Int. J. Soil Sediment Water 2010, 3, 14. [Google Scholar]

- Yang, X.; Xu, G.; Yu, H. Removal of lead from aqueous solutions by ferric activated sludge-based adsorbent derived from biological sludge. Arab. J. Chem. 2019, 12, 4142–4149. [Google Scholar] [CrossRef] [Green Version]

- Kamarudin, S.N.; Jamalludin, M.R.; Rasman, S.N.S.; Hubadillah, S.K.; Pauzan, M.A.B.; Othman, M.H.D. Fabrication and characterization of composite hollow fibre membrane derived from hydroxyapatite cow bone and kaolin. IOP Conf. Series Mater. Sci. Eng. 2021, 1142, 012011. [Google Scholar] [CrossRef]

- Ahmad, N.; Samavati, A.; Nordin, N.A.H.; Jaafar, J.; Ismail, A.F.; Malek, N.A.N.N. Enhanced performance and antibacterial properties of amine-functionalized ZIF-8-decorated GO for ultrafiltration membrane. Sep. Purif. Technol. 2020, 239, 116554. [Google Scholar] [CrossRef]

- Rana, D.; Matsuura, T. Surface modifications for antifouling membranes. Chem. Rev. 2010, 110, 2448–2471. [Google Scholar] [CrossRef]

- Urkiaga, A.; Iturbe, D.; Etxebarria, J. Effect of different additives on the fabrication of hydrophilic polysulfone ultrafiltration membranes. Desalination Water Treat. 2015, 56, 3415–3426. [Google Scholar] [CrossRef]

- Chong, K.C.; Lai, S.O.; Lau, W.J.; Thiam, H.S.; Ismail, A.F.; Roslan, R.A. Preparation, characterization, and performance evaluation of polysulfone hollow fiber membrane with PEBAX or PDMS coating for oxygen enhancement process. Polymers 2018, 10, 126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mansur, S.; Hafiz, M.; Othman, D.; Ismail, A.; Hamimah, S.; Abdul, S.; Kamal, F.; Pei, G.; Hasbullah, H.; Be, N.; et al. Investigation on the Effect of Spinning Conditions on the Properties of Hollow Fibre Membrane for Haemodialysis Application. J. Appl. Polym. Sci. 2016, 133, 43633. [Google Scholar] [CrossRef]

- Singh, S.; Khare, A.; Chaudhari, S. Enhanced fluoride removal from drinking water using non-calcined synthetic hydroxyapatite. J. Environ. Chem. Eng. 2020, 8, 103704. [Google Scholar] [CrossRef]

- Sun, J.; Wu, L. Polyether sulfone/hydroxyapatite mixed matrix membranes for protein purification. Appl. Surf. Sci. 2014, 308, 155–160. [Google Scholar] [CrossRef]

- Jiang, J.-H.; Zhu, L.-P.; Zhang, H.-T.; Zhu, B.-K.; Xu, Y.-Y. Improved hydrodynamic permeability and antifouling properties of poly(vinylidene fluoride) membranes using polydopamine nanoparticles as additives. J. Membr. Sci. 2014, 457, 73–81. [Google Scholar] [CrossRef]

- Kallem, P.; Bharath, G.; Rambabu, K.; Srinivasakannan, C.; Banat, F. Improved permeability and antifouling performance of polyethersulfone ultrafiltration membranes tailored by hydroxyapatite/boron nitride nanocomposites. Chemosphere 2020, 268, 129306. [Google Scholar] [CrossRef]

- Cheah, W.-K.; Sim, Y.-L.; Yeoh, F.-Y. Amine-functionalized mesoporous silica for urea adsorption. Mater. Chem. Phys. 2016, 175, 151–157. [Google Scholar] [CrossRef]

- Abidin, M.N.Z.; Goh, P.S.; Ismail, A.F.; Said, N.; Othman, M.H.D.; Hasbullah, H.; Abdullah, M.S.; Ng, B.C.; Kadir, S.H.S.A.; Kamal, F. Highly adsorptive oxidized starch nanoparticles for e ffi cient urea removal. Carbohydr. Polym. 2018, 201, 257–263. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, N.; Gohari, R.; Yusof, N.; Ismail, A.; Juhana, J.; Lau, W.; Matsuura, T. Polysulfone/hydrous ferric oxide ultrafiltration mixed matrix membrane: Preparation, characterization and its adsorptive removal of lead (II) from aqueous solution. Chem. Eng. J. 2015, 289, 28–37. [Google Scholar] [CrossRef]

- Ismail, S.; Ahmed, A.S.; Anr, R.; Hamdan, S. Biodiesel Production from Castor Oil by Using Calcium Oxide Derived from Mud Clam Shell. J. Renew. Energy 2016, 2016, 5274917. [Google Scholar] [CrossRef]

| Membrane | Inner Dope Solution (wt%) | Outer Dope Solution (wt%) | |||||

|---|---|---|---|---|---|---|---|

| PSf | PVP | NMP | PSF | PVP | HAP | NMP | |

| M0 | 18 | 7 | 75 | - | - | - | - |

| M10 | 18 | 7 | 75 | 15 | 5 | 10 | 70 |

| M20 | 18 | 7 | 75 | 15 | 5 | 20 | 60 |

| M30 | 18 | 7 | 75 | 15 | 5 | 30 | 50 |

| M40 | 18 | 7 | 75 | 15 | 5 | 40 | 40 |

| This Study | Fatimah et al. (2019) | Hajar et al. (2018) | Azis et al. (2015) | |

|---|---|---|---|---|

| Weight (%) | ||||

| Ca | 46.8 | 20.1 | n/d | 22.8 |

| C | 3.0 | n/d | 9.8 | n/d |

| O | 48.7 | 67.8 | 68.4 | n/d |

| P | 0.5 | 11.9 | 8.8 | 12.8 |

| Al | 1.0 | n/d | n/d | 1.0 |

| Co | n/d | n/d | 11.9 | n/d |

| K | n/d | n/d | 0.8 | n/d |

| Langmuir Model | Freundlich Model | ||||

|---|---|---|---|---|---|

| Qmax (mg/g) | b (L/g) | R2 | KF (mmol/g) (L/mmol)1/n | n | R2 |

| 48.309 | 0.265 | 0.9817 | 10.79 | 0.342 | 0.2406 |

| Co (mg/L) | Qe (mg/g) | Pseudo-First-Order Model | Pseudo-Second Order Model | |||

|---|---|---|---|---|---|---|

| k1 (1/h) | R2 | k2 (g/mgh) | Qe (cal) (mg/g) | R2 | ||

| 1000 | 180.8 | 0.59 | 0.7497 | 0.04 | 189.0 | 0.9269 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mansur, S.; Othman, M.H.D.; Ismail, N.J.; Sheikh Abdul Kadir, S.H.; Puteh, M.H.; Abdullah, H.; Jaafar, J.; Rahman, M.A.; Kusworo, T.D.; Ismail, A.F.; et al. Hybrid Inorganic Organic PSF/Hap Dual-Layer Hollow Fibre Membrane for the Treatment of Lead Contaminated Water. Membranes 2023, 13, 170. https://doi.org/10.3390/membranes13020170

Mansur S, Othman MHD, Ismail NJ, Sheikh Abdul Kadir SH, Puteh MH, Abdullah H, Jaafar J, Rahman MA, Kusworo TD, Ismail AF, et al. Hybrid Inorganic Organic PSF/Hap Dual-Layer Hollow Fibre Membrane for the Treatment of Lead Contaminated Water. Membranes. 2023; 13(2):170. https://doi.org/10.3390/membranes13020170

Chicago/Turabian StyleMansur, Sumarni, Mohd Hafiz Dzarfan Othman, Nurul Jannah Ismail, Siti Hamimah Sheikh Abdul Kadir, Mohd Hafiz Puteh, Huda Abdullah, Juhana Jaafar, Mukhlis A. Rahman, Tutuk Djoko Kusworo, Ahmad Fauzi Ismail, and et al. 2023. "Hybrid Inorganic Organic PSF/Hap Dual-Layer Hollow Fibre Membrane for the Treatment of Lead Contaminated Water" Membranes 13, no. 2: 170. https://doi.org/10.3390/membranes13020170