A Production Model for Construction: A Theoretical Framework

Abstract

:1. Introduction

2. A Theoretical Framework

2.1. A Brief Understanding of Construction

2.2. Production Facilities

2.3. Production Run

2.4. Event Termination

2.5. State Condition

2.6. Complexity

2.7. Uncertainty

2.8. Risk

2.9. Variability

2.10. Cone of Uncertainty

2.11. Repetitiveness

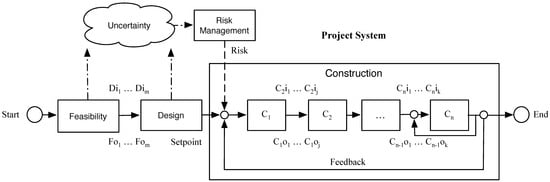

3. Construction Project System

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Levy, S.M. Project Management in Construction; McGraw-Hill: New York, NY, USA, 2012; p. 478. [Google Scholar]

- United States Department of Labor. Bureau of Labor Statistics. Available online: http://www.bls.gov/ (accessed on 24 September 2014).

- McCray, G.E.; Purvis, R.L. Project management under uncertainty: The impact of heuristics and biases. Proj. Manag. J. 2002, 33, 49–57. [Google Scholar]

- Abdelhamid, T.S. The Self-Destruction and Renewal of Lean Construction Theory: A Prediction From Boyd-S Theory. In Proceedings of the 12th Annual Conference of the International Group for Lean Construction, Helsingør, Denmark, 3–5 August 2004.

- Mills, A. A systematic approach to risk management for construction. Struct. Surv. 2001, 19, 245–252. [Google Scholar] [CrossRef]

- Lutz, J.D.; Hijazi, A. Planning repetitive construction: Current practice. Constr. Manag. Econ. 1993, 11, 99–110. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Stanford University: Stanford, CA, USA, 1992; pp. 1–81. [Google Scholar]

- Bertelsen, S. Construction as a Complex System. In Proceedings of the 11th Annual Conference of the International Group for Lean Construction, Blacksburg, VA, USA, 21–24 July 2003.

- Laufer, A. Simultaneous Management: Managing Projects in a Dynamic Environment; American Management Association: New York, NY, USA, 1997; p. 313. [Google Scholar]

- Duenyas, I.; Hopp, W.J. Estimating variance of output from cyclic exponential queueing systems. Queueing Syst. 1990, 7, 337–353. [Google Scholar] [CrossRef]

- Hopp, W.J.; Spearman, M.L. Factory Physics: Foundations of Manufacturing Management, 2nd ed.; Irwin McGraw-Hill: New York, NY, USA, 1996; p. 726. [Google Scholar]

- Kumar, S.A.; Suresh, N. Operation Management; New Age International: New Delhi, India, 2009. [Google Scholar]

- Bernold, L.E. Simulation of nonsteady construction processes. J. Constr. Eng. Manag. 1989, 115, 163–178. [Google Scholar] [CrossRef]

- Koskela, L. An Exploration towards a Production Theory and Its Application to Construction; VTT Technical Research Centre of Finland: Espoo, Finland, 2000. [Google Scholar]

- Walsh, K.D.; Sawhney, A.; Bashford, H.H. Production equations for unsteady-state construction processes. J. Constr. Eng. Manag. 2007, 133, 245–261. [Google Scholar] [CrossRef]

- Ohno, T. O sistema toyota de produção além da produção em larga escala; Bookman: Sao Paolo, Brazil, 1988; p. 139. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World; Harper Perennial: New York, NY, USA, 1991; p. 323. [Google Scholar]

- Poppendieck, M.; Poppendieck, T. Lean Software Development—An Agile Toolkit; Addison-Wesley: New York, NY, USA, 2003. [Google Scholar]

- Ries, E. The Lean Startup: How Today’s Entrepreneurs Use Continuous Innovation to Create Radically Successful Businesses; Crown Business: New York, NY, USA, 2011. [Google Scholar]

- Hopp, W.J.; Spearman, M.L.; Woodruff, D.L. Practical strategies for lead time reduction. Manuf. Rev. 1990, 3, 1–15. [Google Scholar]

- Hopp, W.J.; Wu, S.-C. Machine maintenance with multiple maintenance actions. IIE Trans. 1990, 22, 226–233. [Google Scholar] [CrossRef]

- Spearman, M.L.; Woodruff, D.L.; Hopp, W.J. CONWIP—A pull alternative to Kanban. Int. J. Prod. Res. 1990, 28, 879–894. [Google Scholar] [CrossRef]

- Simon, J.T.; Hopp, W.J. Availability and average inventory of balanced assembly-like flow systems. IIE Trans. 1991, 23, 161–168. [Google Scholar] [CrossRef]

- Koskela, L. Proceedings of the Lean Construction, National Construction and Management Conference, Sydney, Australia, 17–18 February 1994; Wakefield, R.R., Carmichael, D.G., Eds.; Institution of Engineers: Sydney, Australia, 1994; pp. 205–217.

- Project Management Institute. Project Management Institute. Construction Extension to the Pmbok Guide Third Edition, 2nd ed.; Project Management Institute: Newtown Square, PA, USA, 2007; p. 208. [Google Scholar]

- Bossink, B.; Brouwers, H. Construction waste: Quantification and source evaluation. J. Constr. Eng. Manag. 1996, 122, 55–60. [Google Scholar] [CrossRef]

- Hoffman, T.L. Construction management: Added value or added cost? J. Prop. Manag. 1998, 63, 6531300. [Google Scholar]

- Baily, M.N.; Gordon, R.J.; Nordhaus, W.D.; Romer, D. The productivity slowdown, measurement issues, and the explosion of computer power. Brook. Papers Econ. Act. 1988, 19, 347–431. [Google Scholar] [CrossRef]

- Hossain, M.A.; Chua, D.K.H. Overlapping design and construction activities and an optimization approach to minimize rework. Int. J. Proj. Manag. 2014, 32, 983–994. [Google Scholar] [CrossRef]

- Li, R.Y.M.; Poon, S.W. Construction Safety; Springer: Berlin/Heidelberg, Germany, 2013; p. 161. [Google Scholar]

- Project Management Institute. A Guide to the Project Management Body of Knowledge (Pmbok Guide), 5th ed.; Project Management Institute: Newtown Square, PA, USA, 2013; p. 616. [Google Scholar]

- Project Management Institute. A Guide to the Project Management Body of Knowledge (Pmbok Guide), 1st ed.; Project Management Institute: Newtown Square, PA, USA, 1996; p. 182. [Google Scholar]

- International Project Management Association. IPMA Competence Baseline Version 3.0, 3rd ed.; International Project Management Association: Nijkerk, The Netherlands, 2006; p. 212. [Google Scholar]

- Office of Government Commerce. Managing Successful Projects with Prince2, 5th ed.The Stationery Office: London, UK, 2009; p. 346.

- Cho, K.; Hong, T.; Hyun, C. Scheduling model for repetitive construction processes for high-rise buildings. Can. J. Civil Eng. 2010, 38, 36–48. [Google Scholar] [CrossRef]

- Bhoyar, S.; Parbat, D.K. Optimal scheduling for repetitive construction projects with multiple resource crews. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 302–307. [Google Scholar]

- Tommelein, I.; Riley, D.; Howell, G. Parade game: Impact of work flow variability on trade performance. J. Constr. Eng. Manag. 1999, 125, 304–310. [Google Scholar] [CrossRef]

- Alarcon, L.F.; Ashley, D.B. Playing Games: Evaluating the Impact of Lean Production Strategies on Project Cost and Schedule. In Proceedings of the IGLC-7, Berkeley, CA, USA, 26–28 July 1999; pp. 263–274.

- Halpin, D.W.; Kueckmann, M. Lean Construction and Simulation. In Proceedings of the 2002 Winter Simulation Conference, San Diego, CA, USA, 8–11 December 2002; pp. 1697–1703.

- Farag, M.A.M. A bridge between increasing reliability and reducing variability in construction work flow: A fuzzy-based sizing buffer model. J. Adv. Manag. Sci. 2014, 2, 287–294. [Google Scholar] [CrossRef]

- Benjaoran, V.; Dawood, N. Intelligence approach to production planning system for bespoke precast concrete products. Autom. Constr. 2006, 15, 737–745. [Google Scholar] [CrossRef]

- Thomas, H.R.; Maloney, W.F.; Horner, R.M.W.; Smith, G.R.; Handa, V.K.; Sanders, S.R. Modeling construction labor productivity. J. Constr. Eng. Manag. 1990, 116, 705–726. [Google Scholar] [CrossRef]

- Handa, M.V.K.; Barcia, R.M. Linear scheduling using optimal control theory. J. Constr. Eng. Manag. 1986, 112, 387–393. [Google Scholar] [CrossRef]

- Bashford, H.H.; Walsh, K.D.; Sawhney, A. Production system loading-cycle time relationship in residential construction. J. Constr. Eng. Manag. 2005, 131, 15–22. [Google Scholar] [CrossRef]

- Gonzalez, V.; Alarcon, L.F.; Yiu, T.W. Integrated methodology to design and manage work-in-process buffers in repetitive building projects. J. Oper. Res. Soc. 2013, 64, 1182–1193. [Google Scholar] [CrossRef]

- Gonzalez, V.; Alarcon, L.F.; Molenaar, K. Multiobjective design of work-in-process buffer for scheduling repetitive building projects. Autom. Constr. 2009, 18, 95–108. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Building Economics. Available online: http://www.astm.org (accessed on 27 October 2014).

- Smith, N.J.; Merna, T.; Jobling, P. Managing Risk in Construction Projects, 2nd ed.; Blackwell Publishing: Malden, MA, USA, 2006; p. 257. [Google Scholar]

- Association for Project Management. APM Body of Knowledge, 5th ed.; Association for Project Management: Buckinghamshire, UK, 2006; p. 197. [Google Scholar]

- Anderson, D.K.; Merna, T. Project management strategy—Project management represented as a process based set of management domains and the consequences for project management strategy. Int. J. Proj. Manag. 2003, 21, 387–393. [Google Scholar] [CrossRef]

- Project Management Institute. A Guide to the Project Management Body of Knowledge (Pmbok Guide), 3rd ed.; Project Management Institute: Newtown Square, PA, USA, 2004; p. 405. [Google Scholar]

- Gibb, A.; Isack, F. Re-engineering through pre-assembly: Client expectations and drivers. Build. Res. Inf. 2003, 31, 146–160. [Google Scholar] [CrossRef] [Green Version]

- Blismas, N.; Pasquire, C.; Gibb, A. Benefit evaluation for off-site production in construction. Constr. Manag. Econ. 2006, 24, 121–130. [Google Scholar] [CrossRef] [Green Version]

- Borg, R.; Gambatese, J.; Haines, K.; Hendrickson, C.; Hinze, J.; Horvath, A.; Koehn, E.; Moritz, S.; Mass, M.; Haughney, R. Rebuilding the world trade center. Pract. Period. Struct. Des. Constr. 2003, 8, 137–145. [Google Scholar] [CrossRef]

- Wyrik, D.A.; Eschenbach, T.G. Remote oil and gas facility construction. J. Constr. Eng. Manag. 1989, 115, 228–236. [Google Scholar] [CrossRef]

- Briscoe, G.; Dainty, A.R.J.; Millett, S. Construction supply chain partnerships: Skills, knowledge and attitudinal requirements. Eur. J. Purch. Supply Manag. 2001, 7, 243–255. [Google Scholar] [CrossRef]

- Said, H.; El-Rayes, K. Optimal utilization of interior building spaces for material procurement and storage in congested construction sites. Autom. Constr. 2013, 31, 292–306. [Google Scholar] [CrossRef]

- Baye, M.R. Magerial Economics and Business Strategy, 7th ed.; McGraw-Hill: New York, NY, USA, 2010; p. 658. [Google Scholar]

- McGuigan, J.R.; Moyer, R.C.; Harris, F.H.D. Managerial Economics: Applications, Strategy, and Tactics, 12th ed.; South-Western: Mason, OH, USA, 2011; p. 792. [Google Scholar]

- AACE International. Risk Analysis and Contingency Determination Using Expected Value. In TCM Framework: 7.6—Risk Management; AACE International: Morgantown, WV, USA, 2012; Volume 44R-08, pp. 1–14. [Google Scholar]

- Project Management Institute. Managing Change in Organization: A Practice Guide; Project Management Institute: Newtown Square, PA, USA, 2013; p. 141. [Google Scholar]

- Sutherland, J. Scrum Log Jeff Sutherland: Why Gantt Charts Were Banned in the First Scrum. Available online: http://scrum.jeffsutherland.com/2006/02/why-gantt-charts-were-banned-in-first.html (accessed on 14 April 2014).

- Deemer, P.; Benefield, G.; Larman, C.; Vodde, B. The Scrum Primer. A Lightweight Guide to the Theory and Practice of Scrum. Available online: http://assets.scrumfoundation.com/downloads/1/scrumprimer20.pdf?1352449266 (accessed on 2 July 2014).

- Mandal, A.K. Introduction to Control Engineering Modeling, Analysis and Design; New Age International Publishers: New Delhi, India, 2006; p. 633. [Google Scholar]

- Weiss, S.I. Product and Systems Development a Value Approach; John Wiley & Sons: Hoboken, NJ, USA, 2013; p. 275. [Google Scholar]

- Vidal, L.-A.; Marle, F.; Bocquet, J.-C. Modelling project Complexity. In Proceedings of the International Conference on Engineering Design, ICED’07, Paris, France, 28–31 July 2007; pp. 1–10.

- Baccarini, D. The concept of project complexity a review. Int. J. Proj. Manag. 1996, 14, 201–204. [Google Scholar] [CrossRef]

- Mitchell, M. Complexity a Guided Tour; Oxford University Press: Oxford, UK, 2009; p. 366. [Google Scholar]

- Curlee, W.; Gordon, R.L. Complexity Theory and Project Management; John Wiley & Sons: Hoboken, NJ, USA, 2011; p. 419. [Google Scholar]

- Project Management Institute. Practice Standard for Work Breakdown Structures, 2nd ed.; Project Management Institute: Newtown Square, PA, USA, 2006; p. 123. [Google Scholar]

- Project Management Institute. Practice Standard for Work Breakdown Structures, 2nd ed.; Project Management Institute: Newtown Square, PA, USA, 2006; p. 156. [Google Scholar]

- Kezner, H. Strategic Planning for Project Management Using a Project Management Maturity Model; John Wiley & Sons: New York, NY, USA, 2001; p. 271. [Google Scholar]

- Kaimann, R.A. Coefficient of network complexity. Manag. Sci. 1974, 21, 172–177. [Google Scholar] [CrossRef]

- Vidal, L.-A.; Marle, F.; Bocquet, J.-C. Measuring project complexity using the analytic hierarchy process. Int. J. Proj. Manag. 2010, 29, 718–727. [Google Scholar] [CrossRef]

- Project Management Institute. Navigating Complexity: A Practice Guide; Project Management Institute: Newtown Square, PA, USA, 2014; p. 114. [Google Scholar]

- Temperley, H.M.V. Graph Theory and Applications; Halsted Press: New York, NY, USA, 1981; p. 130. [Google Scholar]

- Nassar, K.M.; Hegab, M.Y. Developing a complexity measure for project schedules. J. Constr. Eng. Manag. 2006, 132, 554–561. [Google Scholar] [CrossRef]

- Saaty, T.L. Multicriteria Decision Making: The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation, 2nd ed.; RWS Pubns: Pittsburgh, PA, USA, 1990. [Google Scholar]

- Mello, P.C.D. John Maynard Keynes, Presidente de Companhia de Seguros; Pedro Carvalho de Mello: São Paulo, Brazil, 2011; pp. 1–152. [Google Scholar]

- Keynes, J.M. The General Theory of Employment, Interest, and Money; Harcourt Brace & World: New York, NY, USA, 1936; p. 403. [Google Scholar]

- European Commission. Value Management; European Commission: Brussels, Belgium, 1995; p. 190. [Google Scholar]

- Perminova, O.; Gustafsson, M.; Wikstrom, K. Defining uncertainty in projects—A new perspective. Int. J. Proj. Manag. 2008, 26, 73–79. [Google Scholar] [CrossRef]

- Knight, F.H. Risk, Uncertainty and Profit; Library of Economics and Liberty: Boston, MA, USA, 1921; p. 381. [Google Scholar]

- Crouhy, M.; Galai, D.; Mark, R. The Essentials of Risk Management; McGraw-Hill: New York, NY, USA, 2005; p. 416. [Google Scholar]

- Mun, J. Modeling Risk: Applying Monte Carlo Simulation, Real Options Analysis, Forecasting, and Optimization Techniques; John Wiley & Sons: Hoboken, NJ, USA, 2006; p. 623. [Google Scholar]

- Project Management Institute. A Guide to the Project Management Body of Knowledge (Pmbok Guide), 4th ed.; Project Management Institute: Newtown Square, PA, USA, 2008; p. 507. [Google Scholar]

- Jorion, P. Value at Risk the New Bechmark for Managing Financial Risk, 3rd ed.; McGraw-Hill: New York, NY, USA, 2007; p. 594. [Google Scholar]

- Cleden, D. Managing Project Uncertainty; Gower: Surrey, UK, 2009; p. 146. [Google Scholar]

- Wikipedia. Variability. Available online: https://en.wikipedia.org/wiki/Variability (accessed on 22 April 2014).

- Radosavljević, M.; Horner, R.M.W. The evidence of complex variability in construction labour productivity. Constr. Manag. Econ. 2002, 20, 3–12. [Google Scholar] [CrossRef]

- Atkinson, R.; Crawford, L.; Ward, S. Fundamental uncertainties in projects and the scope of project management. Int. J. Proj. Manag. 2006, 24, 687–698. [Google Scholar] [CrossRef]

- McConnell, S. Software Estimation: Demystifying the Black Art; Microsoft Press: Redmond, WA, USA, 2006; p. 352. [Google Scholar]

- Spencer, M.S.; Cox, J.F. An analysis of the product-process matrix and repetitive manufacturing. Int. J. Prod. Res. 1995, 33, 1275–1294. [Google Scholar] [CrossRef]

- Public Broadcasting Service (PBS). One World Trade Center. In Super Skyscrapers; PBS: Arlington, VA, USA, 2014. [Google Scholar]

- Shaked, D. Strength-Based Lean Six Sigma: Building Positive and Engaging Business Improvement; Kogan Page Ltd.: London, GBR, 2013. [Google Scholar]

- Taghizadegan, S. Essentials of Lean Six Sigma; Elsevier: Amsterdam, NL, USA, 2006; p. 275. [Google Scholar]

- University of Alberta Dictionary. Universal Function Approximator. Available online: http://www.bcp.psych.ualberta.ca/~mike/Pearl_Street/Dictionary/contents/U/universalfn.html (accessed on 5 July 2014).

- Xu, J.-X.; Tan, Y. Linear and Nonlinear Iterative Learning Control; Springer: Berlin, Germany, 2003; Volume 291, p. 177. [Google Scholar]

- Dager, R.; Zuazua, E. Wave Propagation, Observation and Control in 1-d Flexible Multi-Structures; Springer: New York, NY, USA, 2006; Volume 50, p. 227. [Google Scholar]

- Ogata, K. Modern Control Engineering, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2010; p. 905. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antunes, R.; Gonzalez, V. A Production Model for Construction: A Theoretical Framework. Buildings 2015, 5, 209-228. https://doi.org/10.3390/buildings5010209

Antunes R, Gonzalez V. A Production Model for Construction: A Theoretical Framework. Buildings. 2015; 5(1):209-228. https://doi.org/10.3390/buildings5010209

Chicago/Turabian StyleAntunes, Ricardo, and Vicente Gonzalez. 2015. "A Production Model for Construction: A Theoretical Framework" Buildings 5, no. 1: 209-228. https://doi.org/10.3390/buildings5010209