Prediction of Shear Strength for Steel-Fiber High-Strength Concrete Corbels with the Softened Strut-and-Tie Model

Abstract

:1. Introduction

2. Experimental

2.1. Specimens Details

2.2. Mechanical Properties of the Material

2.3. Experimental Results and Analysis

2.3.1. Failure Behavior of the Specimens

2.3.2. Cracking Responses

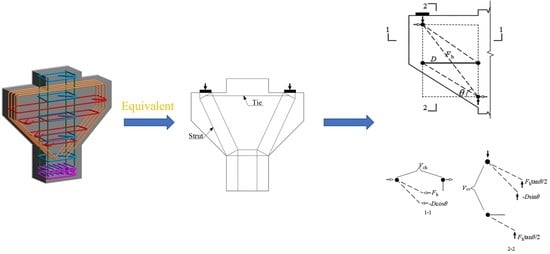

3. Establishment of a Shear Capacity Model

3.1. Equilibrium Conditions

3.2. Constitutive Laws

3.3. Compatibility Conditions

3.4. Solution Process

- Based on the known data, θ, ε0, As,h and Asf,h were calculated, and then γh, Rd and Rh were calculated using Equations (13) to (15).

- Given a shear Vcv, calculate the forces D and Fh using Equations (9) and (10), and then calculate σd,max and εh using Equations (16), (23) and (24).

- Select the value of εd, calculate the concrete softening coefficient ζ using Equation (18), and then calculate εr using Equation (25) to determine the softening effect of concrete. When θ ≤ tan−1 (2), εv in Equation (25) should be 0.002, that is, the vertical tie can transmit the shear force; when θ > tan−1 (2), εv in Equation (25) should be 0, that is, the horizontal tie transmits the shear force.

- Equation (17) is used to calculate the allowable compressive stress σd corresponding to the selected εd. If the calculated absolute value σd,max is less than the absolute value σd, increase Vcv, from step 2 again and until the absolute value of σd is satisfied; when it is greater than or equal to the absolute value σd, proceed to the next step.

- Compare the absolute values of εd and the absolute values of ζε0. If the absolute value of εd is less than the absolute value of ζε0, select εd again, repeat the calculation from step 3 until the absolute value of εd is greater than or equal to the absolute value of ζε0, then end the process.

4. Conclusions

- Experimental studies showed that the addition of steel fibers did not change the failure pattern of the corbels, but delayed the formation of shear cracks and effectively limited the expansion of cracks due to the bridging effect of the fibers.

- In the analysis of the shear capacity of steel-fiber concrete corbels, the randomly distributed steel fibers in the concrete could be equivalent to a horizontal reinforcement according to their mechanical characteristics; their contribution to the shear capacity of the corbels could be clarified.

- Compared with the values obtained according to the various codes and the softened strut-and-tie model, the shear capacity value predicted with the model proposed in this paper was closer to the experimental results, indicating a higher prediction accuracy of our model compared to previous ones. It can be used to calculate the shear capacity of steel-fiber high-strength concrete corbels. Therefore, it can reasonably provide theoretical references for the design of high-strength concrete corbels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| λ | shear span-to-depth ratio, dimensionless | Rd | ratio of the shear force of the corbel resisted by the diagonal mechanism, dimensionless |

| ρs | longitudinal reinforcement ratio, dimensionless | Rh | ratio of the shear force of the corbel resisted by the horizontal mechanism, dimensionless |

| ρsh | stirrup reinforcement ratio, dimensionless | steel fiber volume fraction, dimensionless | |

| fcu | cube compressive strength of concrete, MPa | λf | characteristic parameters of steel fiber, dimensionless |

| fc | prism compressive strength of concrete, MPa | ρs,h | steel fiber along the horizontal direction can be considered as the reinforcement rate, dimensionless |

| ft | splitting tensile strength of concrete, MPa | Astr | cross-sectional area of the concrete compression strut, mm2 |

| Ec | elastic modulus of concrete, MPa | Asf | cross-sectional area of a single steel fiber, mm2 |

| h0 | effective depth of the corbel, mm | λds | influencing factor of steel fiber type |

| fy | specified yield strength for the reinforcement, MPa | Aspf | surface area of steel fiber, mm2 |

| fu | ultimate strength for the reinforcement, MPa | τsf,max | bond strength coefficient of steel fiber and concrete, dimensionless |

| Es | modulus of elasticity of the reinforcement, MPa | lsf | length of the steel fiber, mm |

| cracking load of the normal section, kN | dsf | diameter of the steel fiber, mm | |

| diagonal cracking load, kN | fsf | tensile strength of the steel fiber, mm | |

| ultimate load, kN | Esf | elastic modulus of the steel fiber, MPa | |

| fh | tensile stress of the reinforcement, kN | εyh | strain of horizontal stirrups |

| εsf | strain of the steel fiber | Asf,h | equivalent section area of the horizontal steel fiber tie, mm2 |

| θ | value of the angle between the diagonal strut and the horizontal axial direction | Vcv | vertical shear force, kN |

| ρ | ratio of primary tensile reinforcement, dimensionless | As,h | area of the horizontal stirrup tie, mm2 |

| D | force of the compression in the diagonal strut, kN | fc′ | compression strength of concrete, kN |

| Fh | force of the tension in the horizontal ties, kN | Fsf,h | force of steel fiber tie tension |

| γh | ratio of horizontal tie to horizontal shear force without vertical tie, dimensionless | σd,max | maximum compressive stress |

| b | width of the specimen section, mm | σd | average principal stress of concrete in the d-direction |

| h | depth of the specimen, mm | ζ | softening coefficient of steel-fiber high-strength concrete, dimensionless |

| ε0 | peak strain of steel-fiber concrete | εd | average principal stresses in the d direction |

| as | depth of the steel fiber diagonal strut | εr | average principal stresses in the r direction |

| a | shear span, mm | εh | average normal strains in the h direction |

| n | modular ratio of elasticity, MPa | εv | average normal strains in the v direction |

| k | coefficient | Fs,h | force of the horizontal stirrup tie tension, kN |

| Vcv | horizontal shear force, kN | ρs,f | along the horizontal direction can be considered as the reinforcement rate |

References

- He, Z.Q.; Liu, Z.; Ma, Z. Investigation of Load-Transfer Mechanisms in Deep Beams and Corbels. ACI Struct. J. 2012, 109, 467–476. [Google Scholar] [CrossRef]

- Wilson, H.R.; Yousefpour, H.; Brown, M.D.; Bayrak, O. Investigation of Corbels Designed According to Strut-and- Tie and Empirical Methods. ACI Struct. J. 2018, 115, 813–824. [Google Scholar] [CrossRef]

- Kassem, W. Strength Prediction of Corbels Using Strut-and-Tie Model Analysis. Int. J. Concr. Struct. Mater. 2015, 9, 255–266. [Google Scholar] [CrossRef]

- Yun, Y.M.; Chae, H.S. An Optimum Indeterminate Strut-and-Tie Model for Reinforced Concrete Corbels. Adv. Struct. Eng. 2019, 22, 2557–2571. [Google Scholar] [CrossRef]

- Huang, Y.; Han, B.; Yin, W. Reinforced Concrete Corbels Shear Test: The Triangular-Truss Method Evaluation. Buildings 2022, 12, 1619. [Google Scholar] [CrossRef]

- Almasabha, G.; Murad, Y.; Alghossoon, A.; Saleh, E.; Tarawneh, A. Sustainability of Using Steel Fibers in Reinforced Concrete Deep Beams without Stirrups. Sustainability 2023, 15, 4721. [Google Scholar] [CrossRef]

- Sachdeva, P.; Roy, A.B.D.; Kwatra, N. Behavior of Headed Bars in Steel Fibers Based Concrete. Sādhanā 2023, 48, 4. [Google Scholar] [CrossRef]

- Iliyas, S.S.; Wadekar, D.A.P.; Kakade, D.N.; Students, P. The Behavior of Reinforced Concrete Corbels with Steel Fibers and Shear Strength Prediction. J. Eng. Technol. 2007, 5, 14979–14987. [Google Scholar]

- Fattuhi, N.I. Strength of FRC Corbels in Flexure. J. Struct. Eng. 1994, 120, 360–377. [Google Scholar] [CrossRef]

- Kurtoglu, A.E. Predicting the Shear Strength of Fiber Reinforced Concrete Corbels Via Support Vector Machines. Cumhur. Sci. J. 2018, 39, 496–514. [Google Scholar] [CrossRef]

- Kurtoglu, A.E.; Gulsan, M.E.; Abdi, H.A.; Kamil, M.A.; Cevik, A. Fiber Reinforced Concrete Corbels: Modeling Shear Strength via Symbolic Regression. Comput. Concr. 2017, 20, 65–75. [Google Scholar] [CrossRef]

- Campione, G.; Mendola, L.L.; Mangiavillano, M.L. Steel fiber-reinforced concrete corbels: Experimental behavior and shear strength prediction. ACI Struct. J. 2007, 104, 570–579. [Google Scholar] [CrossRef]

- Faleh, S.K.; Chkheiwer, A.H.; Saleh, I.S. Structural Behavior of High-Strength Concrete Corbels Involving Steel Fibers or Closed Stirrups. Period. Eng. Nat. Sci. (PEN) 2022, 10, 239. [Google Scholar] [CrossRef]

- Gao, D.Y.; Zhao, J.; Zhu, H.T. Experimental study on shear capacity of reinforced concrete corbel with steel fiber. J. Build. Struct. 2006, 27, 100–106. [Google Scholar]

- Zhu, H.T.; Gao, D.Y.; Xu, L. Study on Cracking resistance Load of Diagonal Section for Steel Fiber Reinforced Concrete Corbels. J. Hydroelectr. Eng. 2006, 2, 33–35, 70. [Google Scholar]

- Gao, D.Y.; Zhu, H.T.; Xu, L. Experimental study on flexural capacity of steel fiber reinforced concrete corbel with reinforcement. J. Hydro. Struct. 2005, 24, 68–72. [Google Scholar]

- Gao, J.F.; Qiu, H.X.; Jiang, Y.S. Investigation on design method of the steel-fiber high-strength concrete bracket. J.Southeast Univ. 1993, 23, 41–46. [Google Scholar]

- ACI 318 Committee. Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary (ACI 318R-19); American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- BS EN 1992-1-1:2004; Eurocode 2: Design of concrete structures: Part 1: General rules and rules for buildings. British Standards Institution: Brussels, Belgium, 2004.

- CSA A23.3:19; Design of Concrete Structures. Canadian Standards Association: Mississauga, ON, Canada, 2004.

- Mustafa, T.S.; Beshara, F.B.A.; Mahmoud, A.A.; Khalil, M.M.A. An Improved Strut-and-Tie Model to Predict the Ultimate Strength of Steel Fiber-Reinforced Concrete Corbels. Mater. Struct. 2019, 52, 63. [Google Scholar] [CrossRef]

- Hwang, S.-J.; Lee, H.-J. Strength Prediction for Discontinuity Regions by Softened Strut-and-Tie Model. J. Struct. Eng. 2002, 128, 1519–1526. [Google Scholar] [CrossRef]

- Fattuhi, N.I. Column-Load Effect on Reinforced Concrete Corbels. J. Struct. Eng. 1990, 116, 188–197. [Google Scholar] [CrossRef]

- Lu, W.-Y.; Lin, I.-J.; Hwang, S.-J. Shear Strength of Reinforced Concrete Corbels. Mag. Concr. Res. 2009, 61, 807–813. [Google Scholar] [CrossRef]

- Gulsan, M.E.; Cevik, A.; Mohmmad, S.H. Crack Pattern and Failure Mode Prediction of SFRC Corbels: Experimental and Numerical Study. Comput. Concr. 2021, 28, 507–519. [Google Scholar] [CrossRef]

- Canha, R.M.F.; Kuchma, D.A.; El Debs, M.K.; Souza, R.A. Numerical Analysis of Reinforced High Strength Concrete Corbels. J. Eng. Struct. 2014, 74, 130–144. [Google Scholar] [CrossRef]

- Dang, T.D.; Tran, D.T.; Nguyen-Minh, L.; Nassif, A.Y. Shear resistant capacity of steel fibres reinforced concrete deep beams: An experimental investigation and a new prediction model. Structures 2021, 33, 2284–2300. [Google Scholar] [CrossRef]

- Romualdi, J.P.; Mandel, J.A. Tensile Strength of Concrete Affected by Uniformly Distributed and Closely Spaced Short Lengths of Wire Reinforcement. ACI Struct. J. 1964, 61, 657–672. [Google Scholar] [CrossRef]

- Schafer, K. Strut-and-Tie Models for the Design of Structural Concrete; National Cheng Kung University, Department of Civil Engineering: Tainan City, Taiwan, 1996. [Google Scholar]

- Zhang, L.-X.; Hsu, T.T.C. Behavior and Analysis of 100 MPa Concrete Membrane Elements. J. Struct. Eng. 1998, 124, 24–34. [Google Scholar] [CrossRef]

- Hsu, T.T.C.; Mo, Y.L. Softening of Concrete in Torsional Members—Theroy and Tests. ACI Struct. J. 1985, 82, 290–303. [Google Scholar] [CrossRef]

- Khuntia, M.; Stojadinovic, B.; Goel, S.C. Shear Strength of Normal and High-Strength Fiber Reinforced Concrete Beams without Stirrups. ACI Struct. J. 1999, 96, 282–289. [Google Scholar] [CrossRef]

- Voo, J.Y.L.; Foster, S.J. Variable Engagement Model for Fibre Reinforced Concrete in Tension. In Proceedings of the 3rd Conference on Advanced Materials for Construction of Bridges, Buildings and Other Structures 2003, Davos, Switzerland, 7–12 September 2003; pp. 1–86. [Google Scholar]

| Specimens | λ | ρs/% | ρsh/% | ρf/% | λf |

|---|---|---|---|---|---|

| MC01 | 0.2 | 0.55 | 0.79 | 1.5 | 0.64 |

| MC02 | 0.3 | 0.55 | 0.79 | 1.5 | 0.64 |

| MC03 | 0.4 | 0.55 | 0.79 | 1.5 | 0.64 |

| MC04 | 0.3 | 0.75 | 0.79 | 1.5 | 0.64 |

| MC05 | 0.3 | 0.98 | 0.79 | 1.5 | 0.64 |

| MC06 | 0.3 | 0.55 | 0.39 | 1.5 | 0.64 |

| MC07 | 0.3 | 0.55 | 0.52 | 1.5 | 0.64 |

| MC08 | 0.3 | 0.55 | 0.79 | 0 | 0 |

| MC09 | 0.3 | 0.55 | 0.79 | 0.75 | 0.32 |

| ρf/% | fcu (MPa) | fc (MPa) | ft (MPa) | Ec (MPa) |

|---|---|---|---|---|

| 0 | 73.2 | 55.9 | 4 | 38,700 |

| 0.75 | 69.8 | 51.7 | 3.3 | 37,600 |

| 1.5 | 72.6 | 49.8 | 3.6 | 37,200 |

| Type | d (mm) | fy (MPa) | Es (GPa) | fu (MPa) |

|---|---|---|---|---|

| HPB300 | 10 | 333.7 | 195.95 | 535.8 |

| HRB400 | 12 | 425.2 | 172.6 | 541.4 |

| HRB400 | 14 | 467.8 | 185.0 | 582.3 |

| HRB400 | 16 | 427.3 | 192.5 | 587.7 |

| Number | /kN | /kN | Vu/kN | /Vu | /Vu | Failure Mode |

|---|---|---|---|---|---|---|

| MC-01 | 270 | 400 | 879 | 30.71% | 45.50% | Diagonal shear |

| MC-02 | 220 | 290 | 822 | 26.76% | 35.27% | Diagonal compression |

| MC-03 | 166.5 | 255 | 695 | 23.96% | 36.70% | Diagonal compression |

| MC-04 | 220 | 355 | 874 | 25.17% | 40.62% | Diagonal compression |

| MC-05 | 193 | 386.5 | 981.5 | 19.66% | 39.38% | Diagonal compression |

| MC-06 | 192 | 234.5 | 670.5 | 28.63% | 34.97% | Diagonal compression |

| MC-07 | 164 | 240 | 751 | 21.83% | 31.96% | Diagonal compression |

| MC-08 | 150 | 331 | 775 | 19.35% | 42.71% | Diagonal compression |

| MC-09 | 180 | 381 | 767 | 23.46% | 49.67% | Diagonal compression |

| Reference | Specimen | Experimental Values Vexp/kN | Exp.-to-Predicted Strength Ratio Vexp/V | ||||

|---|---|---|---|---|---|---|---|

| ACI318-19 | EC2 | CSA A23.319 | SSTM | Proposed Model | |||

| Present Study | MC01 | 879.0 | 1.926 | 1.834 | 1.856 | 1.080 | 1.004 |

| MC02 | 822.0 | 1.942 | 1.850 | 1.970 | 1.076 | 1.010 | |

| MC03 | 695.0 | 1.781 | 1.696 | 1.911 | 1.114 | 1.051 | |

| MC04 | 874.0 | 2.065 | 1.967 | 2.095 | 1.092 | 1.028 | |

| MC05 | 981.5 | 2.319 | 2.209 | 2.352 | 1.102 | 1.023 | |

| MC06 | 670.5 | 1.584 | 1.509 | 1.607 | 1.088 | 1.044 | |

| MC07 | 751.0 | 1.774 | 1.690 | 1.800 | 1.068 | 1.029 | |

| MC08 | 775.0 | 1.914 | 1.826 | 1.942 | 1.082 | 1.027 | |

| MC09 | 767.0 | 1.795 | 1.710 | 1.821 | 1.065 | 1.057 | |

| Fattuhi et al. [23] | 1 | 153.0 | 1.471 | 1.457 | 1.723 | 1.239 | 1.172 |

| 2 | 160.0 | 1.457 | 1.443 | 1.768 | 1.278 | 1.151 | |

| 3 | 91.2 | 1.378 | 1.460 | 1.531 | 1.389 | 1.021 | |

| 4 | 93.0 | 1.213 | 1.417 | 1.545 | 1.211 | 1.039 | |

| 5 | 103.0 | 1.819 | 1.598 | 1.513 | 1.223 | 1.201 | |

| 6 | 95.7 | 1.368 | 1.768 | 1.565 | 1.191 | 1.185 | |

| 7 | 53.3 | 1.393 | 1.442 | 1.359 | 1.175 | 1.140 | |

| 8 | 53.1 | 1.649 | 1.548 | 1.769 | 1.260 | 1.202 | |

| 9 | 152.9 | 1.310 | 1.486 | 1.877 | 1.258 | 1.109 | |

| 10 | 102.9 | 1.432 | 1.436 | 1.522 | 1.207 | 1.091 | |

| 11 | 56.0 | 1.584 | 1.457 | 1.684 | 1.223 | 1.004 | |

| 12 | 92.0 | 1.512 | 1.610 | 1.533 | 1.290 | 1.023 | |

| 13 | 111.7 | 1.429 | 1.630 | 1.425 | 1.269 | 1.133 | |

| 14 | 68.3 | 1.406 | 1.439 | 1.405 | 1.185 | 1.146 | |

| 15 | 67.2 | 1.388 | 1.536 | 1.507 | 1.227 | 1.102 | |

| 16 | 114.3 | 1.409 | 1.607 | 1.497 | 1.188 | 1.082 | |

| 18 | 119.0 | 1.563 | 1.605 | 1.895 | 1.165 | 1.055 | |

| Mean Variance | 1.611 | 1.624 | 1.710 | 1.183 | 1.082 | ||

| 0.072 | 0.038 | 0.057 | 0.007 | 0.004 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.-S.; Zheng, J.-Y.; Zhang, F.-J.; Li, H.-M.; Jia, M.-X.; Liu, Z.-J.; Chen, A.-J.; Xie, W. Prediction of Shear Strength for Steel-Fiber High-Strength Concrete Corbels with the Softened Strut-and-Tie Model. Buildings 2023, 13, 1107. https://doi.org/10.3390/buildings13041107

Li S-S, Zheng J-Y, Zhang F-J, Li H-M, Jia M-X, Liu Z-J, Chen A-J, Xie W. Prediction of Shear Strength for Steel-Fiber High-Strength Concrete Corbels with the Softened Strut-and-Tie Model. Buildings. 2023; 13(4):1107. https://doi.org/10.3390/buildings13041107

Chicago/Turabian StyleLi, Shu-Shan, Jin-Yan Zheng, Feng-Jian Zhang, Hong-Mei Li, Ming-Xiao Jia, Zu-Jun Liu, Ai-Jiu Chen, and Wei Xie. 2023. "Prediction of Shear Strength for Steel-Fiber High-Strength Concrete Corbels with the Softened Strut-and-Tie Model" Buildings 13, no. 4: 1107. https://doi.org/10.3390/buildings13041107