Modelling Sorption and Transport of Gases in Polymeric Membranes across Different Scales: A Review

Abstract

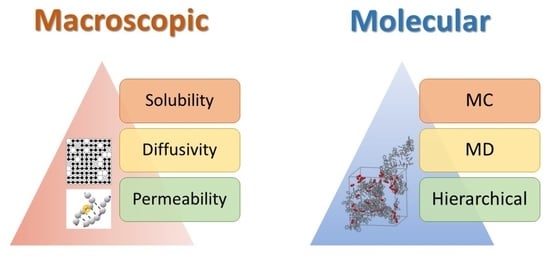

:1. Introduction

2. Modelling Fluid Transport in Dense, Homogenous Polymeric Membranes: The Solution–Diffusion Model

3. Modelling the Upper Bound of Gas Separation Membranes

4. Macroscopic Models for Gas Solubility in Polymers

4.1. Activity Coefficient Models

4.2. EoS Models: Lattice Fluid Equations of State

4.3. EoS Models: Statistical Associating Fluid Theory (SAFT)

- -

- Hard sphere repulsive interaction (hs), which is a property of the reference fluid;

- -

- Attractive dispersion terms (disp), corresponding to the formation of weak interactions;

- -

- Chain formation contribution (chain), relative to the formation of covalent bonds;

- -

- Association interaction contributions (assoc), for polar interactions between groups.

4.4. Non-Equilibrium Thermodynamics for Glassy Polymers (NET-GP)

4.5. Dual-Mode Sorption (DMS) Model for Glassy Polymers

4.6. Guggenheim−Anderson−de Boer (GAB) Model

4.7. Fractal Model for Solubility Coefficients

4.8. Insight on Mixed-Gas Sorption in Polymers: Experimental Trends and Modeling

Modelling Mixed-Gas Sorption of CO2/CH4 Mixture in PIM-1: NELF and DMS Model Results

5. Macroscopic Models for Gas Diffusivity in Polymers

5.1. Free-Volume Theory

- Viscosity versus temperature data for the fluid and the polymer allow calculation of Kij.

- Density data for pure fluid → , .

- Critical volume of pure fluid.

- Glass transition temperature of the polymer, Tg2.

5.2. Fractal Model for Diffusion Coefficients

5.3. Maxwell–Stefan Model

6. Explicit Models for Permeability

6.1. Partial Immobilization Dual-Mobility Model

6.2. Standard Transport Model (STM)

6.3. Transport Models Based on the Maxwell–Stefan Approach

7. Molecular Modelling of Gas Solubility and Diffusivity in Polymers

7.1. Generation of Atomistic Models of Amorphous Polymers

7.2. Molecular Dynamics (MD) Simulations

7.3. Monte Carlo Simulations

- Reptation, which consists of excising one chain end and appending it on the other side of the chain with a random torsion angle;

- Concerted rotations [264] occur around seven consecutive skeletal bonds to modify change conformation without affecting bond lengths and angles;

- In addition, other connectivity-altering moves [265] have been devised, such as end-bridging [266,267], in which a trimer located in the middle of a chain is excised on one side and rotated to be attached to the end of another chain; and double-bridging [268], where two trimers are simultaneously excised from two chains and used to connect each section of the first chain with one section of the other chain.

7.4. Hierarchical Modelling Approaches

7.5. Simulation of Solubility

7.6. Simulation of Diffusivity

7.7. Gas-Induced Swelling

7.8. Atomistic Simulation of Gas-Separation Membranes

7.8.1. Bulk Systems Simulations

7.8.2. Gas–Polymer Interface Simulations

7.8.3. Mixed-Gas Simulations

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Acronyms List

| PDMS | Poly(dimethyl siloxane) |

| XLPEO | Crosslinked Poly(ethylene oxide) |

| PMMA | Poly (methyl methacrylate) |

| PVDF | Polyvinylidene fluoride |

| PPO | Poly(2,6-dimethyl-1,4-phenylene oxide) |

| CTA | Cellulose triacetate |

| PTMSP | Poly(1-trimethylsilyl-1-propyne) |

| 6FDA-TADPO | Hexafluoro dianhydride–3,3,4,4-tetraaminodiphenyl oxide polypyrrolone |

| 6FDA-mPDA | 4,4′-(hexafluoro isopropylidene) diphtalic dianhydride-m-phenylenediamine |

| HAB-6FDA | 3,3′-dihydroxy-4,4′-diamino-biphenyl 2,2′-bis-(3,4-dicarboxyphenyl) hexafluoropropane dianhydride |

| TR450 | Thermally rearranged derivative of HAB-6FDA |

| PIM-1 | Polybenzodioxane |

| TZ-PIM | Tetrazole-modified PIM-1 |

| PIM-Trip-TB | Ladder polymer of intrinsic microporosity including a triptycene group |

| RSE | Relative Standard Error |

| EoS | Equation of State |

| LF | Lattice Fluid |

| NET-GP | Non-Equilibrium Thermodynamics for Glassy Polymers |

| NELF | Non-Equilibrium Lattice Fluid |

| SAFT | Statistical Associating Fluid Theory |

| NRHB | Non-random Hydrogen Bonding |

| DMS | Dual-Mode Sorption |

| GAB | Guggenheim−Anderson−de Boer |

| STM | Standard Transport Model |

| LJ | Lennard-Jones |

| BET | Brunauer–Emmet–Teller |

| MD | Molecular Dynamics |

| NEMD | Non-Equilibrium Molecular Dynamics |

| IAST | Ideal Adsorbed Solution Theory |

| MC | Monte Carlo |

| GCMC | Grand Canonical Monte Carlo |

Appendix B. Other Symbols and Variables

| Generalities | |

| Molar flux of component (gaseous species diffusing across the solid membrane) | |

| Permeability (coefficient) of component (gaseous species diffusing across the solid membrane) | |

| Partial pressure of component in the gas mixture | |

| Fugacity of component in the gas mixture | |

| Membrane thickness | |

| Penetrant molar concentration in the membrane phase | |

| Molar concentration (moles of gas/membrane volume) in the membrane phase on the upstream and downstream sides, respectively | |

| Local diffusivity or diffusion coefficient of species in the membrane | |

| z | Coordinate indicating the position along the membrane thickness |

| Mobility (or self-diffusion diffusivity) of species in the membrane | |

| Chemical potential of species | |

| Solubility coefficient of species in the membrane | |

| Concentration-averaged diffusivity of species in the membrane | |

| Mass fraction of the fluid in the membrane | |

| Selectivity of component versus component j in the membrane | |

| Solubility-Selectivity of component versus component in the membrane | |

| Diffusivity-Selectivity of component versus component in the membrane | |

| Pre-exponential factor for solubility coefficient | |

| Heat of sorption | |

| Pre-exponential factor for diffusion coefficient | |

| Activation energy of diffusion | |

| Pre-exponential factor for permeability coefficient | |

| Activation energy of permeation | |

| Heat of condensation of the fluid species | |

| Heat of mixing of the fluid species in the membrane | |

| Robeson’s upper bound | |

| Gas couple-dependent parameter (position of the upper bound) | |

| Gas couple-dependent parameter (slope of the upper bound) | |

| Kinetic diameter of the larger molecule | |

| Kinetic diameter of the smaller molecule | |

| Parameter used in the correlation for and | |

| Parameter used in the correlation for and | |

| Parameter used in the correlation for and | |

| Activity coefficient models for solubility | |

| Activity coefficient (of the fluid in the membrane) | |

| Number of moles of component in a mixture | |

| Excess Gibbs free energy of a mixture | |

| Partial molar excess Gibbs free energy for a component in a mixture | |

| LF EoS | |

| Gibbs free energy | |

| Total number of molecules | |

| Boltzmann’s constant | |

| Number of components (gases + polymer) | |

| Molar mass of component | |

| Density of component | |

| Molar volume of a lattice cell of component | |

| Number of lattice cells occupied by a molecule of pure component | |

| Non-bonded interaction energy between two lattice cells occupied by component | |

| Characteristic temperature of component | |

| Characteristic pressure of component | |

| Characteristic density of component | |

| Reduced temperature of component | |

| Reduced pressure of component | |

| Reduced density of component | |

| Density of the mixture | |

| Reduced temperature | |

| Reduced pressure | |

| Reduced density | |

| Binary interaction parameter between and | |

| Mass fraction of component | |

| Volume fraction of component in close-packed conditions | |

| Characteristic density of the mixture | |

| Characteristic pressure of the mixture | |

| Characteristic temperature of the mixture | |

| Average close-packed molar volume in the mixture | |

| Number of lattice cells occupied by a molecule in mixture | |

| NRHB EoS | |

| Characteristic energy in the LF model and in the NRHB model | |

| Enthalpic contribution to the characteristic energy | |

| Entropic contribution to the characteristic energy | |

| Association energy between group α and a functional group | |

| Association entropy between a functional group α and a functional group | |

| SAFT EoS | |

| Residual Helmholtz free energy (at fixed temperature and volume) | |

| Hard-sphere term of residual Helmholtz free energy | |

| Dispersion term of residual Helmholtz free energy | |

| Chain term of residual Helmholtz free energy | |

| Association term of residual Helmholtz free energy | |

| Chemical potential of species i in the ideal gas state | |

| NET-GP model for solubility | |

| Non-equilibrium chemical potential of species | |

| Equilibrium chemical potential of species | |

| ρpol | Non-equilibrium density of the glassy polymer |

| Non-equilibrium chemical potential of species in the polymer phase | |

| Equilibrium chemical potential of species in the gas phase | |

| Composition vector in the polymer phase | |

| Composition vector in the gas phase | |

| Non-equilibrium density of the dry glassy polymer | |

| Swelling coefficient correlating the glassy polymer density to the gas partial pressure | |

| DMS model for solubility | |

| Henry’s law constant | |

| Langmuir capacity constant | |

| Langmuir affinity constant | |

| Pre-exponential factor for temperature-dependence of | |

| Pre-exponential factor for temperature-dependence of | |

| Enthalpy of sorption for Henry’s mode of sorption | |

| Enthalpy of sorption for Langmuir’s mode of sorption | |

| GAB model for solubility | |

| Penetrant adsorbed mass ratio | |

| Adsorbate pressure | |

| Reference pressure value associated with the adsorbate | |

| Capacity of the 1st adsorption monolayer | |

| Dimensionless binding parameter | |

| Parameter related to sorbate–sorbate interactions in multicomponent GAB | |

| Parameter related to sorbate–sorbate interactions in multicomponent GAB | |

| Fractal model for solubility coefficient | |

| Effective cross-sectional area of the sorbed gas molecules | |

| Global fractal dimension parameter | |

| Minimum solubility of a gas molecule | |

| Relative fraction of the closely packed segments in clusters | |

| Polymer glass transition temperature | |

| Degree of crystallinity | |

| Fractal dimension of the polymer structure | |

| Cross-sectional area of a macromolecule | |

| Characteristic ratio representing the index of chain flexibility | |

| Free-volume theory for diffusion coefficient | |

| Self-diffusion coefficient of fluid 1 in polymer 2 | |

| Pre-exponential factor = diffusion in a fluid with infinite free volume | |

| Energy required for a jump into an adjacent free-volume void | |

| Coefficient accounting for overlaps of free volume available to adjacent molecules | |

| Occupied volume | |

| Average free volume per jumping unit | |

| Ratio of occupied volumes | |

| Parameters for component i related to pure component viscosity | |

| Thermodynamic factor of mutual diffusivity | |

| Fractional free volume | |

| Adjustable parameters for correlation between diffusivity and FFV | |

| Polymer-specific volume | |

| Polymer-occupied volume | |

| Fractal model for diffusion coefficient | |

| Universal constant of the model, equal to 3.8 × 10−7 cm2/s | |

| Relative free volume | |

| Diameter of a microvoid | |

| Diameter of the penetrant gas molecule | |

| Polymer chain spectral dimension | |

| Maxwell–Stefan model for diffusion coefficient | |

| Maxwell–Stefan diffusivity | |

| Velocity of species A relative to species B | |

| Thermodynamic correction factor | |

| Total molar flux of species (with respect to a fixed reference frame) | |

| Total molar concentration of the fluid mixture | |

| Mole fraction of component in the mixture | |

| Partial Immobilization Dual-Mobility Model for Permeability | |

| Total molar flux of component | |

| Penetrant concentrations in the Henry’s region | |

| Penetrant concentration in the Langmuir’s region | |

| Diffusivity in the Henry region | |

| Diffusivity in the Langmuir region | |

| Ratio between diffusivity in Henry’s region and Langmuir’s regions | |

| Ratio between Dual-Sorption Mode Model parameters | |

| Upstream partial pressure of component | |

| Downstream partial pressure of component | |

| Standard Transport Model for Permeability | |

| Mobility coefficient of component | |

| Infinite dilution mobility coefficient of component | |

| Plasticization factor | |

| Penetrant molecular weight | |

| Penetrant compressibility factor | |

| Polymer density | |

| Size selectivity of the polymer | |

| Polymer-dependent parameter in the empirical correlation between penetrant mobility and critical volume | |

| Pre-exponential factor for parameter | |

| Critical volume of penetrant | |

| Widom insertion method | |

| Excess chemical potential of penetrant inside the polymer | |

| Potential energy of interaction between the test molecule and the other molecules | |

| Simulation of diffusivity | |

| Mean squared displacement (MSD) averaged over all molecules | |

| t | Time |

| Self-diffusion coefficient computed in the MD simulations | |

| Shear viscosity computed in MD simulations | |

| Dimensionless constant equal to 2.837298 for periodic (cubic) lattices | |

| Simulation box length | |

Appendix C. Self-Diffusion Coefficient (Mobility), Mutual-Diffusion Coefficient, and Thermodynamic Factor

References

- Sidhikku Kandath Valappil, R.; Ghasem, N.; Al-Marzouqi, M. Current and future trends in polymer membrane-based gas separation technology: A comprehensive review. J. Ind. Eng. Chem. 2021, 98, 103–129. [Google Scholar] [CrossRef]

- Lu, H.T.; Li, W.; Miandoab, E.S.; Kanehashi, S.; Hu, G. The opportunity of membrane technology for hydrogen purification in the power to hydrogen (P2H) roadmap: A review. Front. Chem. Sci. Eng. 2021, 15, 464–482. [Google Scholar] [CrossRef] [PubMed]

- Russo, F.; Galiano, F.; Iulianelli, A.; Basile, A.; Figoli, A. Biopolymers for sustainable membranes in CO2 separation: A review. Fuel Process. Technol. 2021, 213, 106643. [Google Scholar] [CrossRef]

- Farnam, M.; bin Mukhtar, H.; bin Mohd Shariff, A. A Review on Glassy and Rubbery Polymeric Membranes for Natural Gas Purification. ChemBioEng Rev. 2021, 8, 90–109. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Tomić, M.; Šetka, M.; Vojkůvka, L.; Vallejos, S. VOCs Sensing by Metal Oxides, Conductive Polymers, and Carbon-Based Materials. Nanomaterials 2021, 11, 552. [Google Scholar] [CrossRef]

- Urbano, B.F.; Bustamante, S.; Palacio, D.A.; Vera, M.; Rivas, B.L. Polymer-based chromogenic sensors for the detection of compounds of environmental interest. Polym. Int. 2021, 70, 1202–1208. [Google Scholar] [CrossRef]

- Han, Y.; Ho, W.S.W. Polymeric membranes for CO2 separation and capture. J. Membr. Sci. 2021, 628, 119244. [Google Scholar] [CrossRef]

- Kancherla, R.; Nazia, S.; Kalyani, S.; Sridhar, S. Modeling and simulation for design and analysis of membrane-based separation processes. Comput. Chem. Eng. 2021, 148, 107258. [Google Scholar] [CrossRef]

- Fleming, G.K.; Koros, W.J.; Flemingf, K. Carbon Dioxide Conditioning Effects on Sorption and Volume Dilation Behavior for Bisphenol A-Polycarbonate. Macromolecules 1990, 23, 1353–1360. [Google Scholar] [CrossRef]

- Enscore, D.J.; Hopfenberg, H.B.; Stannett, V.T. Diffusion, swelling, and consolidation in glassy polystyrene microspheres. Polym. Eng. Sci. 1980, 20, 102–107. [Google Scholar] [CrossRef]

- Sarti, G.C.; Gostoli, C.; Masoni, S. Diffusion of alcohols and relaxation in poly(methyl methacrylate): Effect of thermal history. J. Membr. Sci. 1983, 15, 181–192. [Google Scholar] [CrossRef]

- Pope, D.S.; Koros, W.J. Effect of various preexposure agents on methane sorption and dilation in tetramethyl polycarbonate. Macromolecules 1992, 25, 1711–1715. [Google Scholar] [CrossRef]

- Atiq, O.; Ricci, E.; Baschetti, M.G.; De Angelis, M.G. Modelling solubility in semi-crystalline polymers: A critical comparative review. Fluid Phase Equilib. 2022, 556, 113412. [Google Scholar] [CrossRef]

- De Angelis, M.G.; Sarti, G.C. Gas sorption and permeation in mixed matrix membranes based on glassy polymers and silica nanoparticles. Curr. Opin. Chem. Eng. 2012, 1, 148–155. [Google Scholar] [CrossRef]

- Cheng, Y.; Ying, Y.; Japip, S.; Jiang, S.-D.; Chung, T.-S.; Zhang, S.; Zhao, D. Advanced Porous Materials in Mixed Matrix Membranes. Adv. Mater. 2018, 30, 1802401. [Google Scholar] [CrossRef]

- Galizia, M.; Chi, W.S.; Smith, Z.P.; Merkel, T.C.; Baker, R.W.; Freeman, B.D. 50th Anniversary Perspective: Polymers and Mixed Matrix Membranes for Gas and Vapor Separation: A Review and Prospective Opportunities. Macromolecules 2017, 50, 7809–7843. [Google Scholar] [CrossRef]

- Vinh-Thang, H.; Kaliaguine, S. Predictive Models for Mixed-Matrix Membrane Performance: A Review. Chem. Rev. 2013, 113, 4980–5028. [Google Scholar] [CrossRef]

- Matteucci, S.; Yampolskii, Y.; Freeman, B.D.; Pinnau, I. Transport of Gases and Vapor in Glassy and Rubbery Polymers. In Materials Science of Membranes for Gas and Vapor Separation; Yampolskii, Y., Pinnau, I., Freeman, B.D., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Van Krevelen, D.W.; te Nijenhuis, K. Properties of Polymers, 4th ed.; Elsevier Science: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Wijmans, J.G.; Baker, R.W. The Solution-Diffusion model: A unified approach to membrane permeation. In Materials Science of Membranes for Gas and Vapor Separation; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Wijmans, J.G.; Baker, R.W. The solution-diffusion model: A review. J. Membr. Sci. 1995, 107, 1–21. [Google Scholar] [CrossRef]

- Neogi, P. (Ed.) Diffusion in Polymers; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Crank, J.; Park, G. Diffusion in Polymers; CRC Press: Boca Raton, FL, USA, 1968. [Google Scholar]

- Paul, D.R. Relation between hydraulic permeability and diffusion in homogeneous swollen membranes. J. Polym. Sci. Part A-2 Polym. Phys. 1973, 11, 289–296. [Google Scholar] [CrossRef]

- Paul, D.R. Further comments on the relation between hydraulic permeation and diffusion. J. Polym. Sci. Polym. Phys. Ed. 1974, 12, 1221–1230. [Google Scholar] [CrossRef]

- Kamaruddin, H.D.; Koros, W.J. Some observations about the application of Fick’s first law for membrane separation of multicomponent mixtures. J. Membr. Sci. 1997, 135, 147–159. [Google Scholar] [CrossRef]

- Krishna, R.; Wesselingh, J.A. The Maxwell-Stefan approach to mass tranfer. Chem. Eng. Sci. 1997, 52, 861–911. [Google Scholar] [CrossRef]

- Ghosal, K.; Freeman, B.D. Gas separation using polymer membranes: An overview. Polym. Adv. Technol. 2003, 5, 673–697. [Google Scholar] [CrossRef]

- Robeson, L.M.; Dose, M.E.; Freeman, B.D.; Paul, D.R. Analysis of the transport properties of thermally rearranged (TR) polymers and polymers of intrinsic microporosity (PIM) relative to upper bound performance. J. Membr. Sci. 2017, 525, 18–24. [Google Scholar] [CrossRef]

- Robeson, L.M.; Smith, Z.P.; Freeman, B.D.; Paul, D.R. Contributions of diffusion and solubility selectivity to the upper bound analysis for glassy gas separation membranes. J. Membr. Sci. 2014, 453, 71–83. [Google Scholar] [CrossRef]

- Ricci, E.; Benedetti, F.M.; Dose, M.E.; De Angelis, M.G.; Freeman, B.D.; Paul, D.R. Competitive sorption in CO2/CH4 separations: The case of HAB-6FDA polyimide and its TR derivative and a general analysis of its impact on the selectivity of glassy polymers at multicomponent conditions. J. Membr. Sci. 2020, 612, 118374. [Google Scholar] [CrossRef]

- Minelli, M.; Friess, K.; Vopička, O.; De Angelis, M.G. Modeling gas and vapor sorption in a polymer of intrinsic microporosity (PIM-1). Fluid Phase Equilib. 2013, 347, 35–44. [Google Scholar] [CrossRef]

- Mukaddam, M.; Litwiller, E.; Pinnau, I. Pressure-dependent pure- and mixed-gas permeation properties of Nafion®. J. Membr. Sci. 2016, 513, 140–145. [Google Scholar] [CrossRef]

- Chern, R.T.; Koros, W.J.; Sanders, E.S.; Yui, R. “Second component” effects in sorption and permeation of gases in glassy polymers. J. Membr. Sci. 1983, 15, 157–169. [Google Scholar] [CrossRef]

- Chern, R.T.; Koros, W.J.; Yui, B.; Hopfenberg, H.B.; Stannett, V.T. Selective permeation of CO2 and CH4 through kapton polyimide: Effects of penetrant competition and gas-phase nonideality. J. Polym. Sci. Polym. Phys. Ed. 1984, 22, 1061–1084. [Google Scholar] [CrossRef]

- Raymond, P.C.; Koros, W.J.; Paul, D.R. Comparison of mixed and pure gas permeation characteristics for CO2 and CH4 in copolymers and blends containing methyl methacrylate units. J. Membr. Sci. 1993, 77, 49–57. [Google Scholar] [CrossRef]

- Genduso, G.; Ghanem, B.S.; Pinnau, I. Experimental Mixed-Gas Permeability, Sorption and Diffusion of CO2-CH4 Mixtures in 6FDA-mPDA Polyimide Membrane: Unveiling the Effect of Competitive Sorption on Permeability Selectivity. Membranes 2019, 9, 10. [Google Scholar] [CrossRef]

- Vopička, O.; De Angelis, M.G.; Du, N.; Li, N.; Guiver, M.D.; Sarti, G.C. Mixed gas sorption in glassy polymeric membranes: II. CO2/CH4 mixtures in a polymer of intrinsic microporosity (PIM-1). J. Membr. Sci. 2014, 459, 264–276. [Google Scholar] [CrossRef]

- Gemeda, A.E.; De Angelis, M.G.; Du, N.; Li, N.; Guiver, M.D.; Sarti, G.C. Mixed gas sorption in glassy polymeric membranes. III. CO2/CH4 mixtures in a polymer of intrinsic microporosity (PIM-1): Effect of temperature. J. Membr. Sci. 2017, 524, 746–757. [Google Scholar] [CrossRef]

- Ricci, E.; Benedetti, F.M.; Noto, A.; Merkel, T.C.; Jin, J.; De Angelis, M.G. Enabling Experimental Characterization and Prediction of Ternary Mixed-Gas Sorption in Polymers: C2H6/CO2/CH4 in PIM-1. Chem. Eng. J. 2021, 426, 130715. [Google Scholar] [CrossRef]

- Ricci, E.; Gemeda, A.E.; Du, N.; Li, N.; De Angelis, M.G.; Guiver, M.D.; Sarti, G.C. Sorption of CO2/CH4 mixtures in TZ-PIM, PIM-1 and PTMSP: Experimental data and NELF-model analysis of competitive sorption and selectivity in mixed gases. J. Membr. Sci. 2019, 585, 136–149. [Google Scholar] [CrossRef]

- Genduso, G.; Wang, Y.; Ghanem, B.S.; Pinnau, I. Permeation, sorption, and diffusion of CO2-CH4 mixtures in polymers of intrinsic microporosity: The effect of intrachain rigidity on plasticization resistance. J. Membr. Sci. 2019, 584, 100–109. [Google Scholar] [CrossRef]

- Benedetti, F.M.; Ricci, E.; De Angelis, M.G.; Carta, M.; McKeown, N.B. Sorption of CO2/CH4 and their mixtures in PIM-EA-TB. 2022; preprint. [Google Scholar]

- Genduso, G.; Litwiller, E.; Ma, X.; Zampini, S.; Pinnau, I. Mixed-gas sorption in polymers via a new barometric test system: Sorption and diffusion of CO2-CH4 mixtures in polydimethylsiloxane (PDMS). J. Membr. Sci. 2019, 577, 195–204. [Google Scholar] [CrossRef]

- Story, B.J.; Koros, W.J. Sorption of CO2/CH4 mixtures in poly(phenylene oxide) and a carboxylated derivative. J. Appl. Polym. Sci. 1991, 42, 2613–2626. [Google Scholar] [CrossRef]

- Raharjo, R.D.; Freeman, B.D.; Sanders, E.S. Pure and mixed gas CH4 and n-C4H10 sorption and dilation in poly (dimethylsiloxane). J. Membr. Sci. 2007, 292, 45–61. [Google Scholar] [CrossRef]

- Ribeiro, C.P.; Freeman, B.D. Carbon dioxide/ethane mixed-gas sorption and dilation in a cross-linked poly(ethylene oxide) copolymer. Polymer 2010, 51, 1156–1168. [Google Scholar] [CrossRef]

- Sanders, E.S.S.; Koros, W.J.J.; Hopfenberg, H.B.B.; Stannett, V.T.T. Mixed gas sorption in glassy polymers: Equipment design considerations and preliminary results. J. Membr. Sci. 1983, 13, 161–174. [Google Scholar] [CrossRef]

- Sanders, E.S.; Koros, W.J.; Hopfenberg, H.B.; Stannett, V.T. Pure and Mixed Gas Sorption of Carbon Dioxide and Ethylene in Poly(Methyl Methacrylate). J. Membr. Sci. 1984, 18, 53–74. [Google Scholar] [CrossRef]

- Sanders, E.S.; Koros, W.J. Sorption of CO2, C2H4, N2O and their Binary Mixtures in Poly(methyl methacrylate). J. Polym. Sci. B 1986, 188, 175–188. [Google Scholar] [CrossRef]

- Genduso, G.; Pinnau, I. Quantification of sorption, diffusion, and plasticization properties of cellulose triacetate films under mixed-gas CO2/CH4 environment. J. Membr. Sci. 2020, 610, 118269. [Google Scholar] [CrossRef]

- Vopička, O.; De Angelis, M.G.; Sarti, G.C. Mixed gas sorption in glassy polymeric membranes: I. CO2/CH4 and n-C4/CH4 mixtures sorption in poly(1-trimethylsilyl-1-propyne) (PTMSP). J. Membr. Sci. 2014, 449, 97–108. [Google Scholar] [CrossRef]

- Raharjo, R.D.; Freeman, B.D.; Paul, D.R.; Sarti, G.C.; Sanders, E.S. Pure and mixed gas CH4 and n-C4H10 permeability and diffusivity in poly(dimethylsiloxane). Polymer 2007, 306, 75–92. [Google Scholar] [CrossRef]

- Fraga, S.C.; Monteleone, M.; Lanč, M.; Esposito, E.; Fuoco, A.; Giorno, L.; Pilnáček, K.; Friess, K.; Carta, M.; McKeown, N.B.; et al. A novel time lag method for the analysis of mixed gas diffusion in polymeric membranes by on-line mass spectrometry: Method development and validation. J. Membr. Sci. 2018, 561, 39–58. [Google Scholar] [CrossRef]

- Monteleone, M.; Fuoco, A.; Esposito, E.; Rose, I.; Chen, J.; Comesaña-Gándara, B.; Bezzu, C.G.; Carta, M.; McKeown, N.B.; Shalygin, M.G.; et al. Advanced methods for analysis of mixed gas diffusion in polymeric membranes. J. Membr. Sci. 2022, 648, 120356. [Google Scholar] [CrossRef]

- Checchetto, R. Accurate monitoring of gas mixture transport kinetics through polymeric membranes. Sep. Purif. Technol. 2021, 277, 119477. [Google Scholar] [CrossRef]

- Pope, D.S.; Fleming, G.K.; Koros, W.J. Effect of various exposure histories on sorption and dilation in a family of polycarbonates. Macromolecules 1990, 23, 2988–2994. [Google Scholar] [CrossRef]

- Park, C.H.; Tocci, E.; Lee, Y.M.; Drioli, E. Thermal treatment effect on the structure and property change between hydroxy-containing polyimides (HPIs) and thermally rearranged polybenzoxazole (TR-PBO). J. Phys. Chem. B 2012, 116, 12864–12877. [Google Scholar] [CrossRef]

- Petropoulos, J.H. Mechanisms and theories for sorption and diffusion of gases in polymers. In Polymeric Gas Separation Membranes; Paul, D.R., Yampolskii, Y.P., Eds.; CRC Press: Boca Raton, FL, USA, 1994; pp. 17–82. [Google Scholar]

- Koros, W.J.; Paul, R.; Huvard, G.S. Energetics of gas sorption in glassy polymers. Polymer 1979, 20, 956–960. [Google Scholar] [CrossRef]

- Robeson, L.M. The upper bound revisited. J. Membr. Sci. 2008, 320, 390–400. [Google Scholar] [CrossRef]

- Robeson, L.M. Correlation of separation factor versus permeability for polymeric membranes. J. Membr. Sci. 1991, 62, 165–185. [Google Scholar] [CrossRef]

- Park, H.B.; Kamcev, J.; Robeson, L.M.; Elimelech, M.; Freeman, B.D. Maximizing the right stuff: The trade-off between membrane permeability and selectivity. Science 2017, 365, 1138–1148. [Google Scholar] [CrossRef]

- Lin, H.; Freeman, B.D. Materials selection guidelines for membranes that remove CO2 from gas mixtures. J. Mol. Struct. 2005, 739, 57–74. [Google Scholar] [CrossRef]

- Alentiev, A.Y.; Yampolskii, Y. Meares equation and the role of cohesion energy density in diffusion in polymers. J. Membr. Sci. 2002, 206, 291–306. [Google Scholar] [CrossRef]

- Lou, Y.; Hao, P.; Lipscomb, G. NELF predictions of a solubility—Solubility selectivity upper bound. J. Membr. Sci. 2014, 455, 247–253. [Google Scholar] [CrossRef]

- Alentiev, A.Y.Y.; Yampolskii, Y.P. Free volume model and tradeoff relations of gas permeability and selectivity in glassy polymers. J. Membr. Sci. 2000, 165, 201–216. [Google Scholar] [CrossRef]

- Freeman, B.D. Basis of permeability/selectivity tradeoff relations in polymeric gas separation membranes. Macromolecules 1999, 32, 375–380. [Google Scholar] [CrossRef]

- Barrer, R.M. Permeability in relation to viscosity and structure of rubber. Trans. Faraday Soc. 1942, 38, 322. [Google Scholar] [CrossRef]

- Van Amerongen, G.J. The Permeability of Different Rubbers to Gases and Its Relation to Diffusivity and Solubility. J. Appl. Phys. 1946, 17, 972–985. [Google Scholar] [CrossRef]

- Dal-Cin, M.M.; Kumar, A.; Layton, L. Revisiting the experimental and theoretical upper bounds of light pure gas selectivity–Permeability for polymeric membranes. J. Membr. Sci. 2008, 323, 299–308. [Google Scholar] [CrossRef]

- Comesaña-Gándara, B.; Chen, J.; Bezzu, C.G.; Carta, M.; Rose, I.; Ferrari, M.; Esposito, E.; Fuoco, A.; Jansen, J.C.; McKeown, N.B. Redefining the Robeson upper bounds for CO2/CH4 and CO2/N2 separations using a series of ultrapermeable benzotriptycene-based polymers of intrinsic microporosity. Energy Environ. Sci. 2019, 12, 2733–2740. [Google Scholar] [CrossRef]

- Freeman, B.D.; Pinnau, I. Separation of gases using solubility-selective polymers. Trends Polym. Sci. 1997, 5, 167–173. [Google Scholar]

- Merkel, T.C.; Zhou, M.; Baker, R.W. Carbon dioxide capture with membranes at an IGCC power plant. J. Membr. Sci. 2012, 389, 441–450. [Google Scholar] [CrossRef]

- Robeson, L.M.; Liu, Q.; Freeman, B.D.; Paul, D.R. Comparison of transport properties of rubbery and glassy polymers and the relevance to the upper bound relationship. J. Membr. Sci. 2015, 476, 421–431. [Google Scholar] [CrossRef]

- Wu, A.X.; Drayton, J.A.; Smith, Z.P. The perfluoropolymer upper bound. AIChE J. 2019, 65, e16700. [Google Scholar] [CrossRef]

- Alentiev, A.; Yampolskii, Y. Correlation of gas permeability and diffusivity with selectivity: Orientations of the clouds of the data points and the effects of temperature. Ind. Eng. Chem. Res. 2013, 52, 8864–8874. [Google Scholar] [CrossRef]

- Lin, H.; Yavari, M. Upper bound of polymeric membranes for mixed-gas CO2/CH4 separations. J. Membr. Sci. 2015, 475, 101–109. [Google Scholar] [CrossRef]

- Hayek, A.; Shalabi, Y.A.; Alsamah, A. Sour mixed-gas upper bounds of glassy polymeric membranes. Sep. Purif. Technol. 2021, 277, 119535. [Google Scholar] [CrossRef]

- Barbari, T.A.; Koros, W.J.; Paul, D.R. Polymeric membranes based on bisphenol-A for gas separations. J. Membr. Sci. 1989, 42, 69–86. [Google Scholar] [CrossRef]

- Swaidan, R.; Ghanem, B.S.; Litwiller, E.; Pinnau, I. Pure- and mixed-gas CO2/CH4 separation properties of PIM-1 and an amidoxime-functionalized PIM-1. J. Membr. Sci. 2014, 457, 95–102. [Google Scholar] [CrossRef]

- Story, B.J.; Koros, W.J. Comparison of three models for permeation of CO2/CH4 mixtures in poly(phenylene oxide). J. Polym. Sci. Part B Polym. Phys. 1989, 27, 1927–1948. [Google Scholar] [CrossRef]

- Gleason, K.L.; Smith, Z.P.; Liu, Q.; Paul, D.R.; Freeman, B.D. Pure- and mixed-gas permeation of CO2 and CH4 in thermally rearranged polymers based on 3,3′-dihydroxy-4,4′-diamino-biphenyl (HAB) and 2,2′-bis-(3,4-dicarboxyphenyl) hexafluoropropane dianhydride (6FDA). J. Membr. Sci. 2015, 475, 204–214. [Google Scholar] [CrossRef]

- Scholes, C.A.; Kanehashi, S.; Stevens, G.W.; Kentish, S.E. Water permeability and competitive permeation with CO2 and CH4 in perfluorinated polymeric membranes. Sep. Purif. Technol. 2015, 147, 203–209. [Google Scholar] [CrossRef]

- Lacombe, R.H.; Sanchez, I.C. Statistical Thermodynamics of Fluid Mixtures. J. Phys. Chem. 1976, 80, 2568–2580. [Google Scholar] [CrossRef]

- Panayiotou, C.; Pantoula, M.; Stefanis, E.; Tsivintzelis, I.; Economou, I.G. Nonrandom hydrogen-bonding model of fluids and their Mixtures. 1. Pure fluids. Ind. Eng. Chem. Res. 2004, 43, 6592–6606. [Google Scholar] [CrossRef]

- Panayiotou, C.; Tsivintzelis, I.; Economou, I.G. Nonrandom hydrogen-bonding model of fluids and their mixtures. 2. Multicomponent mixtures. Ind. Eng. Chem. Res. 2007, 46, 2628–2636. [Google Scholar] [CrossRef]

- Chapman, W.G.; Gubbins, K.E.; Jackson, G.; Radosz, M. SAFT: Equation-of-state solution model for associating fluids. Fluid Phase Equilib. 1989, 52, 31–38. [Google Scholar] [CrossRef]

- Vieth, W.R.; Tam, P.M.H.I.M.; Michaels, A.S.; Vieth, W.R.; Michaels, A.S. Dual sorption mechanisms in glassy polystyrene. J. Colloid Interface Sci. 1966, 22, 360–370. [Google Scholar] [CrossRef]

- Koros, W.J.; Paul, D.R. Design considerations for measurement of gas sorption in polymers by pressure decay. J. Polym. Sci. Polym. Phys. Ed. 1976, 14, 1903–1907. [Google Scholar] [CrossRef]

- Michaels, A.S.; Vieth, W.R.; Barrie, J.A. Diffusion of gases in polyethylene terephthalate. J. Appl. Phys. 1963, 34, 13–20. [Google Scholar] [CrossRef]

- Koros, W.J.; Paul, D.R.; Rocha, A.A. Carbon dioxide sorption and transport in polycarbonate. J. Polym. Sci. Polym. Phys. 1976, 14, 687–702. [Google Scholar] [CrossRef]

- Paul, D.R.; Koros, W.J. Effect of partially immobilizing sorption on permeability and the diffusion time lag. J. Polym. Sci. Polym. Phys. Ed. 1976, 14, 675–685. [Google Scholar] [CrossRef]

- Fredrickson, G.H.; Helfand, E. Dual-Mode Transport of Penetrants in Glassy Polymers. Macromolecules 1985, 18, 2201–2207. [Google Scholar] [CrossRef]

- Meares, P. The Diffusion of Gases Through Polyvinyl Acetate. J. Am. Chem. Soc. 1954, 76, 3416–3422. [Google Scholar] [CrossRef]

- Meares, P. The solubilities of gases in polyvinyl acetate. Trans. Faraday Soc. 1957, 54, 40–46. [Google Scholar] [CrossRef]

- Barrer, R.M.; Barrie, J.A.; Slater, J. Sorption and Diffusion in Ethyl Cellulose. Part III. Comparison between Ethyl Cellulose and Rubber. J. Polym. Sci. 1958, 27, 177–197. [Google Scholar] [CrossRef]

- Vieth, W.R.; Howell, J.M.; Hsieh, J.H.; Engrneerrng, B.; Unrverslty, R.; Brunswzck, N. Dual sorption theory. J. Membr. Sci. 1976, 1, 177–220. [Google Scholar] [CrossRef]

- Vieth, W.R.; Alcalay, H.H.; Frabetti, A.J. Solution of Gases in Oriented Poly(ethylene Terephthalate). J. Appl. Polym. Sci. 1964, 8, 2125–2138. [Google Scholar] [CrossRef]

- Doghieri, F.; Sarti, G.C. Nonequilibrium Lattice Fluids: A Predictive Model for the Solubility in Glassy Polymers. Macromolecules 1996, 29, 7885–7896. [Google Scholar] [CrossRef]

- Doghieri, F.; Quinzi, M.; Rethwisch, D.G.; Sarti, G.C. Predicting Gas Solubility in Glassy Polymers through Nonequilibrium EOS. In Advanced Materials for Membrane Separations; American Chemical Society: Washington, DC, USA, 2004; pp. 74–90. [Google Scholar]

- De Angelis, M.G.; Sarti, G.C. Solubility of Gases and Liquids in Glassy Polymers. Annu. Rev. Chem. Biomol. Eng. 2011, 2, 97–120. [Google Scholar] [CrossRef]

- Sanchez, I.C.; Lacombe, R.H. An elementary molecular theory of classical fluids. Pure fluids. J. Phys. Chem. 1976, 80, 2352–2362. [Google Scholar] [CrossRef]

- Chapman, W.G.; Jackson, G.; Gubbins, K.E. Phase equilibria of associating fluids. Mol. Phys. 1988, 65, 1057–1079. [Google Scholar] [CrossRef]

- Flory, P.J. Thermodynamics of High Polymer Solutions. J. Chem. Phys. 1942, 10, 51–61. [Google Scholar] [CrossRef]

- Huggins, M.L. Some Properties of Solutions of Long-chain Compounds. J. Phys. Chem. 1942, 46, 151–158. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J. Statistical mechanics of cross-linked polymer networks I. Rubberlike elasticity. J. Chem. Phys. 1943, 11, 512–520. [Google Scholar] [CrossRef]

- Michaels, A.B.; Haussleix, R.W. Elastic factors controlling sorption and transport properties of polyethylene. J. Polym. Sci. Part C Polym. Symp. 2007, 10, 61–86. [Google Scholar] [CrossRef]

- Wu, Y.T.; Zhu, Z.Q.; Lin, D.Q.; Mei, L.H. A modified NRTL equation for the calculation of phase equilibrium of polymer solutions. Fluid Phase Equilib. 1996, 121, 125–139. [Google Scholar] [CrossRef]

- Zafarani-Moattar, M.T.; Majdan-Cegincara, R. New excess Gibbs energy equation for modeling the thermodynamic and transport properties of polymer solutions and nanofluids at different temperatures. Ind. Eng. Chem. Res. 2011, 50, 8245–8262. [Google Scholar] [CrossRef]

- Pappa, G.D.; Voutsas, E.C.; Tassios, D.P. Prediction of activity coefficients in polymer and copolymer solutions using simple activity coefficient models. Ind. Eng. Chem. Res. 1999, 38, 4975–4984. [Google Scholar] [CrossRef]

- Wibawa, G.; Takishima, S.; Sato, Y.; Masuoka, H. Revision of UNIFAC group interaction parameters of group contribution models to improve prediction results of vapor-liquid equilibria for solvent-polymer systems. Fluid Phase Equilib. 2002, 202, 367–383. [Google Scholar] [CrossRef]

- Lipnizki, F.; Trägårdh, G. Modelling of pervaporation: Models to analyze and predict the mass transport in pervaporation. Sep. Purif. Methods 2001, 30, 49–125. [Google Scholar] [CrossRef]

- Sadeghi, A.; Nazem, H.; Rezakazemi, M.; Shirazian, S. Predictive construction of phase diagram of ternary solutions containing polymer/solvent/nonsolvent using modified Flory-Huggins model. J. Mol. Liq. 2018, 263, 282–287. [Google Scholar] [CrossRef]

- Pardo, F.; Gutiérrez-Hernández, S.V.; Hermida-Merino, C.; Araújo, J.M.M.; Piñeiro, M.M.; Pereiro, A.B.; Zarca, G.; Urtiaga, A. Integration of Stable Ionic Liquid-Based Nanofluids into Polymer Membranes. Part II: Gas Separation Properties toward Fluorinated Greenhouse Gases. Nanomaterials 2021, 11, 582. [Google Scholar] [CrossRef]

- Borisov, I.L.; Grushevenko, E.A.; Podtynnikov, I.A.; Bakhtin, D.S.; Bondarenko, G.N. Novel Membrane Material Based on Polybutadiene and Polydimethylsiloxane for Gas Separation and Hydrophobic Pervaporation. Pet. Chem. 2018, 58, 1113–1122. [Google Scholar] [CrossRef]

- López, S.; Ramos, M.J.; García-Vargas, J.M.; García, M.T.; Rodríguez, J.F.; Gracia, I. Carbon dioxide sorption and melting behaviour of mPEG-alkyne. J. Supercrit. Fluids 2021, 171, 105182. [Google Scholar] [CrossRef]

- Ricci, E.; Vergadou, N.; Vogiatzis, G.G.; De Angelis, M.G.; Theodorou, D.N. Molecular Simulations and Mechanistic Analysis of the Effect of CO2 Sorption on Thermodynamics, Structure, and Local Dynamics of Molten Atactic Polystyrene. Macromolecules 2020, 53, 3669–3689. [Google Scholar] [CrossRef]

- Rezakazemi, M.; Shirazian, S. Gas permeation prediction through polymeric membranes using compressible regular solution theory. Int. J. Hydrog. Energy 2018, 43, 22357–22364. [Google Scholar] [CrossRef]

- Ricci, E.; De Angelis, M.G.; Minelli, M. A comprehensive theoretical framework for the sub and supercritical sorption and transport of CO2 in polymers. Chem. Eng. J. 2022, 435, 135013. [Google Scholar] [CrossRef]

- Shamu, A.; Dunnewold, M.; Miedema, H.; Borneman, Z.; Nijmeijer, K. Permeation of supercritical CO2 through dense polymeric membranes. J. Supercrit. Fluids 2019, 144, 63–70. [Google Scholar] [CrossRef]

- Sirard, S.M.; Green, P.F.; Johnston, K.P. Spectroscopic ellipsometry investigation of the swelling of poly(dimethylsiloxane) thin films with high pressure carbon dioxide. J. Phys. Chem. B 2001, 105, 766–772. [Google Scholar] [CrossRef]

- De Angelis, M.G.; Merkel, T.C.; Bondar, V.I.; Freeman, B.D.; Doghieri, F.; Sarti, G.C. Hydrocarbon and fluorocarbon solubility and dilation in poly(dimethylsiloxane): Comparison of experimental data with predictions of the Sanchez-Lacombe equation of state. J. Polym. Sci. Part B Polym. Phys. 1999, 37, 3011–3026. [Google Scholar] [CrossRef]

- Garg, A.; Gulari, E.; Manke, C.W. Thermodynamics of Polymer Melts Swollen with Supercritical Gases. Macromolecules 1994, 27, 5643–5653. [Google Scholar] [CrossRef]

- Fredenslund, A.; Sorensen, M.J. Group Contribution Estimation Method. In Models for Thermodynamic and Phase Equilibria Calculations; Sandler, S., Ed.; Marcel Dekker Inc.: New York, NY, USA, 1994. [Google Scholar]

- Fredenslund, A.; Jones, R.L.; Prausnitz, J.M. Group-contribution estimation of activity coefficients in nonideal liquid mixtures. AIChE J. 1975, 21, 1086–1099. [Google Scholar] [CrossRef]

- Chapman, W.G.; Gubbins, K.E.; Jackson, G.; Radosz, M. New reference equation of state for associating liquids. Ind. Eng. Chem. Res. 1990, 29, 1709–1721. [Google Scholar] [CrossRef]

- Huang, S.H.; Radosz, M. Equation of state for small, large, polydisperse and associating molecules. Ind. Eng. Chem. Res. 1990, 29, 2284–2294. [Google Scholar] [CrossRef]

- Economou, I.G. Statistical associating fluid theory: A successful model for the calculation of thermodynamic and phase equilibrium properties of complex fluid mixtures. Ind. Eng. Chem. Res. 2002, 41, 953–962. [Google Scholar] [CrossRef]

- Tan, S.P.; Adidharma, H.; Radosz, M. Recent advances and applications of statistical associating fluid theory. Ind. Eng. Chem. Res. 2008, 47, 8063–8082. [Google Scholar] [CrossRef]

- Wertheim, M.S. Fluids with highly directional attractive forces. I. Statistical thermodynamics. J. Stat. Phys. 1984, 35, 19–34. [Google Scholar] [CrossRef]

- Wertheim, M.S. Fluids with highly directional attractive forces. II. Thermodynamic perturbation theory and integral equations. J. Stat. Phys. 1984, 35, 35–47. [Google Scholar] [CrossRef]

- Wertheim, M.S. Fluids with highly directional attractive forces. III. Multiple attraction sites. J. Stat. Phys. 1986, 42, 459–476. [Google Scholar] [CrossRef]

- Gross, J.; Sadowski, G. Perturbed-Chain SAFT: An Equation of State Based on a Perturbation Theory for Chain Molecules. Ind. Eng. Chem. Res. 2001, 40, 1244–1260. [Google Scholar] [CrossRef]

- Giacinti Baschetti, M.; De Angelis, M.G. Vapour permeation modelling. In Pervaporation, Vapour Permeation and Membrane Distillation; Elsevier: Amsterdam, The Netherlands, 2015; pp. 203–246. [Google Scholar]

- Liu, L.; Kentish, S.E. Modelling of methane and n-butane sorption, diffusion and permeation in polydimethylsiloxane using PC-SAFT. J. Membr. Sci. 2020, 597, 117642. [Google Scholar] [CrossRef]

- Yang, Y.; Narayanan Nair, A.K.; Sun, S. Sorption and Diffusion of Methane, Carbon Dioxide, and Their Mixture in Amorphous Polyethylene at High Pressures and Temperatures. Ind. Eng. Chem. Res. 2021, 60, 7729–7738. [Google Scholar] [CrossRef]

- Feng, Z.; Panuganti, S.R.; Chapman, W.G. Predicting solubility and swelling ratio of blowing agents in rubbery polymers using PC-SAFT Equation of State. Chem. Eng. Sci. 2018, 183, 306–328. [Google Scholar] [CrossRef]

- Liu, L.; Kentish, S.E. Pervaporation performance of crosslinked PVA membranes in the vicinity of the glass transition temperature. J. Membr. Sci. 2018, 553, 63–69. [Google Scholar] [CrossRef]

- Krenn, P.; Zimmermann, P.; Fischlschweiger, M.; Zeiner, T. SAFT-Based Maxwell–Stefan Approach to Model the Diffusion through Epoxy Resins. J. Chem. Eng. Data 2020, 65, 5677–5687. [Google Scholar] [CrossRef]

- Sarti, G.C.; Doghieri, F. Predictions of the solubility of gases in glassy polymers based on the NELF model. Chem. Eng. Sci. 1998, 53, 3435–3447. [Google Scholar] [CrossRef]

- Jordan, S.S.; Koros, W.J. A Free Volume Distribution Model of Gas Sorption and Dilation in Glassy Polymers. Macromolecules 1995, 28, 2228–2235. [Google Scholar] [CrossRef]

- Minelli, M.; Doghieri, F. Predictive model for gas and vapor solubility and swelling in glassy polymers I: Application to different polymer/penetrant systems. Fluid Phase Equilib. 2014, 381, 1–11. [Google Scholar] [CrossRef]

- Hasani, M.; Soltani Panah, H.; Abdollahi, M. New Insight into Solubility Prediction of Carbon Dioxide and Methane in Different Glassy Homopolymers and Their Polymer Blends Using the NET-GP Model through an Explicit Solution for Swelling Coefficient. Ind. Eng. Chem. Res. 2021, 60, 14884–14902. [Google Scholar] [CrossRef]

- Shoghl, S.N.; Raisi, A.; Aroujalian, A. A predictive model for gas and vapor sorption into glassy membranes at high pressure. RSC Adv. 2016, 6, 57683–57694. [Google Scholar] [CrossRef]

- Marshall, B.D.; Mathias, R.; Lively, R.P.; McCool, B.A. Theoretically Self-Consistent Nonequilibrium Thermodynamics of Glassy Polymer Theory for the Solubility of Vapors and Liquids in Glassy Polymers. Ind. Eng. Chem. Res. 2021, 60, 13377–13387. [Google Scholar] [CrossRef]

- Doghieri, F.; Sarti, G.C. Predicting the low pressure solubility of gases and vapors in glassy polymers by the NELF model. J. Membr. Sci. 1998, 147, 73–86. [Google Scholar] [CrossRef]

- Sanchez, I.C.; Lacombe, R.H. Statistical Thermodynamics of Polymer Solutions. Macomolecules 1978, 11, 1145–1156. [Google Scholar] [CrossRef]

- El-Okazy, M.A.; Liu, L.; Abdellah, M.H.; Goudeli, E.; Kentish, S.E. Gas sorption and diffusion in perfluoro(butenyl vinyl ether) based perfluoropolymeric membranes. J. Membr. Sci. 2022, 644, 120095. [Google Scholar] [CrossRef]

- Wu, A.X.; Drayton, J.A.; Ren, X.; Mizrahi Rodriguez, K.; Grosz, A.F.; Lee, J.-W.; Smith, Z.P. Non-equilibrium Lattice Fluid Modeling of Gas Sorption for Fluorinated Poly(ether imide)s. Macromolecules 2021, 54, 6628–6638. [Google Scholar] [CrossRef]

- Shoghl, S.N.; Pazuki, G.; Raisi, A. A model to predict the solubility and permeability of gaseous penetrant in the glassy polymeric membrane at high pressure. J. Appl. Polym. Sci. 2021, 138, 50548. [Google Scholar] [CrossRef]

- Minelli, M.; De Angelis, M.G. An equation of state (EoS) based model for the fluid solubility in semicrystalline polymers. Fluid Phase Equilib. 2014, 367, 173–181. [Google Scholar] [CrossRef]

- Fernández-Barquín, A.; Rea, R.; Venturi, D.; Giacinti-Baschetti, M.; De Angelis, M.G.; Casado-Coterillo, C.; Irabien, Á. Effect of relative humidity on the gas transport properties of zeolite A/PTMSP mixed matrix membranes. RSC Adv. 2018, 8, 3536–3546. [Google Scholar] [CrossRef]

- Doghieri, F.; Ghedini, M.; Quinzi, M.; Rethwisch, D.; Sarti, G.C. Gas solubility in glassy polymers: Predictions from non-equilibrium EoS. Desalination 2002, 144, 73–78. [Google Scholar] [CrossRef]

- Davis, E.M.; Elabd, Y.A. Prediction of Water Solubility in Glassy Polymers Using Nonequilibrium Thermodynamics. Ind. Eng. Chem. Res. 2013, 52, 12865–12875. [Google Scholar] [CrossRef]

- Mensitieri, G.; Scherillo, G.; La Manna, P.; Musto, P. Sorption Thermodynamics of CO2, H2O, and CH3OH in a Glassy Polyetherimide: A Molecular Perspective. Membranes 2019, 9, 23. [Google Scholar] [CrossRef]

- Scherillo, G.; La Manna, P.; Musto, P.; Mensitieri, G. Water sorption thermodynamics in glassy polymers endowed with hydrogen bonding interactions. Sci. China Physics, Mech. Astron. 2020, 63, 247012. [Google Scholar] [CrossRef]

- Baldanza, A.; Loianno, V.; Mensitieri, G.; Scherillo, G. Predictive Approach for the Solubility and Permeability of Binary Gas Mixtures in Glassy Polymers Based on an NETGP-NRHB Model. Ind. Eng. Chem. Res. 2022, 61, 3439–3456. [Google Scholar] [CrossRef]

- Baldanza, A.; Loianno, V.; Mensitieri, G.; Panayiotou, C.; Scherillo, G. On the thermodynamic consistency of non-random hydrogen bonding lattice-fluid model for multicomponent mixtures. Fluid Phase Equilib. 2022, 553, 113302. [Google Scholar] [CrossRef]

- Chan, A.H.; Koros, W.J.; Paul, D.R. Analysis of hydrocarbon gas sorption and transport in ethyl cellulose using the dual sorption/partial immobilization models. J. Membr. Sci. 1978, 3, 117–130. [Google Scholar] [CrossRef]

- Kanehashi, S.; Nagai, K. Analysis of dual-mode model parameters for gas sorption in glassy polymers. J. Membr. Sci. 2005, 253, 117–138. [Google Scholar] [CrossRef]

- Koros, W.J.; Paul, D.R. CO2 sorption in poly(ethylene terephthalate) above and below the glass transition. J. Polym. Sci. Part B Polym. Phys. 1978, 16, 1947–1963. [Google Scholar] [CrossRef]

- Koros, W.J.; Engineering, C.; State, N.C. Model for sorption of mixed gases in glassy polymers. J. Polym. Sci. Polym. Phys. Ed. 1980, 18, 981–992. [Google Scholar] [CrossRef]

- Ricci, E.; De Angelis, M.G. Modelling Mixed-Gas Sorption in Glassy Polymers for CO2 Removal: A Sensitivity Analysis of the Dual Mode Sorption Model. Membranes 2019, 9, 8. [Google Scholar] [CrossRef]

- Doghieri, F.; Biavati, D.; Sarti, G.C. Solubility and Diffusivity of Ethanol in PTMSP: Effects of Activity and of Polymer Aging. Ind. Eng. Chem. Res. 1996, 35, 2420–2430. [Google Scholar] [CrossRef]

- Feng, H. Modeling of vapor sorption in glassy polymers using a new dual mode sorption model based on multilayer sorption theory. Polymer 2007, 48, 2988–3002. [Google Scholar] [CrossRef]

- Bondar, V.I.; Kamiya, Y.; Yampol’skii, Y.P. On pressure dependence of the parameters of the dual-mode sorption model. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 369–378. [Google Scholar] [CrossRef]

- Fleming, G.K.; Koros, W.J. Dilation of Polymers by Sorption of Carbon Dioxide at Elevated Pressures. 1. Silicone Rubber and Unconditioned Polycarbonate. Macromolecules 1986, 19, 2285–2291. [Google Scholar] [CrossRef]

- Minelli, M.; Sarti, G.C. 110th Anniversary: Gas and Vapor Sorption in Glassy Polymeric Membranes—Critical Review of Different Physical and Mathematical Models. Ind. Eng. Chem. Res. 2020, 59, 341–365. [Google Scholar] [CrossRef]

- Guggenheim, E.A. Applications of Statistical Mechanics; Clarendon Press: Oxford, UK, 1966. [Google Scholar]

- Anderson, R.B. Modifications of the Brunauer, Emmett and Teller Equation. J. Am. Chem. Soc. 1946, 68, 686–691. [Google Scholar] [CrossRef]

- De Boer, J.H. The Dynamical Character of Adsorption; Clarendon Press: Oxford, UK, 1953. [Google Scholar]

- Zou, L.; Gong, L.; Xu, P.; Feng, G.; Liu, H. Modified GAB model for correlating multilayer adsorption equilibrium data. Sep. Purif. Technol. 2016, 161, 38–43. [Google Scholar] [CrossRef]

- Timmermann, E.O. A B. E. T.-like three sorption stage isotherm. J. Chem. Soc. Faraday Trans. 1 Phys. Chem. Condens. Phases 1989, 85, 1631. [Google Scholar] [CrossRef]

- Vopička, O.; Friess, K. Analysis of gas sorption in glassy polymers with the GAB model: An alternative to the dual mode sorption model. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 1490–1495. [Google Scholar] [CrossRef]

- Vopička, O.; Friess, K.; Hynek, V.; Sysel, P.; Zgažar, M.; Šípek, M.; Pilnáček, K.; Lanč, M.; Jansen, J.C.; Mason, C.R.; et al. Equilibrium and transient sorption of vapours and gases in the polymer of intrinsic microporosity PIM-1. J. Membr. Sci. 2013, 434, 148–160. [Google Scholar] [CrossRef]

- Vopička, O.; Lanč, M.; Friess, K. Phenomenology of vapour sorption in polymers of intrinsic microporosity PIM-1 and PIM-EA-TB: Envelopment of sorption isotherms. Curr. Opin. Chem. Eng. 2022, 35, 100786. [Google Scholar] [CrossRef]

- Vopička, O.; Pilnáček, K.; Číhal, P.; Friess, K. Sorption of methanol, dimethyl carbonate, methyl acetate, and acetone vapors in CTA and PTMSP: General findings from the GAB Analysis. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 561–569. [Google Scholar] [CrossRef]

- Vopička, O.; Radotínský, D.; Friess, K. Sorption of vapour mixtures of methanol and dimethyl carbonate in PDMS: Experimental study. Eur. Polym. J. 2015, 73, 480–486. [Google Scholar] [CrossRef]

- Mandelbrot B The Fractal Geometry of Nature; Free-man & Company: New York, NY, USA, 1983.

- Kozlov; Zaikov, G. The Structural Stabilization of Polymers: Fractal Models; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9789047418252. [Google Scholar]

- Novikov, V.U.; Kozlov, G.V. Fractal analysis of macromolecules. Russ. Chem. Rev. 2000, 69, 378–399. [Google Scholar] [CrossRef]

- Kozlov, G.V.; Cruz-Morales, J.A.; Vargas, J.; Tlenkopatchev, M.A. The Solubility of Hydrocarbon Gases in Glassy Polymers: Fractal Modeling. Int. J. Polym. Sci. 2013, 2013, 529021. [Google Scholar] [CrossRef]

- Cruz-Morales, J.A.; Vargas, J.; Santiago, A.A.; Burelo, M.; Gutiérrez, S. Application of the fractal model to estimate the diffusion and solubility of gases in non-porous membranes based on aromatic polynorbornene dicarboximides. J. Polym. Res. 2021, 28, 248. [Google Scholar] [CrossRef]

- Kozlov, G.V.; Zaikov, G.E.; Mikitaev, A.K. The Fractal Analysis of Gas Transport in Polymers: The Theory and Practical Applications; Nova Science Publishers: Hauppauge, NY, USA, 2009. [Google Scholar]

- Aharoni, S.M. On entanglements of flexible and rodlike polymers. Macromolecules 1983, 16, 1722–1728. [Google Scholar] [CrossRef]

- Haselwander, T.F.A.; Heitz, W.; Krügel, S.A.; Wendorff, J.H. Rigid Random Coils: Rotationally Confined Chain Molecules. Macromolecules 1997, 30, 5345–5351. [Google Scholar] [CrossRef]

- Wu, S. Chain structure and entanglement. J. Polym. Sci. Part B Polym. Phys. 1989, 27, 723–741. [Google Scholar] [CrossRef]

- Minelli, M.; De Angelis, M.G.; Baschetti, M.G.; Doghieri, F.; Sarti, G.C.; Ribeiro, C.P.; Freeman, B.D. Equation of State Modeling of the Solubility of CO2/C2H6 Mixtures in Cross-Linked Poly(ethylene oxide). Ind. Eng. Chem. Res. 2015, 54, 1142–1152. [Google Scholar] [CrossRef]

- Ricci, E. Thermodynamic and Molecular Simulation of Pure and Mixed Gas Sorption in Polymeric Membranes. Ph.D. Thesis, Alma Mater Studiorum Università di Bologna, Bologna, Italy, 2020. [Google Scholar]

- Raharjo, R.D.; Freeman, B.D.; Sanders, E.S. Pure and mixed gas CH4 and n-C4H10 sorption and dilation in poly(1-trimethylsilyl-1-propyne). Polymer 2007, 48, 6097–6114. [Google Scholar] [CrossRef]

- Doghieri, F.; Sarti, G.C. Solubility, diffusivity, and mobility ofn-pentane and ethanol in poly(1-trimethylsilyl-1-propyne). J. Polym. Sci. Part B Polym. Phys. 1997, 35, 2245–2258. [Google Scholar] [CrossRef]

- De Angelis, M.G.; Lodge, S.; Giacinti Baschetti, M.; Sarti, G.C.; Doghieri, F.; Sanguineti, A.; Fossati, P. Water sorption and diffusion in a short-side-chain perfluorosulfonic acid ionomer membrane for PEMFCS: Effect of temperature and pre-treatment. Desalination 2006, 193, 398–404. [Google Scholar] [CrossRef]

- Giacinti Baschetti, M.; Doghieri, F.; Freeman, B.; Sarti, G.C. Transient and steady-state effective diffusivity in high free volume glassy polymers. J. Membr. Sci. 2009, 344, 144–154. [Google Scholar] [CrossRef]

- Cohen, M.H.; Turnbull, D. Molecular transport in liquids and glasses. J. Chem. Phys. 1959, 31, 1164–1169. [Google Scholar] [CrossRef]

- Park, J.Y.; Paul, D.R. Correlation and prediction of gas permeability in glassy polymer membrane materials via a modified free volume based group contribution method. J. Membr. Sci. 1997, 125, 23–39. [Google Scholar] [CrossRef]

- Fujita, H. Diffusion in polymer-diluent systems. Fortschr. Hochpolym. 1961, 3, 1–47. [Google Scholar] [CrossRef]

- Vrentas, J.S.; Duda, J.L. Diffusion in Polymer—Solvent Systems-I. Reexamination of the Free-Volume Theory. J. Polym. Sci. Polym. Phys. Ed. 1977, 15, 403–416. [Google Scholar] [CrossRef]

- Vrentas, J.S.; Duda, J.L. Diffusion in polymer–solvent systems. II. A predictive theory for the dependence of diffusion coefficients on temperature, concentration, and molecular weight. J. Polym. Sci. Polym. Phys. Ed. 1977, 15, 417–439. [Google Scholar] [CrossRef]

- Van Krevelen, D.W.; Te Nijenhuis, K. Volumetric Properties. In Properties of Polymers; Elsevier: Amsterdam, The Netherlands, 2009; pp. 71–108. ISBN 9780080548197. [Google Scholar]

- Bicerano, J. Prediction of Polymer Properties; CRC Press: Boca Raton, FL, USA, 2002; ISBN 9780429222283. [Google Scholar]

- Calero-Rubio, C.; Strab, C.; Barnett, G.V.; Roberts, C.J. Protein Partial Molar Volumes in Multicomponent Solutions from the Perspective of Inverse Kirkwood–Buff Theory. J. Phys. Chem. B 2017, 121, 5897–5907. [Google Scholar] [CrossRef]

- Kirkwood, J.G.; Buff, F.P. The Statistical Mechanical Theory of Solutions. I. J. Chem. Phys. 1951, 19, 774–777. [Google Scholar] [CrossRef]

- Duda, J.L.; Zielinski, J.M. Free-Volume Theory. Diffus. Polym. 1996, 32, 143–171. [Google Scholar]

- Zielinski, J.M.; Duda, J.L. Predicting polymer/solvent diffusion coefficients using free-volume theory. AIChE J. 1992, 38, 405–415. [Google Scholar] [CrossRef]

- Costa, L.I.; Storti, G. Self-diffusion of small molecules into rubbery polymers: A lattice free-volume theory. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 529–540. [Google Scholar] [CrossRef]

- Hirayama, Y.; Yoshinaga, T.; Kusuki, Y.; Ninomiya, K.; Sakakibara, T.; Tamari, T. Relation of gas permeability with structure of aromatic polyimides II. J. Membr. Sci. 1996, 111, 183–192. [Google Scholar] [CrossRef]

- Shantarovich, V.P.; Kevdina, I.B.; Yampolskii, Y.P.; Alentiev, A.Y. Positron annihilation lifetime study of high and low free volume glassy polymers: Effects of free volume sizes on the permeability and permselectivity. Macromolecules 2000, 33, 7453–7466. [Google Scholar] [CrossRef]

- Fujita, H. Free-volume model of diffusion in polymer solutions. Adv. Polym. Sci. 1961, 3, 1–47. [Google Scholar]

- Horn, N.R. A critical review of free volume and occupied volume calculation methods. J. Membr. Sci. 2016, 518, 289–294. [Google Scholar] [CrossRef]

- Kozlov, G.V.; Nafadzokova, L.K.; Zaikov, G.E. Fractal model of the free volume of vitreous poly(vinyltrimethylsilane) from data on gas diffusion. Glas. Phys. Chem. 2007, 33, 481–485. [Google Scholar] [CrossRef]

- Khalikov, R.M.; Kozlov, G.V. Multifractal model of gas diffusion in polymers. Polym. Sci. Ser. B 2006, 48, 84–87. [Google Scholar] [CrossRef]

- Berens, A.R.; Hopfenberg, H.B. Diffusion of organic vapors at low concentrations in glassy PVC, polystyrene, and PMMA. J. Membr. Sci. 1982, 10, 283–303. [Google Scholar] [CrossRef]

- Alexander, S.; Orbach, R. Density of states on fractals: «fractons». J. Phys. Lett. 1982, 43, 625–631. [Google Scholar] [CrossRef]

- Marshall, B.D.; Allen, J.W.; Lively, R.P. A model for the separation of complex liquid mixtures with glassy polymer membranes: A thermodynamic perspective. J. Membr. Sci. 2022, 647, 120316. [Google Scholar] [CrossRef]

- Ebneyamini, A.; Azimi, H.; Thibault, J.; Tezel, F.H. Description of butanol aqueous solution transport through commercial PDMS pervaporation membrane using extended Maxwell–Stefan model. Sep. Sci. Technol. 2018, 53, 1611–1627. [Google Scholar] [CrossRef]

- Koros, W.J.; Chern, R.T.; Stannett, V.; Hopfenberg, H.B. A model for permeation of mixed gases and vapors in glassy polymers. J. Polym. Sci. Polym. Phys. Ed. 1981, 19, 1513–1530. [Google Scholar] [CrossRef]

- Moon, J.D.; Galizia, M.; Borjigin, H.; Liu, R.; Riffle, J.S.; Freeman, B.D.; Paul, D.R. Modeling water diffusion in polybenzimidazole membranes using partial immobilization and free volume theory. Polymer 2020, 189, 122170. [Google Scholar] [CrossRef]

- Park, J.; Yoon, H.W.; Paul, D.R.; Freeman, B.D. Gas transport properties of PDMS-coated reverse osmosis membranes. J. Membr. Sci. 2020, 604, 118009. [Google Scholar] [CrossRef]

- Balçık, M.; Tantekin-Ersolmaz, S.B.; Pinnau, I.; Ahunbay, M.G. CO2/CH4 mixed-gas separation in PIM-1 at high pressures: Bridging atomistic simulations with process modeling. J. Membr. Sci. 2021, 640, 119838. [Google Scholar] [CrossRef]

- Miandoab, E.S.; Kentish, S.E.; Scholes, C.A. Modelling competitive sorption and plasticization of glassy polymeric membranes used in biogas upgrading. J. Membr. Sci. 2021, 617, 118643. [Google Scholar] [CrossRef]

- Suhaimi, N.H.; Yeong, Y.F.; Jusoh, N.; Chew, T.L.; Bustam, M.A.; Mubashir, M. Altering sorption and diffusion coefficients of gases in 6FDA-based membrane via addition of functionalized Ti-based fillers. Polym. Compos. 2022, 43, 440–453. [Google Scholar] [CrossRef]

- Lim, Y.-G.; Bak, C.; Kim, Y.-D. Comprehensive experimental and theoretical insights into the performance of polysulfone hollow-fiber membrane modules in biogas purification process. Chem. Eng. J. 2022, 433, 134616. [Google Scholar] [CrossRef]

- Ghoreyshi, A.A.; Asadi, H.; Pirzadeh, K. A generic transport model for separation of gas mixtures by glassy polymer membranes based on Maxwell–Stefan formulation. RSC Adv. 2015, 5, 48207–48216. [Google Scholar] [CrossRef]

- Monsalve-Bravo, G.M.; Smart, S.; Bhatia, S.K. Simulation of Multicomponent Gas Transport through Mixed-Matrix Membranes. J. Membr. Sci. 2019, 577, 219–234. [Google Scholar] [CrossRef]

- Mathias, R.; Weber, D.J.; Thompson, K.A.; Marshall, B.D.; Finn, M.G.; Scott, J.K.; Lively, R.P. Framework for predicting the fractionation of complex liquid feeds via polymer membranes. J. Membr. Sci. 2021, 640, 119767. [Google Scholar] [CrossRef]

- Shoghl, S.N.; Raisi, A.; Aroujalian, A. Modeling of gas solubility and permeability in glassy and rubbery membranes using lattice fluid theory. Polymer 2017, 115, 184–196. [Google Scholar] [CrossRef]

- Bounaceur, R.; Berger, E.; Pfister, M.; Ramirez Santos, A.A.; Favre, E. Rigorous variable permeability modelling and process simulation for the design of polymeric membrane gas separation units: MEMSIC simulation tool. J. Membr. Sci. 2017, 523, 77–91. [Google Scholar] [CrossRef]

- Minelli, M.; Sarti, G.C. Permeability and diffusivity of CO2 in glassy polymers with and without plasticization. J. Membr. Sci. 2013, 435, 176–185. [Google Scholar] [CrossRef]

- Minelli, M.; Sarti, G.C. Elementary prediction of gas permeability in glassy polymers. J. Membr. Sci. 2017, 521, 73–83. [Google Scholar] [CrossRef]

- Toni, E.; Minelli, M.; Sarti, G.C. A predictive model for the permeability of gas mixtures in glassy polymers. Fluid Phase Equilib. 2018, 455, 54–62. [Google Scholar] [CrossRef]

- Samei, M.; Raisi, A. Multi-stage gas separation process for separation of carbon dioxide from methane: Modeling, simulation, and economic analysis. Chem. Eng. Process. Process Intensif. 2022, 170, 108676. [Google Scholar] [CrossRef]

- Krishna, R. Describing mixture permeation across polymeric membranes by a combination of Maxwell-Stefan and Flory-Huggins models. Polymer 2016, 103, 124–131. [Google Scholar] [CrossRef]

- Petropoulos, J.H. Formulation of dual-mode mixed gas transport in glassy polymers. J. Membr. Sci. 1990, 48, 79–90. [Google Scholar] [CrossRef]

- Petropoulos, J.H. Plasticization effects on the gas permeability and permselectivity of polymer membranes. J. Membr. Sci. 1992, 75, 47–59. [Google Scholar] [CrossRef]

- Minelli, M.; Sarti, G.C.; Civile, I.; Studiorum, A.M. Thermodynamic Model for the Permeability of Light Gases in Glassy Polymers. AIChE J. 2015, 61, 2776–2788. [Google Scholar] [CrossRef]

- Minelli, M.; Sarti, G.C. Thermodynamic basis for vapor permeability in Ethyl Cellulose. J. Membr. Sci. 2015, 473, 137–145. [Google Scholar] [CrossRef]

- Minelli, M.; Sarti, G.C. Gas permeability in glassy polymers: A thermodynamic approach. Fluid Phase Equilib. 2015, 424, 44–51. [Google Scholar] [CrossRef]

- Minelli, M.; De Angelis, M.G.; Sarti, G.C. Predictive calculations of gas solubility and permeability in glassy polymeric membranes: An overview. Front. Chem. Sci. Eng. 2017, 11, 405–413. [Google Scholar] [CrossRef]

- Toi, K.; Morel, G.; Paul, D.R. Gas sorption and transport in poly(phenylene oxide) and comparisons with other glassy polymers. J. Appl. Polym. Sci. 1982, 27, 2997–3005. [Google Scholar] [CrossRef]

- Bird, R.B.; Klingenberg, D.J. Multicomponent diffusion-A brief review. Adv. Water Resour. 2013, 62, 238–242. [Google Scholar] [CrossRef]

- Byron Bird, R.; Klingenberg, D.J. Corrigendum to “Multicomponent diffusion-A brief review” [Adv. Water Res. 62PB (2013) 238–242]. Adv. Water Resour. 2014, 73, 254. [Google Scholar] [CrossRef]

- Kupgan, G.; Abbott, L.J.; Hart, K.E.; Colina, C.M. Modeling Amorphous Microporous Polymers for CO2 Capture and Separations. Chem. Rev. 2018, 118, 5488–5538. [Google Scholar] [CrossRef]

- Theodorou, D.N. Principles of Molecular Simulation of Gas Transport in Polymers. In Materials Science of Membranes for Gas and Vapor Separation; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 047085345X. [Google Scholar]

- Vergadou, N.; Theodorou, D.N. Molecular modeling investigations of sorption and diffusion of small molecules in Glassy polymers. Membranes 2019, 9, 98. [Google Scholar] [CrossRef]

- Fried, J.R. Molecular Simulation of Gas and Vapor Transport in Highly Permeable Polymers. In Materials Science of Membranes for Gas and Vapor Separation; Freeman, B.D., Yampolskii, Y., Pinnau, I., Eds.; Wiley: Hoboken, NJ, USA, 2006; pp. 95–136. [Google Scholar]

- Monticelli, L.; Tieleman, D.P. Force Fields for Classical Molecular Dynamics. Biomol. Simul. 2013, 924, 197–213. [Google Scholar]

- Schmidt, J.R.; Yu, K.; McDaniel, J.G. Transferable Next-Generation Force Fields from Simple Liquids to Complex Materials. Acc. Chem. Res. 2015, 48, 548–556. [Google Scholar] [CrossRef]

- Riniker, S. Fixed-Charge Atomistic Force Fields for Molecular Dynamics Simulations in the Condensed Phase: An Overview. J. Chem. Inf. Model. 2018, 58, 565–578. [Google Scholar] [CrossRef]

- Brown, D.; Clarke, J.H.R.; Okuda, M.; Yamazaki, T. The preparation of polymer melt samples for computer simulation studies. J. Chem. Phys. 1994, 100, 6011–6018. [Google Scholar] [CrossRef]

- Martínez, L.; Andrade, R.; Birgin, E.G.; Martínez, J.M. PACKMOL: A package for building initial configurations for molecular dynamics simulations. J. Comput. Chem. 2009, 30, 2157–2164. [Google Scholar] [CrossRef]

- Sliozberg, Y.R.; Kröger, M.; Chantawansri, T.L. Fast equilibration protocol for million atom systems of highly entangled linear polyethylene chains. J. Chem. Phys. 2016, 144, 154901. [Google Scholar] [CrossRef]

- Kröger, M. Efficient hybrid algorithm for the dynamic creation of wormlike chains in solutions, brushes, melts and glasses. Comput. Phys. Commun. 2019, 241, 178–179. [Google Scholar] [CrossRef]

- Gao, J. An efficient method of generating dense polymer model melts by computer simulation. J. Chem. Phys. 1995, 102, 1074–1077. [Google Scholar] [CrossRef]

- Flory, P.J. Statistical Mechanics of Chain Molecules; Interscience: New York, NY, USA, 1969. [Google Scholar]

- Theodorou, D.N.; Suter, U.W. Detailed Molecular Structure of a Vinyl Polymer Glass. Macromolecules 1985, 18, 1467–1478. [Google Scholar] [CrossRef]

- Frenkel, D.; Smit, B. Understanding Molecular Simulation: From Algorithms to Applications; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Allen, M.P.; Tildesley, D.J. Computer Simulation of Liquids; Clarendon Press: Wotton-under-Edge, UK, 1989; ISBN 9780198556459. [Google Scholar]

- Rapaport, D.C. The Art of Molecular Dynamics Simulation; Cambridge University Press: New York, NY, USA, 2002. [Google Scholar]

- Metropolis, N.; Rosenbluth, A.W.; Rosenbluth, M.N.; Teller, A.H.; Teller, E. Equation of State Calculations by Fast Computing Machines. J. Chem. Phys. 1953, 21, 1087–1092. [Google Scholar] [CrossRef]

- Siepmann, J.I.; Frenkel, D. Configurational bias Monte Carlo: A new sampling scheme for flexible chains. Mol. Phys. 1992, 75, 59–70. [Google Scholar] [CrossRef]

- Rosenbluth, M.N.; Rosenbluth, A.W. Monte Carlo Calculation of the Average Extension of Molecular Chains. J. Chem. Phys. 1955, 23, 356–359. [Google Scholar] [CrossRef]

- Dodd, L.R.; Boone, T.D.; Theodorou, D.N. A concerted rotation algorithm for atomistic Monte Carlo simulation of polymer melts and glasses. Mol. Phys. 1993, 78, 961–996. [Google Scholar] [CrossRef]

- Theodorou, D.N. Variable-Connectivity Monte Carlo Algorithms for the Atomistic Simulation of Long-Chain Polymer Systems. In Bridging Time Scales: Molecular Simulations for the Next Decade; Springer: Berlin/Heidelberg, Germany, 2002; pp. 67–127. [Google Scholar]

- Pant, P.V.K.; Theodorou, D.N. Variable connectivity method for the atomistic Monte Carlo simulation of polydisperse polymer melts. Macromolecules 1995, 28, 7224–7234. [Google Scholar] [CrossRef]

- Mavrantzas, V.G.; Boone, T.D.; Zervopoulou, E.; Theodorou, D.N. End-bridging Monte Carlo: A fast algorithm for atomistic simulation of condensed phases of long polymer chains. Macromolecules 1999, 32, 5072–5096. [Google Scholar] [CrossRef]

- Karayiannis, N.C.; Giannousaki, A.E.; Mavrantzas, V.G.; Theodorou, D.N. Atomistic Monte Carlo simulation of strictly monodisperse long polyethylene melts through a generalized chain bridging algorithm. J. Chem. Phys. 2002, 117, 5465–5479. [Google Scholar] [CrossRef]

- Theodorou, D.N. Equilibration and Coarse-Graining Methods for Polymers. In Computer Simulations in Condensed Matter Systems: From Materials to Chemical Biology Volume 2; Ferrario, M., Ciccotti, G., Binder, K., Eds.; Springer: Berlin-Heidelberg, Germany, 2006; pp. 419–448. [Google Scholar]

- Gooneie, A.; Schuschnigg, S.; Holzer, C. A Review of Multiscale Computational Methods in Polymeric Materials. Polymers 2017, 9, 16. [Google Scholar] [CrossRef]

- Theodorou, D.N. Hierarchical modelling of polymeric materials. Chem. Eng. Sci. 2007, 62, 5697–5714. [Google Scholar] [CrossRef]

- Grotendorst, J.; Sutmann, G.; Gompper, G.; Marx, D. Hierarchical Methods for Dynamics in Complex Molecular Systems: Lecture Notes; Forschungszentrum Jülich: Jülich, Germant, 2012; ISBN 9783893367689. [Google Scholar]

- Müller-Plathe, F.; Florian, M.; Müller-Plathe, F. Coarse-graining in polymer simulation: From the atomistic to the mesoscopic scale and back. ChemPhysChem 2002, 3, 754–769. [Google Scholar] [CrossRef]

- Krajniak, J.; Zhang, Z.; Pandiyan, S.; Nies, E.; Samaey, G. Reverse mapping method for complex polymer systems. J. Comput. Chem. 2018, 39, 648–664. [Google Scholar] [CrossRef]

- Santangelo, G.; Di Matteo, A.; Müller-Plathe, F.; Milano, G. From mesoscale back to atomistic models: A fast reverse-mapping procedure for vinyl polymer chains. J. Phys. Chem. B 2007, 111, 2765–2773. [Google Scholar] [CrossRef]

- Krajniak, J.; Pandiyan, S.; Nies, E.; Samaey, G. Generic Adaptive Resolution Method for Reverse Mapping of Polymers from Coarse-Grained to Atomistic Descriptions. J. Chem. Theory Comput. 2016, 12, 5549–5562. [Google Scholar] [CrossRef]

- Potestio, R.; Peter, C.; Kremer, K. Computer Simulations of Soft Matter: Linking the Scales. Entropy 2014, 16, 4199–4245. [Google Scholar] [CrossRef]

- Wang, W.; Gómez-Bombarelli, R. Coarse-graining auto-encoders for molecular dynamics. Npj Comput. Mater. 2019, 5, 125. [Google Scholar] [CrossRef]

- Ruza, J.; Wang, W.; Schwalbe-Koda, D.; Axelrod, S.; Harris, W.H.; Gómez-Bombarelli, R. Temperature-transferable coarse-graining of ionic liquids with dual graph convolutional neural networks. J. Chem. Phys. 2020, 153, 164501. [Google Scholar] [CrossRef] [PubMed]

- Marrink, S.J.; Risselada, H.J.; Yefimov, S.; Tieleman, D.P.; De Vries, A.H. The MARTINI Force Field: Coarse Grained Model for Biomolecular Simulations. J. Phys. Chem. B 2007, 111, 7812–7824. [Google Scholar] [CrossRef]

- Brini, E.; Algaer, E.A.; Ganguly, P.; Li, C.; Rodríguez-Ropero, F.; van der Vegt, N.F.A. Systematic coarse-graining methods for soft matter simulations—A review. Soft Matter 2013, 9, 2108–2119. [Google Scholar] [CrossRef]

- Reith, D.; Puetz, M.; Mueller-Plathe, F. Deriving effective mesoscale potentials from atomistic simulations. J. Comput. Chem. 2003, 24, 1624–1636. [Google Scholar] [CrossRef]

- Ercolessi, F.; Adams, J.B. Interatomic Potentials from First-Principles Calculations: The Force-Matching Method. Europhys. Lett. 1994, 26, 583–588. [Google Scholar] [CrossRef]

- Lyubartsev, A.P.; Laaksonen, A. Calculation of effective interaction potentials from radial distribution functions: A reverse Monte Carlo approach. Phys. Rev. E 1995, 52, 3730–3737. [Google Scholar] [CrossRef]

- Chaimovich, A.; Shell, M.S. Coarse-graining errors and numerical optimization using a relative entropy framework. J. Chem. Phys. 2011, 134, 094112. [Google Scholar] [CrossRef] [PubMed]

- Shell, M.S. The relative entropy is fundamental to multiscale and inverse thermodynamic problems. J. Chem. Phys. 2008, 129, 144108. [Google Scholar] [CrossRef]

- De Nicola, A.; Kawakatsu, T.; Milano, G. Generation of well-relaxed all-atom models of large molecular weight polymer melts: A hybrid particle-continuum approach based on particle-field molecular dynamics simulations. J. Chem. Theory Comput. 2014, 10, 5651–5667. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Wu, L.; Xiong, H.; Sun, H. A Transferrable Coarse-Grained Force Field for Simulations of Polyethers and Polyether Blends. Macromolecules 2019, 52, 249–261. [Google Scholar] [CrossRef]

- Kuo, A.-T.; Okazaki, S.; Shinoda, W. Transferable coarse-grained model for perfluorosulfonic acid polymer membranes. J. Chem. Phys. 2017, 147, 094904. [Google Scholar] [CrossRef]

- Noé, F.; Tkatchenko, A.; Müller, K.-R.; Clementi, C. Machine Learning for Molecular Simulation. Annu. Rev. Phys. Chem. 2020, 71, 361–390. [Google Scholar] [CrossRef]

- Ye, H.; Xian, W.; Li, Y. Machine Learning of Coarse-Grained Models for Organic Molecules and Polymers: Progress, Opportunities, and Challenges. ACS Omega 2021, 6, 1758–1772. [Google Scholar] [CrossRef]

- Bartók, A.P.; Payne, M.C.; Kondor, R.; Csányi, G. Gaussian Approximation Potentials: The Accuracy of Quantum Mechanics, without the Electrons. Phys. Rev. Lett. 2010, 104, 136403. [Google Scholar] [CrossRef]

- Gkeka, P.; Stoltz, G.; Barati Farimani, A.; Belkacemi, Z.; Ceriotti, M.; Chodera, J.D.; Dinner, A.R.; Ferguson, A.L.; Maillet, J.-B.; Minoux, H.; et al. Machine learning force fields and coarse-grained variables in molecular dynamics: Application to materials and biological systems. J. Chem. Theory Comput. 2020, 16, 4757–4775. [Google Scholar] [CrossRef]

- Kanellopoulos, V.; Mouratides, D.; Pladis, P.; Kiparissides, C. Prediction of Solubility of α-Olefins in Polyolefins Using a Combined Equation of State Molecular Dynamics Approach. Ind. Eng. Chem. Res. 2006, 45, 5870–5878. [Google Scholar] [CrossRef]

- Minelli, M.; De Angelis, M.G.; Hofmann, D. A novel multiscale method for the prediction of the volumetric and gas solubility behavior of high-T g polyimides. Fluid Phase Equilib. 2012, 333, 87–96. [Google Scholar] [CrossRef]

- Ricci, E.; Minelli, M.; De Angelis, M.G. A multiscale approach to predict the mixed gas separation performance of glassy polymeric membranes for CO2 capture: The case of CO2/CH4 mixture in Matrimid®. J. Membr. Sci. 2017, 539, 88–100. [Google Scholar] [CrossRef]

- Tylianakis, E.; Froudakis, G.E. Grand canonical Monte Carlo method for gas adsorption and separation. J. Comput. Theor. Nanosci. 2009, 6, 335–348. [Google Scholar] [CrossRef]

- Heuchel, M.; Böhning, M.; Hölck, O.; Siegert, M.R.; Hofmann, D. Atomistic packing models for experimentally investigated swelling states induced by CO2 in glassy polysulfone and poly(ether sulfone). J. Polym. Sci. Part B Polym. Phys. 2006, 44, 1874–1897. [Google Scholar] [CrossRef]

- Panagiotopoulos, A.Z. Direct determination of phase coexistence properties of fluids by Monte Carlo simulation in a new ensemble. Mol. Phys. 1987, 61, 813–826. [Google Scholar] [CrossRef]

- Kofke, D.A.; Glandt, E.D. Monte Carlo simulation of multicomponent equilibria in a semigrand canonical ensemble. Mol. Phys. 1988, 64, 1105–1131. [Google Scholar] [CrossRef]

- Duane, S.; Kennedy, A.D.; Pendleton, B.J.; Roweth, D. Hybrid Monte Carlo. Phys. Lett. B 1987, 195, 216–222. [Google Scholar] [CrossRef]

- Mehta, M.; Kofke, D.A. Coexistence diagrams of mixtures by molecular simulation. Chem. Eng. Sci. 1994, 49, 2633–2645. [Google Scholar] [CrossRef]

- Theodorou, D.N. Molecular Simulations of Sorption and Diffusion in Amorphous Polymers. In Diffusion in Polymers; Neogi, P., Ed.; Marcel Dekker: New York, NY, USA; Basel, Switzerland; Honk Kong, China, 1996; pp. 67–142. [Google Scholar]

- Spyriouni, T.; Economou, I.G.; Theodorou, D.N. Phase Equilibria of Mixtures Containing Chain Molecules Predicted through a Novel Simulation Scheme. Phys. Rev. Lett. 1998, 80, 4466–4469. [Google Scholar] [CrossRef]

- Escobedo, F.A. Novel pseudoensembles for simulation of multicomponent phase equilibria. J. Chem. Phys. 1998, 108, 8761–8772. [Google Scholar] [CrossRef]

- Brennan, J.K.; Madden, W.G. Phase Coexistence Curves for Off-Lattice Polymer−Solvent Mixtures: Gibbs-Ensemble Simulations. Macromolecules 2002, 35, 2827–2834. [Google Scholar] [CrossRef]

- Lachet, V.; Teuler, J.-M.M.; Rousseau, B. Classical force field for hydrofluorocarbon molecular simulations. Application to the study of gas solubility in poly(vinylidene fluoride). J. Phys. Chem. A 2015, 119, 140–151. [Google Scholar] [CrossRef]

- Hölck, O.; Böhning, M.; Heuchel, M.; Siegert, M.R.; Hofmann, D. Gas sorption isotherms in swelling glassy polymers—Detailed atomistic simulations. J. Membr. Sci. 2013, 428, 523–532. [Google Scholar] [CrossRef]

- Vrabec, J.; Hasse, H. Grand equilibrium: Vapour-liquid equilibria by a new molecular simulation method. Mol. Phys. 2002, 100, 3375–3383. [Google Scholar] [CrossRef]

- Eslami, H.; Mu, F.; Muller-Plathe, F. Molecular Dynamics Simulation in the Grand Canonical Ensemble. J. Comput. Chem. 2007, 28, 1763–1773. [Google Scholar] [CrossRef]

- Shi, W.; Maginn, E.J. Continuous Fractional Component Monte Carlo: An Adaptive Biasing Method for Open System Atomistic Simulations. J. Chem. Theory Comput. 2007, 3, 1451–1463. [Google Scholar] [CrossRef]

- Widom, B. Some Topics in the Theory of Fluids. J. Chem. Phys. 1963, 39, 2808–2812. [Google Scholar] [CrossRef]

- Cuthbert, T.; Wagner, N.; Paulaitis, M. Molecular simulation of glassy polystyrene: Size effects on gas solubilities. Macromolecules 1997, 30, 3058–3065. [Google Scholar] [CrossRef]

- Dömötör, G.; Hentschke, R. Efficient molecular simulation of chemical potentials. J. Chem. Phys. 1989, 90, 2370–2385. [Google Scholar] [CrossRef]